东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 57-76.DOI: 10.12068/j.issn.1005-3026.2025.20240202

李松, 于艺弘, 秦高梧

收稿日期:2024-11-04

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

李松

作者简介:李 松(1979—),男,山东济宁人,东北大学教授,博士生导师基金资助:Song LI, Yi-hong YU, Gao-wu QIN

Received:2024-11-04

Online:2025-08-15

Published:2025-11-24

Contact:

Song LI

摘要:

传统金属材料的制备大都在近热力学平衡条件下进行,制备过程存在多个耦合的子过程限制了结构调控的空间.在时空维度上精确调控系统热力学参量,使材料体系处于远平衡区,有望通过动力学解耦子过程获得超越平衡相图预测范围的独特成分和微观结构,开辟材料制备的新路径.基于这一原理,研究者已成功开发了超快热处理、焦耳热制备、碳热冲击等远平衡制备技术,借此发现了多种具有优异性能的新型金属结构材料或功能材料.围绕远平衡金属材料制备的原理和策略,重点阐述从时间和空间上控制热力学条件的方法,深入探讨其在新材料开发中的应用前景,不仅深化了对非平衡过程本质的认识,也为突破传统材料性能极限提供了创新性的设计思路.

中图分类号:

李松, 于艺弘, 秦高梧. 热力学远平衡条件下制备金属新材料[J]. 东北大学学报(自然科学版), 2025, 46(8): 57-76.

Song LI, Yi-hong YU, Gao-wu QIN. Fabricating Novel Metallic Materials Under Thermodynamic Far-from-Equilibrium Conditions[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 57-76.

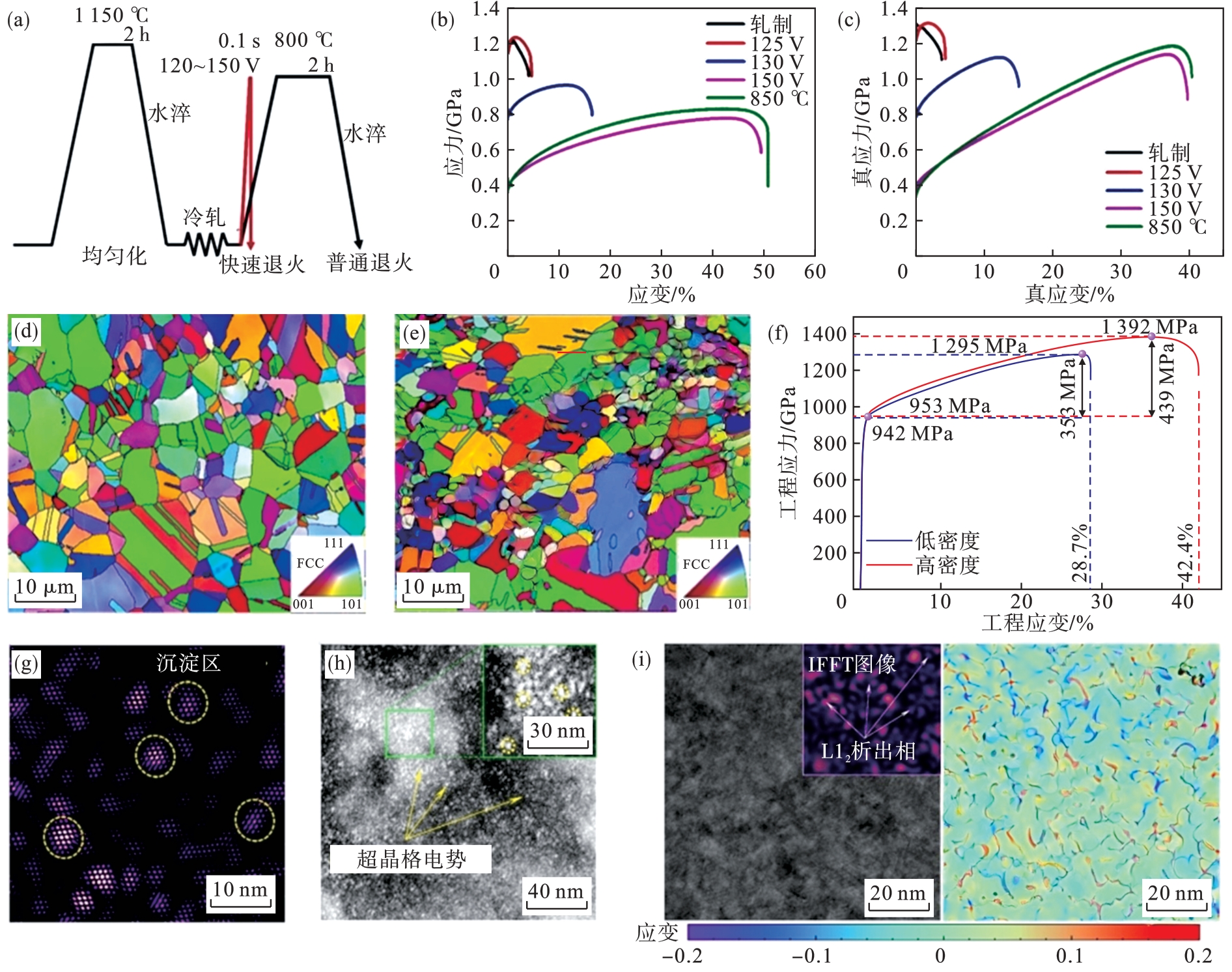

图2 高熵合金闪热处理实现高密度纳米沉淀强化提升材料塑韧性[37-38]

Fig.2 Flash heat treatment of high-entropy alloys achieves high-density nanoprecipitation strengthening, enhancing the material’s ductility and toughness[37-38]

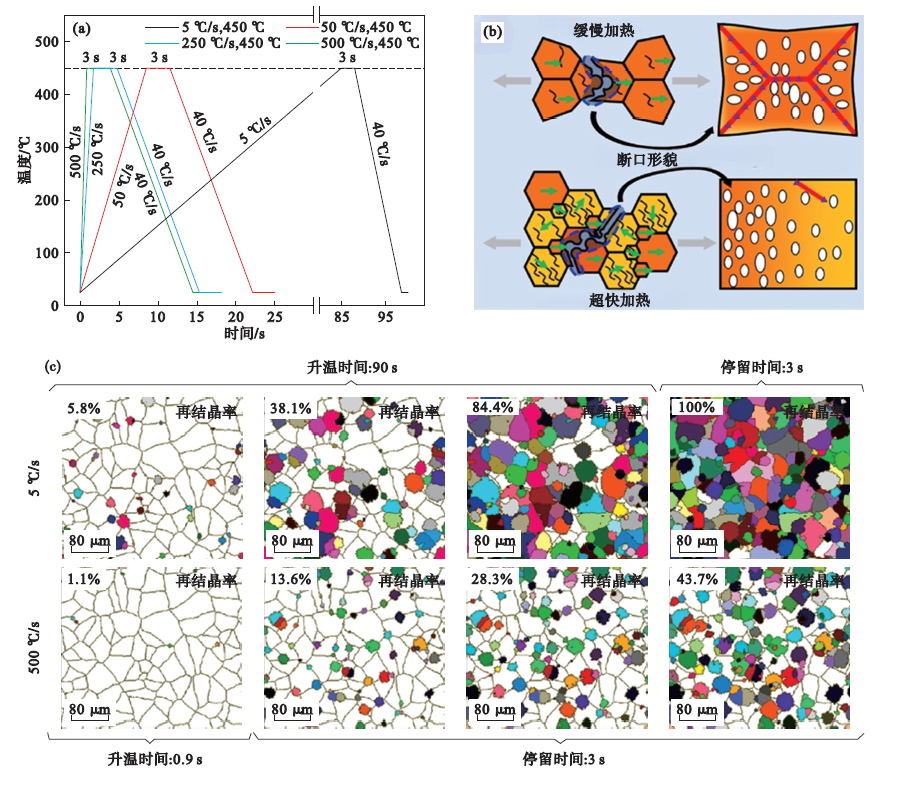

图4 5052铝合金在不同加热速率退火后组织演变及机制模型[50](a)—超快速退火工艺; (b)—在慢速与超快速加热条件下退火试样的断裂模型;(c)—采用元胞自动机模拟5052合金在分别以5 ℃/s和500 ℃/s加热至450 ℃条件下的形核与晶粒生长过程.

Fig.4 Tensile fracture morphology and evolution of 5052 aluminum alloy annealed with different heating rates[50]

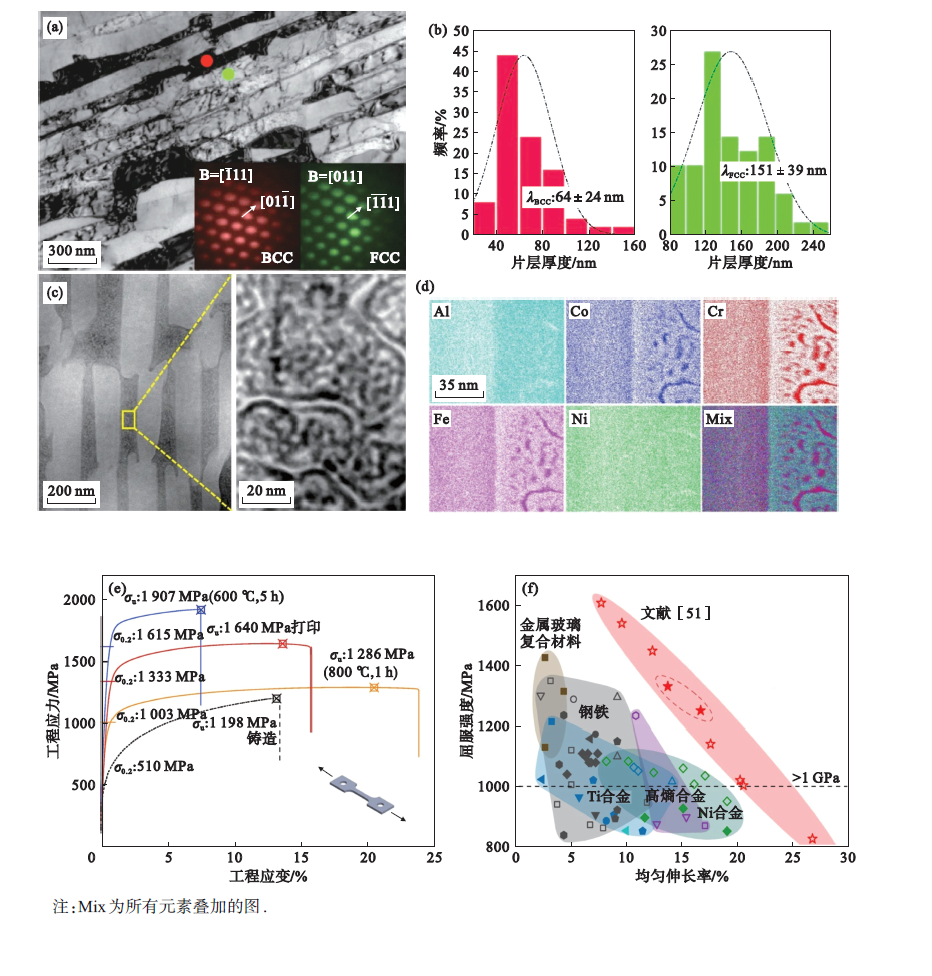

图6 激光粉末床熔融(L-PBF)技术打印的双相纳米层状高熵合金(HEAs)AlCoCrFeNi2.1的结构及性能[51]注:Mix为所有元素叠加的图.

Fig.6 The structure and properties of dual phase nano layered high entropy alloy (HEAs) AlCoCrFeNi2.1 printed by laser powder bed melting (L-PBF) technology[51]

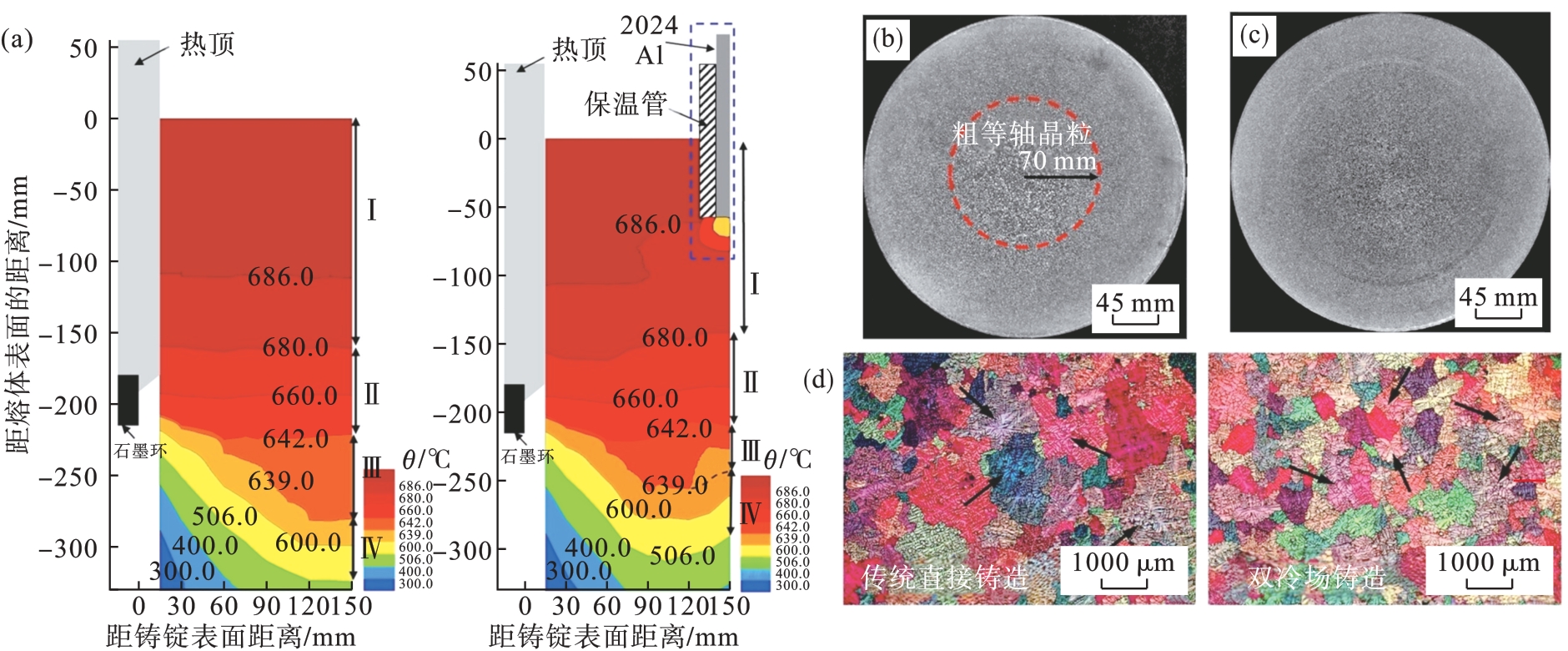

图7 热顶双冷场辅助直接冷却铸造大尺寸2024铝合金锭坯[15]注:Ⅰ为高温熔体区;Ⅱ为液相冷却区;Ⅲ为浆料区;Ⅳ为糊状区.(a)—无(左图)和有(右图)2024铝插块的直流铸造工艺的温度分布; (b)—未加入2024铝插块的锭坯宏观组织;(c)—加入2024铝插块的锭坯宏观组织; (d)—未加入(左图)和加入(右图)2024铝插块的锭坯显微组织对比.

Fig.7 Hot-top direct chill casting of large-size 2024 aluminum alloy ingots assisted by a twin-cooling field[15]

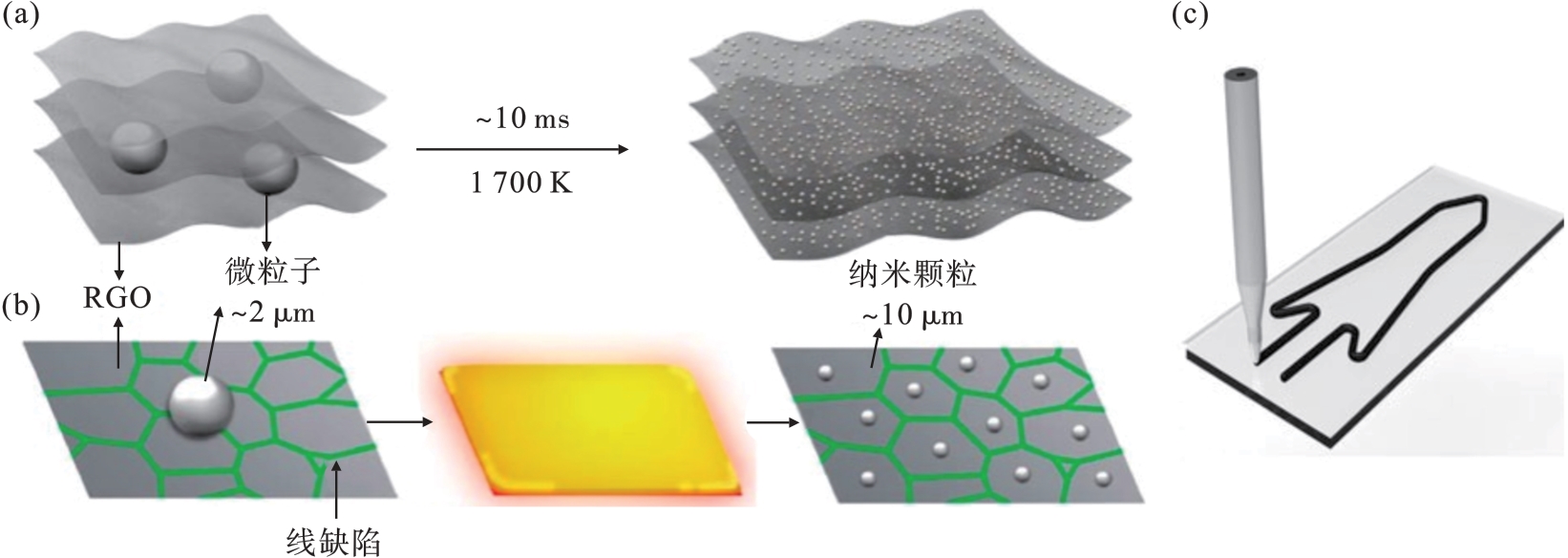

图9 原位铝纳米颗粒自组装过程示意图[68](a)—导电还原氧化石墨烯(RGO)网络基质中的微米级颗粒(左)通过直接焦耳加热(约10 ms)自组装成纳米颗粒(右); (b)—提出的纳米颗粒形成机制:微米级颗粒在加热时熔化,并由于RGO片层缺陷的限制作用自组装成纳米颗粒;(c)—原材料可用于3D打印,在导电的RGO基质中形成纳米颗粒.

Fig.9 Schematic diagram of the in situ self-assembly process of aluminum nanoparticles[68]

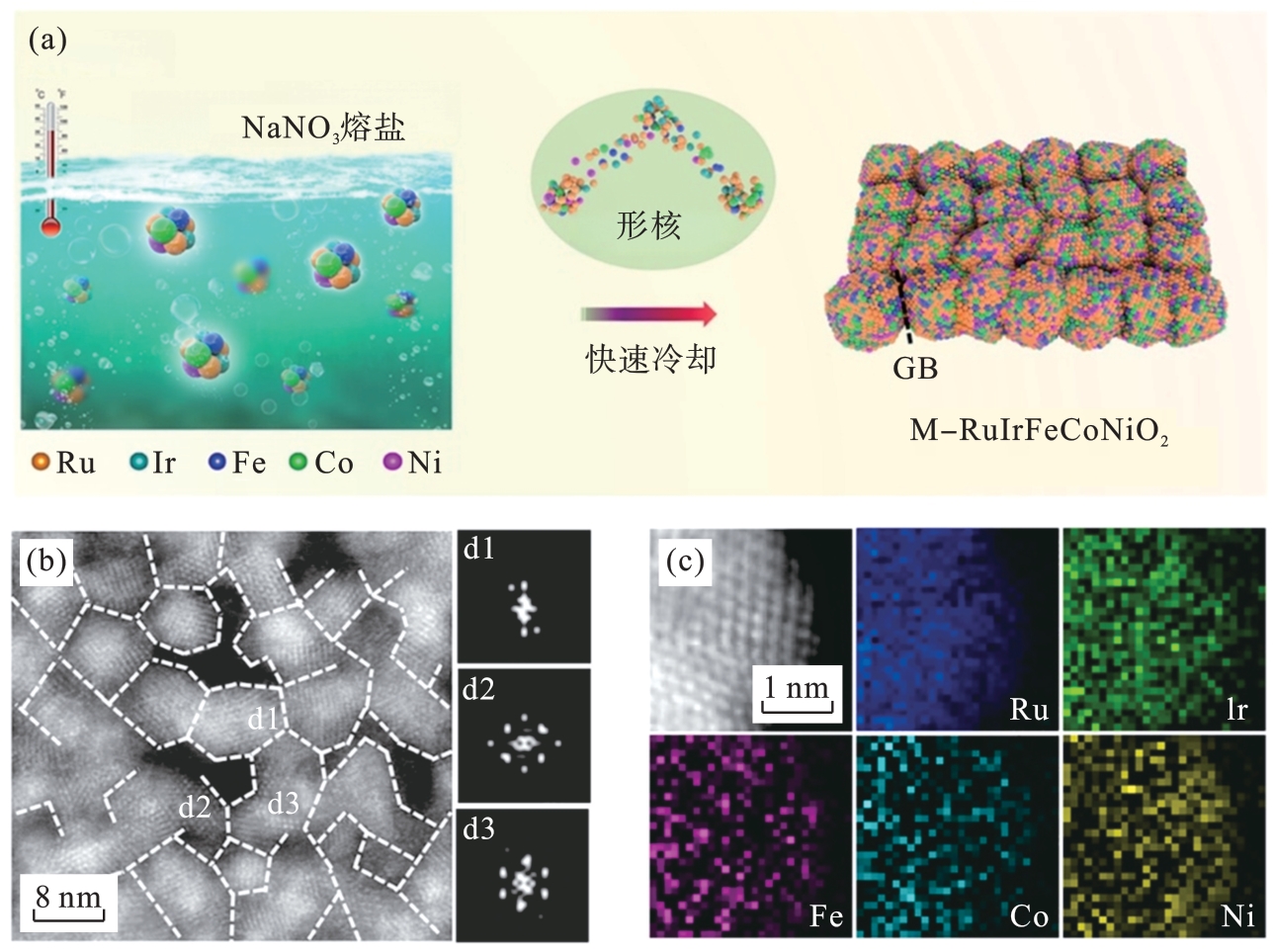

图10 高熵M-RuIrFeCoNiO2的合成与表征[70](a)—快速非平衡合成M-RuIrFeCoNiO2的示意图,展示了晶界(GB)的生成; (b)—经像差校正的高角环形暗场扫描透射电子显微镜(HAADF-STEM)图像,左图中用白色虚线标记了丰富的晶界(GB),快速傅里叶变换(FFT)图案显示了纳米颗粒的不同取向(右图); (c)—HAADF-STEM图像及M-RuIrFeCoNiO2的元素分布图.

Fig.10 Synthesis and characterization of high-entropy M-RuIrFeCoNiO2[70]

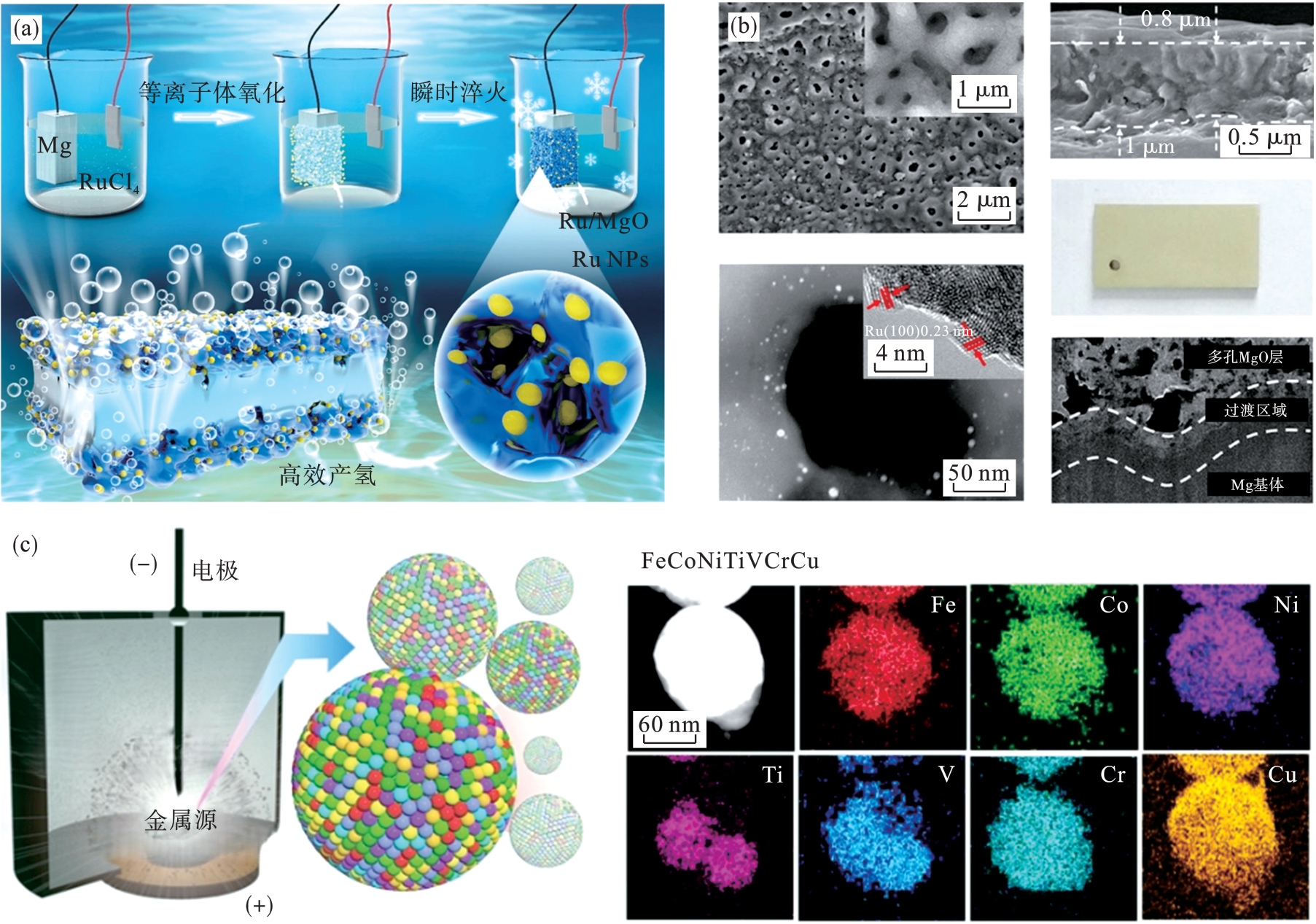

图12 通过高温等离子体电解氧化[81]和电弧放电[85]的方法制备远平衡功能材料

Fig.12 Preparation of far-from-equilibrium functional materials via high-temperature plasma electrolytic oxidation[81] and arc discharge[85] methods

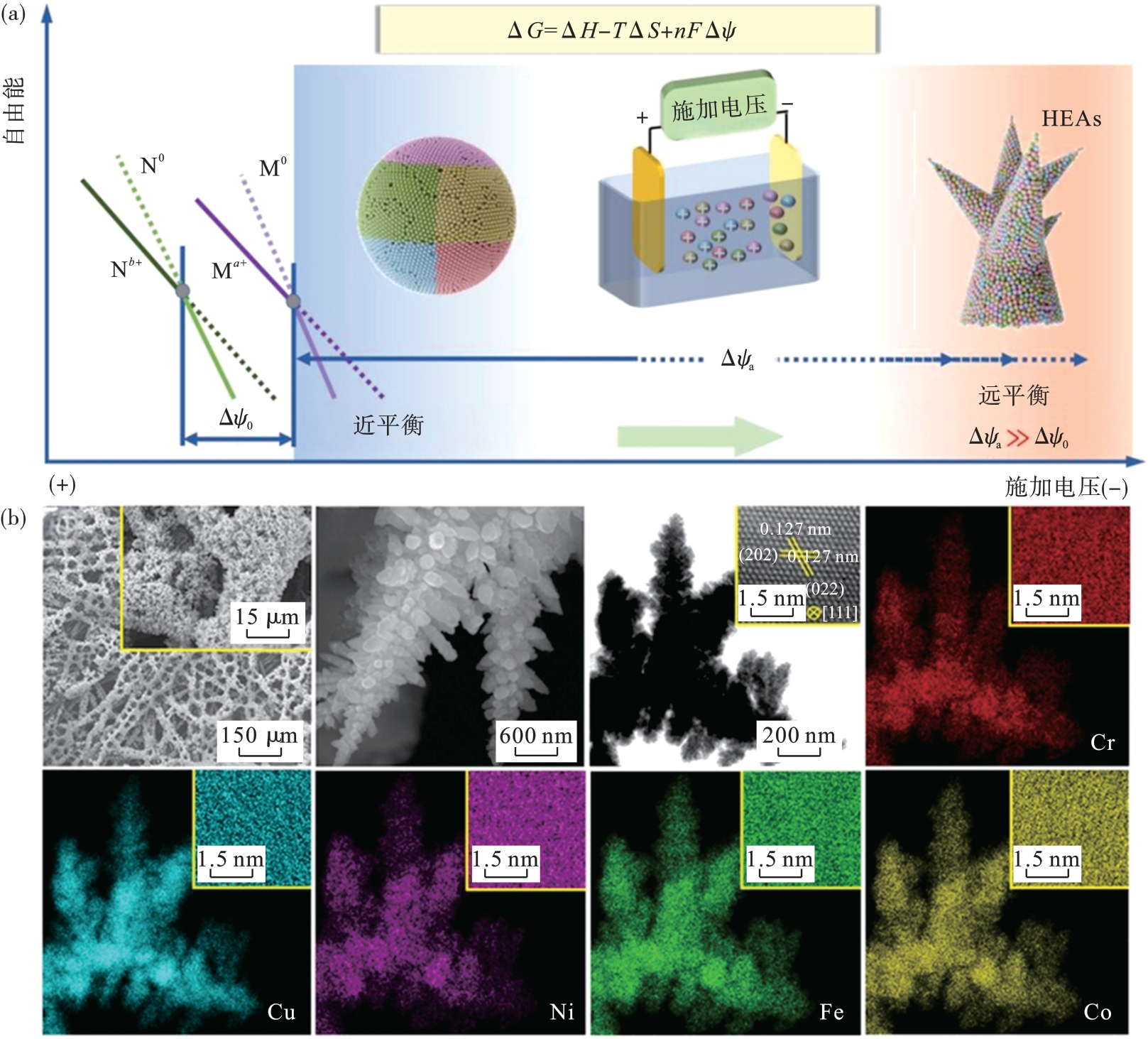

图13 通过超大过电势的电化学方法制备纳米多孔分级高熵合金[86](a)—远平衡电化学方法合成HEAs机理图; (b)—电沉积分级结构FeCoNiCrCu高熵合金形貌的SEM图和HAADF-STEM图像对应的EDS元素分布.

Fig.13 Nanoporous hierarchical high-entropy alloys via an electrochemical method with ultrahigh overpotential[86]

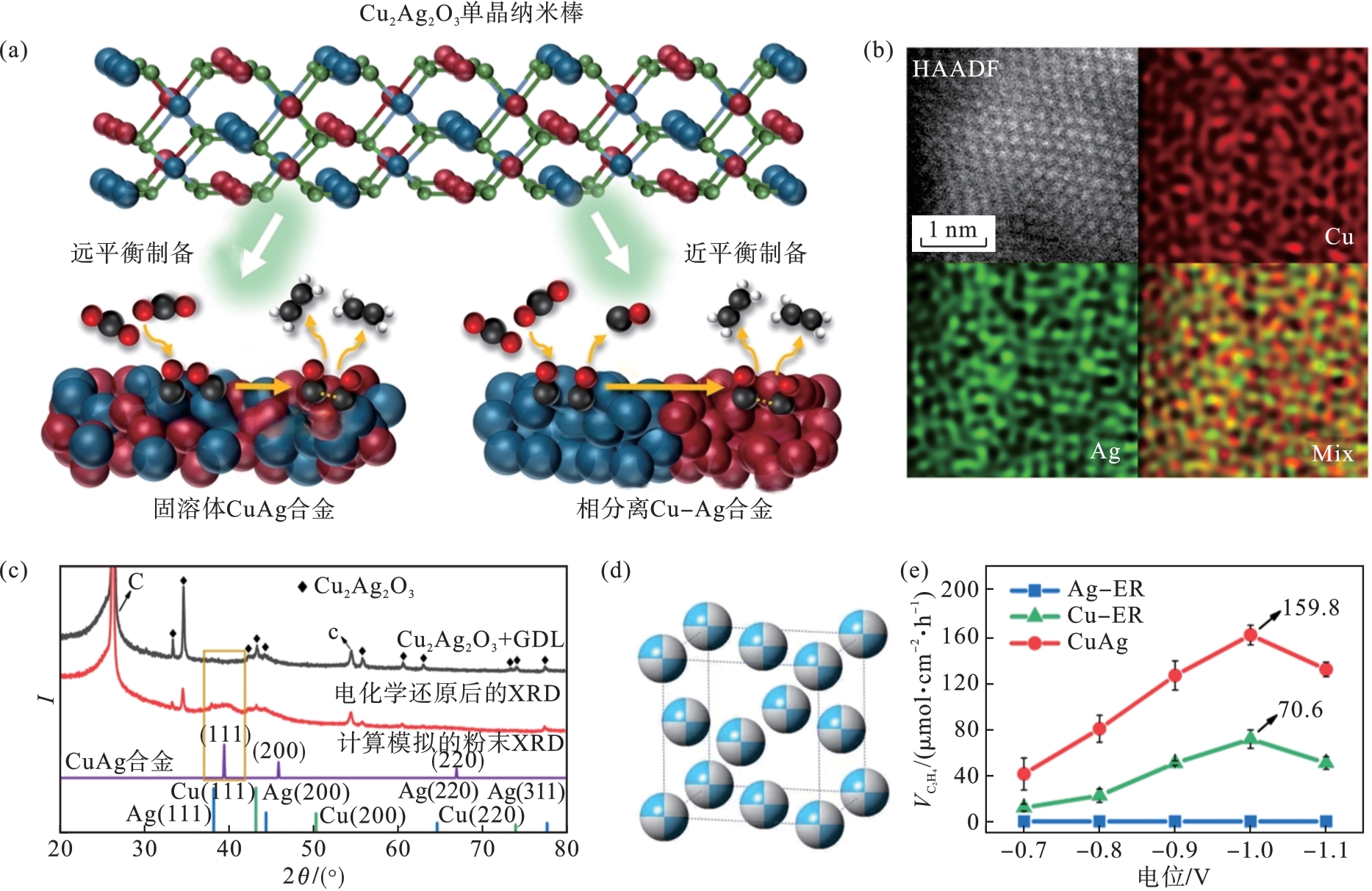

图14 通过超大过电势的电化学方法制备固溶体CuAg纳米合金[89]注:ER表示电化学还原.(a)—远平衡电化学方法制备固溶体CuAg合金示意图; (b)—原子级分辨下的HADDF-STEM的EDS元素分布;(c)—XRD谱; (d)—CuAg固溶体FCC晶胞示意图; (e)—CuAg固溶体的二氧化碳还原(CO2RR)性能.

Fig.14 Preparation of solid solution CuAg nanoalloys via an electrochemical method with ultrahigh overpotential[89]

| 技术类型 | 材料类型 | 性能指标类别 | 代表性评价指标 |

|---|---|---|---|

| 超快热处理(FJH,CTS等) | 高熵合金、钢铁 | 力学性能 | 屈服强度(σ)、抗拉强度(UTS)、断后伸长率(EL)、强度与塑性积(UTS×EL) |

| 显微结构参数 | 晶粒尺寸分布、位错密度、析出物密度(/m3)、平均粒径、孪晶密度 | ||

| 空间温差调控(增材制造等) | 铝合金、HEAs | 组织均匀性 | 晶粒尺寸梯度、组织双峰程度、元素偏析因子、冷却速率、热流密度 |

| 焦耳热/放电等极端加热 | 功能氧化物、MOFs | 电催化性能 | 起始过电位、Tafel斜率、电化学活性表面积(ECSA)、金属负载量、粒径分布 |

| 电化学合成(电沉积、脉冲) | HER/ORR/CO2RR | 催化效率 | 法拉第效率、电流密度(mA/cm2)、生成速率(μmol/cm2·s) |

表1 不同远平衡技术路径的典型材料类型与可比性能指标 (processing techniques)

Table 1 Representative material types and unified performance metrics across various far-from-equilibrium

| 技术类型 | 材料类型 | 性能指标类别 | 代表性评价指标 |

|---|---|---|---|

| 超快热处理(FJH,CTS等) | 高熵合金、钢铁 | 力学性能 | 屈服强度(σ)、抗拉强度(UTS)、断后伸长率(EL)、强度与塑性积(UTS×EL) |

| 显微结构参数 | 晶粒尺寸分布、位错密度、析出物密度(/m3)、平均粒径、孪晶密度 | ||

| 空间温差调控(增材制造等) | 铝合金、HEAs | 组织均匀性 | 晶粒尺寸梯度、组织双峰程度、元素偏析因子、冷却速率、热流密度 |

| 焦耳热/放电等极端加热 | 功能氧化物、MOFs | 电催化性能 | 起始过电位、Tafel斜率、电化学活性表面积(ECSA)、金属负载量、粒径分布 |

| 电化学合成(电沉积、脉冲) | HER/ORR/CO2RR | 催化效率 | 法拉第效率、电流密度(mA/cm2)、生成速率(μmol/cm2·s) |

| [1] | Li Z W, Gan M Y, Wang Y, et al. Superior activity and durability of Co3Mo correlated with interfacial microenvironment for hydrogen evolution[J]. Applied Catalysis B: Environmental and Energy, 2024, 358: 124395. |

| [2] | Yu Z R, Zhu L, Xu H X, et al. Selective enhancement of ethylene epoxidation via directing reaction pathways over Ag single-atom catalyst[J]. Industrial & Engineering Chemistry Research, 2024, 63(7): 3044-3056. |

| [3] | Dai Y Z, Li H, Wang C H, et al. Manipulating local coordination of copper single atom catalyst enables efficient CO2-to-CH4 conversion[J]. Nature Communications, 2023, 14(1): 3382. |

| [4] | 武晓雷,朱运田.异构金属材料及其塑性变形与应变硬化[J].金属学报,2022,58(11):1349-1359. |

| Wu Xiao-lei, Zhu Yun-tian. Heterostructured metallic materials: plastic deformation and strain hardening[J]. Acta Metallurgica Sinica, 2022, 58(11): 1349-1359. | |

| [5] | Zhu W, Gao X, Yao Y Y, et al. Nanostructured high entropy alloys as structural and functional materials[J]. ACS Nano, 2024, 18(20): 12672-12706. |

| [6] | Mishra R S, Gupta S. Microstructural engineering through high enthalpy states: implications for far-from-equilibrium processing of structural alloys[J]. Frontiers in Metals and Alloys, 2023(2): 1135481. |

| [7] | Yao G Y, Dong Q, Brozena A, et al. High-entropy nanoparticles: synthesis-structure-property relationships and data-driven discovery[J]. Science, 2022, 376(6589): eabn3103. |

| [8] | Yu Y H, Qin Z P, Zhang X F, et al. Far-from-equilibrium processing opens kinetic paths for engineering novel materials by breaking thermodynamic limits[J]. ACS Materials Letters, 2024, 7(1): 319-332. |

| [9] | Jiang R, Da Y M, Han X P, et al. Ultrafast synthesis for functional nanomaterials[J]. Cell Reports Physical Science, 2021, 2(1): 100302. |

| [10] | Eddy L, Xu S C, Liu C H, et al. Electric field effects in flash joule heating synthesis[J]. Journal of the American Chemical Society, 2024, 146(23): 16010-16019. |

| [11] | Skrabalak S E. Mashing up metals with carbothermal shock[J]. Science, 2018, 359(6383): 1467. |

| [12] | Liang Z, Sasikumar K, Keblinski P. Liquid phase stability under an extreme temperature gradient[J]. Physical Review Letters, 2013, 111(22): 225701. |

| [13] | Ramirez-Ledesma A L, Luna-Manuel J C, Lopez H F, et al. Defects induced through rapid solidification in a Co-20 Cr alloy[J]. Materials Science and Engineering: A, 2022, 844: 143161. |

| [14] | Yao Y G, Huang Z N, Xie P F, et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles[J]. Science, 2018, 359(6383): 1489-1494. |

| [15] | Zhu C, Zhao Z H, Zhu Q F, et al. Hot-top direct chill casting assisted by a twin-cooling field: improving the ingot quality of a large-size 2024 Al alloy[J]. Journal of Materials Science & Technology, 2022, 112: 114-122. |

| [16] | Yang C, Ko B H, Hwang S, et al. Overcoming immiscibility toward bimetallic catalyst library[J]. Science Advances, 2020, 6(17): eaaz6844. |

| [17] | Silvestroni L, Rueschhoff L M, Acord K A, et al. Synthesis of far-from-equilibrium materials for extreme environments[J]. MRS Bulletin, 2022, 47(11): 1143-1153. |

| [18] | Jung C, Ihm Y, Cho D H, et al. Inducing thermodynamically blocked atomic ordering via strongly driven nonequilibrium kinetics[J]. Science Advances, 2021, 7(52): eabj8552. |

| [19] | Düvel M, Merboldt M, Bange J P, et al. Far-from-equilibrium electron-phonon interactions in optically excited graphene[J]. Nano Letters, 2022, 22(12): 4897-4904. |

| [20] | Zhang Z M, Lu Z Y. Nonequilibrium theoretical framework and universal design principles of oscillation-driven catalysis[J]. Journal of Physical Chemistry Letters, 2023, 14(33): 7541-7548. |

| [21] | Bianchini M, Wang J, Clément R J, et al. The interplay between thermodynamics and kinetics in the solid-state synthesis of layered oxides[J]. Nature Materials, 2020, 19(10): 1088-1095. |

| [22] | Haugerud I S, Jaiswal P, Weber C A. Nonequilibrium wet-dry cycling acts as a catalyst for chemical reactions[J]. The Journal of Physical Chemistry B, 2024, 128(7): 1724-1736. |

| [23] | Tong X, Zhang Y E, Shang B S, et al. Breaking the vitrification limitation of monatomic metals[J]. Nature Materials, 2024, 23(9): 1193-1199. |

| [24] | Min Y, Kwak J, Soon A, et al. Nonstoichiometric nucleation and growth of multicomponent nanocrystals in solution[J]. Accounts of Chemical Research, 2014, 47(10): 2887-2893. |

| [25] | Xing Z Y, Lu J, Ji X L. A brief review of metallothermic reduction reactions for materials preparation[J]. Small Methods, 2018, 2(12): 1800062. |

| [26] | Maklar J, Windsor Y W, Nicholson C W, et al. Nonequilibrium charge-density-wave order beyond the thermal limit[J]. Nature Communications, 2021, 12: 2499. |

| [27] | Prigogine I, Stengers I. Order out of chaos: man’s new dialogue with nature [M]. New York: Bantam Books, 1984. |

| [28] | Dong Q, Lele A D, Zhao X P, et al. Depolymerization of plastics by means of electrified spatiotemporal heating[J]. Nature, 2023, 616(7957): 488-494. |

| [29] | Han Y C, Cao P Y, Tian Z Q. Controllable synthesis of solid catalysts by high-temperature pulse[J]. Accounts of Materials Research, 2023, 4(8): 648-654. |

| [30] | Goldstein R, Eddir T, Buchner E, et al. Modeling of temperature gradients during short time dilatometry testing[J]. Journal of Materials Engineering and Performance, 2020, 29(6): 3638-3660. |

| [31] | Chen A N, Wang W Y, Mao Z Y, et al. Multimaterial 3D and 4D bioprinting of heterogenous constructs for tissue engineering[J]. Advanced Materials, 2024, 36(34): 2307686. |

| [32] | Zhu C, Gemeda H B, Duoss E B, et al. Toward multiscale, multimaterial 3D printing[J]. Advanced Materials, 2024, 36(34): 2314204. |

| [33] | 马恩,刘畅.如何使合金兼具高强度与高塑性[J].金属学报,2025,61(5):665-673. |

| Ma En, Liu Chang. Achieving alloys with concurrent high strength and high ductility[J]. Acta Metallurgica Sinica, 2025, 61(5): 665-673. | |

| [34] | Li W D, Xie D, Li D Y, et al. Mechanical behavior of high-entropy alloys[J]. Progress in Materials Science, 2021, 118: 100777. |

| [35] | Miracle D B, Senkov O N. A critical review of high entropy alloys and related concepts[J]. Acta Materialia, 2017, 122: 448-511. |

| [36] | Wu Q F, He F, Li J J, et al. Phase-selective recrystallization makes eutectic high-entropy alloys ultra-ductile[J]. Nature Communications, 2022, 13(1): 4697. |

| [37] | Wang N, Nutor R K, Li Y X, et al. Tuning mechanical properties of high entropy alloys by electro-pulsing method[J]. Journal of Alloys and Compounds, 2022, 902: 163684. |

| [38] | Liu L Y, Zhang Y, Rogozhkin S, et al. Enhanced ductility via high-density nanoprecipitates driven by chemical supersaturation in a flash-heated precipitation-strengthened high-entropy alloy[J]. Acta Materialia, 2024, 281: 120434. |

| [39] | Mishnev R, Borisova Y, Kniaziuk T, et al. Phase transformations during partitioning in a Q&P steel with blocky retained austenite[J]. Materials Science and Engineering: A, 2024, 915: 147184. |

| [40] | Speer J, Matlock D K, de Cooman B C, et al. Carbon partitioning into austenite after martensite transformation[J]. Acta Materialia, 2003, 51(9): 2611-2622. |

| [41] | Toji Y, Miyamoto G, Raabe D. Carbon partitioning during quenching and partitioning heat treatment accompanied by carbide precipitation[J]. Acta Materialia, 2015, 86: 137-147. |

| [42] | Papaefthymiou S, Banis A, Bouzouni M, et al. Effect of ultra-fast heat treatment on the subsequent formation of mixed martensitic/bainitic microstructure with carbides in a CrMo medium carbon steel[J]. Metals, 2019, 9(3): 312. |

| [43] | Valdes-Tabernero M A, Vercruysse F, Sabirov I, et al. Effect of ultrafast heating on the properties of the microconstituents in a low-carbon steel[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2018, 49(8): 3145-3150. |

| [44] | de Knijf D, Puype A, Föjer C, et al. The influence of ultra-fast annealing prior to quenching and partitioning on the microstructure and mechanical properties[J]. Materials Science and Engineering: A, 2015, 627: 182-190. |

| [45] | Tan X D, Lu W J, Rao X. Effect of ultra-fast heating on microstructure and mechanical properties of cold-rolled low-carbon low-alloy Q&P steels with different austenitizing temperature[J]. Materials Characterization, 2022, 191: 112086. |

| [46] | Bertolo V, Vilasi L, Jiang Q, et al. Grain refinement by rapid cyclic heating and its effect on cleavage fracture behaviour of an S690 high strength steel[J]. Journal of Materials Research and Technology, 2023, 23: 1919-1933. |

| [47] | Yuan Q, Ren J, Mo J, et al. Effects of rapid heating on the phase transformation and grain refinement of a low-carbon mciroalloyed steel[J]. Journal of Materials Research and Technology, 2023, 23: 3756-3771. |

| [48] | Wen P Y, Hu B, Han J S, et al. A strong and ductile medium Mn steel manufactured via ultrafast heating process[J]. Journal of Materials Science & Technology, 2022, 97: 54-68. |

| [49] | Li Z H, Zhang J H, Xiao T X, et al. Regulating microstructure and improving precipitation hardening response of fine-grained Mg-RE-Ag hot-extruded alloy by extreme short-time heat treatment[J]. Materials Science and Engineering: A, 2024, 892: 146059. |

| [50] | Wen W Y, Zhao Y J, Deng Y J, et al. “Soft-hard” microstructure evolution and its relevance to high strength-plasticity and low plastic anisotropy of Al-Mg alloys based on ultra-fast heating[J]. Materials Science and Engineering: A, 2024, 893: 146154. |

| [51] | Ren J, Zhang Y, Zhao D X, et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing[J]. Nature, 2022, 608(7921): 62-68. |

| [52] | Liu Q, Chu S J, Zhang X, et al. Laser shock processing of titanium alloys: a critical review on the microstructure evolution and enhanced engineering performance[J]. Journal of Materials Science & Technology, 2025, 209: 262-291. |

| [53] | DePond P J, Fuller J C, Khairallah S A, et al. Laser-metal interaction dynamics during additive manufacturing resolved by detection of thermally-induced electron emission[J]. Communications Materials, 2020(1): 92. |

| [54] | Kermani M, Dong J, Biesuz M, et al. Ultrafast high-temperature sintering (UHS) of fine grained α-Al2O3 [J]. Journal of the European Ceramic Society, 2021, 41(13): 6626-6633. |

| [55] | Karma A, Tourret D. Atomistic to continuum modeling of solidification microstructures[J]. Current Opinion in Solid State and Materials Science, 2016, 20(1): 25-36. |

| [56] | Tourret D, Liu H, LLorca J. Phase-field modeling of microstructure evolution: recent applications, perspectives and challenges[J]. Progress in Materials Science, 2022, 123: 100810. |

| [57] | Ji K H, Dorari E, Clarke A J, et al. Microstructural pattern formation during far-from-equilibrium alloy solidification[J]. Physical Review Letters, 2023, 130(2): 026203. |

| [58] | Kavousi S, Novak B R, Hoyt J, et al. Interface kinetics of rapid solidification of binary alloys by atomistic simulations: application to Ti-Ni alloys[J]. Computational Materials Science, 2020, 184: 109854. |

| [59] | Li Y, Wang L, Wang Z J, et al. A phase-field model bridging near-equilibrium and far-from-equilibrium alloy solidification[J]. Acta Materialia, 2025, 284: 120596. |

| [60] | Haapalehto M, Pinomaa T, Wang L, et al. An atomistic simulation study of rapid solidification kinetics and crystal defects in dilute Al-Cu alloys[J]. Computational Materials Science, 2022, 209: 111356. |

| [61] | Antillon E A, Hareland C A, Voorhees P W. Solute trapping and solute drag during non-equilibrium solidification of Fe-Cr alloys[J]. Acta Materialia, 2023, 248: 118769. |

| [62] | Zhu C, Zhao Z H, Zhu Q F, et al. Floating grain formation and macrosegregation in a 2024 Al alloy prepared by hot-top DC casting with a 2024 Al alloy insert[J]. Metallurgical and Materials Transactions A, 2021, 52(8): 3342-3352. |

| [63] | Zhu C, Zhao Z H, Wang G S, et al. Effect of 2024 Al alloy insert on the grain refinement of a 2024 Al alloy prepared via insert mold casting[J]. Metals, 2019, 9(10): 1126. |

| [64] | Zhu C, Zhao Z H, Zhu Q F, et al. Structures and macrosegregation of a 2024 aluminum alloy fabricated by direct chill casting with double cooling field[J]. China Foundry, 2022, 19(1): 1-8. |

| [65] | Liu Y L, Chen H, Xu C J, et al. Control of catalytic activity of nano-Au through tailoring the Fermi level of support[J]. Small, 2019, 15(34): 1901789. |

| [66] | Li C Y, Wang Z J, Liu M D, et al. Ultrafast self-heating synthesis of robust heterogeneous nanocarbides for high current density hydrogen evolution reaction[J]. Nature Communications, 2022, 13(1): 3338. |

| [67] | Ahn J, Park S, Oh D H, et al. Rapid joule heating synthesis of oxide-socketed high-entropy alloy nanoparticles as CO2 conversion catalysts[J]. ACS Nano, 2023, 17(13): 12188-12199. |

| [68] | Chen Y N, Egan G C, Wan J Y, et al. Ultra-fast self-assembly and stabilization of reactive nanoparticles in reduced graphene oxide films[J]. Nature Communications, 2016, 7: 12332. |

| [69] | Dou S M, Xu J, Zhang D F, et al. Ultrarapid nanomanufacturing of high-quality bimetallic anode library toward stable potassium-ion storage[J]. Angewandte Chemie International Edition, 2023, 62(26): e202303600. |

| [70] | Hu C, Yue K, Han J, et al. Misoriented high-entropy iridium ruthenium oxide for acidic water splitting[J]. Science Advances, 2023, 9(37): eadf9144. |

| [71] | Dou X W, Hasa I, Saurel D, et al. Hard carbons for sodium-ion batteries: structure, analysis, sustainability, and electrochemistry[J]. Materials Today, 2019, 23: 87-104. |

| [72] | Luong D X, Bets K V., Algozeeb W A, et al. Gram-scale bottom-up flash graphene synthesis[J]. Nature, 2020, 577(7792): 647-651. |

| [73] | Stanford M G, Bets K V, Luong D X, et al. Flash graphene morphologies[J]. ACS Nano, 2020, 14(10): 13691-13699. |

| [74] | Liu J J, You Y W, Huang L, et al. Precisely tunable instantaneous carbon rearrangement enables low-working-potential hard carbon toward sodium-ion batteries with enhanced energy density[J]. Advanced Materials, 2024, 36(44): 2407369. |

| [75] | Au H, Alptekin H, Jensen A C S, et al. A revised mechanistic model for sodium insertion in hard carbons[J]. Energy & Environmental Science, 2020, 13(10): 3469-3479. |

| [76] | Chen D Q, Zhang W, Luo K Y, et al. Hard carbon for sodium storage: mechanism and optimization strategies toward commercialization[J]. Energy & Environmental Science, 2021, 14(4): 2244-2262. |

| [77] | Han Y C, Yi J, Pang B B, et al. Graphene-confined ultrafast radiant heating for high-loading subnanometer metal cluster catalysts[J]. National Science Review, 2023, 10(6): nwad081. |

| [78] | Han Y C, Liu M L, Sun L, et al. A general strategy for overcoming the trade-off between ultrasmall size and high loading of MOF-derived metal nanoparticles by millisecond pyrolysis[J]. Nano Energy, 2022, 97: 107125. |

| [79] | Xie H, Hong M, Hitz E M, et al. High-temperature pulse method for nanoparticle redispersion[J]. Journal of the American Chemical Society, 2020, 142(41): 17364-17371. |

| [80] | Ntomprougkidis V, Martin J, Nominé A, et al. Sequential run of the PEO process with various pulsed bipolar current waveforms[J]. Surface and Coatings Technology, 2019, 374: 713-724. |

| [81] | Cao X Q, Zhou J, Zhai Z P, et al. Synchronous growth of porous MgO and half-embedded nano-Ru on a Mg plate: a monolithic catalyst for fast hydrogen production[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(9): 3616-3623. |

| [82] | Cao X Q, Zhou J, Li S, et al. Ultra-stable metal nano-catalyst synthesis strategy: a perspective[J]. Rare Metals, 2020, 39(2): 113-130. |

| [83] | Cao X Q, Zhou J, Wang H N, et al. Abnormal thermal stability of sub-10 nm Au nanoparticles and their high catalytic activity[J]. Journal of Materials Chemistry A, 2019, 7(18): 10980-10987. |

| [84] | Li Y X, Liao Y J, Ji L Z, et al. Quinary high-entropy-alloy@graphite nanocapsules with tunable interfacial impedance matching for optimizing microwave absorption[J]. Small, 2022, 18(4): 2107265. |

| [85] | Li Y X, Liao Y J, Zhang P J, et al. High-entropy-alloy nanoparticles with enhanced interband transitions for efficient photothermal conversion[J]. Angewandte Chemie:International Edition, 2021, 60(52): 27113-27118. |

| [86] | Wang Y N, Yang H, Zhang Z, et al. Far-from-equilibrium electrosynthesis ramifies high-entropy alloy for alkaline hydrogen evolution[J]. Journal of Materials Science & Technology, 2023, 166: 234-240. |

| [87] | Wu C Y, Hsiao Y C, Chen Y, et al. A catalyst family of high-entropy alloy atomic layers with square atomic arrangements comprising iron-and platinum-group metals[J]. Science Advances, 2024, 10(30): eadl3693. |

| [88] | Mattarozzi L, Cattarin S, Comisso N, et al. Electrodeposition of metastable Ag-Rh alloys and study of their hydrogen storage ability in comparison with Pd[J]. Electrochimica Acta, 2018, 271: 370-378. |

| [89] | Yu Y H, Wang D, Hong Y M, et al. Bulk-immiscible CuAg alloy nanorods prepared by phase transition from oxides for electrochemical CO2 reduction[J]. Chemical Communications, 2022, 58(79): 11163-11166. |

| [90] | Wang Y F, Hall A S. Pulsed electrodeposition of metastable Pd31Bi12 nanoparticles for oxygen reduction electrocatalysis[J]. ACS Energy Letters, 2020, 5(1): 17-22. |

| [1] | 公卫江;谢雪峰;魏国柱;. 受多体效应影响的平行双量子点结构中的自旋输运[J]. 东北大学学报(自然科学版), 2010, 31(5): 753-756. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||