东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (6): 816-822.DOI: 10.12068/j.issn.1005-3026.2024.06.008

• 材料与冶金 • 上一篇

收稿日期:2023-02-24

出版日期:2024-06-15

发布日期:2024-09-18

通讯作者:

罗洪杰

作者简介:赵家豪(1998-),男,河北保定人,东北大学硕士研究生基金资助:

Jia-hao ZHAO1, Yang QU1, Hong-jie LUO1,2( ), Shi-jie YANG1

), Shi-jie YANG1

Received:2023-02-24

Online:2024-06-15

Published:2024-09-18

Contact:

Hong-jie LUO

About author:LUO Hong-jie, E-mail: luohjedu@sina.com摘要:

烧结作为多孔钛成型过程中的关键步骤之一,通过控制烧结条件能够赋予多孔钛优异的力学性能.以镁粉和镁颗粒作为造孔剂,采用真空蒸馏烧结在不同烧结条件下制备了造孔剂添加量为60%的液固过滤用多孔钛,并对其微观结构、压缩性能和抗弯性能进行了表征和测试.研究表明:随烧结温度的升高和烧结时间的延长,多孔钛的孔径减小、孔隙率下降、孔隙球化;当烧结温度低于1 150 ℃时,多孔钛的轴向收缩始终大于径向收缩;屈服强度和弯曲强度在烧结温度为1 150 ℃、烧结时间为180 min时达到最大,分别为158.60和230.40 MPa.

中图分类号:

赵家豪, 曲扬, 罗洪杰, 杨世杰. 烧结工艺对多孔钛微观结构及力学性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(6): 816-822.

Jia-hao ZHAO, Yang QU, Hong-jie LUO, Shi-jie YANG. Effect of Sintering Process on Microstructure and Mechanical Property of Porous Ti[J]. Journal of Northeastern University(Natural Science), 2024, 45(6): 816-822.

| 原料 | 质量分数/% | 平均粒度/μm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Mg | Fe | Mn | Cl | Zn | O | C | N | H | Si | ||

| 钛粉 | 99.8 | 0.01 | 0.06 | 0.01 | 0.03 | — | 0.32 | 0.03 | 0.02 | 0.02 | 0.02 | 50 |

| 镁粉 | — | 99.9 | 0.01 | 0.008 | 0.003 | 0.008 | — | — | — | — | — | 35 |

| 镁颗粒 | — | 99.9 | 0.01 | 0.008 | 0.003 | 0.008 | — | — | — | — | — | 1 500 |

表1 钛粉、镁粉和镁颗粒的化学成分

Table 1 Chemical composition of Ti powder, Mg powder and Mg particles

| 原料 | 质量分数/% | 平均粒度/μm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | Mg | Fe | Mn | Cl | Zn | O | C | N | H | Si | ||

| 钛粉 | 99.8 | 0.01 | 0.06 | 0.01 | 0.03 | — | 0.32 | 0.03 | 0.02 | 0.02 | 0.02 | 50 |

| 镁粉 | — | 99.9 | 0.01 | 0.008 | 0.003 | 0.008 | — | — | — | — | — | 35 |

| 镁颗粒 | — | 99.9 | 0.01 | 0.008 | 0.003 | 0.008 | — | — | — | — | — | 1 500 |

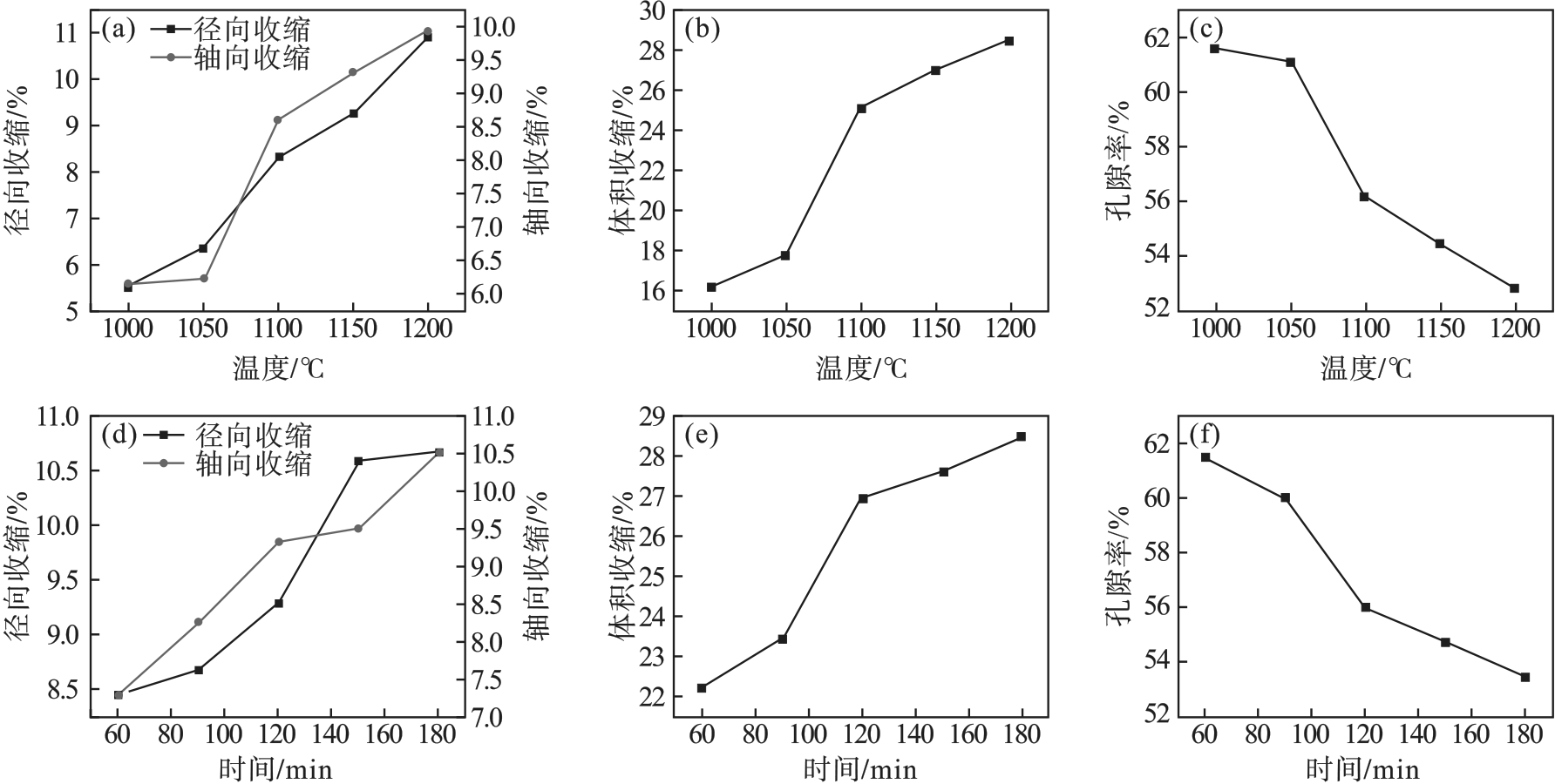

图3 烧结温度、烧结时间与多孔钛内部收缩情况(a)—径向、轴向收缩; (b)—体积收缩; (c)—孔隙率; (d)—径向、轴向收缩; (e)—体积收缩; (f)—孔隙率.

Fig.3 Sintering temperature, sintering time and internal shrinkage of Porous Ti

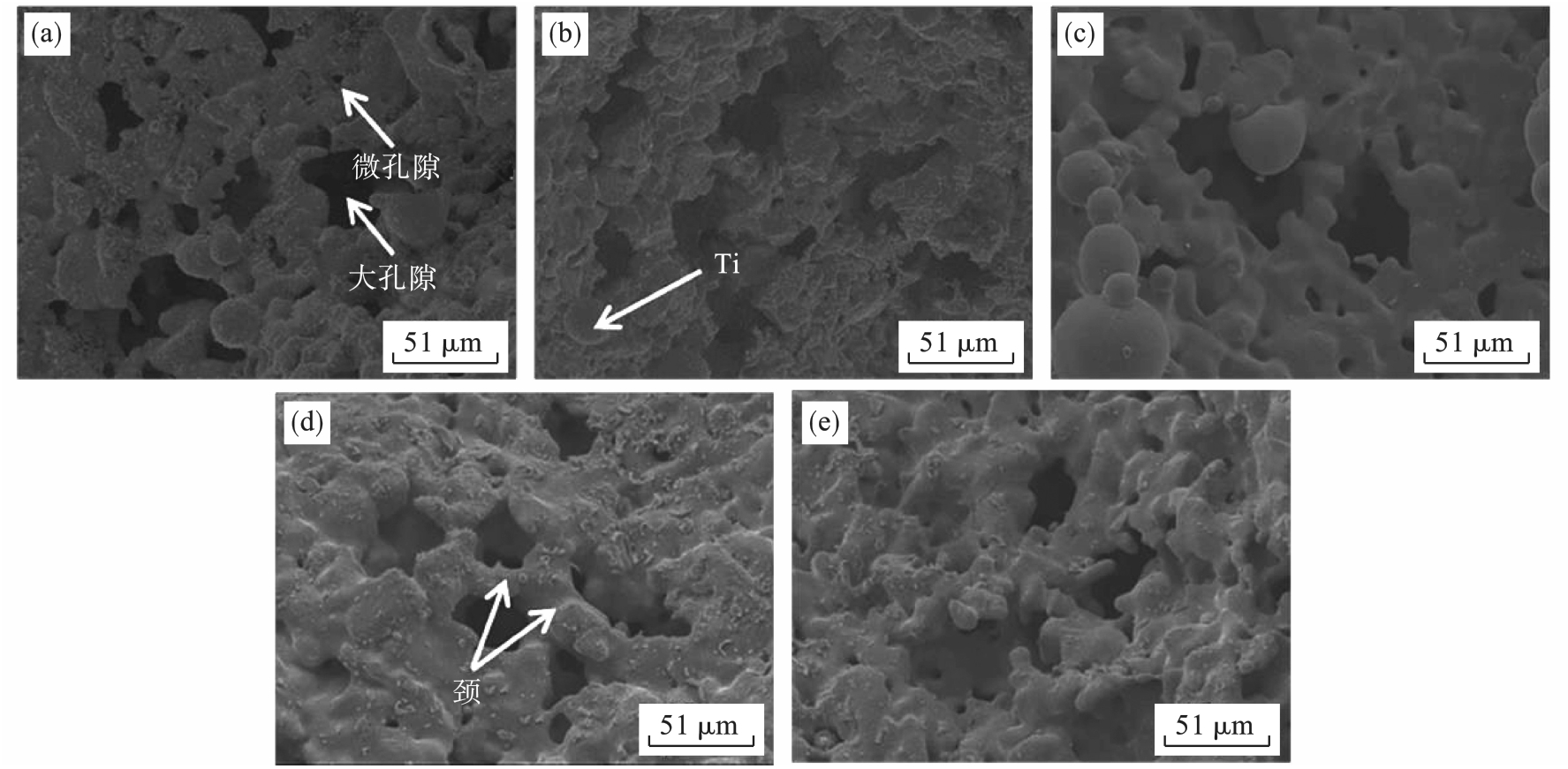

图5 不同温度烧结120 min多孔钛毫米孔内部SEM图(a)—1 000 ℃; (b)—1 050 ℃; (c)—1 100 ℃; (d)—1 150 ℃; (e)—1 200 ℃.

Fig.5 SEM images of millimeter-level pore interior of porous Ti sintered at different temperature for 120 min

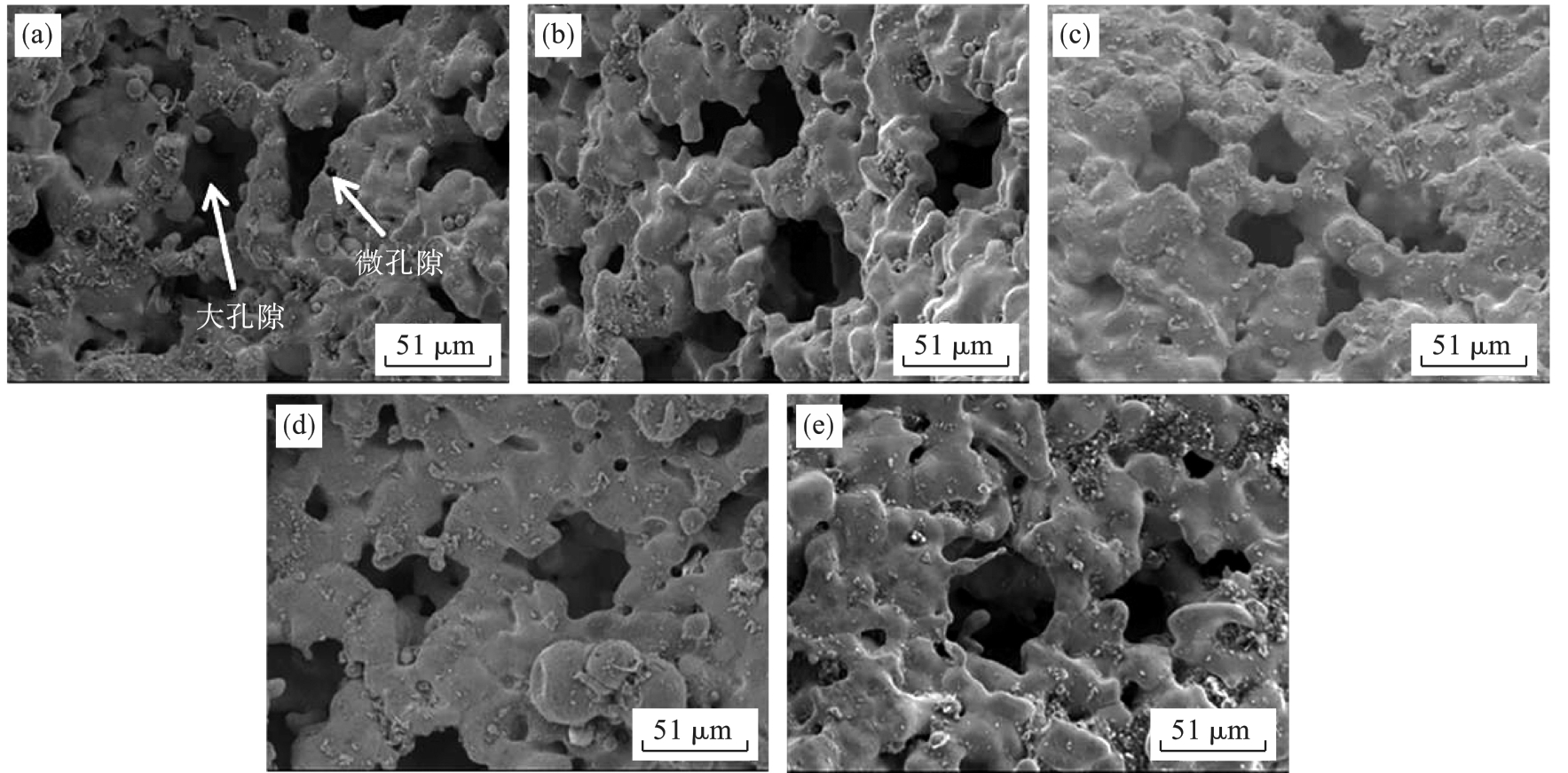

图6 1 150 ℃烧结不同时间多孔钛毫米孔内部SEM图(a)—60 min; (b)—90 min; (c)—120 min; (d)—150 min; (e)—180 min.

Fig.6 SEM images of millimeter-level pore interior of porous Ti sintered at 1 150 ℃ for different time

| 烧结温度 | 烧结时间 | 屈服强度 | 弹性模量 | 能量吸收 | 能量吸收效率 | 弯曲强度 | 弯曲模量 |

|---|---|---|---|---|---|---|---|

| ℃ | min | MPa | GPa | MJ·m-3 | MPa | GPa | |

| 1 000 | 120 | 75.50 | 0.88 | 27.29 | 0.68 | 113.40 | 4.94 |

| 1 050 | 87.41 | 1.08 | 38.32 | 0.66 | 122.40 | 6.73 | |

| 1 100 | 89.47 | 1.13 | 42.94 | 0.64 | 159.30 | 8.29 | |

| 1 150 | 131.11 | 1.26 | 48.37 | 0.62 | 182.40 | 8.76 | |

| 1 200 | 142.73 | 1.50 | 59.01 | 0.58 | 209.40 | 9.15 |

表2 不同烧结温度下多孔钛力学性能参数

Table 2 Mechanical properties of porous Ti at different sintering temperatures

| 烧结温度 | 烧结时间 | 屈服强度 | 弹性模量 | 能量吸收 | 能量吸收效率 | 弯曲强度 | 弯曲模量 |

|---|---|---|---|---|---|---|---|

| ℃ | min | MPa | GPa | MJ·m-3 | MPa | GPa | |

| 1 000 | 120 | 75.50 | 0.88 | 27.29 | 0.68 | 113.40 | 4.94 |

| 1 050 | 87.41 | 1.08 | 38.32 | 0.66 | 122.40 | 6.73 | |

| 1 100 | 89.47 | 1.13 | 42.94 | 0.64 | 159.30 | 8.29 | |

| 1 150 | 131.11 | 1.26 | 48.37 | 0.62 | 182.40 | 8.76 | |

| 1 200 | 142.73 | 1.50 | 59.01 | 0.58 | 209.40 | 9.15 |

| 烧结温度 | 烧结时间 | 屈服强度 | 弹性模量 | 能量吸收 | 能量吸收效率 | 弯曲强度 | 弯曲模量 |

|---|---|---|---|---|---|---|---|

| ℃ | min | MPa | GPa | MJ·m-3 | MPa | GPa | |

| 1 150 | 60 | 87.29 | 1.14 | 41.55 | 0.64 | 152.70 | 5.39 |

| 90 | 98.90 | 1.21 | 44.50 | 0.63 | 157.50 | 3.69 | |

| 120 | 131.11 | 1.26 | 48.37 | 0.62 | 182.40 | 8.76 | |

| 150 | 134.97 | 1.28 | 48.49 | 0.61 | 267.00 | 7.19 | |

| 180 | 158.60 | 1.33 | 59.12 | 0.59 | 230.40 | 10.16 |

表3 不同烧结时间下多孔钛力学性能参数

Table 3 Mechanical properties of porous Ti at different sintering time

| 烧结温度 | 烧结时间 | 屈服强度 | 弹性模量 | 能量吸收 | 能量吸收效率 | 弯曲强度 | 弯曲模量 |

|---|---|---|---|---|---|---|---|

| ℃ | min | MPa | GPa | MJ·m-3 | MPa | GPa | |

| 1 150 | 60 | 87.29 | 1.14 | 41.55 | 0.64 | 152.70 | 5.39 |

| 90 | 98.90 | 1.21 | 44.50 | 0.63 | 157.50 | 3.69 | |

| 120 | 131.11 | 1.26 | 48.37 | 0.62 | 182.40 | 8.76 | |

| 150 | 134.97 | 1.28 | 48.49 | 0.61 | 267.00 | 7.19 | |

| 180 | 158.60 | 1.33 | 59.12 | 0.59 | 230.40 | 10.16 |

| 1 | Esen Z, Bor S.Processing of titanium foams using magnesium spacer particles[J].Scripta Materialia,2007,56(5):341-344. |

| 2 | Innocentini M D M, Faleiros R K, Jr Pisani R,et al.Permeability of porous gelcast scaffolds for bone tissue engineering[J].Journal of Porous Materials,2010,17(5):615-627. |

| 3 | Asaoka K, Kuwayama N, Okuno O,et al.Mechanical properties and biomechanical compatibility of porous titanium for dental implants[J].Journal of Biomedical Materials Research,1985,19(6):699-713. |

| 4 | Zhang Y P, Li D S, Zhang X P.Gradient porosity and large pore size NiTi shape memory alloys[J].Scripta Materialia,2007,57(11):1020-1023. |

| 5 | Bobbert F S L, Lietaert K, Eftekhari A A,et al.Additively manufactured metallic porous biomaterials based on minimal surfaces:a unique combination of topological,mechanical,and mass transport properties[J].Acta Biomaterialia,2017,53:572-584. |

| 6 | 汤慧萍,王建.多孔钛的研究进展[J].中国材料进展,2014,33(sup1):576-585,594. |

| Tang Hui‑ping, Wang Jian.Progress in research and development of porous titanium materials[J].Materials China,2014,33(sup1):576-585,594. | |

| 7 | Rausch G, Hartwig T, Weber M,et al.Herstellung und eigenschaften von titanschäumen[J].Materialwissenschaft und Werkstofftechnik,2000,31(6):412-414. |

| 8 | Mondal D P, Patel M, Jain H,et al.The effect of the particle shape and strain rate on microstructure and compressive deformation response of pure Ti‑foam made using acrowax as space holder[J].Materials Science and Engineering A,2015,625:331-342. |

| 9 | Ye B, Dunand D C.Titanium foams produced by solid‑state replication of NaCl powders[J].Materials Science and Engineering A,2010,528(2):691-697. |

| 10 | Rao X, Chu C L, Zheng Y Y.Phase composition,microstructure,and mechanical properties of porous Ti‑Nb‑Zr alloys prepared by a two‑step foaming powder metallurgy method[J].Journal of the Mechanical Behavior of Biomedical Materials,2014,34:27-36. |

| 11 | Liao B, Xu C, Li W,et al.Bionic mechanical design and SLM manufacture of porous Ti6Al4V scaffolds for load‑bearing cancellous bone implants[J].Acta of Bioengineering and Biomechanics,2021,23(3):97-107. |

| 12 | Tange M, Manonukul A, Srikudvien P.The effects of organic template and thickening agent on structure and mechanical properties of titanium foam fabricated by replica impregnation method[J].Materials Science and Engineering A,2015,641:54-61. |

| 13 | Liu P S, Qing H B, Hou H L.Primary investigation on sound absorption performance of highly porous titanium foams[J].Materials and Design,2015,85:275-281. |

| 14 | Abhash A, Yadav B N, Pandey A,et al.Partially open cell Ti‑6Al‑2Co ternary alloy foams with a range of size and volume fraction of spacer particle[J].Materials Letters,2021,290:129463. |

| 15 | Nakaş G I, Dericioglu A F, Bor S.Fatigue behavior of TiNi foams processed by the magnesium space holder technique[J].Journal of the Mechanical Behavior of Biomedical Materials,2011,4(8):2017-2023. |

| 16 | Bram M, Stiller C, Buchkremer H P,et al.High‑porosity titanium,stainless steel,and superalloy parts[J].Advanced Engineering Materials,2000,2(4):196-199. |

| 17 | Ipek Nakaş G, Dericioǧlu A F, Bor T.Monotonic and cyclic compressive behavior of superelastic TiNi foams processed by sintering using magnesium space holder technique[J].Materials Science and Engineering A,2013,582:140-146. |

| 18 | Nakaş G I, Aşık E E, Tunca B,et al.Fatigue and fracture behavior of porous TiNi alloys[J].Materials Science Forum,2014,783/784/785/786:591-596. |

| 19 | Bafti H, Habibolahzadeh A.Compressive properties of aluminum foam produced by powder‑Carbamide spacer route[J].Materials and Design,2013,52:404-411. |

| 20 | Bafti H, Habibolahzadeh A.Production of aluminum foam by spherical carbamide space holder technique‑processing parameters[J].Materials and Design,2010,31(9):4122-4129. |

| 21 | Ibrahim A, Zhang F, Otterstein E,et al.Processing of porous Ti and Ti5Mn foams by spark plasma sintering[J].Materials and Design,2011,32(1):146-153. |

| 22 | Oh I H, Nomura N, Hanada S.Microstructures and mechanical properties of porous titanium compacts prepared by powder sintering[J].Materials Transactions,2002,43(3):443-446. |

| 23 | Klemm A, Tiainen H.Highly porous Sr‑doped TiO2 ceramics maintain compressive strength after grain boundary corrosion[J].Journal of the European Ceramic Society,2021,41(11):5721-5727. |

| 24 | Aşik E E, Bor Ş.Fatigue behavior of Ti‑6Al‑4V foams processed by magnesium space holder technique[J].Materials Science and Engineering A,2015,621:157-165. |

| [1] | 陈崇枫, 徐涛, Heap Michael,杨天鸿. 孔径及孔隙率对火山岩强度特性影响的模拟[J]. 东北大学学报:自然科学版, 2017, 38(5): 725-729. |

| [2] | 支颖,田野,张金连,刘相华. 冷轧差厚板退火组织性能的实验研究[J]. 东北大学学报:自然科学版, 2014, 35(5): 671-675. |

| [3] | 高强健,姜鑫,魏国,沈峰满. 压汞法表征铁矿球团固结程度[J]. 东北大学学报(自然科学版), 2013, 34(6): 832-835. |

| [4] | 张大勇;史培阳;姜茂发;. w(MgO)/w(SiO_2)对转炉渣系微晶玻璃结构和性能的影响[J]. 东北大学学报(自然科学版), 2009, 30(3): 381-383+404. |

| [5] | 徐娜;宗亚平;张芳;杨玉芳;. 颗粒形状对铝基复合材料力学行为影响的模拟[J]. 东北大学学报(自然科学版), 2007, 28(2): 213-216. |

| [6] | 张锦刚;蒋奇武;刘沿东;左良. 热轧工艺中加热温度对IF钢组织性能的影响[J]. 东北大学学报(自然科学版), 2005, 26(11): 49-52. |

| [7] | 魏莉;姚广春;张晓明;罗洪杰. 粉末冶金法制备泡沫铝材料[J]. 东北大学学报(自然科学版), 2003, 24(11): 1071-1074. |

| [8] | 李帼昌;刘之洋;冯国会;吴献. 自应力钢管轻骨料混凝土轴压短柱的承载力计算[J]. 东北大学学报:自然科学版, 1997, 18(6): 4--. |

| [9] | 陈瑞;庞维成;阎荫槐;宋小平;李家宝. 硬状态材料喷丸表面的屈服强度[J]. 东北大学学报:自然科学版, 1997, 18(5): 4--. |

| [10] | -. 我院科技成果简讯[J]. 东北大学学报:自然科学版, 1990, 11(4): 427-428. |

| [11] | 曾梅光;H.L.Marcus. 单试样测定铝合金J_(Ic)的新方法[J]. 东北大学学报:自然科学版, 1983, 4(4): 5-11+129. |

| [12] | -. 关于不合格海绵锆二次蒸馏问题的研究[J]. 东北大学学报:自然科学版, 1975, -(3): 13-15. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||