东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (5): 87-94.DOI: 10.12068/j.issn.1005-3026.2025.20230320

收稿日期:2023-11-30

出版日期:2025-05-15

发布日期:2025-08-07

通讯作者:

黄贤振

基金资助:

Xian-zhen HUANG1,2( ), Ming-fei MA1, Zhi-yuan JIANG1, Kai-hui QIU3

), Ming-fei MA1, Zhi-yuan JIANG1, Kai-hui QIU3

Received:2023-11-30

Online:2025-05-15

Published:2025-08-07

Contact:

Xian-zhen HUANG

摘要:

为了保证回转工作台刚度的同时尽可能地降低质量,并提高其可靠性,提出了一种回转工作台可靠性优化方法.该方法考虑了回转工作台内部结构之间装配关系的不变性,并引入了随机不确定性因素.通过灵敏度分析确定对回转工作台性能影响较大的尺寸参数,并进行优化.与传统优化方法不同,本文采用Kriging代理模型代替耗时的有限元分析.此外,在优化过程中引入了一种高效的元启发式算法来求解所提出的可靠性优化问题.随后,研究了各种参数配置对回转工作台变形可靠性的影响.最后,通过实例验证了所提优化方法的有效性和鲁棒性.

中图分类号:

黄贤振, 马明斐, 姜智元, 邱开慧. 数控机床回转工作台可靠性优化[J]. 东北大学学报(自然科学版), 2025, 46(5): 87-94.

Xian-zhen HUANG, Ming-fei MA, Zhi-yuan JIANG, Kai-hui QIU. Reliability Optimization of CNC Machine Tool Rotary Tables[J]. Journal of Northeastern University(Natural Science), 2025, 46(5): 87-94.

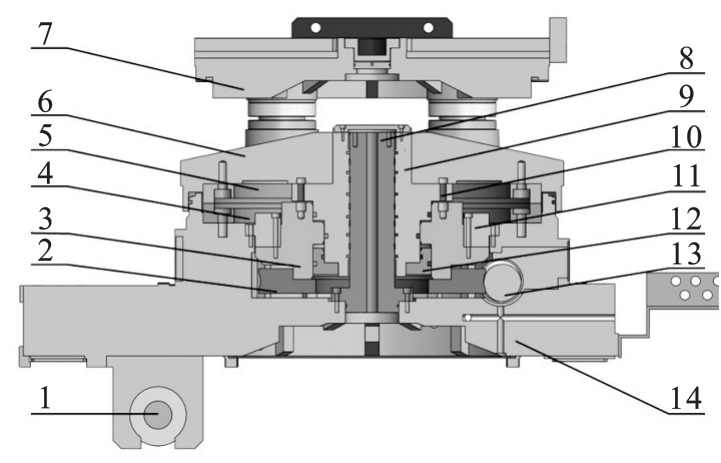

图1 牙盘式回转工作台结构示意图1—丝杆; 2—蜗轮; 3—油缸体; 4—下牙盘; 5—上牙盘;6—回转座; 7—工作台板; 8—分油轴; 9—活塞; 10—销;11—转台轴承; 12—油缸端盖; 13—蜗杆; 14—滑座.

Fig.1 Schematic diagram of the tooth disc-type rotary table structure

| 零件 | 材料 | 质量/kg |

|---|---|---|

| 工作台板 | HT300 | 188 |

| 回转座 | HT300 | 150 |

| 滑座 | HT300 | 580 |

| 鼠牙盘 | 38CrMoAlA | 20×2 |

| 分油轴 | 45钢 | 13.7 |

| 活塞 | 45钢 | 39 |

| 油缸体 | 45钢 | 62 |

| 油缸端盖 | 45钢 | 5.6 |

| 蜗轮 | ZQSn10-1 | 29.6 |

| 蜗杆 | 38CrMoAlA | 9.2 |

| 转台轴承 | GCR15SiMn | 25 |

表1 回转工作台主要结构与材料属性

Table 1 Main structure and material properties of the rotary table

| 零件 | 材料 | 质量/kg |

|---|---|---|

| 工作台板 | HT300 | 188 |

| 回转座 | HT300 | 150 |

| 滑座 | HT300 | 580 |

| 鼠牙盘 | 38CrMoAlA | 20×2 |

| 分油轴 | 45钢 | 13.7 |

| 活塞 | 45钢 | 39 |

| 油缸体 | 45钢 | 62 |

| 油缸端盖 | 45钢 | 5.6 |

| 蜗轮 | ZQSn10-1 | 29.6 |

| 蜗杆 | 38CrMoAlA | 9.2 |

| 转台轴承 | GCR15SiMn | 25 |

| 参数 | 分布类型 | 初始值/mm | 变异系数 |

|---|---|---|---|

| A1 | 正态分布 | 490 | 0.02 |

| A2 | 正态分布 | 20 | 0.02 |

| B1 | 正态分布 | 130 | 0.02 |

| C1 | 正态分布 | 22.5 | 0.02 |

| C2 | 正态分布 | 14 | 0.02 |

| C3 | 正态分布 | 36 | 0.02 |

| D1 | 正态分布 | 103 | 0.02 |

| D2 | 正态分布 | 25 | 0.02 |

| D3 | 正态分布 | 35.5 | 0.02 |

| D4 | 正态分布 | 128 | 0.02 |

| D5 | 正态分布 | 70 | 0.02 |

| D6 | 正态分布 | 30 | 0.02 |

| D7 | 正态分布 | 45 | 0.02 |

| D8 | 正态分布 | 30 | 0.02 |

| D9 | 正态分布 | 125 | 0.02 |

表2 设计变量的初值及分布细节

Table 2 Initial values and distribution details of the design variables

| 参数 | 分布类型 | 初始值/mm | 变异系数 |

|---|---|---|---|

| A1 | 正态分布 | 490 | 0.02 |

| A2 | 正态分布 | 20 | 0.02 |

| B1 | 正态分布 | 130 | 0.02 |

| C1 | 正态分布 | 22.5 | 0.02 |

| C2 | 正态分布 | 14 | 0.02 |

| C3 | 正态分布 | 36 | 0.02 |

| D1 | 正态分布 | 103 | 0.02 |

| D2 | 正态分布 | 25 | 0.02 |

| D3 | 正态分布 | 35.5 | 0.02 |

| D4 | 正态分布 | 128 | 0.02 |

| D5 | 正态分布 | 70 | 0.02 |

| D6 | 正态分布 | 30 | 0.02 |

| D7 | 正态分布 | 45 | 0.02 |

| D8 | 正态分布 | 30 | 0.02 |

| D9 | 正态分布 | 125 | 0.02 |

| 参数 | 区间/mm | 参数 | 区间/mm |

|---|---|---|---|

| A1 | 460~570 | D3 | 20~50 |

| A2 | 5~30 | D4 | 115~145 |

| B1 | 70~150 | D5 | 60~80 |

| C1 | 10~80 | D6 | 20~40 |

| C2 | 5~32 | D7 | 35~55 |

| C3 | 5~50 | D8 | 15~45 |

| D1 | 80~115 | D9 | 80~130 |

| D2 | 20~40 |

表3 设计变量的优化区间

Table 3 Optimization intervals of design variables

| 参数 | 区间/mm | 参数 | 区间/mm |

|---|---|---|---|

| A1 | 460~570 | D3 | 20~50 |

| A2 | 5~30 | D4 | 115~145 |

| B1 | 70~150 | D5 | 60~80 |

| C1 | 10~80 | D6 | 20~40 |

| C2 | 5~32 | D7 | 35~55 |

| C3 | 5~50 | D8 | 15~45 |

| D1 | 80~115 | D9 | 80~130 |

| D2 | 20~40 |

| 变量 | 无优化 | 确定性优化 | 可靠性优化 |

|---|---|---|---|

| A1/mm | 490 | 537.922 | 538.236 |

| A2/mm | 20 | 18.000 | 18.191 |

| B1/mm | 130 | 138.480 | 140.000 |

| C1/mm | 22.5 | 48.275 | 68.082 |

| C2/mm | 14 | 24.961 | 25.000 |

| C3/mm | 36 | 15.968 | 15.636 |

| D1/mm | 103 | 80.000 | 80.000 |

| D2/mm | 25 | 37.538 | 27.536 |

| D3/mm | 35.5 | 20.000 | 21.276 |

| D4/mm | 128 | 130.932 | 148.201 |

| D5/mm | 70 | 60.750 | 60.152 |

| D6/mm | 30 | 20.143 | 20.001 |

| D7/mm | 45 | 35.486 | 35.995 |

| D8/mm | 30 | 24.068 | 18.437 |

| D9/mm | 125 | 103.489 | 123.492 |

| 变形/mm | 0.020 | 0.020 | 0.020 |

| 质量/t | 0.960 | 0.878 | 0.881 |

| 可靠性/% | 49.11 | 60.95 | 90.35 |

表4 优化结果对比

Table 4 Comparison of the optimization results

| 变量 | 无优化 | 确定性优化 | 可靠性优化 |

|---|---|---|---|

| A1/mm | 490 | 537.922 | 538.236 |

| A2/mm | 20 | 18.000 | 18.191 |

| B1/mm | 130 | 138.480 | 140.000 |

| C1/mm | 22.5 | 48.275 | 68.082 |

| C2/mm | 14 | 24.961 | 25.000 |

| C3/mm | 36 | 15.968 | 15.636 |

| D1/mm | 103 | 80.000 | 80.000 |

| D2/mm | 25 | 37.538 | 27.536 |

| D3/mm | 35.5 | 20.000 | 21.276 |

| D4/mm | 128 | 130.932 | 148.201 |

| D5/mm | 70 | 60.750 | 60.152 |

| D6/mm | 30 | 20.143 | 20.001 |

| D7/mm | 45 | 35.486 | 35.995 |

| D8/mm | 30 | 24.068 | 18.437 |

| D9/mm | 125 | 103.489 | 123.492 |

| 变形/mm | 0.020 | 0.020 | 0.020 |

| 质量/t | 0.960 | 0.878 | 0.881 |

| 可靠性/% | 49.11 | 60.95 | 90.35 |

| [1] | Kroll L, Blau P, Wabner M, et al. Lightweight components for energy-efficient machine tools[J]. CIRP Journal of Manufacturing Science and Technology, 2011, 4(2): 148-160. |

| [2] | Bok H L, Han J O, Hwan C O, et al. Structural design optimization of the rotary table of a floor type boring machine for minimum weight and compliance by using GA[J]. Applied Mechanics and Materials, 2012, 271/272: 1421-1426. |

| [3] | Deng H X, Zhao L, Ma J F, et al. Structural bionic design for high-speed machine tool working table based on distribution rules of leaf veins[J]. Science China Technological Sciences, 2012, 55(8): 2091-2098. |

| [4] | Gao Q D, Zhang F, Mao Y Z, et al. Application of honeycomb structure in machine tool table[J]. Advanced Materials Research, 2011, 1377: 1233-1237. |

| [5] | Zhao H W, Cheng L Y, Xiao P X, et al. Layout design of stiffened plates for large-scale box structure under moving loads based on topology optimization[J]. Mathematical Problems in Engineering, 2020, 2020: 1-11. |

| [6] | Zheng B, Ying G F, Huang H, et al. Optimization design for fixed table of gantry machining center based on sensitivity and topology analyses[J]. Journal of Donghua University, 2013, 30(4): 263-268. |

| [7] | 郭垒,张辉,叶佩青,等.基于灵敏度分析的机床轻量化设计[J].清华大学学报(自然科学版), 2011,51(6): 846-850. |

| Guo Lei, Zhang Hui, Ye Pei-qing, et al. Lightweight design of machine tools based on sensitivity analysis [J]. Journal of Tsinghua University (Natural Science), 2011, 51(6): 846-850. | |

| [8] | 刘成颖,谭锋,王立平,等.面向机床整机动态性能的立柱结构优化设计研究[J].机械工程学报,2016,52(3):161-168. |

| Liu Cheng-ying, Tan Feng, Wang Li-ping, et al. Research on optimal design of column structure for the dynamic performance of machine tools [J]. Transactions of the Chinese Society of Mechanical Engineering, 2016, 52(3): 161-168. | |

| [9] | 姜衡,管贻生,邱志成,等.基于响应面法的立式加工中心动静态多目标优化[J].机械工程学报,2011,47(11): 125-133. |

| Jiang Heng, Guan Yi-sheng, Qiu Zhi-cheng, et al. Dynamic and static multi-objective optimization of vertical machining center based on response surface method [J]. Transactions of the Chinese Society of Mechanical Engineering, 2011, 47(11): 125-133. | |

| [10] | Wu B C, Young G S, Huang T Y. Application of a two-level optimization process to conceptual structural design of a machine tool[J]. International Journal of Machine Tools and Manufacture, 2000, 40(6): 783-794. |

| [11] | Jiang Z Y, Huang X Z, Ding P F, et al. Reliability-based design optimization of the spiral water jacket for motorized spindle[J]. Case Studies in Thermal Engineering, 2023, 51: 103665. |

| [12] | Chen J, Qiu H B, Gao L, et al. Real-time estimation error-guided active learning Kriging method for time-dependent reliability analysis[J]. Applied Mathematical Modelling, 2020, 77(1): 82-98. |

| [13] | Ma M F, Liu H Q, Wu X J, et al. Global reliability sensitivity analysis of cradle-type double rotary table[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2025, 239(5): 1492-1505. |

| [14] | Sun Z L, Wang J, Li R, et al. LIF: a new Kriging based learning function and its application to structural reliability analysis[J]. Reliability Engineering and System Safety, 2017, 157: 152-165. |

| [15] | Mirjalili S, Lewis A. The whale optimization algorithm[J]. Advances in Engineering Software, 2016, 95: 51-67. |

| [16] | Ohadi S, Jafari-Asl J. Multi-objective reliability-based optimization for design of trapezoidal labyrinth weirs[J]. Flow Measurement and Instrumentation, 2021, 77: 101787. |

| [17] | Verma S K, Tiwari R. Robust optimum design of tapered roller bearings based on maximization of fatigue life using evolutionary algorithm[J]. Mechanism and Machine Theory, 2020, 152: 103894. |

| [18] | Jafari-Asl J, Seghier M E A B, Ohadi S, et al. Efficient method using whale optimization algorithm for reliability-based design optimization of labyrinth spillway[J]. Applied Soft Computing, 2021, 101: 107036. |

| [1] | 黄贤振, 王旭, 丁鹏飞, 姜智元. 考虑铣削表面形貌的工艺参数可靠性优化[J]. 东北大学学报(自然科学版), 2025, 46(3): 80-87. |

| [2] | 罗忠, 罗永恒, 熊鑫, 吴法勇. 装配工艺参数对止口螺栓连接结构力学特性的影响分析[J]. 东北大学学报(自然科学版), 2024, 45(9): 1268-1276. |

| [3] | 宋翰生, 马辉, 刘子濛, 黄文康. 含有不同裂纹类型的弧齿锥齿轮副啮合特性分析[J]. 东北大学学报(自然科学版), 2024, 45(8): 1096-1106. |

| [4] | 王衍, 王者超, 李昌昊, 崔鹏. 含小型粗骨料UHPC中栓钉连接件的抗剪性能[J]. 东北大学学报(自然科学版), 2024, 45(11): 1604-1611. |

| [5] | 柏谦, 赵文, 曹文欣, 卢彦军. 管幕和横梁作用下大断面开挖变形响应研究[J]. 东北大学学报(自然科学版), 2024, 45(1): 129-136. |

| [6] | 徐宏阳, 杨阳, 王鹏飞, 马辉. 含不对中与滚珠分布误差的球轴承刚度波动特性[J]. 东北大学学报(自然科学版), 2023, 44(3): 382-391. |

| [7] | 李寿涛, 魏玉博, 李秋媛, 于丁力. 考虑车辆侧偏刚度变化的MPC稳定性控制方法[J]. 东北大学学报(自然科学版), 2023, 44(2): 162-167. |

| [8] | 黄贤振, 张鹏, 李红雷, 吕中. 风力发电机主轴轴承零游隙位置概率分析[J]. 东北大学学报(自然科学版), 2023, 44(10): 1440-1447. |

| [9] | 罗忠 , 刘家希 , 刘凯宁 , 孙凯. 弹性环式支承结构动刚度分析及其对转子系统的影响[J]. 东北大学学报(自然科学版), 2022, 43(5): 667-673. |

| [10] | 黄贤振, 孙良仕, 丁鹏飞, 朱会彬. 基于可靠性的GH4169车削参数优化[J]. 东北大学学报(自然科学版), 2022, 43(5): 696-702. |

| [11] | 高幸, 王维玉, 贾金青. 型钢框架-锚索-岩土体耦合蠕变行为[J]. 东北大学学报(自然科学版), 2022, 43(12): 1792-1799. |

| [12] | 马辉, 高昂, 杨天瑞, 官宏. 止口及螺栓对法兰盘结构静力学特性的影响[J]. 东北大学学报(自然科学版), 2022, 43(10): 1438-1445. |

| [13] | 杨周, 朴银成 , 权哲优. 盘式制动器热-机耦合渐变可靠性灵敏度分析[J]. 东北大学学报(自然科学版), 2022, 43(1): 48-56. |

| [14] | 贾鹏蛟, 史培新, 关永平, 赵文. STS管幕结构横向抗弯刚度计算模型及参数优化[J]. 东北大学学报(自然科学版), 2021, 42(8): 1159-1165. |

| [15] | 马辉, 于明月, 高昂, 赵晨光. 基于非线性虚拟材料栓接结合部动力学建模方法[J]. 东北大学学报(自然科学版), 2021, 42(8): 1111-1119. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||