东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 113-123.DOI: 10.12068/j.issn.1005-3026.2025.20240214

• 研究论文 • 上一篇

孟凡帝, 万心语, 蔡亚慧, 刘莉

收稿日期:2024-11-19

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

孟凡帝

作者简介:孟凡帝(1988—),男,黑龙江大庆人,东北大学副教授,博士生导师.

基金资助:Fan-di MENG, Xin-yu WAN, Ya-hui CAI, Li LIU

Received:2024-11-19

Online:2025-08-15

Published:2025-11-24

Contact:

Fan-di MENG

摘要:

涂料体系中填料/树脂的界面相容性是提高涂层防护性能的关键.有机防腐涂层中常用的云母填料经过处理后,采用常温、不同温度热场辅助条件下的机械力化学法制备云母-环氧树脂改性填料,通过傅里叶变换红外光谱(FTIR)、热重分析(TGA)等测试评价了填料/涂层界面化学键合的可行性.结果表明,热场辅助机械力化学法可实现常规情况下树脂与云母不易进行的化学反应.通过耐蚀测试证明了添加改性云母的环氧涂层具有更优异的耐蚀性能,同时探讨了改性云母填料对涂层的作用机理,为热场辅助机械力化学法调控环氧涂层防腐性能研究提供了理论依据.

中图分类号:

孟凡帝, 万心语, 蔡亚慧, 刘莉. 热场辅助机械力化学法制备界面化学键合防腐涂层[J]. 东北大学学报(自然科学版), 2025, 46(8): 113-123.

Fan-di MENG, Xin-yu WAN, Ya-hui CAI, Li LIU. Interface Chemical Bonded Anticorrosion Coatings of Prepared by Thermal Field-Assisted Mechanochemistry[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 113-123.

| C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|

| 0.17 | 0.35 | 1.40 | 0.012 | 0.015 | 余量 |

表1 Q235钢的化学成分(质量分数) ((mass fraction) %)

Table 1 Chemical composition of Q235 steel

| C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|

| 0.17 | 0.35 | 1.40 | 0.012 | 0.015 | 余量 |

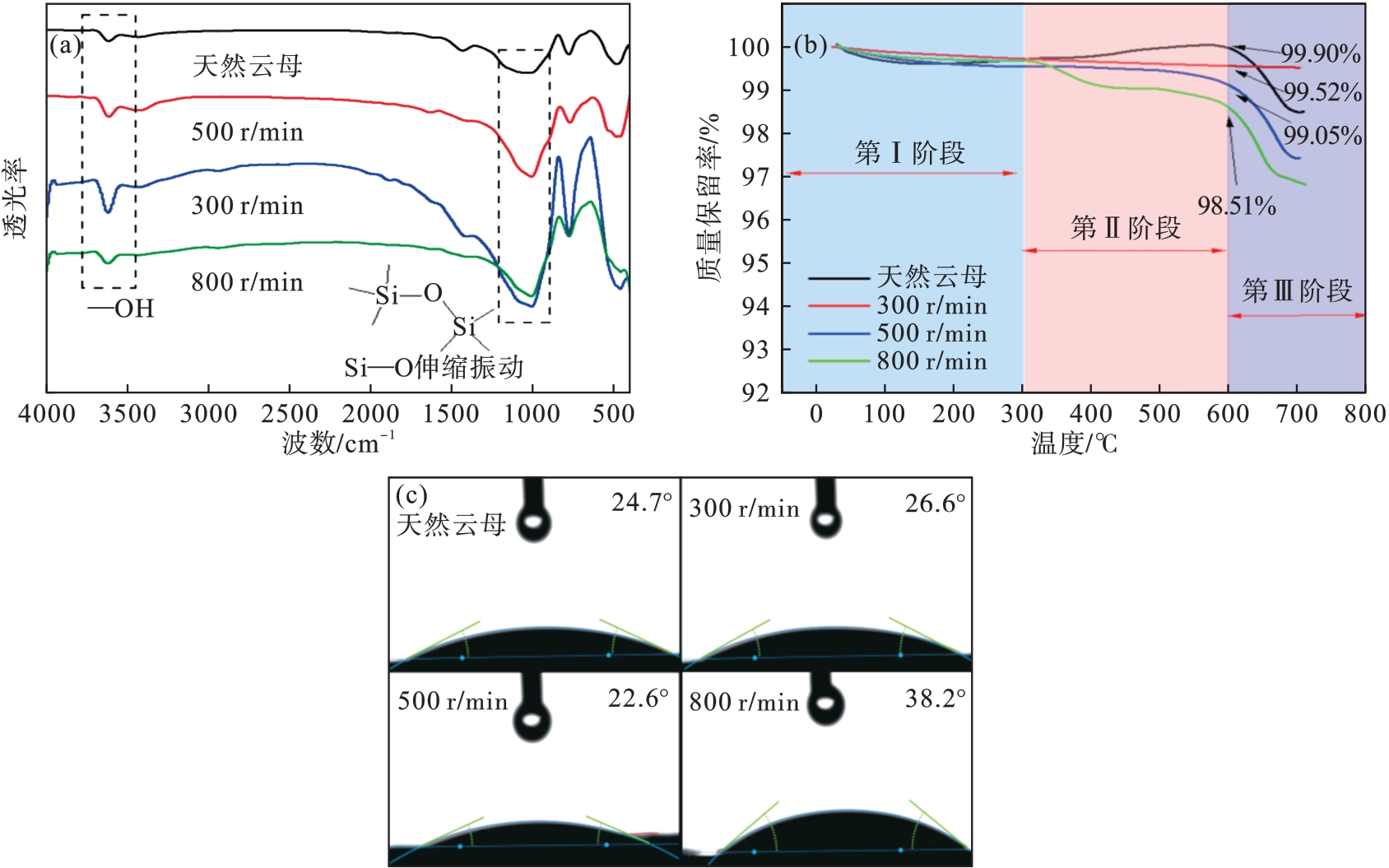

图2 天然云母与常温下不同转速机械力化学处理云母后的粉末表征结果(a)—填料粉末的红外光谱; (b)—填料粉末的热重结果; (c)—填料粉末的接触角结果.

Fig.2 Powder characterization results of untreated mica and mechanochemically treated mica at different rotational speeds at room temperature

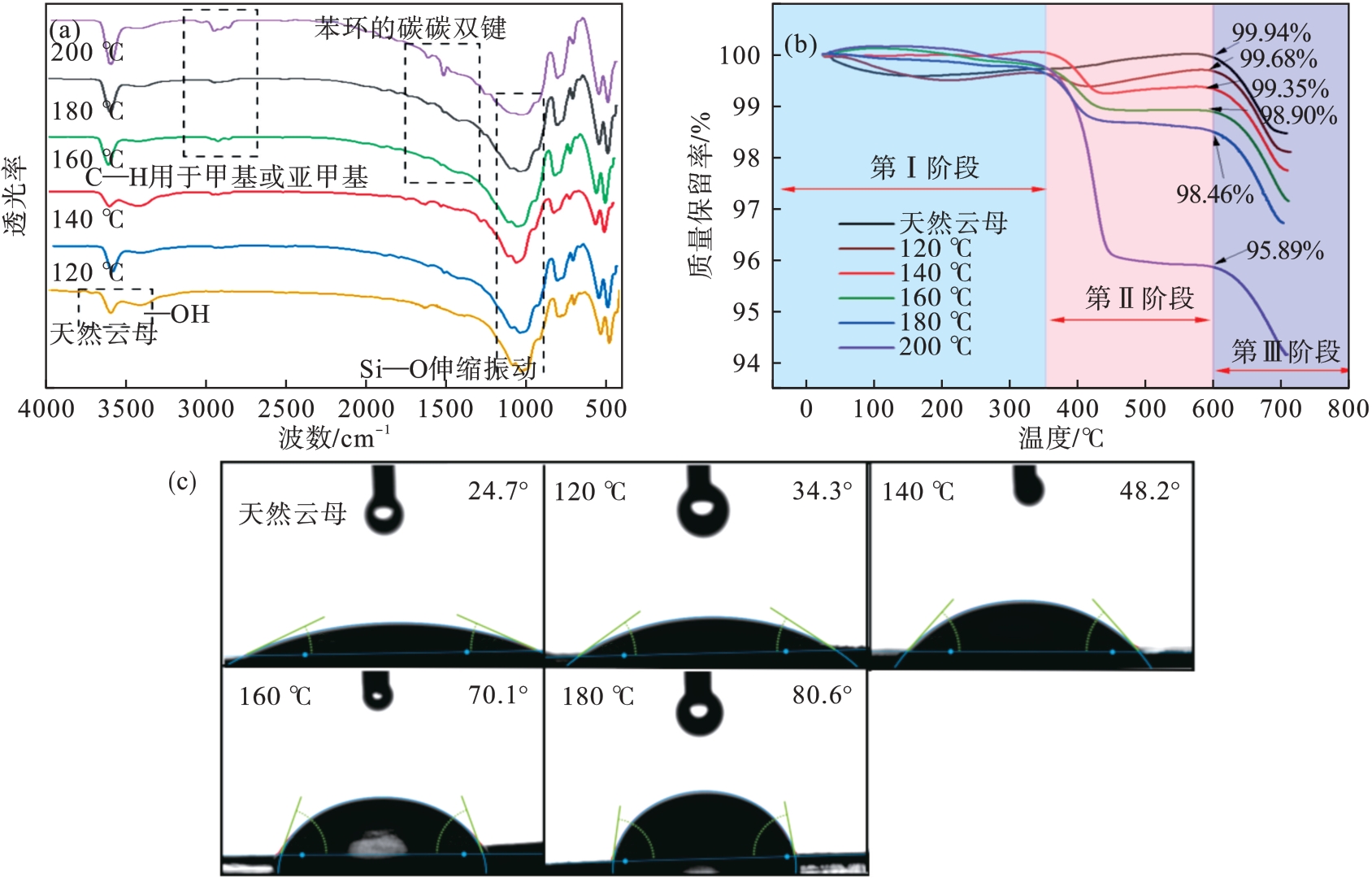

图3 天然云母与不同温度加热处理后的云母粉末表征结果(a)—填料粉末的红外光谱; (b)—填料粉末的热重结果; (c)—填料粉末的接触角结果.

Fig.3 Characterization results of untreated mica and heated mica at different temperatures

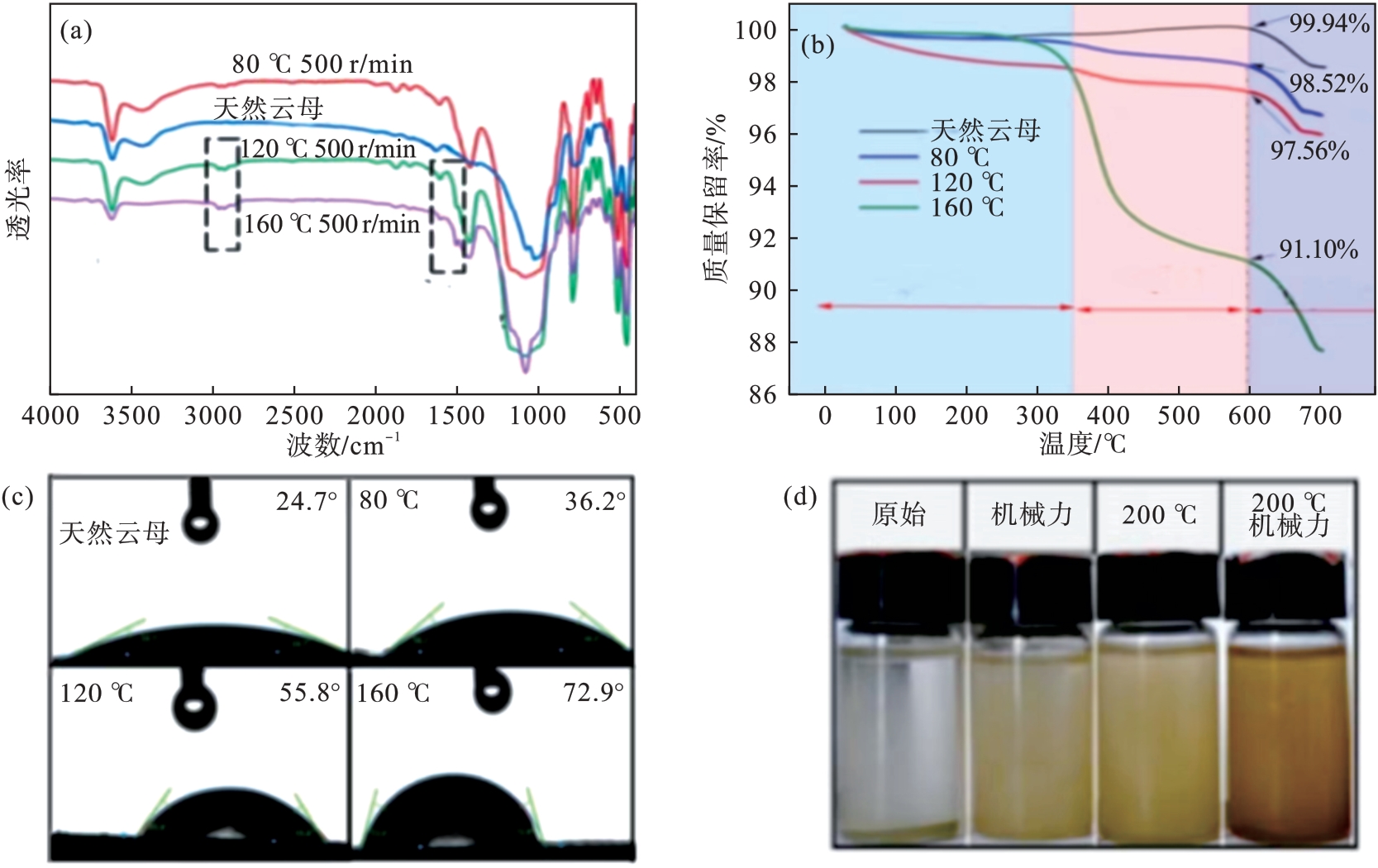

图4 热场辅助机械力化学法处理后的云母粉末表征结果(a)—填料粉末的红外光谱; (b)—填料粉末的热重结果; (c)—填料粉末的接触角结果;(d)—热场辅助机械力法处理填料与其他状态的填料7 d沉降测试结果对比.

Fig.4 Characterization results of mica treated by thermal field-assisted mechanochemistry

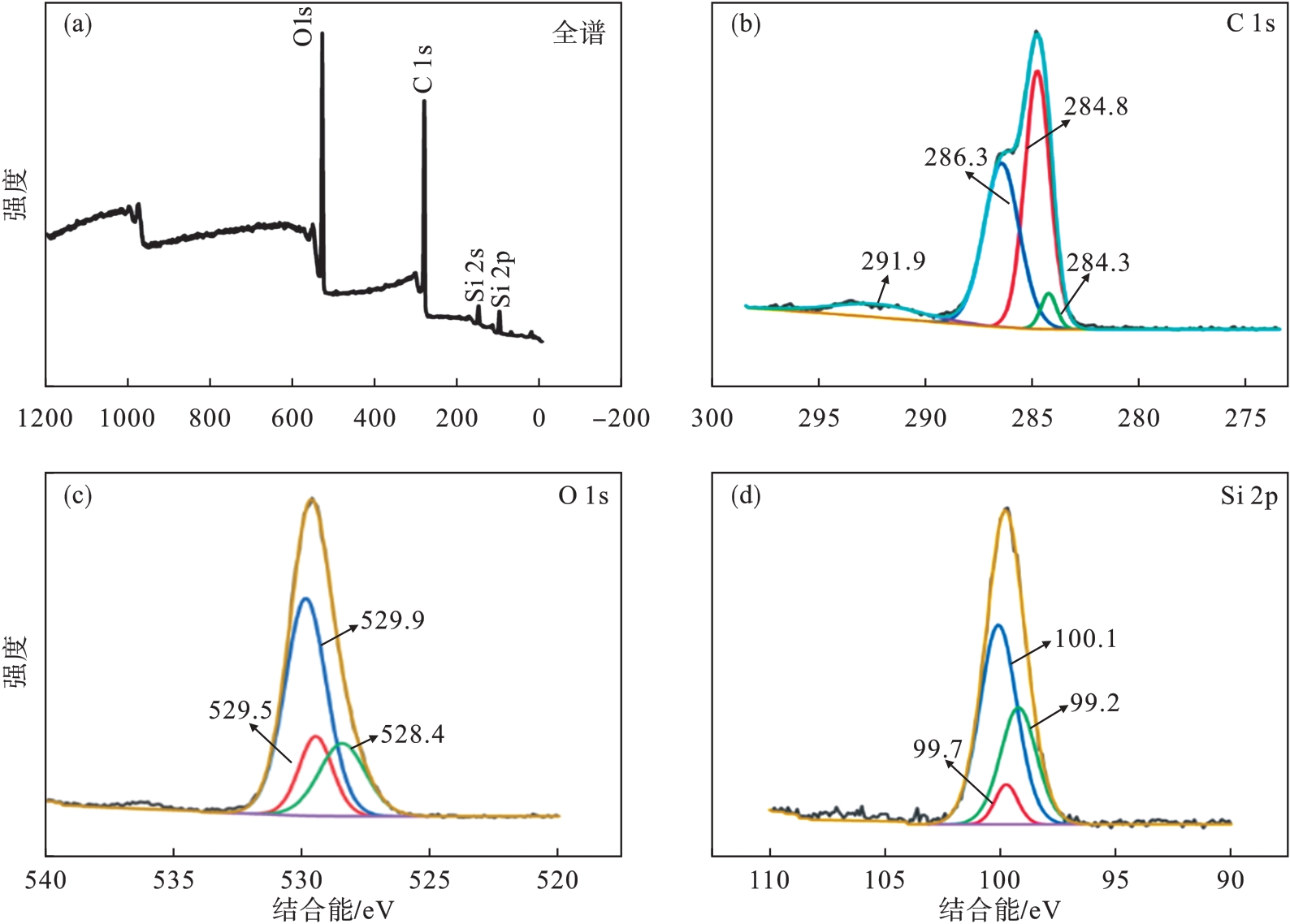

图7 160 ℃,600 r/min热场辅助机械力化学法处理后云母粉末的XPS谱(a)—全谱扫描; (b)—C元素高分辨扫描拟合谱; (c)—O元素高分辨扫描拟合谱; (d)—Si元素高分辨扫描拟合谱.

Fig.7 XPS spectra of mica power treated by thermal field-assisted mechanochemistry at 160 °C and 600 r/min

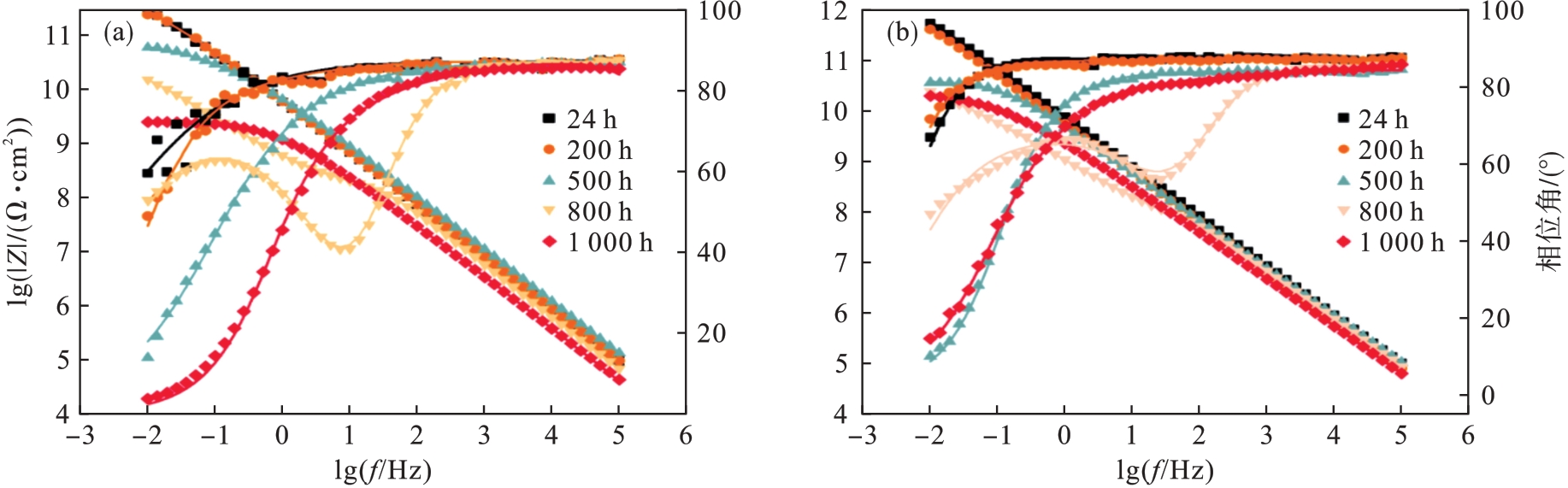

图11 涂层浸泡不同时间的电化学阻抗谱波特图(a)—改性云母/环氧树脂涂层; (b)—天然云母/环氧树脂涂层.

Fig.11 Bode plots of electrochemical impedance spectra of coatings with different immersion times

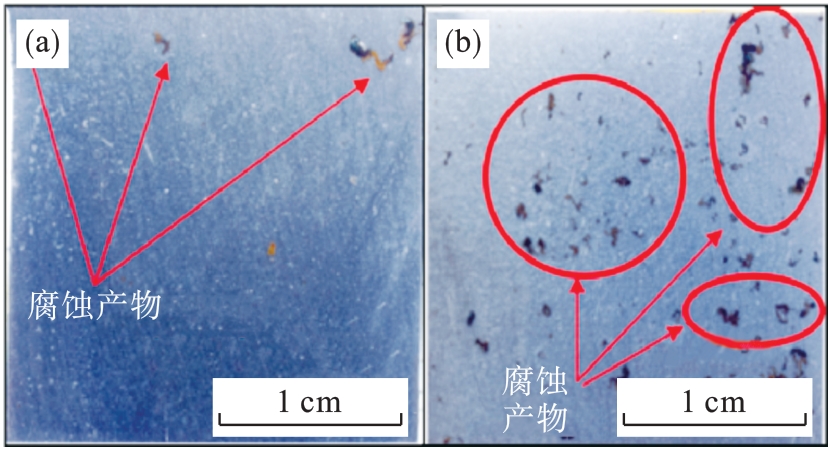

图12 改性前后云母/环氧树脂涂层在质量分数为3.5%的NaCl溶液浸泡3 840 h后的表面形貌(a)—天然云母/环氧树脂涂层;(b)—改性云母/环氧树脂涂层.

Fig.12 Surface morphology of mica/epoxy coating before and after modification after immersion in 3.5% NaCl solution for 3 840 h

| [1] | Clemente G, Gonçalves G H, Nassar E J, et al. The use of hybrid or nanocomposite materials as steel anticorrosive coatings [J]. Quimica Nova, 2021, 44(9): 1219-1223. |

| [2] | De Aguiar M F, Borges R A, Rocha M F B, et al. Synthesis and characterization of polypyrrole/Fe3O4 nanocomposites: a promising material against carbon steel corrosion [J]. Materials Research-Ibero-American Journal of Materials, 2023, 26(sup1): e20220549. |

| [3] | Blustein G, Di Sarli A R, Romagnoli R, et al. Estudio de las propiedades anticorrosivas del benzoato de hierro (III) en pinturas base solvente [J]. Información Tecnológica, 2006, 17(3): 95-98. |

| [4] | Loperena A P, Lehr I L, González M B, et al. Duplex coatings of cerium and epoxy modified with polypyrrole and silver nanoparticles formed onto AZ91D Mg alloy [J]. Materia-Rio De Janeiro, 2022, 27(2):e13170. |

| [5] | He X L, Li S H, Shen R B A, et al. A high-performance waterborne polymeric composite coating with long-term anti-corrosive property based on phosphorylation of chitosan-functionalized Ti3C2T x MXene [J]. Advanced Composites and Hybrid Materials, 2022, 5(3): 1699-1711. |

| [6] | Zhang T Y, Zhang T, He Y T, et al. Corrosion and aging of organic aviation coatings: a review [J]. Chinese Journal of Aeronautics, 2023, 36(4): 1-35. |

| [7] | Ramezanzadeh M, Ramezanzadeh B, Mahdavian M. Graphene skeletal nanotemplate coordinated with pH-responsive porous double-ligand metal-organic frameworks (DL-MOFs) through ligand exchange theory for high-performance smart coatings [J]. Chemical Engineering Journal, 2023, 461: 141869. |

| [8] | Lashgari S M, Yari H, Mahdavian M, et al. Synthesis of graphene oxide nanosheets decorated by nanoporous zeolite-imidazole (ZIF-67) based metal-organic framework with controlled-release corrosion inhibitor performance: experimental and detailed DFT-D theoretical explorations [J]. Journal of Hazardous Materials, 2021, 404: 124068. |

| [9] | Zhan B. Flame retardant anti-corrosion powder coating formulation for preparing coating e.g. oil paint, comprises e.modified epoxy resingg., resinepoxy, modified crosslinking agent, catalyst, pigmenttitanium, agentwetting, precipitated barium sulfate, agentleveling, benzoin and activated silica powder, 117487436-A[P]. 2024-02-02. |

| [10] | Cui G, Bi Z X, Zhang R Y, et al. A comprehensive review on graphene-based anti-corrosive coatings [J]. Chemical Engineering Journal, 2019, 373: 104-121. |

| [11] | Feng L M, Yuan P Y. Corrosion protection mechanism of aluminum triphosphate modified by organic acids as a rust converter [J]. Progress in Organic Coatings, 2020, 140: 105508. |

| [12] | Khan A R, Zhang H J, Jun Z, et al. Electrochemical corrosion protection of neat and zinc phosphate modified epoxy coating: a comparative physical aging study on Al alloy 6101[J]. Frontiers in Chemistry, 2023, 11: 1142050. |

| [13] | Solano R, Patiño-Ruiz D, Herrera A. Preparation of modified paints with nano-structured additives and its potential applications [J]. Nanomaterials and Nanotechnology, 2020, 10: 184798042090918. |

| [14] | Pélissier K, Thierry D. Powder and high-solid coatings as anticorrosive solutions for marine and offshore applications? a review [J]. Coatings, 2020, 10(10) : 916. |

| [15] | Li R, Fan G S, Wang P, et al. Effects of silane coupling agent modifications of hollow glass microspheres on syntactic foams with epoxy matrix [J]. Polymers & Polymer Composites, 2021, 29(sup9): S1191-S1203. |

| [16] | Mizuta Y, Sugimoto R, Okada H, et al. Graft polymerization of methyl methacrylate on the surface of poly(ethylene-co-tetrafluoroethylene) using benzoyl peroxide as initiator [J]. Journal of Applied Polymer Science, 2022, 139(25) : e52415. |

| [17] | Azzian M I M, Mohamad S F, Abd Rahim N M F H, et al. Radiation-induced admicellar graft polymerization of 2-hydroxyethyl methacrylate onto polyvinylidene fluoride membranes using an electron beam accelerator [J]. Chemical Engineering & Technology, 2023, 46(12): 2617-2625. |

| [18] | Li X K, Sun K, Wu J J, et al. Thermal-triggered phase separation and ion exchange enables photoluminescence tuning of stable mixed-halide perovskite nanocrystals for dynamic display[J]. Laser & Photonics Reviews, 2024, 18(5) : 2301244. |

| [19] | 叶贝. 等离子体预处理速率对碳纤维复合材料力学性能影响研究[D]. 重庆: 重庆交通大学, 2024. |

| Ye Bei. Effect of plasma pretreatment rate on mechanical properties of carbon fiber composites [D]. Chongqing: Chongqing Jiaotong University, 2024. | |

| [20] | Hu W Z, Ru X, Zhang Y C, et al. Effects of sericite modified by macromolecular dispersant on the thermal, mechanical and electrical properties of the NR/SBR composites[J]. Journal of Macromolecular Science: Part A, 2011, 48(11): 962-968. |

| [21] | Meng F D, Liu L, Tian W L, et al. The influence of the chemically bonded interface between fillers and binder on the failure behaviour of an epoxy coating under marine alternating hydrostatic pressure[J]. Corrosion Science, 2015, 101: 139-154. |

| [22] | 佟钰, 齐成成, 艾小玲, 等. 矿渣-石灰混合粉碎过程的机械力化学活化效应[J]. 中国粉体技术, 2022, 28(6): 31-36. |

| Tong Yu, Qi Cheng-cheng, Ai Xiao-ling, et al. Effect of mechanochemical activation in mixed pulverizing process of slag and lime [J]. China Powder Science and Technology, 2022, 28(6): 31-36. | |

| [23] | Liu X L, Shao Y W, Zhang Y J, et al. Using high-temperature mechanochemistry treatment to modify iron oxide and improve the corrosion performance of epoxy coating-I. high-temperature ball milling treatment [J]. Corrosion Science, 2015,90:451-462. |

| [24] | Cai Y H, Meng F D, Liu L, et al. The effect of the modification of mica by high-temperature mechanochemistry on the anticorrosion performance of epoxy coatings[J]. Polymers, 2021, 13(3): 378. |

| [1] | 马廉洁, 蔡重延, 毕长波, 张力. 车削氟金云母陶瓷脆性破碎机理及表面粗糙度模型[J]. 东北大学学报:自然科学版, 2019, 40(2): 239-244. |

| [2] | 佟安时, 谢里阳, 刘建中, 白恩军. 静力拉伸载荷下纤维金属层板的变形行为[J]. 东北大学学报:自然科学版, 2017, 38(1): 91-94. |

| [3] | 张晋霞, 冯雅丽, 牛福生. 矿浆中金属离子对蓝晶石矿物浮选行为的影响[J]. 东北大学学报:自然科学版, 2014, 35(12): 1787-1791. |

| [4] | 李健;郭星辉;郭明涛;颜云辉;. 复合材料薄壁圆柱壳动态弹性模量的研究[J]. 东北大学学报(自然科学版), 2008, 29(12): 1770-1773. |

| [5] | 秦小梅;孙祥云. 可切削玻璃陶瓷的透明玻璃形成及云母析晶[J]. 东北大学学报(自然科学版), 2000, 21(6): 656-658. |

| [6] | -. 动、静载破岩比功测定[J]. 东北大学学报:自然科学版, 1978, -(4): 73-95. |

| [7] | -. 对于岩石分级的意见[J]. 东北大学学报:自然科学版, 1975, -(4): 18-23. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||