东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (2): 187-192.DOI: 10.12068/j.issn.1005-3026.2024.02.005

• 材料与冶金 • 上一篇

李美杭1, 苗思雨2, 张巍巍2, 胡恩柱1

收稿日期:2022-10-17

出版日期:2024-02-15

发布日期:2024-05-14

作者简介:李美杭(1997-),女,辽宁鞍山人,东北大学硕士研究生基金资助:Mei-hang LI1, Si-yu MIAO2, Wei-wei ZHANG2, En-zhu HU1

Received:2022-10-17

Online:2024-02-15

Published:2024-05-14

摘要:

以钢铁冶金废渣(钢渣、含钛高炉渣、提钒尾渣)活化过硫酸盐降解水中的丁基黄药.分析了废渣种类与用量、过硫酸盐浓度、初始pH等因素对丁基黄药降解效能的影响,采用双因素方差分析揭示了不同因素之间的交互特征.结果表明丁基黄药的降解率随废渣用量和过硫酸盐浓度增加而增大.在废渣用量1 g/L,过硫酸盐浓度为0.5 mmol/L,反应时间96 h时,钢渣、含钛高炉渣、提钒尾渣活化过硫酸钠对丁基黄药的降解率分别可达96.47%,97.70%和95.12%.三种废渣活化效能分别在碱性、近中性和酸性条件下达到最优.其中钢渣活化以非自由基(1O2)和SO4·-,HO·共同作用;含钛高炉渣以1O2为主,伴随着HO·的产生;提钒尾渣则仅以1O2为主.

中图分类号:

李美杭, 苗思雨, 张巍巍, 胡恩柱. 钢铁冶金废渣活化过硫酸盐降解丁基黄药[J]. 东北大学学报(自然科学版), 2024, 45(2): 187-192.

Mei-hang LI, Si-yu MIAO, Wei-wei ZHANG, En-zhu HU. Degradation of Butyl Xanthate Using Persulfate Activated with Iron and Steel Metallurgical Slag[J]. Journal of Northeastern University(Natural Science), 2024, 45(2): 187-192.

| 成分 | 钢渣 | 含钛高炉渣 | 提钒尾渣 |

|---|---|---|---|

CaO Fe2O3 SiO2 MgO Al2O3 TiO2 | 41.45 18.29 15.17 11.29 9.95 0.57 | 21.85 2.95 46.17 5.39 12.65 8.22 | 1.40 54.45 15.47 1.19 2.06 9.23 |

表1 钢铁冶金废渣的化学成分(质量分数) (%)

Table 1 Chemical composition of iron and steel metallurgical slags (mass fraction)

| 成分 | 钢渣 | 含钛高炉渣 | 提钒尾渣 |

|---|---|---|---|

CaO Fe2O3 SiO2 MgO Al2O3 TiO2 | 41.45 18.29 15.17 11.29 9.95 0.57 | 21.85 2.95 46.17 5.39 12.65 8.22 | 1.40 54.45 15.47 1.19 2.06 9.23 |

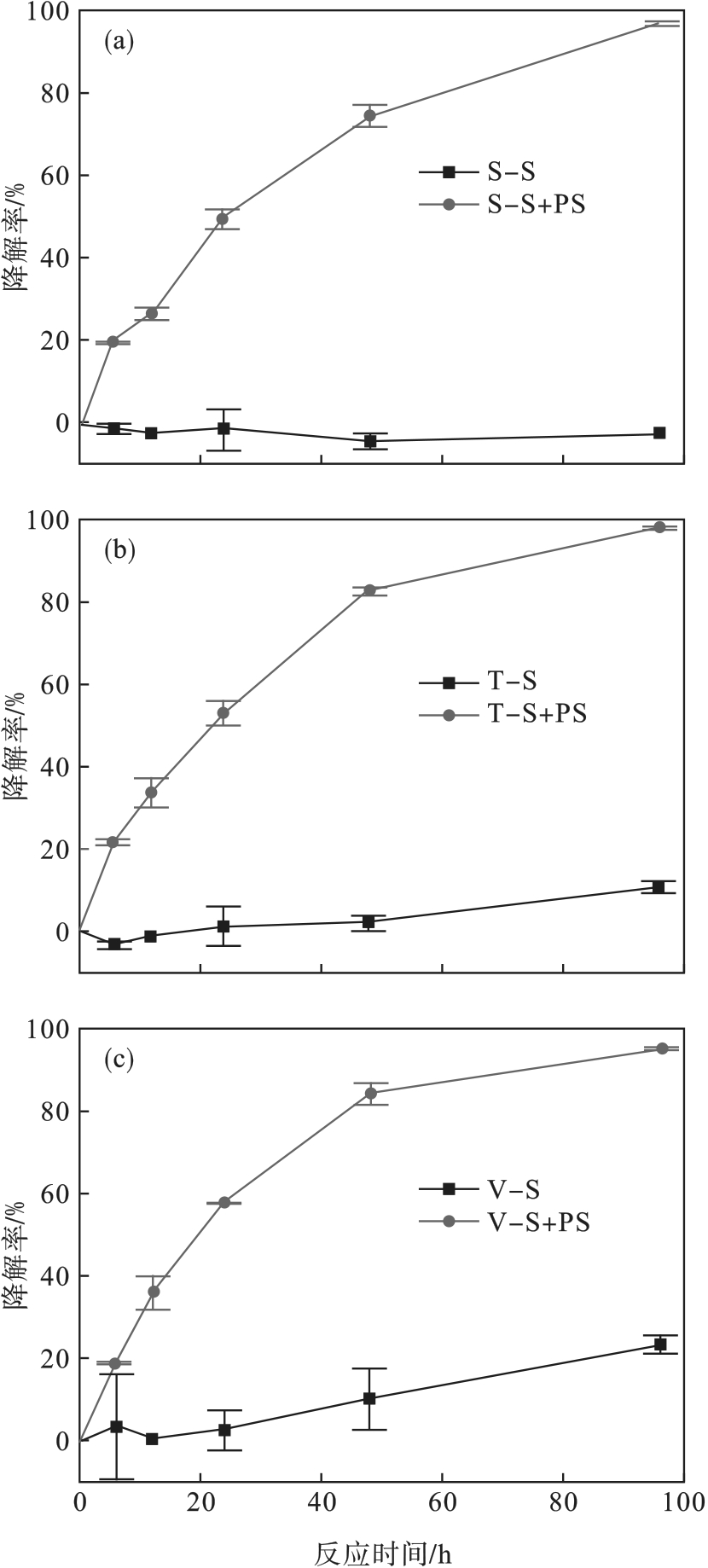

图2 不同种类的钢铁冶金废渣对丁基黄药的吸附和催化降解效果

Fig. 2 Catalytic degradation and adsorption ofbutyl xanthate by different iron and steel metallurgical slags(a)—S-S:钢渣; (b)—T-S:含钛高炉渣;(c)—V-S:提钒尾渣.

| 1 | 曾艳,唐琳,张明青.选矿废水中残留黄药处理技术及机理研究进展[J].工业水处理,2010,30(7):8-10,49. |

| Zeng Yan, Tang Lin, Zhang Ming‐qing.Progress research on the treatment technology of residual xanthate in mineral concentration wastewater and its mechanism[J].Industrial Water Treatment,2010,30(7):8-10,49. | |

| 2 | Nleya Y, Simate G S, Ndlovu S.Sustainability assessment of the recovery and utilisation of acid from acid mine drainage[J]. Journal of Cleaner Production,2016,113:17-27. |

| 3 | 夏丽娟,胡学伟,张雅琳,等.选矿废水中黄药的生化处理[J].环境工程学报,2016,10(1):21-26. |

| Xia Li‐juan, Hu Xue‐wei, Zhang Ya‐lin,et al.Biological treatment of xanthate in floatation wastewater[J].Chinese Journal of Environmental Engineering,2016,10(1):21-26. | |

| 4 | Bararunyeretse P, Ji H B, Yao J.Toxicity of nickel to soil microbial community with and without the presence of its mineral collectors - a calorimetric approach[J].Environmental Science and Pollution Research,2017,24(17):15134-15147. |

| 5 | 国家环境保护总局,国家质量监督检验检疫总局. 地表水环境质量标准 [S].北京:中国环境科学出版社,2002. |

| National Environmental Protection Administration,General Administration of Quality Supervision,Inspection and Quarantine of the People's Republic of China. Environmental quality standards for surface water [S].Beijing:China Environmental Science Press,2002. | |

| 6 | Wang J L, Wang S Z.Activation of persulfate (PS) and peroxymonosulfate (PMS) and application for the degradation of emerging contaminants[J].Chemical Engineering Journal,2018,334:1502-1517. |

| 7 | Goi A, Viisimaa M, Karpenko O.DDT‑contaminated soil treatment with persulfate and hydrogen peroxide utilizing different activation aids and the chemicals combination with biosurfactant[J].Journal of Advanced Oxidation Technologies,2012,15(1):41-52. |

| 8 | Tian H F, Wang Z X, Zhu T L,et al.Degradation prediction and products of polycyclic aromatic hydrocarbons in soils by highly active bimetals/AC‐activated persulfate[J]. ACS ES&T Engineering,2021,1(8):1183-1192. |

| 9 | Cai S, Hu X X, Lu D,et al.Ferrous‑activated persulfate oxidation of triclosan in soil and groundwater:the roles of natural mineral and organic matter[J].Science of the Total Environment,2021,762:143092. |

| 10 | Lyu C, He D, Chang Y M,et al.Cobalt oxyhydroxide as an efficient heterogeneous catalyst of peroxymonosulfate activation for oil‐contaminated soil remediation[J].Science of the Total Environment,2019,680:61-69. |

| 11 | 曾琪静,丁丽,文方,等.优化过硫酸盐体系处理石油类污染土壤[J].环境工程,2019,37(2):170-174. |

| Zeng Qi‑jing, Ding Li, Wen Fang,et al.Treatment of petroleum‐contaminated soil by optimized persulfate system[J].Environmental Engineering,2019,37(2):170-174. | |

| 12 | Jo Y H, Do S H, Kong S H.Persulfate activation by iron oxide‐immobilized MnO2 composite:identification of iron oxide and the optimum pH for degradations[J].Chemosphere,2014,95:550-555. |

| 13 | Wang Y, Chen S Y, Yang X,et al.Degradation of 2,2′,4,4′‐tetrabromodiphenyl ether (BDE-47) by a nano zerovalent iron‐activated persulfate process:the effect of metal ions[J].Chemical Engineering Journal,2017,317:613-622. |

| 14 | Xiao S, Cheng M, Zhong H,et al.Iron‐mediated activation of persulfate and peroxymonosulfate in both homogeneous and heterogeneous ways:a review[J].Chemical Engineering Journal,2020,384:123265. |

| 15 | Hu E Z, He Z, Nan X L,et al.Removal of phenanthrene and pyrene from contaminated sandy soil using hydrogen peroxide oxidation catalyzed by basic oxygen furnace slag[J]. Environmental Science and Pollution Research,2019,26(9):9281-9292. |

| 16 | 环境保护部. 水质丁基黄原酸的测定 紫外分光光度法 [S].北京:中国环境科学出版社,2015. |

| Ministry of Environmental Protection. Water quality‑determination of butyl xanthate—UV spectrophotometric method [S].Beijing:China Environmental Science Press,2015. | |

| 17 | 刘言,鲍建国,毛启迪,等.Fe2O3/MoS2复合材料活化过硫酸盐降解磺胺嘧啶[J].环境科学与技术,2022,45(8):38-45. |

| Liu Yan, Bao Jian‑guo, Mao Qi‑di,et al.Activation of persulfate by Fe2O3/MoS2 composite for degradation of sulfadiazine[J]. Environmental Science & Technology,2022,45(8):38-45. | |

| 18 | 熊玲,张敏,陈绍华.氮掺杂碳纳米管活化过硫酸盐降解丁基黄药[J].化工环保,2021,41(3):296-302. |

| Xiong Ling, Zhang Min, Chen Shao‐hua.Degradation of butyl xanthate using persulfate activated with nitrogen‐doped carbon nanotube[J].Environmental Protection of Chemical Industry,2021,41(3):296-302. | |

| 19 | 吴楠,王三反,李乐卓,等.碱热活化过硫酸盐降解柴油精制废水中的有机硫化合物[J].环境污染与防治,2019,41(4):435-438,444. |

| Wu Nan, Wang San‐fan, Li Le‐zhuo,et al.Degradation of organosulfur compound in wastewater of diesel refining by alkali heat activated persulfate[J].Environmental Pollution & Control,2019,41(4):435-438,444. | |

| 20 | 郑立庆,林宜动,李春立,等.利用热激活过硫酸钾技术降解噻虫胺[J].工业水处理,2016,36(3):66-70. |

| Zheng Li‐qing, Lin Yi‐dong, Li Chun‐li,et al.Degradation of clothianidin by heat‑activated potassium persulfate process[J].Industrial Water Treatment,2016,36(3):66-70. | |

| 21 | 郭飞飞,张黎明,何昱轩,等.热激活过硫酸盐降解丁基黄药的研究[J].工业水处理,2018,38(5):71-74. |

| Guo Fei‐fei, Zhang Li‐ming, He Yu‐xuan,et al.Research on the heat‐activation of persulfate for the degradation of butyl xanthate[J].Industrial Water Treatment,2018,38(5):71-74. | |

| 22 | Xia D H, Li Y, Huang G C,et al.Activation of persulfates by natural magnetic pyrrhotite for water disinfection:efficiency,mechanisms,and stability[J].Water Research,2017,112:236-247. |

| 23 | Li M K, Zhong H, He Z G,et al.Degradation of various thiol collectors in simulated and real mineral processing wastewater of sulfide ore in heterogeneous modified manganese slag/PMS system[J].Chemical Engineering Journal,2021,413:127478. |

| 24 | 王肖磊,吴根华,方国东,等.过渡金属活化过硫酸盐在环境修复领域的研究进展[J].生态与农村环境学报,2021,37(2):145-154. |

| Wang Xiao‑lei, Wu Gen‑hua, Fang Guo‑dong,et al.Transition metal activated persulfate for environmental remediation:a review[J].Journal of Ecology and Rural Environment,2021,37(2):145-154. | |

| 25 | Ding Y B, Wang X R, Fu L B,et al.Nonradicals induced degradation of organic pollutants by peroxydisulfate (PDS) and peroxymonosulfate (PMS):recent advances and perspective[J].Science of the Total Environment,2021,765:142794. |

| 26 | Jawad A, Zhan K, Wang H B,et al.Tuning of persulfate activation from a free radical to a nonradical pathway through the incorporation of non‑redox magnesium oxide[J].Environmental Science & Technology,2020,54(4):2476-2488. |

| 27 | Yang Y, Banerjee G, Brudvig G W,et al.Oxidation of organic compounds in water by unactivated peroxymonosulfate[J].Environmental Science & Technology,2018,52(10):5911-5919. |

| 28 | Chen J B, Fang C, Xia W J,et al.Selective transformation of β‐Lactam antibiotics by peroxymonosulfate:reaction kinetics and nonradical mechanism[J].Environmental Science & Technology,2018,52(3):1461-1470. |

| 29 | Zhu S S, Li X J, Kang J,et al.Persulfate activation on crystallographic manganese oxides:mechanism of singlet oxygen evolution for nonradical selective degradation of aqueous contaminants[J].Environmental Science & Technology,2018,53(1):307-315. |

| 30 | 费家通,林匡飞,崔长征,等.NiO/Fe3O4@g-C3N4活化过硫酸盐去除苯并(a)芘的非自由基途径研究[J].现代化工,2021,41(11):132-137. |

| Fei Jia‑tong, Lin Kuang‑fei, Cui Chang‑zheng,et al.Removal of benzo(a) pyrene by NiO/Fe3O4@g-C3N4 activated persulfate through nonradical pathway[J].Modern Chemical Industry,2021,41(11):132-137. |

| [1] | 成丽, 梁海军, 南相莉, 胡恩柱. 丁基黄药在金属负载石英砂中的迁移特性[J]. 东北大学学报(自然科学版), 2023, 44(5): 712-718. |

| [2] | 胡恩柱, 李秋燕, 高涵, 王娜娜. 钢渣吸附去除水中亚甲基蓝[J]. 东北大学学报:自然科学版, 2018, 39(4): 516-521. |

| [3] | 张悦, 薛向欣. 由含钛高炉渣制备叶面肥及甜玉米栽培实验研究[J]. 东北大学学报:自然科学版, 2016, 37(4): 504-507. |

| [4] | 杨合, 王振, 韩冲, 薛向欣. 钢渣非均相类Fenton反应降解亚甲基蓝的研究[J]. 东北大学学报:自然科学版, 2016, 37(3): 347-351. |

| [5] | 杨合, 王振. 反应条件对钢渣除磷的影响[J]. 东北大学学报:自然科学版, 2015, 36(11): 1605-1608. |

| [6] | 石俊杰, 李杰, 孙丽枫, 姜茂发. 含钛高炉渣活度模型的建立及热力学分析[J]. 东北大学学报:自然科学版, 2015, 36(1): 43-47. |

| [7] | 操龙虎, 封胜克, 刘承军, 姜茂发. 不锈钢渣凝固过程中物相转变的热力学分析[J]. 东北大学学报:自然科学版, 2014, 35(12): 1738-1742. |

| [8] | 付念新;娄太平;都兴红;隋智通;. 添加剂对改性含钛高炉渣氯化过程的影响[J]. 东北大学学报(自然科学版), 2012, 33(5): 698-701. |

| [9] | 雷雪飞;薛向欣;. 甲基橙对含钛炉渣可见光催化还原Cr(Ⅵ)的影响[J]. 东北大学学报(自然科学版), 2011, 32(8): 1133-1136. |

| [10] | 张悦;杨合;薛向欣;. 由含钛高炉渣合成复合肥料及甜菜栽培实验研究[J]. 东北大学学报(自然科学版), 2011, 32(12): 1721-1723+1736. |

| [11] | 张悦;杨合;王丽;薛向欣;. 用含钛高炉渣制备肥料[J]. 东北大学学报(自然科学版), 2010, 31(8): 1161-1164+1169. |

| [12] | 张玉柱;龙跃;王少宁;邢宏伟;. 相似原理在冷态模拟粒化钢渣中的应用[J]. 东北大学学报(自然科学版), 2010, 31(2): 207-209. |

| [13] | 薛向欣;王辉;杨合;李述贤;. 热处理时间对钒掺杂钛高炉渣材料性能的影响[J]. 东北大学学报(自然科学版), 2010, 31(1): 84-87. |

| [14] | 马兴冠;刘剑梅;韩冲;薛向欣;. 含钛高炉渣吸附水中磷的实验[J]. 东北大学学报(自然科学版), 2009, 30(9): 1286-1290. |

| [15] | 薛向欣;雷雪飞;杨合;段培宁;. 硫酸盐修饰的含钛高炉渣光催化还原Cr(Ⅵ)[J]. 东北大学学报(自然科学版), 2009, 30(2): 217-220. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||