东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (9): 41-50.DOI: 10.12068/j.issn.1005-3026.2025.20240029

收稿日期:2024-02-02

出版日期:2025-09-15

发布日期:2025-12-03

通讯作者:

曲迎霞

作者简介:齐 霖(1998—),男,黑龙江绥化人,东北大学硕士研究生基金资助:

Lin QI1,2, Ying-xia QU1,2( ), Da-peng JIANG3, Zong-shu ZOU1,2

), Da-peng JIANG3, Zong-shu ZOU1,2

Received:2024-02-02

Online:2025-09-15

Published:2025-12-03

Contact:

Ying-xia QU

摘要:

为探究旋风炉在闪速还原炼铁技术中的应用状况与前景,气相采用欧拉模型,颗粒相采用DPM(discrete phase model)对旋风炉内气相流场和颗粒运动轨迹进行了数值模拟.分析了上升气体(熔融还原炉煤气)速度和铁矿粉粒度对气固两相流动特性的影响.结果表明:旋流场的切向速度在喷枪区域呈近似“凹”字形分布,在喷枪以上区域呈近似“M”形分布;上升气体速度由4 m/s增至8 m/s,气体切向速度最大值减小,铁矿粉捕集率由98.99%降至93.51%,但强旋湍流区逐渐上移,铁矿粉运动路径变长,更有利于其熔化和还原.此外,捕集率随着粒度的增大先减小后增大,但大粒度铁矿粉几乎不发生螺旋向上运动.

中图分类号:

齐霖, 曲迎霞, 姜大鹏, 邹宗树. 旋风炉内气固两相流动特性的数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(9): 41-50.

Lin QI, Ying-xia QU, Da-peng JIANG, Zong-shu ZOU. Numerical Simulation of Gas-Solid Two-Phase Flow Characteristics in Cyclone Furnace[J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 41-50.

| 参数 | 尺寸 |

|---|---|

| 炉高H/ m | 6 |

| 炉径D/ m | 3 |

| 喷枪直径Ф/ m | 0.032 |

| 喷枪层间间距h/ m | 0.250 |

| 铁矿粉喷枪径向夹角 | 18.5 |

| 两类喷枪径向连线夹角 | 35.0 |

表1 物理模型几何参数

Table 1 Geometric parameters of physical model

| 参数 | 尺寸 |

|---|---|

| 炉高H/ m | 6 |

| 炉径D/ m | 3 |

| 喷枪直径Ф/ m | 0.032 |

| 喷枪层间间距h/ m | 0.250 |

| 铁矿粉喷枪径向夹角 | 18.5 |

| 两类喷枪径向连线夹角 | 35.0 |

图3 不同网格数量下旋风炉Z=0 m纵截面上Y=4 m处二氧化碳气体速度

Fig.3 Carbon dioxide gas velocity at Y=4 m on Z=0 m longitudinal section of cyclone furnace with different grid numbers

| 算例 | |||

|---|---|---|---|

| Case 1 | 4 | 30 | 30 |

| Case 2 | 6 | 30 | 30 |

| Case 3 | 8 | 30 | 30 |

| Case 4 | 8 | 30 | 100 |

| Case 5 | 8 | 30 | 300 |

表2 不同算例中的主要操作参数 (cases)

Table 2 Main operating parameters of different

| 算例 | |||

|---|---|---|---|

| Case 1 | 4 | 30 | 30 |

| Case 2 | 6 | 30 | 30 |

| Case 3 | 8 | 30 | 30 |

| Case 4 | 8 | 30 | 100 |

| Case 5 | 8 | 30 | 300 |

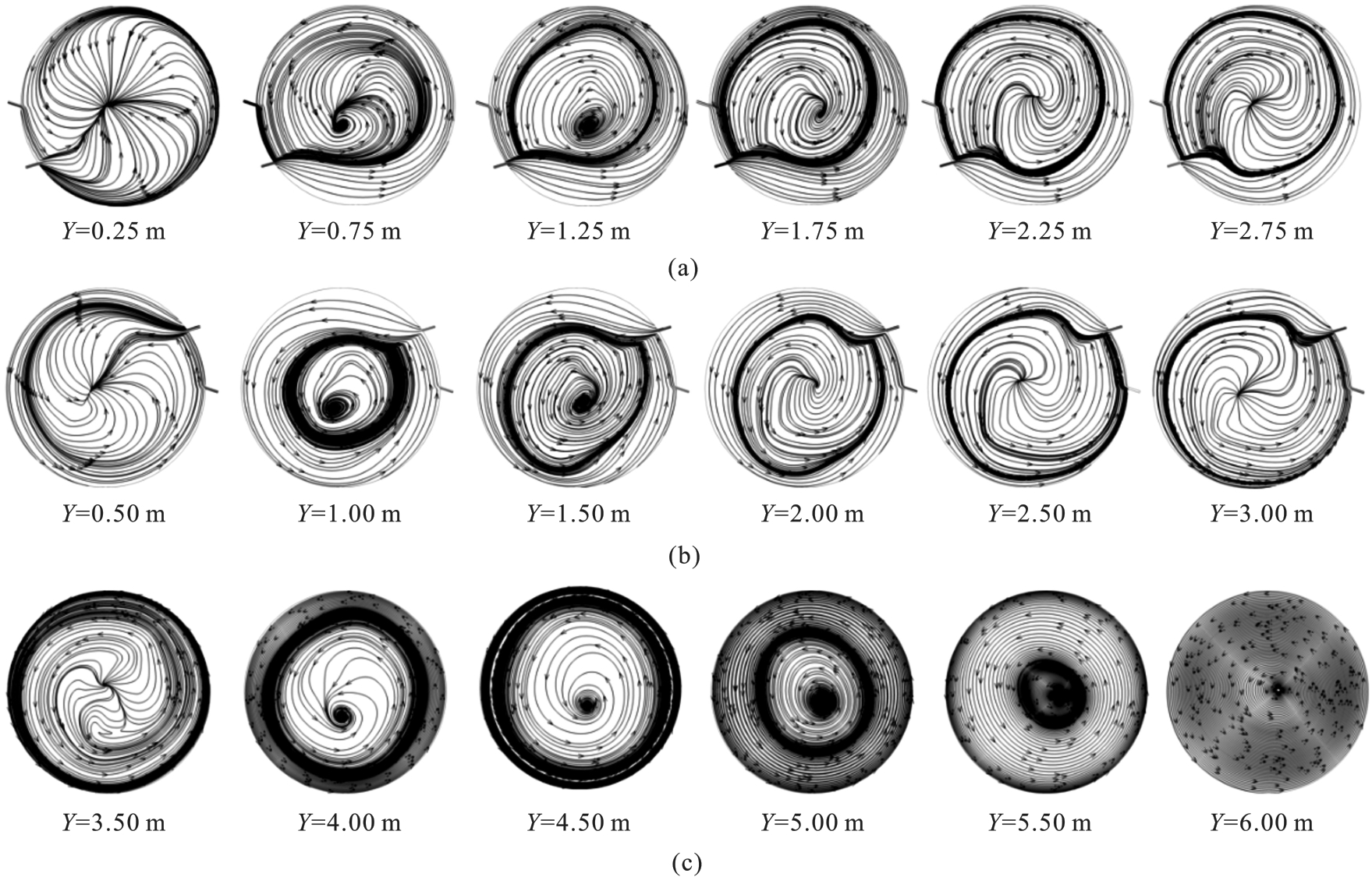

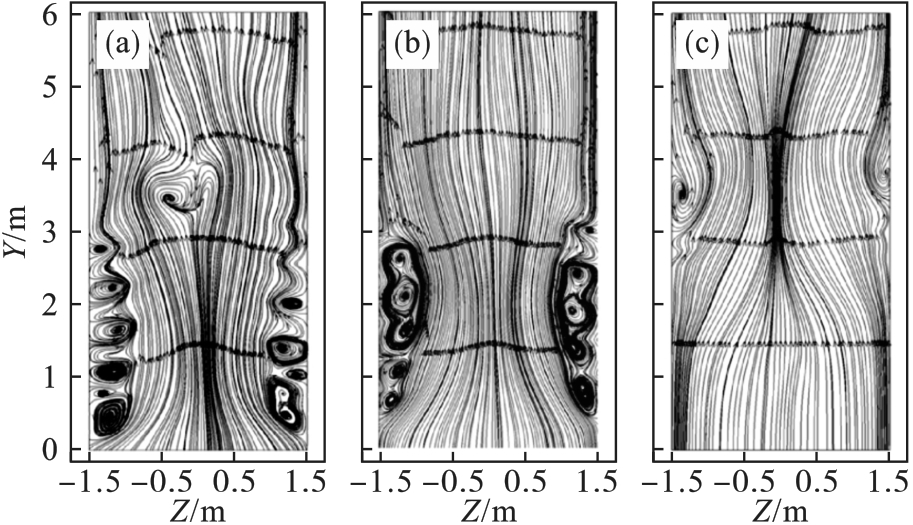

图6 上升气体速度为4 m/s时不同高度处的气体流线图(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上各高度.

Fig.6 Gas streamline diagram at different heights when rising gas velocity is 4 m/s

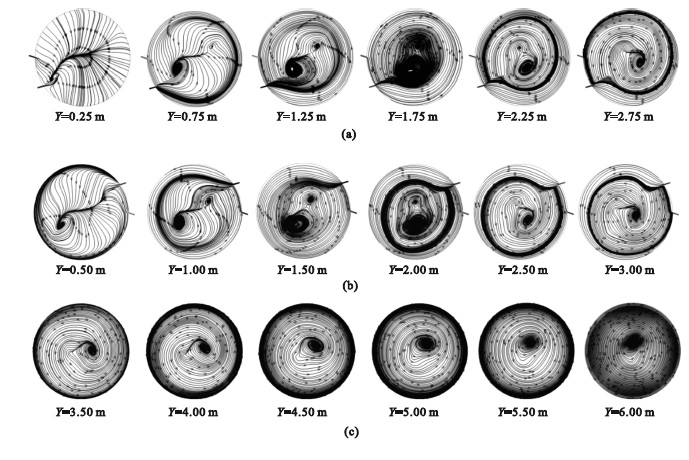

图7 上升气体速度为6 m/s时不同高度处的气体流线图(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上高度.

Fig.7 Gas streamline diagram at different heights when rising gas velocity is 6 m/s

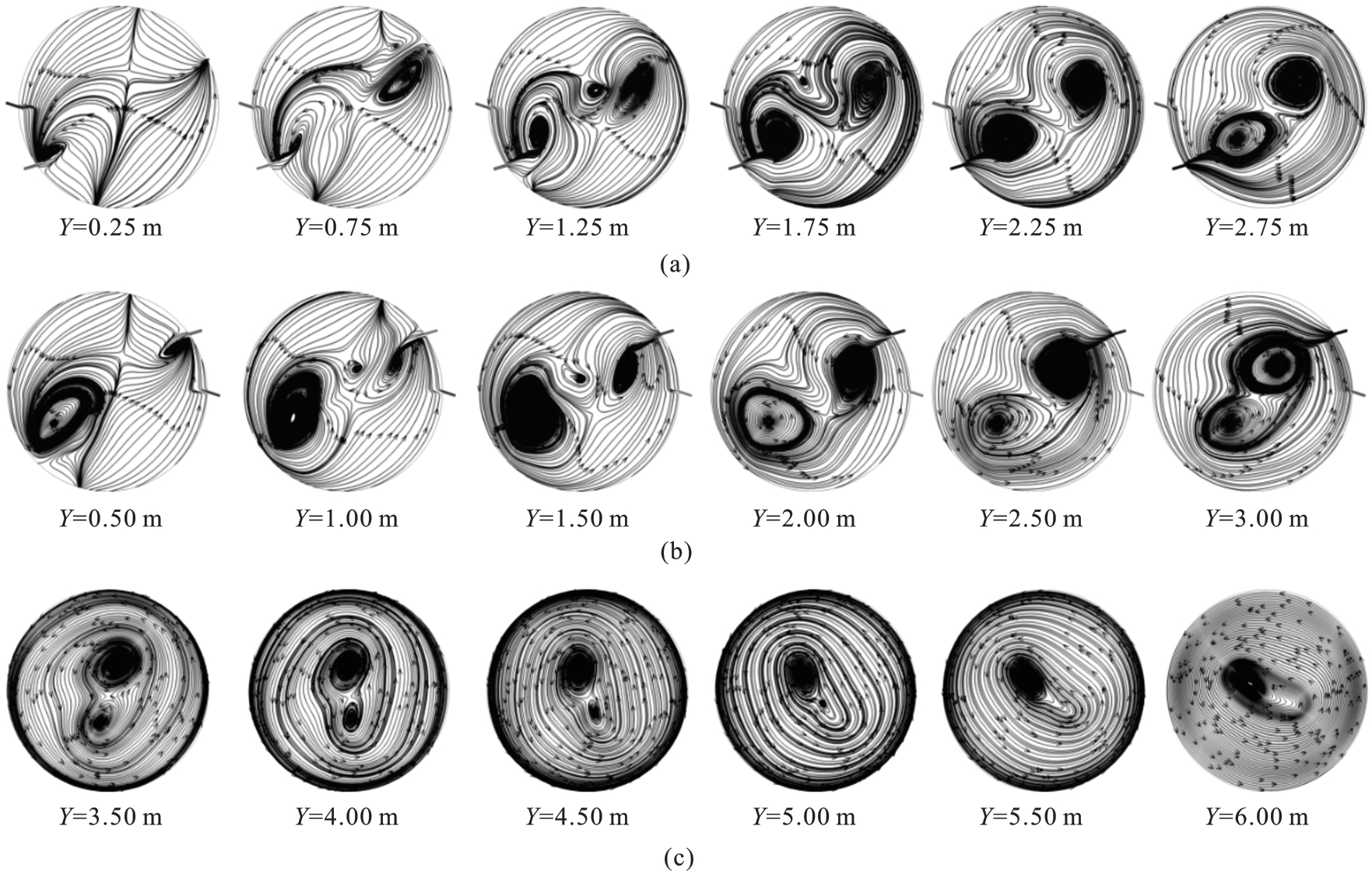

图8 上升气体速度为8 m/s时不同高度处的气体流线图(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上高度.

Fig.8 Gas streamline diagram at different heights when rising gas velocity is 8 m/s

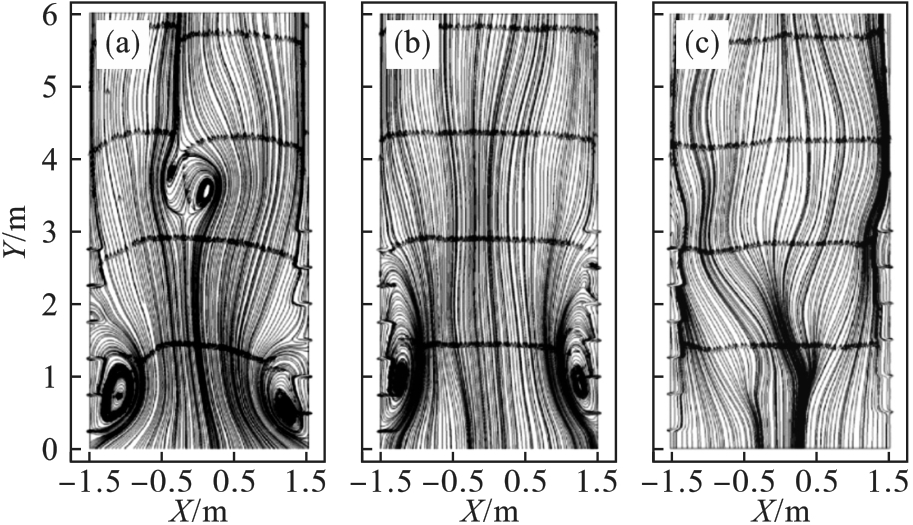

图9 旋风炉Z=0 m处纵剖面上的气体流线图(a)—上升气体速度4 m/s; (b)—上升气体速度6 m/s; (c)—上升气体速度8 m/s.

Fig.9 Gas streamline diagram of cyclone furnace in longitudinal section at Z=0 m

图10 旋风炉X=0 m处纵剖面上的气体流线图(a)—上升气体速度4 m/s; (b)—上升气体速度6 m/s; (c)—上升气体速度8 m/s.

Fig.10 Gas streamline diagram of cyclone furnace in longitudinal section at X=0 m

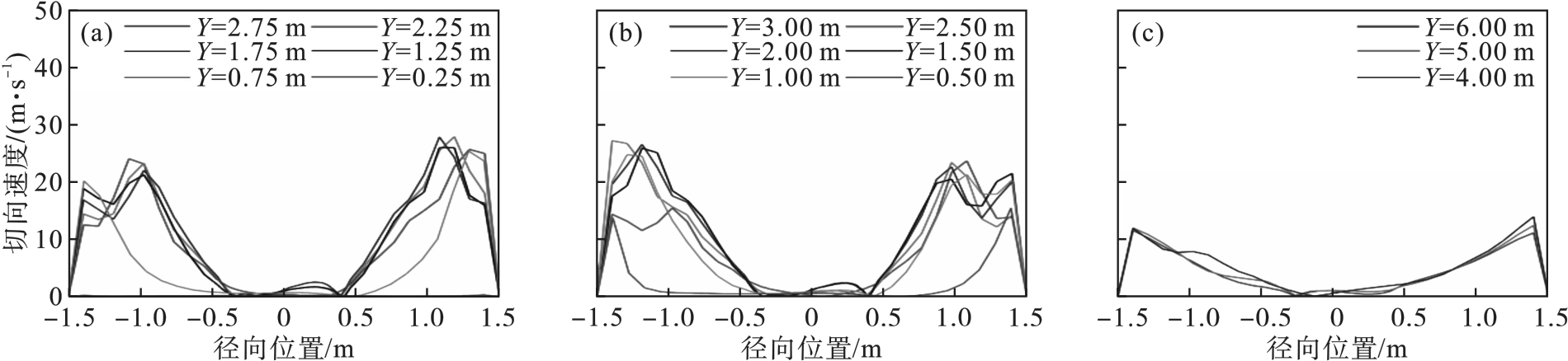

图11 上升气体速度为4 m/s时切向速度在不同横截面径向位置上的分布(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上各高度.

Fig.11 Distribution of tangential velocity at different cross-sectional radial positions when rising gas velocity is 4 m/s

图12 上升气体速度为6 m/s时切向速度在不同横截面径向位置上的分布(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上各高度.

Fig.12 Distribution of tangential velocity at different cross-sectional radial positions when rising gas velocity is 6 m/s

图13 上升气体速度为8 m/s时切向速度在不同横截面径向位置上的分布(a)—左侧喷枪所在高度; (b)—右侧喷枪所在高度; (c)—喷枪以上各高度.

Fig.13 Distribution of tangential velocity at different cross-sectional radial positions when rising gas velocity is 8 m/s

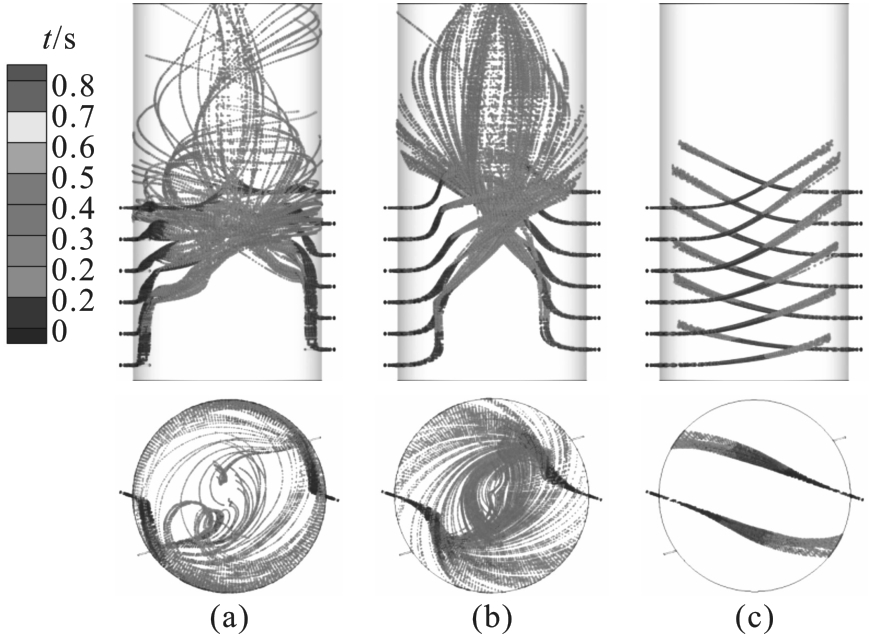

图15 旋风炉不同粒径颗粒运动轨迹(a)—30 μm主视图和侧视图; (b)—100 μm主视图和侧视图; (c)—300 μm主视图和侧视图.

Fig.15 Motion trajectory of particles with different sizes in cyclone furnace

| [1] | 何桂珍,都兴红,曲赫威,等. 非高炉冶炼技术的发展现状与展望[J]. 矿产综合利用,2014, 35(3):1-7. |

| He Gui-zhen, Dou Xing-hong, Qu He-wei, et al. Present status and development perspective of non-blast furnace ironmaking technology[J]. Multipurpose Utilization of Mineral Resources, 2014, 35(3): 1-7. | |

| [2] | 张晓华, 师学峰, 赵凯, 等. 非高炉炼铁工艺流程发展现状及前景展望[J]. 矿产综合利用, 2020(2): 8-15. |

| Zhang Xiao-hua, Shi Xue-feng, Zhao Kai, et al. Development status and prospect of smelting reduction ironmaking process[J]. Multipurpose Utilization of Mineral Resources, 2020(2): 8-15. | |

| [3] | 张福君,杨树峰,李京社,等. “双碳”背景下低碳排炼钢流程选择及关键技术[J]. 工程科学学报, 2022, 44(9):1483-1495. |

| Zhang Fu-jun, Yang Shu-feng, Li Jing-she,et al. Selection and key technologies of low-carbon steelmaking processes under the background of “double carbon”[J]. Chinese Journal of Engineering,2022,44(9):1483-1495. | |

| [4] | 崔志峰,徐安军,上官方钦. 国内外钢铁行业低碳发展策略分析[J]. 工程科学学报,2022, 44(9):1496-1506. |

| Cui Zhi-feng, Xu An-jun, Shangguan Fang-qin. Low-carbon development strategy analysis of the domestic and foreign steel industry[J]. Chinese Journal of Engineering, 2022, 44(9): 1496-1506. | |

| [5] | Quader M A, Ahmed S, Dawal S Z,et al. Present needs,recent progress and future trends of energy-efficient ultra-low carbon dioxide (CO2) steelmaking (ULCOS) program[J]. Renewable&Sustainable Energy Reviews,2016, 55:537-549. |

| [6] | 严珺洁. 超低二氧化碳排炼钢项目的进展与未来[J]. 中国冶金,2017, 27(2):6-11. |

| Yan Jun-jie. Progress and future of uItra-low carbon dioxide emision steelmaking project[J]. China Metallurgical, 2017, 27(2): 6-11. | |

| [7] | Sripriya R, Peeters T, Meijer K, et al. Computational fluid dynamics and combustion modelling of HIsarna incinerator[J]. Ironmaking&Steelmaking, 2016, 43(3): 192-202. |

| [8] | Schrama F N H, Beunder E M, J W K van Boggelen, et al. Desulphurisation of HIsarna hot metal-a comparison study based on plant data[C]//3rd International Conference on Science and Technology of Ironmaking & Steelmaking. Kanpur,2017: 419-422. |

| [9] | Van Boggelen J W K, Meijer H K A, Zeilstra C, et al. HIsarna-demonstrating low CO2 ironmaking at pilot scale[J]. Steel VIA, 2018: 25-27. |

| [10] | Meijer H K A, Laar J, Knoop D W, et al. 旋流转换炉(CCF)装置的工艺设计[J]. 燃料与化工,1998(5):277-281. |

| Meijer H K A, Laar J, Knoop D W, et al. Process design of cyclone converter furnace (CCF) device[J]. Fuel & Chemical Processes, 1998(5): 277-281. | |

| [11] | Cao C, Meng Y, Mei C, et al. Latest progress in industrialization of HIsmelt process[C]//11th Iron and Steel Conference of China Proceedings.Beijing, 2017: 1-7. |

| [12] | Khasraw D, Spooner S, Hage H, et al. Evaluation of devolatilization behaviour of different carbonaceous materials under rapid heating for the novel HIsarna ironmaking process[J]. Fuel, 2021, 292: 120329. |

| [13] | Khasraw D, Htet T T, Yang X L, et al. Gasification and structural behaviour of different carbon sources and resultant chars from rapid devolatilization for HIsarna alternative ironmaking process[J]. Fuel, 2022, 309: 122210. |

| [14] | Denys M B. Dynamical modelling of the cyclone converter furnace[D]. Delft: Delft University of Technology, 1997. |

| [15] | Link J. IRMA-flowsheet model examples of application[J]. Metallurgical Research & Technology, 2009, 106(10): 398-403. |

| [16] | Chaghakaboodi H A, Saidi M. Numerical study of gas-solid flow in a square cyclone separator with different vortex finders[J]. Chemical Engineering Research&Design, 2023, 194: 621-635. |

| [17] | Venkatesh S, Sivapirakasam S P, Sakthivel M, et al. Experimental and numerical investigation in the series arrangement square cyclone separator[J]. Powder Technology, 2021, 383: 93-103. |

| [18] | 林秀丽, 曹亚平, 夏祉君, 等. 轴流旋风分离器特性的数值模拟[J]. 东北大学学报(自然科学版), 2019, 40(9): 1360-1364. |

| Lin Xiu-li, Cao Ya-ping, Xia Zhi-jun, et al. Numerical simulation on characteristics of the axial flow cyclone separator[J]. Journal of Northeastern University (Natural Science), 2019, 40(9): 1360-1364. | |

| [19] | Wasilewski M, Brar L S, Ligus G. Effect of the central rod dimensions on the performance of cyclone separators-optimization study[J]. Separation&Purification Technology, 2021, 274: 119020. |

| [20] | Zhu L, Wang S, Ru Y, et al. Numerical investigation on dynamic characteristics of flow field in cyclone separators with different dust hopper structures[J]. Particuology, 2023, 82: 134-145. |

| [21] | Dong S J, Jiang Y C, Jin R Z, et al. Numerical study of vortex eccentricity in a gas cyclone[J]. Applied Mathematical Modelling, 2020, 80: 683-701. |

| [22] | Dong S J, Wang C W, Zhang Z H, et al. Numerical study of short-circuiting flow and particles in a gas cyclone[J]. Particuology, 2023, 72: 81-93. |

| [23] | Parvaz F, Hosseini S H, Elsayed K, et al. Influence of the dipleg shape on the performance of gas cyclones[J]. Separation&Purification Technology, 2020, 223: 116000. |

| [24] | Dziubak T, Bąkała L, Karczewski M, et al. Numerical research on vortex tube separator for special vehicle engine inlet air filter[J]. Separation&Purification Technology, 2020, 239: 116588. |

| [25] | Pang X X, Wang C Y, Yang W, et al. Numerical simulation of a cyclone separator to recycle the active components of waste lithium batteries[J].Engineering Applications of Computational Fluid Mechanics, 2022, 16(1): 937-951. |

| [26] | Zhang Z H, Dong S J, Jin R Z, et al. Vortex characteristics of a gas cyclone determined with different vortex identification methods[J]. Powder Technology, 2022, 404: 117370. |

| [27] | Liu G H, Wang W B, Yu J Z, et al. Effect of extra inlets structure on cyclone wall erosion[J]. Powder Technology, 2022, 411: 117926. |

| [28] | Zhang L L, Chen Y X, Zhao B, et al. Numerical simulation on structure optimization of escape-pipe of cyclone separator with downward outlet [J]. Powder Technology, 2022, 411: 117588. |

| [29] | 王晨雯. 旋风分离器内短路流的流动特征与形成机理研究[D]. 兰州:兰州大学,2020. |

| Wang Chen-wen. Study on flow characteristics and formation mechanism of short-circuit flow in cyclone separator[D]. Lanzhou: Lanzhou University, 2020. | |

| [30] | Zhang Z H, Yan S J, Dong S J, et al. Study of the short-circuit flow and circulation flow’s impact on separation performance of cyclone separator with volute-helical inlet[J]. Advanced Powder Technology, 2024, 35(1): 104281. |

| [1] | 辛博, 程光, 姚俊, 巩亚东. 自适应FGM激光熔覆成形的粉体快速混合机理[J]. 东北大学学报:自然科学版, 2020, 41(8): 1123-1128. |

| [2] | 林秀丽, 曹亚平, 夏祉君, 柳静献. 轴流旋风分离器特性的数值模拟[J]. 东北大学学报:自然科学版, 2019, 40(9): 1360-1364. |

| [3] | 徐海良, 周永兴, 徐聪, 赵宏强. 基于排屑性能的扩孔气动冲击器设计方法[J]. 东北大学学报:自然科学版, 2018, 39(6): 844-849. |

| [4] | 陈举师, 蒋仲安, 张义坤. 破碎硐室粉尘质量浓度分布规律的实验研究[J]. 东北大学学报:自然科学版, 2015, 36(7): 1051-1055. |

| [5] | 吴铿,王梦,赵勇,王崇茂. 测定铁矿粉同化特性新方法的探索[J]. 东北大学学报(自然科学版), 2013, 34(7): 961-965. |

| [6] | 刘仁学;金锋;陆增喜;王师. 单支管中气固两相流质量流量测量的新方法[J]. 东北大学学报(自然科学版), 1999, 20(4): 369-372. |

| [7] | 车传仁;胡安生. 高炉喷吹铁矿粉工业性试验结果分析[J]. 东北大学学报:自然科学版, 1997, 18(1): 4--. |

| [8] | 王天明;邹宗树;李殷泰;窦权菊. 待发表文章摘要预报Al_2O-3─C质耐火材料中SiC晶须的形成及其对机械性能的影响[J]. 东北大学学报:自然科学版, 1996, 17(6): 2--. |

| [9] | 肖兴国. 高温气流中铁矿粉热分解和还原行为数学模型[J]. 东北大学学报:自然科学版, 1993, 14(5): 439-444. |

| [10] | 王志荣;李殷泰. 加煤铬铁矿粉流化床流化性质和还原行为[J]. 东北大学学报:自然科学版, 1993, 14(2): 176-181. |

| [11] | 肖兴国. 高温气流中铁矿粉的热分解和还原行为[J]. 东北大学学报:自然科学版, 1993, 14(2): 166-170. |

| [12] | 战明;王师. 气固两相流电容传感器环形电极检测特性分析[J]. 东北大学学报:自然科学版, 1988, 9(3): 281-286. |

| [13] | 彭一川;肖泽强. 等截面管道中气固两相流的颗粒速度的理论计算[J]. 东北大学学报:自然科学版, 1985, 6(3): 55-60. |

| [14] | 郭燕杰;冯学渊;李诗久. 燃油化铁炉内旋风燃烧的某些理论问题[J]. 东北大学学报:自然科学版, 1978, -(3): 57-74. |

| [15] | -. 关于鑄铁熔化利用多种燃料问题的探封[J]. 东北大学学报:自然科学版, 1974, -(1): 29-50. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||