东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (9): 95-101.DOI: 10.12068/j.issn.1005-3026.2025.20230263

收稿日期:2023-09-07

出版日期:2025-09-15

发布日期:2025-12-03

通讯作者:

李曙光

作者简介:姜世杰(1985—),男,辽宁营口人,东北大学副教授,博士.

基金资助:

Shi-jie JIANG1,2, Shu-guang LI1( ), Zi-zhao XU1, Fei WANG1

), Zi-zhao XU1, Fei WANG1

Received:2023-09-07

Online:2025-09-15

Published:2025-12-03

Contact:

Shu-guang LI

摘要:

针对金属材料挤出成型(metal material extrusion,MME)增材制品静力学性能研究不足的问题,首先制备了3种不同配比的17-4PH不锈钢粉末/聚合物复合丝材;然后利用普通材料挤出成型设备完成了静力学性能实验生坯试件的准备工作,以确定自制丝材的可成型性;最后通过拉伸、压缩及弯曲性能实验,分析其静力学性能并探究不同金属粉末填充率的影响.结果发现:自制的复合丝材能够成型质量稳定的生坯制品;当17-4PH不锈钢粉末填充率由40%提高至50%时,试件的拉伸强度降低约7.8%,压缩强度降低约39.2%,弯曲强度降低约30%.

中图分类号:

姜世杰, 李曙光, 许子沼, 王菲. 金属材料挤出成型生坯试件的静力学性能[J]. 东北大学学报(自然科学版), 2025, 46(9): 95-101.

Shi-jie JIANG, Shu-guang LI, Zi-zhao XU, Fei WANG. Static Mechanical Properties of Green Compact Specimens Fabricated by Metal Material Extrusion[J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 95-101.

| D10 | D50 | D90 |

|---|---|---|

| 17.417 | 30.663 | 52.869 |

表1 17-4PH不锈钢粉末颗粒属性 (powder particles)

Table 1 Properties of 17-4PH stainless steel

| D10 | D50 | D90 |

|---|---|---|

| 17.417 | 30.663 | 52.869 |

| 过程参数 | 设置 |

|---|---|

| 填充比例/% | 100 |

| 填充方式 | 直线填充 |

| 成型速度/(mm·s-1) | 10 |

| 平台温度/℃ | 90 |

| 喷嘴直径/mm | 0.6 |

| 成型温度/℃ | 240 |

| 层厚/mm | 0.25 |

表2 过程参数设置

Table 2 Processing parameter setting

| 过程参数 | 设置 |

|---|---|

| 填充比例/% | 100 |

| 填充方式 | 直线填充 |

| 成型速度/(mm·s-1) | 10 |

| 平台温度/℃ | 90 |

| 喷嘴直径/mm | 0.6 |

| 成型温度/℃ | 240 |

| 层厚/mm | 0.25 |

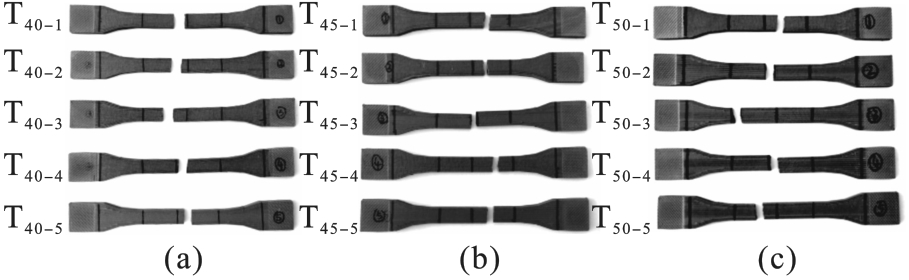

图7 拉伸实验后的不同17-4PH不锈钢粉末填充率生坯试件(a)—40%; (b)—45%; (c)—50%.

Fig.7 Green compact specimens with different 17-4PH stainless steel powder filling rates after tensile test

| 试件 | 平均最大拉伸力/N | 平均拉伸强度/MPa | 平均拉伸模量/MPa | 平均断裂应变/% |

|---|---|---|---|---|

| T40 | 359.5 | 9.0 | 530.3 | 4.01 |

| T45 | 351.9 | 8.8 | 615.2 | 3.30 |

| T50 | 332.8 | 8.3 | 751.1 | 2.16 |

| FFF PLA试件[ | — | 30~70 | 1 890~3 900 | 2~5 |

表3 不同自制复合丝材成型生坯试件的拉伸实验结果

Table 3 Tensile test results of green compact specimens fabricated from different self-made composite filaments

| 试件 | 平均最大拉伸力/N | 平均拉伸强度/MPa | 平均拉伸模量/MPa | 平均断裂应变/% |

|---|---|---|---|---|

| T40 | 359.5 | 9.0 | 530.3 | 4.01 |

| T45 | 351.9 | 8.8 | 615.2 | 3.30 |

| T50 | 332.8 | 8.3 | 751.1 | 2.16 |

| FFF PLA试件[ | — | 30~70 | 1 890~3 900 | 2~5 |

| 试件 | 平均最大压缩力/N | 平均压缩强度/MPa | 平均压缩模量/MPa |

|---|---|---|---|

| C40 | 6 853.3 | 54.1 | 533.8 |

| C45 | 5 421.1 | 42.8 | 628.7 |

| C50 | 4 171.6 | 32.9 | 725.4 |

表4 不同自制复合丝材成型生坯试件的压缩实验结果

Table 4 Compression test results of green compact specimens fabricated from different self-made composite filaments

| 试件 | 平均最大压缩力/N | 平均压缩强度/MPa | 平均压缩模量/MPa |

|---|---|---|---|

| C40 | 6 853.3 | 54.1 | 533.8 |

| C45 | 5 421.1 | 42.8 | 628.7 |

| C50 | 4 171.6 | 32.9 | 725.4 |

| 试件 | 最大弯曲力/N | 平均弯曲强度/MPa | 平均弯曲模量/MPa | 平均断裂应变/% |

|---|---|---|---|---|

| F40 | 29.4 | 17.6 | 1092.6 | 2.81 |

| F45 | 24.9 | 14.9 | 1366.7 | 2.00 |

| F50 | 20.6 | 12.3 | 1582.9 | 1.48 |

表5 不同自制复合丝材成型生坯试件的弯曲实验结果

Table 5 Flexural test results of green compact specimens fabricated from different self-made composite filaments

| 试件 | 最大弯曲力/N | 平均弯曲强度/MPa | 平均弯曲模量/MPa | 平均断裂应变/% |

|---|---|---|---|---|

| F40 | 29.4 | 17.6 | 1092.6 | 2.81 |

| F45 | 24.9 | 14.9 | 1366.7 | 2.00 |

| F50 | 20.6 | 12.3 | 1582.9 | 1.48 |

| [1] | Thompson Y, Gonzalez-Gutierrez J, Kukla C, et al. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel[J]. Additive Manufacturing, 2019, 30: 100861. |

| [2] | Suwanpreecha C, Manonukul A. A review on material extrusion additive manufacturing of metal and how it compares with metal injection moulding[J]. Metals, 2022, 12(3): 429. |

| [3] | Gloeckle C, Konkol T, Jacobs O, et al. Processing of highly filled polymer-metal feedstocks for fused filament fabrication and the production of metallic implants[J]. Materials, 2020, 13(19): 4413. |

| [4] | Shaikh M Q, Nath S D, Akilan A A, et al. Investigation of patient-specific maxillofacial implant prototype development by metal fused filament fabrication (MF3) of Ti-6Al-4V[J]. Dentistry Journal, 2021, 9(10): 109. |

| [5] | Sargini M I M, Masood S H, Palanisamy S, et al. Additive manufacturing of an automotive brake pedal by metal fused deposition modelling[J]. Materials Today: Proceedings, 2021, 45: 4601-4605. |

| [6] | 果春焕, 严家印, 王泽昌, 等. 金属激光熔丝增材制造工艺的研究进展[J]. 热加工工艺, 2020, 49(16): 5-10. |

| Guo Chun-huan, Yan Jia-yin, Wang Ze-chang, et al. Research progress on metal laser fuse additive manufacturing process[J]. Hot Working Technology, 2020, 49(16): 5-10. | |

| [7] | Zhao C, Parab N D, Li X X, et al. Critical instability at moving keyhole tip generates porosity in laser melting[J]. Science, 2020, 370(6520): 1080-1086. |

| [8] | 张云舒, 吴斌涛, 赵昀, 等. 电弧熔丝增材制造传热传质数值模拟研究现状与展望[J]. 机械工程学报, 2024, 60(8): 65-80. |

| Zhang Yun-shu, Wu Bin-tao, Zhao Yun, et al. Research progress in the numerical simulation of heat and mass transfer during wire arc additive manufacturing[J]. Journal of Mechanical Engineering, 2024, 60(8): 65-80. | |

| [9] | 刘伟, 李素丽, 寇丹阳, 等. 不同扫描速度下金属熔丝增材制造应力应变场分析[J]. 焊接技术, 2023, 52(7): 1-5. |

| Liu Wei, Li Su-li, Kou Dan-yang, et al. Analysis of stress-strain field in metal melt additive manufacturing by different scanning speeds[J]. Welding Technology, 2023, 52(7): 1-5. | |

| [10] | 赵沧, 杨源祺, 师博, 等. 金属激光增材制造微观结构和缺陷原位实时监测[J]. 科学通报, 2022, 67(25): 3036-3053. |

| Zhao Cang, Yang Yuan-qi, Shi Bo, et al. Operando monitoring microstructures and defects in laser fusion additive manufacturing of metals[J]. Chinese Science Bulletin, 2022, 67(25): 3036-3053. | |

| [11] | Godec D, Cano S, Holzer C, et al. Optimization of the 3D printing parameters for tensile properties of specimens produced by fused filament fabrication of 17-4PH stainless steel[J]. Materials, 2020, 13(3): 774. |

| [12] | Masood S H, Song W Q. Development of new metal/polymer materials for rapid tooling using fused deposition modelling [J]. Materials & Design, 2004, 25(7): 587-594. |

| [13] | Ren L Q, Zhou X L, Song Z Y, et al. Process parameter optimization of extrusion-based 3D metal printing utilizing PW-LDPE-SA binder system[J]. Materials, 2017, 10(3): 305. |

| [14] | 冯建, 张静, 李邦怿, 等. FDM用93W-Ni-Cu/ABS复合丝材的制备及表征[J]. 稀有金属与硬质合金, 2019, 47(5): 19-24, 28. |

| Feng Jian, Zhang Jing, Li Bang-yi, et al. Preparation and characterization of 93W-Ni-Cu/ABS composite filaments for FDM process[J]. Rare Metals and Cemented Carbides, 2019, 47(5): 19-24, 28. | |

| [15] | 胡祥芬, 牛富荣, 周哲, 等. 熔融沉积(FDM)工艺参数对SiC陶瓷微观结构和力学性能影响[J]. 硬质合金, 2021, 38(3): 201-210. |

| Hu Xiang-fen, Niu Fu-rong, Zhou Zhe, et al. Effect of fused deposition modeling(FDM) process parameters on microstructure and mechanical properties of SiC ceramics[J]. Cemented Carbide, 2021, 38(3): 201-210. | |

| [16] | 张力, 杨现锋, 徐协文, 等. 熔融沉积法3D打印制备氧化锆陶瓷及其力学性能研究[J]. 无机材料学报, 2021, 36(4): 436. |

| Zhang Li, Yang Xian-feng, Xu Xie-wen, et al. 3D printed zirconia ceramics via fused deposit modeling and its mechanical properties[J]. Journal of Inorganic Materials, 2021, 36(4): 436. | |

| [17] | Suwanpreecha C, Manonukul A. On the build orientation effect in as-printed and as-sintered bending properties of 17-4PH alloy fabricated by metal fused filament fabrication[J]. Rapid Prototyping Journal, 2022, 28(6): 1076-1085. |

| [18] | Sotomayor M E, Várez A, Levenfeld B. Influence of powder particle size distribution on rheological properties of 316L powder injection moulding feedstocks[J]. Powder Technology, 2010, 200(1/2): 30-36. |

| [19] | Fayazbakhsh K, Movahedi M, Kalman J. The impact of defects on tensile properties of 3D printed parts manufactured by fused filament fabrication[J]. Materials Today Communications, 2019, 18: 140-148. |

| [20] | Medibew T M. A comprehensive review on the optimization of the fused deposition modeling process parameter for better tensile strength of PLA printed parts[J]. Advances in Materials Science and Engineering, 2022, 2022(1): 5490831. |

| [21] | Cojocaru V, Frunzaverde D, Miclosina C O, et al. The influence of the process parameters on the mechanical properties of PLA specimens produced by fused filament fabrication: a review[J]. Polymers, 2022, 14(5): 886. |

| [22] | Houshyar S, Shanks R A, Hodzic A. The effect of fiber concentration on mechanical and thermal properties of fiber-reinforced polypropylene composites[J]. Journal of Applied Polymer Science, 2005, 96(6): 2260-2272. |

| [1] | 张荣闯, 李明. 基于曲面修剪的直齿轮铣削刀具与工件切触区域的计算[J]. 东北大学学报(自然科学版), 2025, 46(9): 87-94. |

| [2] | 杨震宇, 邹平, 周亮, 王安琪. 单颗CBN磨粒超声振动辅助磨削AISI 304材料去除机理[J]. 东北大学学报(自然科学版), 2024, 45(7): 1011-1019. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||