东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (7): 148-162.DOI: 10.12068/j.issn.1005-3026.2025.20250085

• 智能矿山 • 上一篇

陈炳瑞1,2( ), 王旭2, 姜桂鹏3, 贺飞4, 韩佳霖5, 郝剑钧2

), 王旭2, 姜桂鹏3, 贺飞4, 韩佳霖5, 郝剑钧2

收稿日期:2025-07-07

出版日期:2025-07-15

发布日期:2025-09-24

通讯作者:

陈炳瑞

基金资助:

Bing-rui CHEN1,2( ), Xu WANG2, Gui-peng JIANG3, Fei HE4, Jia-lin HAN5, Jian-jun HAO2

), Xu WANG2, Gui-peng JIANG3, Fei HE4, Jia-lin HAN5, Jian-jun HAO2

Received:2025-07-07

Online:2025-07-15

Published:2025-09-24

Contact:

Bing-rui CHEN

摘要:

针对深部金属矿隧道掘进机(tunnelling boring machine, TBM)开拓岩爆微震监测与预警自动化、智能化不足的问题,开展了基于深度机器视觉DPED(drilling profile ellipse detection)-AT(accurate location of drilling multidimensional features based on anchor tracking)方法的钻孔多维参数识别研究、微震传感器自动拆装装置研发与决策系统设计,实现了TBM开拓微震传感器自动拆装;研发了微震智能变频采集技术,实现了岩爆孕育过程岩石破裂信息连续、保真采集;研发了改进神经网络破裂信号识别与到时实时拾取算法,及岩爆孕育微震源概率场三维表征算法,初步实现TBM开拓岩爆孕育信息智能解译与精细化预警,最终建立了融合钻孔智能识别、传感器自动拆装、信号智能采集-解译的岩爆智能监测预警技术体系.招金矿业瑞海金矿应用表明,该技术初步实现了岩爆微震自动监测、解译与预警,为深部金属矿TBM开拓的少人化、无人化提供有力支撑.

中图分类号:

陈炳瑞, 王旭, 姜桂鹏, 贺飞, 韩佳霖, 郝剑钧. 深部金属矿TBM开拓岩爆微震智能监测与预警[J]. 东北大学学报(自然科学版), 2025, 46(7): 148-162.

Bing-rui CHEN, Xu WANG, Gui-peng JIANG, Fei HE, Jia-lin HAN, Jian-jun HAO. Intelligent Microseismic Monitoring and Early Warning for Rock Burst During TBM Excavation of Deep Metal Mines[J]. Journal of Northeastern University(Natural Science), 2025, 46(7): 148-162.

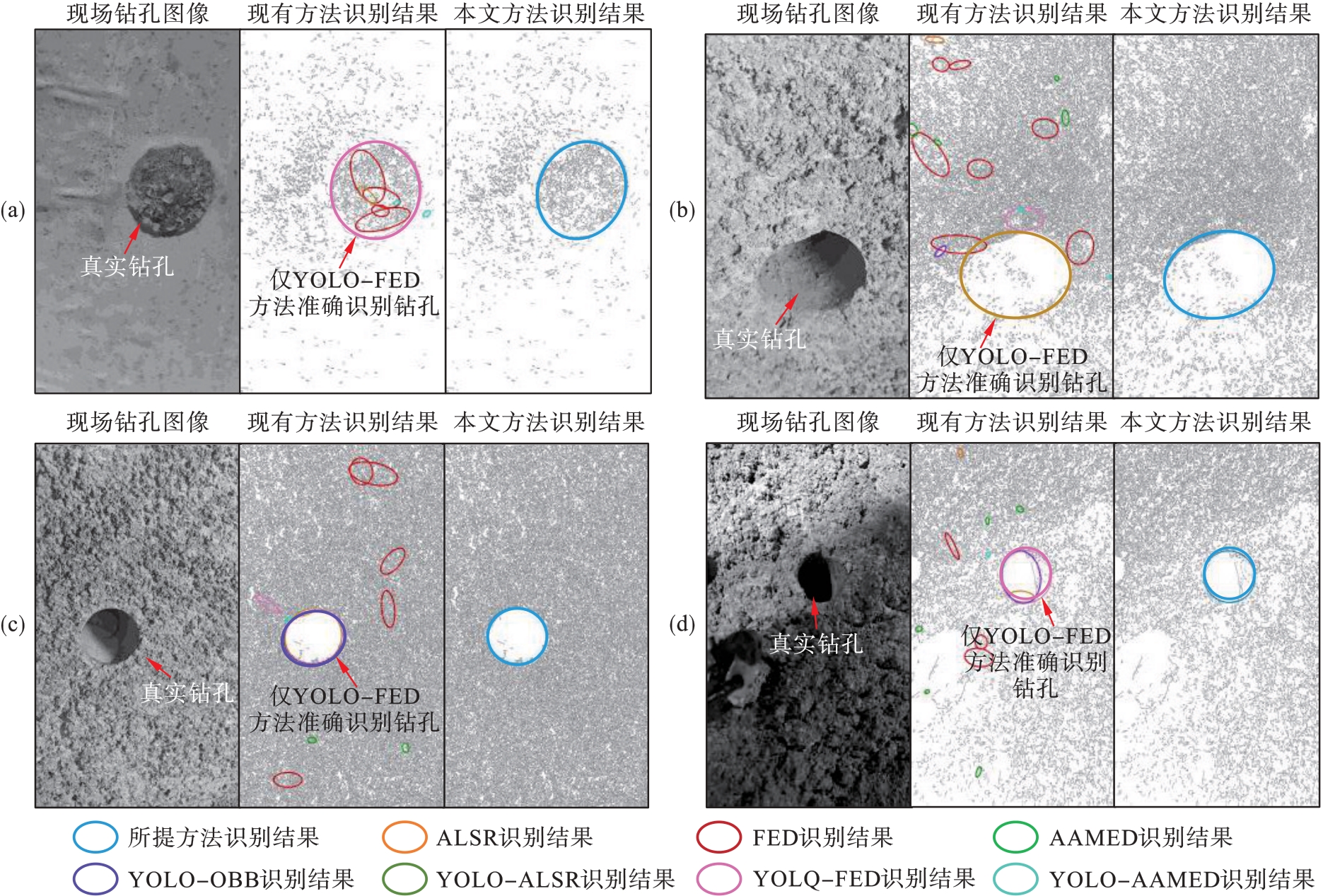

图2 不同钻孔条件下的钻孔轮廓检测效果(a)—孔底有碎石的浅钻孔; (b)—倾斜钻孔; (c)—有阴影的钻孔; (d)—有阴影且孔口凸凹不平的钻孔.

Fig.2 Detection effect of drilling hole contour under different drilling conditions

| 方法 | 准确率/% | |||||

|---|---|---|---|---|---|---|

| 0 dB | 5 dB | 10 dB | 15 dB | 20 dB | 25 dB | |

| CNN | 88.5 | 89.5 | 92.0 | 94.4 | 94.9 | 94.9 |

| ECNN | 94.7 | 94.5 | 96.0 | 96.0 | 96.0 | 96.3 |

表1 不同信噪比样本的识别结果 (signal-to-noise ratios)

Table 1 Recognition results of samples with different

| 方法 | 准确率/% | |||||

|---|---|---|---|---|---|---|

| 0 dB | 5 dB | 10 dB | 15 dB | 20 dB | 25 dB | |

| CNN | 88.5 | 89.5 | 92.0 | 94.4 | 94.9 | 94.9 |

| ECNN | 94.7 | 94.5 | 96.0 | 96.0 | 96.0 | 96.3 |

| [1] | 陈炳瑞, 冯夏庭, 曾雄辉, 等. 深埋隧洞TBM掘进微震实时监测与特征分析[J]. 岩石力学与工程学报, 2011, 30(2): 275-283. |

| Chen Bing-rui, Feng Xia-ting, Zeng Xiong-hui, et al. Real-time microseismic monitoring and its characteristic analysis during tbm tunneling in deep-buried tunnel[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2): 275-283. | |

| [2] | Li P X, Chen B R, Xiao Y X, et al. Rockburst and microseismic activity in a lagging tunnel as the spacing between twin TBM excavated tunnels changes: a case from the Neelum-Jhelum hydropower project[J]. Tunnelling and Underground Space Technology, 2023, 132: 104884. |

| [3] | 冯欢欢, 洪开荣, 杨延栋, 等. 极端复杂地质条件下TBM隧道施工关键技术研究及应用[J]. 现代隧道技术, 2022, 59(1): 42-54. |

| Feng Huan-huan, Hong Kai-rong, Yang Yan-dong, et al. Research and application of key construction technologies for TBM-driven tunnels under extreme complex geological conditions[J]. Modern Tunnelling Technology, 2022, 59(1): 42-54. | |

| [4] | 刘泉声, 刘滨, 唐彬, 等. 煤矿深部巷道碎胀大变形灾害控制及大变形灾变环境下TBM快速成巷技术[J]. 煤炭学报, 2025, 50(1): 224-244. |

| Liu Quan-sheng, Liu Bin, Tang Bin, et al. The control of fragmenting swelling deformation disasters in deep mine roadways and the efficient TBM tunneling technology under such conditions[J]. Journal of China Coal Society, 2025, 50(1): 224-244. | |

| [5] | 刘泉声, 黄兴, 潘玉丛, 等. TBM在煤矿巷道掘进中的技术应用和研究进展[J]. 煤炭科学技术, 2023, 51(1): 242-259. |

| Liu Quan-sheng, Huang Xing, Pan Yu-cong, et al. Application and research progress of TBM tunneling in coal mine roadway[J]. Coal Science and Technology, 2023, 51(1): 242-259. | |

| [6] | 钱七虎. 地下工程建设安全面临的挑战与对策[J]. 岩石力学与工程学报, 2012, 31(10): 1945-1956. |

| Qian Qi-hu. Challenges faced by underground projects construction safety and countermeasures[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(10): 1945-1956. | |

| [7] | Ma T H, Tang C N, Tang S B, et al. Rockburst mechanism and prediction based on microseismic monitoring[J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 110: 177-188. |

| [8] | Feng G L, Chen B R, Xiao Y X, et al. Microseismic characteristics of rockburst development in deep TBM tunnels with alternating soft-hard strata and application to rockburst warning: a case study of the Neelum-Jhelum hydropower project[J]. Tunnelling and Underground Space Technology, 2022, 122: 104398. |

| [9] | Cao A Y, Dou L M, Wang C B, et al. Microseismic precursory characteristics of rock burst hazard in mining areas near a large residual coal pillar: a case study from Xuzhuang Coal Mine, Xuzhou, China[J]. Rock Mechanics and Rock Engineering, 2016, 49(11): 4407-4422. |

| [10] | Feng G L, Feng X T, Chen B R, et al. Microseismic sequences associated with rockbursts in the tunnels of the Jinping II hydropower station[J]. International Journal of Rock Mechanics and Mining Sciences, 2015, 80: 89-100. |

| [11] | 陈炳瑞,王旭,朱新豪,等.一种TBM搭载微震传感器自动拆装装置: 202010136759.8[P].2021-03-23. |

| Chen Bing-rui, Wang Xu, Zhu Xin-hao, et al. A TBM equipped with an automatic installation and removal device for microseismic sensors: 202010136759.8[P].2021-03-23. | |

| [12] | 张鹏海,程关文,杨天鸿,等. 在破碎易塌孔岩体中安装和回收微震传感器的装置及方法: 201910033928.2[P].2025-05-18. |

| Zhang Peng-hai, Cheng Guan-wen, Yang Tian-hong, et al. Device and method for installing and recovering microseismic sensor in broken collapsible rock mass: 201910033928.2[P].2025-05-18. | |

| [13] | 丰光亮, 冯夏庭, 陈炳瑞, 等. 一种孔内及孔外双重固定可回收式微震传感器安装方法: 201711406469.5[P]. 2020-07-10. |

| Feng Guang-liang, Feng Xia-ting, Chen Bing-rui, et al. Hole inside and hole outside double-fixing recyclable micro-seismic sensor installation method: 201711406469.5[P]. 2020-07-10. | |

| [14] | 陈东方, 游喻豪, 任高峰, 等. 一种基于热熔胶的微震传感器孔内安装回收装置: 201910299197.6 [P]. 2021-05-18. |

| Chen Dong-fang, You Yu-hao, Ren Gao-feng, et al. In-hole installation and recovery device for micro-seismic sensor on the basis of hot melt adhesive: 201910299197.6 [P]. 2021-05-18. | |

| [15] | Nippress S E J, Rietbrock A, Heath A E. Optimized automatic pickers: application to the ANCORP data set[J]. Geophysical Journal International, 2010, 181(2): 911-925. |

| [16] | Saragiotis C D, Hadjileontiadis L J, Panas S M. PAI-S/K: a robust automatic seismic P phase arrival identification scheme[J]. IEEE Transactions on Geoscience and Remote Sensing, 2002, 40(6): 1395-1404. |

| [17] | Allen R V. Automatic earthquake recognition and timing from single traces[J]. Bulletin of the Seismological Society of America, 1978, 68(5): 1521-1532. |

| [18] | Allen R. Automatic phase pickers: their present use and future prospects[J]. Bulletin of the Seismological Society of America, 1982, 72(6B): S225-S242. |

| [19] | Li X B, Shang X Y, Morales-Esteban A, et al. Identifying P phase arrival of weak events: the akaike information criterion picking application based on the empirical mode decomposition[J]. Computers & Geosciences, 2017, 100: 57-66. |

| [20] | Maeda N. A method for reading and checking phase time in auto-processing system of seismic wave data[J]. Zisin, 1985, 38(3): 365-379. |

| [21] | Zhu D, Li Y, Zhang C. Automatic time picking for microseismic data based on a fuzzy C-means clustering algorithm[J]. IEEE Geoscience and Remote Sensing Letters, 2016, 13(12): 1900-1904. |

| [22] | Ma H T, Wang T, Li Y, et al. A time picking method for microseismic data based on LLE and improved PSO clustering algorithm[J]. IEEE Geoscience and Remote Sensing Letters, 2018, 15(11): 1677-1681. |

| [23] | Zhu X H, Chen B R, Wang X, et al. Time series segmentation clustering: a new method for S-phase picking in microseismic data[J]. IEEE Geoscience and Remote Sensing Letters, 2021, 19: 7504605. |

| [24] | Gibowicz S J, Kijko A. An introduction to mining seismology[M]. London: Academic Press Limited, 1994. |

| [25] | Kijko A, Sciocatti M. Optimal spatial distribution of seismic stations in mines[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1995, 32(6): 607-615. |

| [26] | 曹安业, 王常彬, 杨旭, 等. 微震定位精度影响下采场裂隙表征与冲击地压预警[J]. 煤炭科学技术, 2024, 52(2): 1-9. |

| Cao An-ye, Wang Chang-bin, Yang Xu, et al. Fractures characterization in mining field considering seismic location accuracy and its application on pre-warning coal burst hazards[J]. Coal Science and Technology, 2024, 52(2): 1-9. | |

| [27] | 国家能源局. 水电工程岩体稳定性微震监测技术规范: [S]. 北京: 中国电力出版社, 2021. |

| National Energy Bureau of the People’s Republic of China. Technical code for microseismic monitoring of rockmass stability of hydropower projects: [S]. Beijing: China Electric Power Press, 2021. | |

| [28] | 王旭.TBM施工岩爆微震全自动监测与预警信息三维表征研究[D].武汉:中国科学院大学,2024. |

| Wang Xu. Research on three-dimensional representation of microseismic automatic monitoring and early warning information for rockburst during construction[D].Wuhan: University of Chinese Academy of Sciences,2024. | |

| [29] | 陈炳瑞, 王旭. 一种TBM施工岩爆微震自动监测智能预警系统及方法: 202210315604.X [P]. 2022-06-24. |

| Chen Bing-rui, Wang Xu. TBM construction rockburst micro-seismic automatic monitoring and intelligent early warning system and method: 202210315604.X[P]. 2022-06-24. | |

| [30] | 王旭, 陈炳瑞, 冯夏庭, 等. 一种TBM搭载微震传感器自动部署装置: 202011004514.6 [P]. 2021-01-05. |

| Wang Xu, Chen Bing-rui, Feng Xia-ting, et al. TBM-carried micro-seismic sensor automatic deployment device: 202011004514.6 [P]. 2021-01-05. | |

| [31] | 陈炳瑞, 郝剑钧, 王旭, 等. 一种TBM施工轨缝自适应跨越行走装置和方法: 202211272850.8[P]. 2023-02-03. |

| Chen Bing-rui, Hao Jian-jun, Wang Xu, et al. TBM construction rail seam self-adaptive spanning walking device and TBM construction rail seam self-adaptive spanning walking method: 202211272850.8 [P]. 2023-02-03. | |

| [32] | 王旭, 巩晓雯, 黄其帅, 等. 基于深度机器视觉的香炉山隧洞钻孔多维特征精准定位[J]. 清华大学学报(自然科学版), 2024, 64(7): 1278-1292. |

| Wang Xu, Gong Xiao-wen, Huang Qi-shuai, et al. Precise multi-dimensional features positioning of Xianglushan tunnel drilling based on deep-machine vision[J]. Journal of Tsinghua University (Science and Technology), 2024, 64(7): 1278-1292. | |

| [33] | 王旭, 陈炳瑞, 谢厚霖, 等. 一种基于机器视觉的钻孔多维特征精准识别方法: 202311441411.X [P]. 2024-02-06. |

| Wang Xu, Chen Bing-rui, Xie Hou-lin, et al. Drilling multi-dimensional feature accurate recognition method based on machine vision: 202311441411.X[P]. 2024-02-06. | |

| [34] | 王旭, 陈炳瑞, 肖亚勋, 等. 一种复杂环境钻孔轮廓精准拟合方法: 202410652956.3[P]. 2024-08-30. |

| Wang Xu, Chen Bing-rui, Xiao Ya-xun, et al. Precise fitting method for drilling contour in complex environment: 202410652956.3 [P]. 2024-08-30. | |

| [35] | Wang W, Wang G, Hu C L, et al. Robust ellipse fitting based on maximum correntropy criterion with variable center[J]. IEEE Transactions on Image Processing, 2023, 32: 2520-2535. |

| [36] | Fornaciari M, Prati A, Cucchiara R. A fast and effective ellipse detector for embedded vision applications[J]. Pattern Recognition, 2014, 47(11): 3693-3708. |

| [37] | 贾棋, 梁景朝, 王祎, 等. 基于区域检测和弧筛选的椭圆检测方法[J]. 计算机辅助设计与图形学学报, 2022, 34(11): 1784-1794. |

| Jia Qi, Liang Jing-chao, Wang Yi, et al. Ellipse detection combining region detection and arc filtering[J]. Journal of Computer-Aided Design & Computer Graphics, 2022, 34(11): 1784-1794. | |

| [38] | Otsu N. A threshold selection method from gray-level histograms[J]. IEEE Transactions on Systems, Man, and Cybernetics, 1979, 9(1): 62-66. |

| [39] | 魏振忠, 张广军. 视觉检测中椭圆中心成像畸变误差模型研究[J]. 北京航空航天大学学报, 2003, 29(2): 140-143. |

| Wei Zhen-zhong, Zhang Guang-jun. Distortion error model of image of ellipse center in 3D visual inspection[J]. Journal of Beijing University of Aeronautics and Astronautics, 2003, 29(2): 140-143. | |

| [40] | 赵志成, 罗泽, 王鹏彦, 等. 基于深度残差网络图像分类算法研究综述[J]. 计算机系统应用, 2020, 29(1): 14-21. |

| Zhao Zhi-cheng, Luo Ze, Wang Peng-yan, et al. Survey on image classification algorithms based on deep residual network[J]. Computer Systems & Applications, 2020, 29(1): 14-21. | |

| [41] | Miller J R, Goldman R N. Using tangent balls to find plane sections of natural quadrics[J]. IEEE Computer Graphics and Applications, 1992, 12(2): 68-82. |

| [42] | 蒋弘毅, 王永娟, 康锦煜. 目标检测模型及其优化方法综述[J]. 自动化学报, 2021, 47(6): 1232-1255. |

| Jiang Hong-yi, Wang Yong-juan, Kang Jin-yu. A survey of object detection models and its optimization methods[J]. Acta Automatica Sinica, 2021, 47(6): 1232-1255. | |

| [43] | Jia Q, Fan X, Luo Z X, et al. A fast ellipse detector using projective invariant pruning[J]. IEEE Transactions on Image Processing, 2017, 26(8): 3665-3679. |

| [44] | Lu C S, Xia S Y, Shao M, et al. Arc-support line segments revisited: an efficient high-quality ellipse detection[J]. IEEE Transactions on Image Processing, 2019, 29: 768-781. |

| [45] | Meng C, Li Z X, Bai X Z, et al. Arc adjacency matrix-based fast ellipse detection[J]. IEEE Transactions on Image Processing, 2020, 29: 4406-4420. |

| [46] | Varghese R M S. YOLOv8: a novel object detection algorithm with enhanced performance and robustness[C]//2024 International Conference on Advances in Data Engineering and Intelligent Computing Systems (ADICS). Chennai, 2024: 1-6. |

| [47] | 陈炳瑞, 王旭, 朱新豪. 一种嵌入式TBM搭载微震监测装置: 201911368376.7 [P]. 2021-01-29. |

| Chen Bing-rui, Wang Xu, Zhu Xin-hao. Embedded TBM carried micro-seismic monitoring device: 201911368376.7 [P]. 2021-01-29. | |

| [48] | 陈炳瑞, 李华方, 杨为, 等. 一种高精度智能变频微震采集方法: 202410856722.0 [P]. 2024-10-01. |

| Chen Bing-rui, Li Hua-fang, Yang Wei, et al. High-precision intelligent variable-frequency micro-seismic acquisition method: 202410856722.0 [P]. 2024-10-01. | |

| [49] | Nyquist H. Certain factors affecting telegraph speed[J]. Transactions of the American Institute of Electrical Engineers, 1924, 3(2): 324-346. |

| [50] | Wang X, Chen B R, Ran Y C, et al. Application of deep learning in microseismic waveform classification: a case study of the Yebatan hydropower station project[C]//2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and Utilization Forum (ICHCE).Xi’an, 2022:1292-1298. |

| [51] | Chen B R, Wang X, Zhu X H, et al. Real-time arrival picking of rock microfracture signals based on convolutional-recurrent neural network and its engineering application[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2024, 16(3): 761-777. |

| [52] | Zhang J L, Sheng G Q. First arrival picking of microseismic signals based on nested U-Net and Wasserstein generative adversarial network[J]. Journal of Petroleum Science and Engineering, 2020, 195: 107527. |

| [53] | 丰光亮. 基于微震信息的深埋隧洞岩爆孕育过程的动态预警方法研究[D]. 北京: 中国科学院大学, 2015. |

| Feng Guang-liang. Study on dynamic early warning method of rock burst gestation process in deep-buried tunnel based on microseismic information[D]. Beijing: University of Chinese Academy of Sciences, 2015. | |

| [54] | 杜岩,谢谟文,蒋宇静,等.基于固有振动频率的危岩安全监测试验研究[J]. 岩土力学, 2016, 37(10):3035-3040. |

| Du Yan, Xie Mo-wen, Jiang Yu-jing, et al. Safety monitoring experiment of unstable rock based on natural vibration frequency[J]. Rock and Soil Mechanics, 2016, 37(10): 3035-3040. | |

| [55] | 姜彤, 万里, 黄坤, 等. 基于固有频率的岩石压剪断裂演化过程试验研究[J]. 中国矿业大学学报, 2024, 53(5): 901-914. |

| Jiang Tong, Wan Li, Huang Kun, et al. Experimental investigation on the evolution of rock compression-shear fracture using the natural frequency[J]. Journal of China University of Mining & Technology, 2024, 53(5): 901-914. | |

| [56] | 蒋宇静, 吴法博, 张学朋, 等. 基于激光多普勒测振的混凝土损伤量化评价研究[J]. 中国矿业大学学报, 2023, 52(5): 889-903. |

| Jiang Yu-jing, Wu Fa-bo, Zhang Xue-peng, et al. Non-destructive quantitative assessment on the damage of concrete structure based on laser Doppler vibrometer technology[J]. Journal of China University of Mining & Technology, 2023, 52(5): 889-903. | |

| [57] | 陈晨, 谢谟文, 孙广存, 等. 基于多时域指标的危岩体崩塌安全评价模型研究[J]. 矿业研究与开发, 2022, 42(4): 45-49. |

| Chen Chen, Xie Mo-wen, Sun Guang-cun, et al. Research on safety evaluation model of dangerous rock mass collapse based on multiple time domain indicators[J]. Mining Research and Development, 2022, 42(4): 45-49. | |

| [58] | 贺宁波, 范庆龙, 侯争军, 等. 非接触式应急监测技术在震区高位危岩崩塌边坡中的应用研究[J]. 水电站设计, 2024, 40(2): 93-96, 103. |

| He Ning-bo, Fan Qing-long, Hou Zheng-jun, et al. Non-contact emergency monitoring technology for high level slope dangerous rockfall in earthquake region[J]. Design of Hydroelectric Power Station, 2024, 40(2): 93-96, 103. | |

| [59] | 韩学辉, 王桂香. 氡法监测地震的理想曲线模型探讨[J]. 太原理工大学学报, 2000, 31(1): 101-103. |

| Han Xue-hui, Wang Gui-xiang. Theideal curve model on earthquake prediction by radon monitoring[J]. Journal of Taiyuan University of Technology, 2000, 31(1): 101-103. | |

| [60] | 范树全, 高清武. 氡预报地震的实验研究[J]. 地震地质, 1982, 4(1): 45-56. |

| Fan Shu-quan, Gao Qing-wu. Experimental study for earthquake prediction by radon anomalies[J]. Seismology and Geology, 1982, 4(1): 45-56. | |

| [61] | Mollo S, Tuccimei P, Heap M J, et al. Increase in radon emission due to rock failure: an experimental study[J]. Geophysical Research Letters, 2011, 38(14): L14304. |

| [62] | Girault F, Schubnel A, Pili É. Transient radon signals driven by fluid pressure pulse, micro-crack closure, and failure during granite deformation experiments[J]. Earth and Planetary Science Letters, 2017, 474: 409-418. |

| [63] | Li L Y, Zhang C Q, Tao Z G, et al. Study on radon release of intact rocks during direct shear[J]. Journal of Central South University, 2022, 29(12): 4021-4034. |

| [1] | 牟文强, 李连崇, 刘洪磊, 余国锋. 遗留煤柱诱发岩层破断微震响应及前兆特征[J]. 东北大学学报(自然科学版), 2024, 45(8): 1167-1177. |

| [2] | 孙浩, 代宗晟, 金爱兵, 陈岩. 基于AttentionR2U-net的岩石(体)关键节理智能识别与参数提取[J]. 东北大学学报(自然科学版), 2024, 45(1): 101-110. |

| [3] | 赵永, 焦诗卉, 赵乾百. 基于Mel频谱和LSTM-DCNN的矿山微震信号混合识别模型[J]. 东北大学学报(自然科学版), 2023, 44(10): 1481-1489. |

| [4] | 夏毅敏, 郭子泺, 邓朝辉, 龙斌. 基于点云的TBM隧道成型质量检测方法及应用[J]. 东北大学学报(自然科学版), 2021, 42(6): 864-870. |

| [5] | 张鹏海, 张子麟, 李明, 张潦源. 低渗储油层水力压裂裂缝延伸过程及成缝机理[J]. 东北大学学报:自然科学版, 2019, 40(5): 745-749. |

| [6] | 郭伟, 刘小庆, 刘建琴, 孙红艳. 基于破岩比能的刀盘滚刀优化布置设计[J]. 东北大学学报:自然科学版, 2018, 39(2): 242-248. |

| [7] | 刘洪磊, 周靖人, 杨天鸿, 张鹏海. 矿山注浆帷幕渗水通道形成过程[J]. 东北大学学报:自然科学版, 2018, 39(10): 1447-1452. |

| [8] | 张飞, 杨天鸿, 王植, 肖平. 某露天矿南帮滑体西部边界形态测定[J]. 东北大学学报:自然科学版, 2017, 38(9): 1335-1340. |

| [9] | 李杨,杨天鸿,侯宪港,汪泓. 基于微震监测的高强度开采工作面围岩响应规律[J]. 东北大学学报:自然科学版, 2017, 38(6): 854-858. |

| [10] | 刘晓明, 赵君杰, 王运敏, 彭平安. 基于改进的STA/LTA方法的微地震P波自动拾取技术[J]. 东北大学学报:自然科学版, 2017, 38(5): 740-745. |

| [11] | 张楚旋, 李夕兵, 董陇军, 姚金蕊. 微震监测传感器布设方案评价模型及应用[J]. 东北大学学报:自然科学版, 2016, 37(4): 594-599. |

| [12] | 马天辉,张文东,徐涛. 节理岩体中隧洞围岩的损伤破坏机理[J]. 东北大学学报(自然科学版), 2013, 34(10): 1485-1489. |

| [13] | 赵兴东;李元辉;刘建坡;田军;. 红透山矿深部开采岩爆潜在区微震活动性研究[J]. 东北大学学报(自然科学版), 2009, 30(9): 1330-1333. |

| [14] | 赵兴东;石长岩;刘建坡;李元辉;. 红透山铜矿微震监测系统及其应用[J]. 东北大学学报(自然科学版), 2008, 29(3): 399-402. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||