东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (6): 66-75.DOI: 10.12068/j.issn.1005-3026.2025.20240096

辛博, 李宏亮, 孙文鑫, 刘洺君

收稿日期:2023-08-27

出版日期:2025-06-15

发布日期:2025-09-01

作者简介:辛 博(1988—),男,吉林通化人,东北大学副教授,博士生导师.

基金资助:Bo XIN, Hong-liang LI, Wen-xin SUN, Ming-jun LIU

Received:2023-08-27

Online:2025-06-15

Published:2025-09-01

摘要:

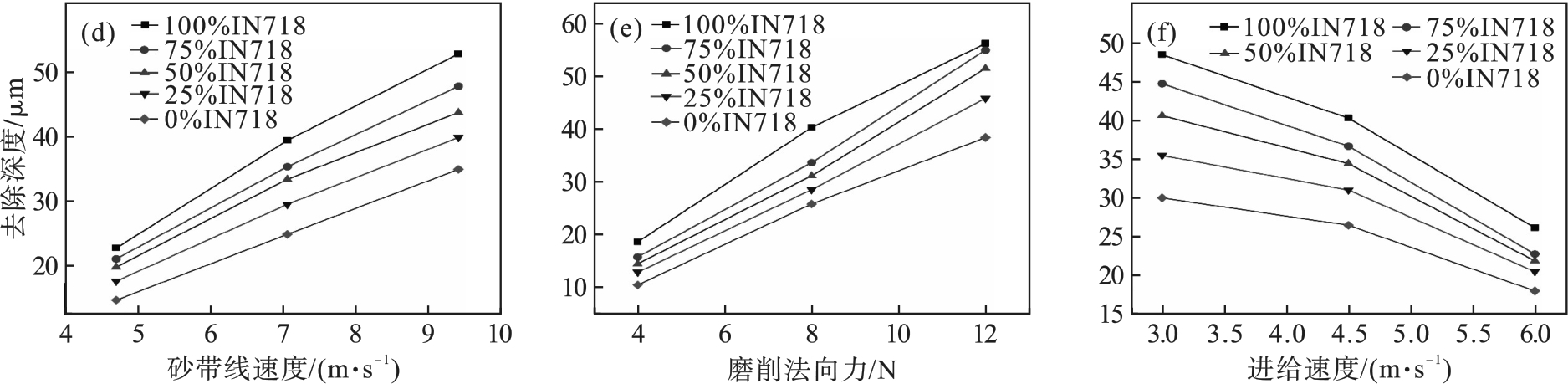

为提高镍钴功能梯度材料(nickel-cobalt-functional gradient materials, NiCo-FGM)去除深度的一致性,采用自适应磨削力控制系统对5种不同质量分数IN718的NiCo-FGM进行恒力分区磨削实验,探究工艺参数对材料去除深度及表面粗糙度的影响趋势及程度.然后对迁移学习进行可行性分析并对比迁移学习与经验公式的去除深度建模精度.最后对比恒力与变力磨削的去除深度预测结果.结果表明:法向力对材料去除深度与表面粗糙度的影响最显著.迁移学习预测的平均误差降低了4.07%,且效率更高.恒力磨削下其余含量的IN718与50%IN718去除深度最大差值为8.955 μm,100%IN718与0%IN718去除深度最大差值为15.619 μm,而通过变力磨削可以提高去除深度一致性.

中图分类号:

辛博, 李宏亮, 孙文鑫, 刘洺君. 基于迁移学习的NiCo-FGM机器人砂带磨削工艺[J]. 东北大学学报(自然科学版), 2025, 46(6): 66-75.

Bo XIN, Hong-liang LI, Wen-xin SUN, Ming-jun LIU. Transfer Learning-Based Robotic Belt Grinding Process for NiCo-FGM[J]. Journal of Northeastern University(Natural Science), 2025, 46(6): 66-75.

| 参数 | IN718 | Stellite 6 |

|---|---|---|

| 弹性模量/GPa | 205 | 230 |

| 泊松比 | 0.3 | 0.34 |

| 线膨胀系数×106/℃-1 | 13.0 | 13.6 |

| 导热系数/[W·(m·K)-1] | 11.4 | 13.6 |

| 比热容/[J·(kg·K)-1] | 435 | 500 |

表1 IN718和Stellite 6的热物性参数(20 ℃)

Table 1 Thermophysical parameters of IN718 and Stellite 6 (20 ℃)

| 参数 | IN718 | Stellite 6 |

|---|---|---|

| 弹性模量/GPa | 205 | 230 |

| 泊松比 | 0.3 | 0.34 |

| 线膨胀系数×106/℃-1 | 13.0 | 13.6 |

| 导热系数/[W·(m·K)-1] | 11.4 | 13.6 |

| 比热容/[J·(kg·K)-1] | 435 | 500 |

| 参数名称 | 值 |

|---|---|

| 水质量分数×108/% | <4 |

| 氧质量分数×108/% | <100 |

| 激光功率/W | 1 800 |

| 扫描速率/(mm∙min-1) | 600 |

| 送粉速率/(g∙min-1) | 15 |

表2 实验参数

Table 2 Experimental parameters

| 参数名称 | 值 |

|---|---|

| 水质量分数×108/% | <4 |

| 氧质量分数×108/% | <100 |

| 激光功率/W | 1 800 |

| 扫描速率/(mm∙min-1) | 600 |

| 送粉速率/(g∙min-1) | 15 |

| 粉末材料 | C | Si | Mn | Cr | Mo | Ti | Fe | Al | Co | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| IN718 | 0.05 | 0.71 | 0.16 | 18.17 | 2.32 | 0.93 | 20.89 | 0.63 | — | 余量 |

| Stellite 6 | 1.15 | 1.58 | 0.75 | 31.25 | 0.89 | — | 3.54 | — | 余量 | 2.54 |

表3 粉末材料的化学成分(质量分数) (%)

Table 3 Chemical composition of powder material (mass fraction)

| 粉末材料 | C | Si | Mn | Cr | Mo | Ti | Fe | Al | Co | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| IN718 | 0.05 | 0.71 | 0.16 | 18.17 | 2.32 | 0.93 | 20.89 | 0.63 | — | 余量 |

| Stellite 6 | 1.15 | 1.58 | 0.75 | 31.25 | 0.89 | — | 3.54 | — | 余量 | 2.54 |

| 水平 | 因素 | ||

|---|---|---|---|

| vs /(m·s-1) | Fn /N | vw /(mm·s-1) | |

| 1 | 4.712 | 4 | 3 |

| 2 | 7.069 | 8 | 4.5 |

| 3 | 9.425 | 12 | 6 |

表4 不同质量分数IN718的正交实验水平表 (with different mass fractions)

Table 4 Orthogonal experimental level table of IN718

| 水平 | 因素 | ||

|---|---|---|---|

| vs /(m·s-1) | Fn /N | vw /(mm·s-1) | |

| 1 | 4.712 | 4 | 3 |

| 2 | 7.069 | 8 | 4.5 |

| 3 | 9.425 | 12 | 6 |

| 水平 | 因素 | ||

|---|---|---|---|

| vs /(m·s-1) | Fn /N | vw /(mm·s-1) | |

| 1 | 5.312 | 5 | 3.4 |

| 2 | 7.669 | 9 | 4.9 |

| 3 | 10.025 | 13 | 6.4 |

表5 75%IN718正交实验水平表 (75%IN718)

Table 5 Orthogonal experimental level table of

| 水平 | 因素 | ||

|---|---|---|---|

| vs /(m·s-1) | Fn /N | vw /(mm·s-1) | |

| 1 | 5.312 | 5 | 3.4 |

| 2 | 7.669 | 9 | 4.9 |

| 3 | 10.025 | 13 | 6.4 |

| 编号 | vw/(mm·s-1) | Fn/N | vs/(m·s-1) | 去除深度h/μm | 预测误差/% | ||

|---|---|---|---|---|---|---|---|

| 神经网络 | 经验公式 | 迁移学习 | |||||

| 平均 | — | — | — | — | 38.071 | 9.405 | 5.336 |

| 1 | 5.312 | 5 | 3.4 | 15.545 | 24.451 | 19.735 | 15.840 |

| 2 | 5.312 | 9 | 4.9 | 28.655 | 43.600 | 8.909 | 5.362 |

| 3 | 5.312 | 13 | 6.4 | 35.296 | 68.530 | 11.249 | 2.596 |

| 4 | 7.669 | 5 | 4.9 | 22.247 | 94.781 | 10.042 | 10.366 |

| 5 | 7.669 | 9 | 6.4 | 28.181 | 35.695 | 7.294 | 2.882 |

| 6 | 7.669 | 13 | 3.4 | 67.068 | 0.298 | 6.957 | 1.644 |

| 7 | 10.025 | 5 | 6.4 | 23.442 | 53.298 | 10.014 | 7.087 |

| 8 | 10.025 | 9 | 3.4 | 59.917 | 6.311 | 5.153 | 0.769 |

| 9 | 10.025 | 13 | 4.9 | 74.106 | 15.670 | 5.295 | 1.477 |

表6 75%IN718去除深度经验公式、神经网络与迁移学习误差对比 (of 75%IN718)

Table 6 Comparison of empirical formulas, neural networks and transfer learning errors in the removal depth

| 编号 | vw/(mm·s-1) | Fn/N | vs/(m·s-1) | 去除深度h/μm | 预测误差/% | ||

|---|---|---|---|---|---|---|---|

| 神经网络 | 经验公式 | 迁移学习 | |||||

| 平均 | — | — | — | — | 38.071 | 9.405 | 5.336 |

| 1 | 5.312 | 5 | 3.4 | 15.545 | 24.451 | 19.735 | 15.840 |

| 2 | 5.312 | 9 | 4.9 | 28.655 | 43.600 | 8.909 | 5.362 |

| 3 | 5.312 | 13 | 6.4 | 35.296 | 68.530 | 11.249 | 2.596 |

| 4 | 7.669 | 5 | 4.9 | 22.247 | 94.781 | 10.042 | 10.366 |

| 5 | 7.669 | 9 | 6.4 | 28.181 | 35.695 | 7.294 | 2.882 |

| 6 | 7.669 | 13 | 3.4 | 67.068 | 0.298 | 6.957 | 1.644 |

| 7 | 10.025 | 5 | 6.4 | 23.442 | 53.298 | 10.014 | 7.087 |

| 8 | 10.025 | 9 | 3.4 | 59.917 | 6.311 | 5.153 | 0.769 |

| 9 | 10.025 | 13 | 4.9 | 74.106 | 15.670 | 5.295 | 1.477 |

图12 均值分析结果(a)—砂带线速度对表面粗糙度的影响; (b)—磨削法向力对表面粗糙度的影响; (c)—进给速度对表面粗糙度的影响;(d)—砂带线速度对去除深度的影响; (e)—磨削法向力对去除深度的影响; (f)—进给速度对去除深度的影响.

Fig.12 Mean value analysis results

| 目标去除深度h/μm | 磨削法向力/N | ||||

|---|---|---|---|---|---|

| 100%IN718 | 75%IN718 | 50%IN718 | 25%IN718 | 0%IN718 | |

| 20 | 3.929 | 5.012 | 5.370 | 5.784 | 7.074 |

| 22 | 4.397 | 5.459 | 5.877 | 6.277 | 7.591 |

| 24 | 4.865 | 5.905 | 6.383 | 6.761 | 8.095 |

| 26 | 5.333 | 6.348 | 6.885 | 7.237 | 8.587 |

| 28 | 5.801 | 6.789 | 7.386 | 7.707 | 9.071 |

| 30 | 6.270 | 7.227 | 7.885 | 8.174 | 9.549 |

| 32 | 6.739 | 7.662 | 8.382 | 8.640 | 10.024 |

| 34 | 7.208 | 8.095 | 8.878 | 9.108 | 10.498 |

| 36 | 7.678 | 8.527 | 9.372 | 9.580 | 10.974 |

表7 相同去除深度下不同IN718含量的磨削法向力

Table 7 Grinding normal forces with different IN718 contents at the same removal depth

| 目标去除深度h/μm | 磨削法向力/N | ||||

|---|---|---|---|---|---|

| 100%IN718 | 75%IN718 | 50%IN718 | 25%IN718 | 0%IN718 | |

| 20 | 3.929 | 5.012 | 5.370 | 5.784 | 7.074 |

| 22 | 4.397 | 5.459 | 5.877 | 6.277 | 7.591 |

| 24 | 4.865 | 5.905 | 6.383 | 6.761 | 8.095 |

| 26 | 5.333 | 6.348 | 6.885 | 7.237 | 8.587 |

| 28 | 5.801 | 6.789 | 7.386 | 7.707 | 9.071 |

| 30 | 6.270 | 7.227 | 7.885 | 8.174 | 9.549 |

| 32 | 6.739 | 7.662 | 8.382 | 8.640 | 10.024 |

| 34 | 7.208 | 8.095 | 8.878 | 9.108 | 10.498 |

| 36 | 7.678 | 8.527 | 9.372 | 9.580 | 10.974 |

| 磨削法向力Fn/N | 去除深度/μm | ||||

|---|---|---|---|---|---|

| 100%IN718 | 75%IN718 | 50%IN718 | 25%IN718 | 0%IN718 | |

| 5.370 | 26.419 | 21.309 | 20.000 | 17.882 | 15.593 |

| 5.877 | 28.760 | 23.728 | 22.000 | 19.869 | 17.380 |

| 6.383 | 31.075 | 26.110 | 24.000 | 21.838 | 19.114 |

| 6.885 | 33.378 | 28.472 | 26.000 | 23.803 | 20.810 |

| 7.386 | 35.676 | 30.835 | 28.000 | 25.778 | 22.485 |

| 7.885 | 37.979 | 33.217 | 30.000 | 27.779 | 24.158 |

| 8.382 | 40.292 | 35.635 | 32.000 | 29.817 | 25.849 |

| 8.878 | 42.617 | 38.099 | 34.000 | 31.896 | 27.573 |

| 9.372 | 44.955 | 40.607 | 36.000 | 34.013 | 29.336 |

表8 相同磨削法向力下不同IN718含量的去除深度

Table 8 Removal depths of different IN718 contents under the same grinding normal force

| 磨削法向力Fn/N | 去除深度/μm | ||||

|---|---|---|---|---|---|

| 100%IN718 | 75%IN718 | 50%IN718 | 25%IN718 | 0%IN718 | |

| 5.370 | 26.419 | 21.309 | 20.000 | 17.882 | 15.593 |

| 5.877 | 28.760 | 23.728 | 22.000 | 19.869 | 17.380 |

| 6.383 | 31.075 | 26.110 | 24.000 | 21.838 | 19.114 |

| 6.885 | 33.378 | 28.472 | 26.000 | 23.803 | 20.810 |

| 7.386 | 35.676 | 30.835 | 28.000 | 25.778 | 22.485 |

| 7.885 | 37.979 | 33.217 | 30.000 | 27.779 | 24.158 |

| 8.382 | 40.292 | 35.635 | 32.000 | 29.817 | 25.849 |

| 8.878 | 42.617 | 38.099 | 34.000 | 31.896 | 27.573 |

| 9.372 | 44.955 | 40.607 | 36.000 | 34.013 | 29.336 |

| [1] | Loh G H, Pei E, Harrison D, et al. An overview of functionally graded additive manufacturing[J]. Additive Manufacturing, 2018, 23: 34-44. |

| [2] | Wang Y F, Chen X Z, Su C C. Microstructure and mechanical properties of Inconel 625 fabricated by wire-arc additive manufacturing[J]. Surface and Coatings Technology, 2019, 374: 116-123. |

| [3] | Bobbio L D, Otis R A, Borgonia J P, et al. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: experimental characterization and thermodynamic calculations[J]. Acta Materialia, 2017, 127: 133-142. |

| [4] | 于富明. 基于工件曲率的变压力砂带磨削技术研究[D]. 沈阳:东北大学,2017. |

| Yu Fu-ming. Research on variable pressure abrasive belt grinding technology based on workpiece curvature [D]. Shenyang: Northeastern University,2017. | |

| [5] | 王恭硕. 面向航空发动机整体叶盘材料去除精度要求的机器人磨抛技术研究[D]. 武汉:华中科技大学,2022. |

| Wang Gong-shuo. Research on robotic grinding and polishing technology for aero-engine integral blisk material removal accuracy requirements [D]. Wuhan: Huazhong University of Science and Technology, 2022. | |

| [6] | 巩亚东,赵显力,张伟健,等.机器人砂带磨削单磨粒材料去除影响因素[J].东北大学学报(自然科学版),2023,44(9):1285-1291. |

| Gong Ya-dong, Zhao Xian-li, Zhang Wei-jian,et al. Factors influencing single abrasive material removal for robotic abrasive belt grinding[J]. Journal of Northeastern University(Natural Science), 2023, 44(9): 1285-1291. | |

| [7] | Preston F W. The theory and design of plate glass polishing machines [J]. Journal of the Society of Glass Technology, 1927(11):277-281. |

| [8] | 计时鸣, 李琛, 谭大鹏, 等. 基于Preston方程的软性磨粒流加工特性[J].机械工程学报, 2011,47(17):156-163. |

| Ji Shi-ming, Li Chen, Tan Da-peng, et al. Study on machinability of softness abrasive flow based on Preston equation[J]. Journal of Mechanical Engineering, 2011,47(17):156-163. | |

| [9] | 张雷, 袁楚明, 周祖德, 等. 模具曲面抛光时表面去除的建模与试验研究[J]. 机械工程学报, 2002, 38(12):98-102. |

| Zhang Lei, Yuan Chu-ming, Zhou Zu-de, et al. Modeling and experiment of material removal in polishing on mold curved surfaces[J]. Chinese Journal of Mechanical Engineering, 2002, 38(12):98-102. | |

| [10] | Cabaravdic M, Kuhlenköetter B. Optimising belt grinding processes[J]. Metal Surface, 2005(4):44-47. |

| [11] | Himeur Y, Elnour M, Fadli F, et al. Next-generation energy systems for sustainable smart cities: roles of transfer learning[J]. Sustainable Cities and Society, 2022, 85: 104059. |

| [12] | Hazarika D, Poria S, Zimmermann R, et al. Conversational transfer learning for emotion recognition[J]. Information Fusion, 2021, 65: 1-12. |

| [13] | Lu J, Bebbood V, Hao P, et al. Transfer learning using computational intelligence: a survey[J]. Knowledge-Based Systems, 2015, 80: 14-23. |

| [14] | Zhuang F Z, Qi Z Y, Duan K Y, et al. A comprehensive survey on transfer learning[J]. Proceedings of the IEEE, 2021, 109(1): 43-76. |

| [15] | Wang J D, Chen Y Q, Feng W J, et al. Transfer learning with dynamic distribution adaptation[J]. ACM Transactions on Intelligent Systems and Technology, 2020, 11(1): 1-25. |

| [16] | Tzeng E, Hoffman J, Darrell T, et al. Simultaneous deep transfer across domains and tasks[C]// 2015 IEEE International Conference on Computer Vision(ICCV). Santiago, 2015: 4068-4076. |

| [17] | Pardoe D, Stone P. Boosting for regression transfer[C]// 27th International Conference on Machine Learning. Haifa, 2010: 863-870. |

| [18] | 杨吉祥,王恭硕,叶葱葱, 等. 一种基于迁移学习的材料去除率模型的建立方法和装置: CN202110230749.5[P]. 2021-07-06. |

| Yang Ji-xiang, Wang Gong-shuo, Ye Cong-cong, et al. A method and device for establishing a material removal rate model based on transfer learning: CN202110230749.5 [P]. 2021-07-06. |

| [1] | 李凌轩, 马振玮, 于泽峻, 邢壮. 基于MTF和改进残差网络的轴承故障定量诊断方法[J]. 东北大学学报(自然科学版), 2024, 45(5): 697-706. |

| [2] | 巩亚东, 赵显力, 张伟健, 唐本甲. 机器人砂带磨削单磨粒材料去除影响因素[J]. 东北大学学报(自然科学版), 2023, 44(9): 1285-1291. |

| [3] | 赵海, 王相, 施瀚, 陈佳伟. 一种应用于脑电情感识别的迁移学习框架[J]. 东北大学学报(自然科学版), 2023, 44(7): 913-921. |

| [4] | 赵海, 陈佳伟, 施瀚, 王相. 一种应用于人体活动识别的迁移学习算法[J]. 东北大学学报(自然科学版), 2022, 43(6): 776-782. |

| [5] | 侯东晓, 穆金涛, 方成, 时培明. 基于GADF与引入迁移学习的ResNet34对变速轴承的故障诊断[J]. 东北大学学报(自然科学版), 2022, 43(3): 383-389. |

| [6] | 王新刚, 韩凯忠, 王超, 李林. 基于迁移学习的轴承剩余使用寿命预测方法[J]. 东北大学学报(自然科学版), 2021, 42(5): 665-672. |

| [7] | 王姝, 关展旭, 王晶, 孙晓辉. 基于迁移学习的贝叶斯网络参数学习方法[J]. 东北大学学报(自然科学版), 2021, 42(4): 509-515. |

| [8] | 徐礼胜, 张闻勖, 庞宇轩, 吴承暘. 基于短时心电信号的疲劳驾驶检测算法[J]. 东北大学学报:自然科学版, 2019, 40(7): 937-941. |

| [9] | 齐林, 吕旭阳, 杨本强, 徐礼胜. 基于全卷积网络迁移学习的左心室内膜分割[J]. 东北大学学报:自然科学版, 2018, 39(11): 1577-1582. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||