东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 11-19.DOI: 10.12068/j.issn.1005-3026.2025.20250092

吴思炜, 周晓光, 刘振宇, 王国栋

收稿日期:2025-07-23

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

刘振宇

作者简介:吴思炜(1989—),男,辽宁阜新人,东北大学副教授基金资助:Si-wei WU, Xiao-guang ZHOU, Zhen-yu LIU, Guo-dong WANG

Received:2025-07-23

Online:2025-08-15

Published:2025-11-24

Contact:

Zhen-yu LIU

摘要:

本文梳理了钢材组织性能预测模型研究进展,重点介绍人机混合智能驱动的热轧工业模型及其组成;通过综合利用物理冶金原理和人工智能技术,解析轧制过程显微组织演变机制.此外,围绕钢材热轧过程显微组织演变与力学性能高效预测、高强钢合金减量化设计和宽厚板高效轧制工艺开发3个方面,介绍了基于人机混合智能驱动的热轧工业模型典型应用案例,为推动钢铁研发由经验试错向人机混合智能驱动的钢铁材料理性设计提供参考.

中图分类号:

吴思炜, 周晓光, 刘振宇, 王国栋. 热轧钢材组织性能预测——从物理模型到人机混合智能的发展与展望[J]. 东北大学学报(自然科学版), 2025, 46(8): 11-19.

Si-wei WU, Xiao-guang ZHOU, Zhen-yu LIU, Guo-dong WANG. Microstructure and Property Prediction of Hot-Rolled Steel: Development and Prospects from Physical Models to Human-Machine Hybrid Intelligence[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 11-19.

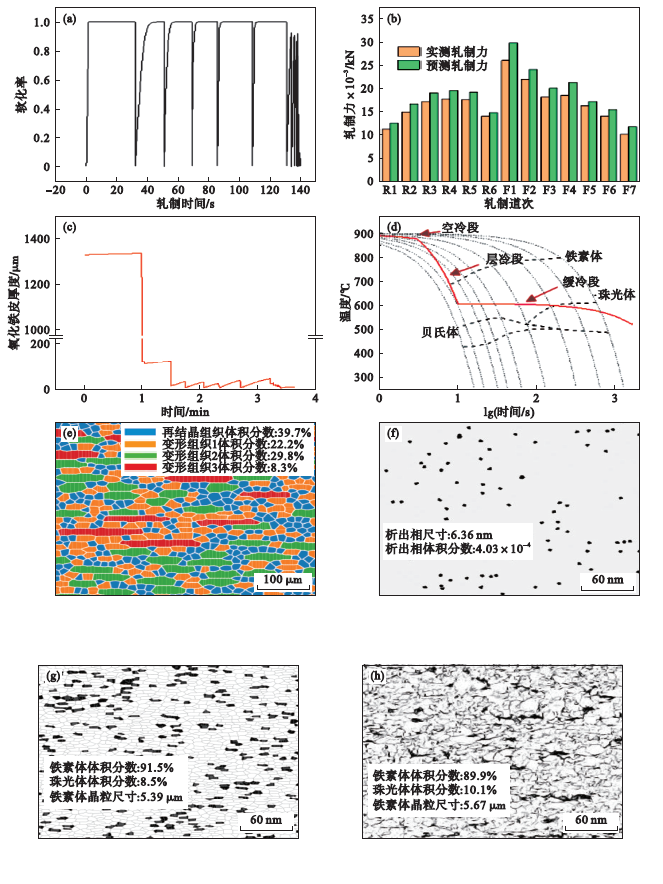

图2 S420MC热轧过程显微组织演变计算结果(a)—软化率; (b)—轧制力; (c)—氧化铁皮厚度; (d)—CCT曲线; (e)—奥氏体组织形态;(f)—析出形貌; (g)—最终显微组织计算结果; (h)—最终显微组织实测结果.

Fig.2 Calculation results of microstructure evolution during hot rolling process of S420MC

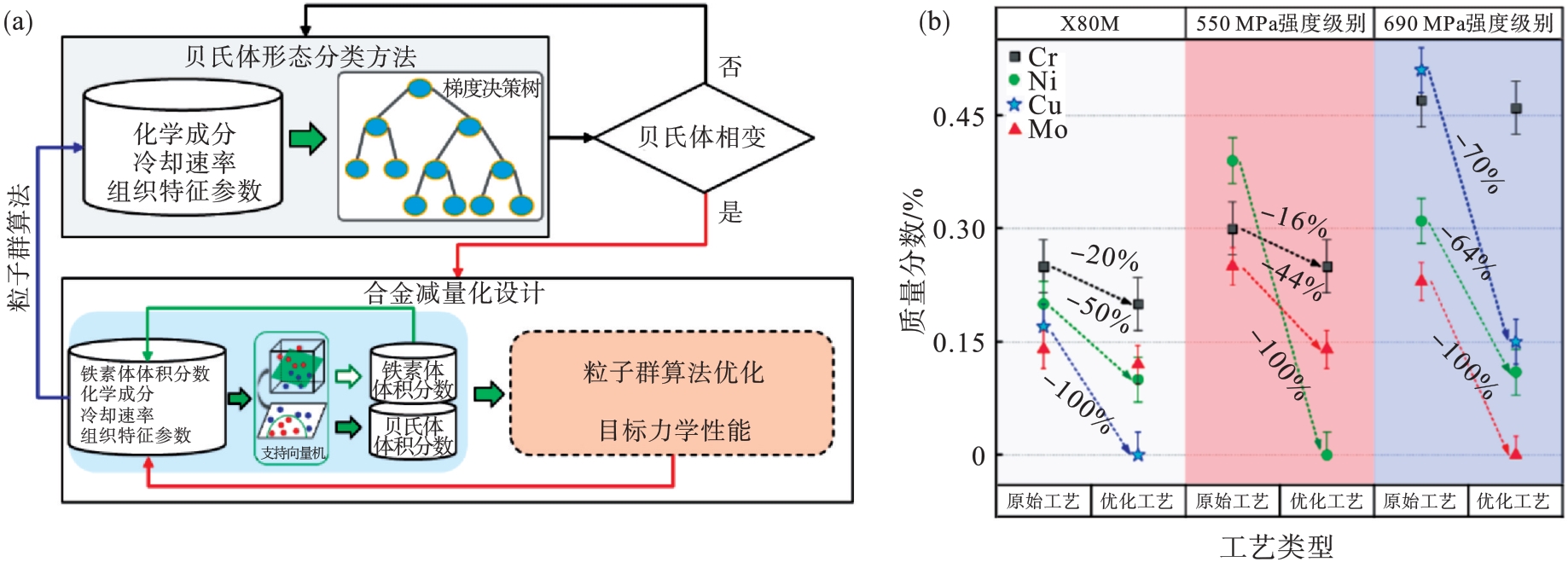

图5 高强钢主要合金元素减量化的应用效果(a)—合金元素减量化设计及工艺参数优化的集成模型架构; (b)—原始合金元素与机器学习模型优化后元素含量的对比.

Fig.5 Application effect of reduction of main alloy elements in high-strength steel

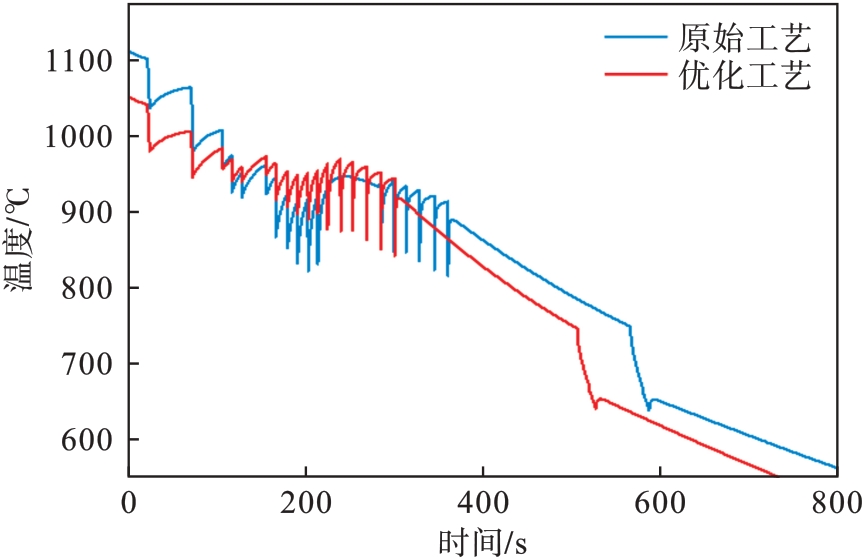

图6 高强船板钢工艺优化前后温度场对比(w(C):0.17%;w(Si):0.28%;w(Mn):1.45%;厚度:20 mm)

Fig.6 Comparison of temperature field before and after process optimization of high-strength ship plate steel (w(C):0.17%;w(Si):0.28%;w(Mn):1.45%;thickness:20 mm)

| [1] | 丁敬国, 金利, 孙丽荣, 等. 板带热轧过程智能化建模方法的研究现状与展望[J]. 冶金自动化, 2022, 46(6): 25-37. |

| Ding Jing-guo, Jin Li, Sun Li-rong, et al. Research status and prospect of intelligent modeling method for hot strip rolling process [J]. Metallurgical Industry Automation, 2022, 46(6): 25-37. | |

| [2] | 孙一康. 带钢热连轧的模型与控制[M]. 北京: 冶金工业出版社, 2002. |

| Sun Yi-kang. Model and control of hot strip rolling [M]. Beijing: Metallurgical Industry Press, 2002. | |

| [3] | 刘玠, 孙一康. 带钢热连轧计算机控制[M]. 北京: 机械工业出版社, 1997. |

| Liu Jie, Sun Yi-kang. Computer control of hot strip rolling [M]. Beijing: China Machine Press, 1997. | |

| [4] | 刘振宇, 曹光明, 周晓光, 等. 组织性能预测技术及其在智能热轧中的核心作用[J]. 轧钢, 2019, 36(2): 1-7. |

| Liu Zhen-yu, Cao Guang-ming, Zhou Xiao-guang, et al. The predicting technologies for microstructure and properties and their core roles in smart hot rolling processes [J]. Steel Rolling, 2019, 36(2): 1-7. | |

| [5] | Ma L Q, Yuan X Q, Jiao S H, et al. Modeling of dynamic recrystallization and flow stress of Nb-bearing steels[J]. Multidiscipline Modeling in Materials and Structures, 2007, 3(1): 27-41. |

| [6] | Siciliano F J, Minami K, Maccagno T M, et al. Mathematical modeling of the mean flow stress, fractional softening and grain size during the hot strip rolling of C-Mn steels[J]. ISIJ International, 1996, 36(12): 1500-1506. |

| [7] | Martin H, Amoako-Yirenkyi P, Pohjonen A, et al. Statistical modeling for prediction of CCT diagrams of steels involving interaction of alloying elements[J]. Metallurgical and Materials Transactions B, 2021, 52(1): 223-235. |

| [8] | Van Bohemen S M C, Sietsma J. Modeling of isothermal bainite formation based on the nucleation kinetics[J]. International Journal of Materials Research, 2008, 99(7): 739-747. |

| [9] | Sellars C M, Whiteman J A. Recrystallization and grain growth in hot rolling[J]. Metal Science, 1979, 13(3/4): 187-194. |

| [10] | Sellars C M. The kinetics of softening processes during hot working of austenite[J]. Czechoslovak Journal of Physics B, 1985, 35(3): 239-248. |

| [11] | Wang L, Ji L K, Yang K, et al. The flow stress-strain and dynamic recrystallization kinetics behavior of high-grade pipeline steels[J]. Materials, 2022, 15(20): 7356. |

| [12] | Zurob H S, Hutchinson C R, Brechet Y, et al. Rationalization of the softening and recrystallization behaviour of microalloyed austenite using mechanism maps[J]. Materials Science and Engineering: A, 2004, 382(1/2): 64-81. |

| [13] | Zurob H S, Hutchinson C R, Brechet Y, et al. Modeling recrystallization of microalloyed austenite: effect of coupling recovery, precipitation and recrystallization[J]. Acta Materialia, 2002, 50(12): 3077-3094. |

| [14] | Collins J, Piemonte M, Taylor M, et al. A rapid, open-source CCT predictor for low-alloy steels, and its application to compositionally heterogeneous material[J]. Metals, 2023, 13(7): 1168. |

| [15] | Zhang S H, Deng L, Che L Z. An integrated model of rolling force for extra-thick plate by combining theoretical model and neural network model[J]. Journal of Manufacturing Processes, 2022, 75: 100-109. |

| [16] | Shen S H, Guye D, Ma X P, et al. Multistep networks for roll force prediction in hot strip rolling mill[J]. Machine Learning with Applications, 2022, 7: 100245. |

| [17] | 李元, 刘文仲, 孙一康. 神经元网络在热连轧精轧机组轧制力预报的应用[J]. 钢铁, 1996(1): 54-57, 39. |

| Li Yuan, Liu Wen-zhong, Sun Yi-kang. Application of neural network to predicting rolling force for the finisher [J]. Iron and Steel, 1996(1): 54-57, 39. | |

| [18] | Dong Z S, Li X, Luan F, et al. Fusion of theory and data-driven model in hot plate rolling: a case study of rolling force prediction[J]. Expert Systems with Applications, 2024, 245: 123047. |

| [19] | Wang Q N, Song L B, Zhao J W, et al. Application of the gradient boosting decision tree in the online prediction of rolling force in hot rolling[J]. The International Journal of Advanced Manufacturing Technology, 2023, 125(1/2): 387-397. |

| [20] | Rahaman M, Mu W Z, Odqvist J, et al. Machine learning to predict the martensite start temperature in steels[J]. Metallurgical and Materials Transactions A, 2019, 50(5): 2081-2091. |

| [21] | Pattanayak S, Dey S, Chatterjee S, et al. Computational intelligence based designing of microalloyed pipeline steel[J]. Computational Materials Science, 2015, 104: 60-68. |

| [22] | Hu X B, Li H, Liu C, et al. Multi-objective design of Ni-B-Al master alloy by adaptive machine learning-driven aluminothermic reduction experiment[J]. Journal of Alloys and Compounds, 2025, 1010: 177403. |

| [23] | Conrad F, Stöcker J P, Signorini C, et al. Exploring design space: machine learning for multi-objective materials design optimization with enhanced evaluation strategies[J]. Computational Materials Science, 2025, 246: 113432. |

| [24] | Wu S W, Zhou X G, Ren J K, et al. Optimal design of hot rolling process for C-Mn steel by combining industrial data-driven model and multi-objective optimization algorithm[J]. Journal of Iron and Steel Research International, 2018, 25(7): 700-705. |

| [25] | Pan G F, Wang F Y, Shang C L, et al. Advances in machine learning-and artificial intelligence-assisted material design of steels[J]. International Journal of Minerals, Metallurgy and Materials, 2023, 30(6): 1003-1024. |

| [26] | Wang X J, Li X, Yuan H, et al. Prediction and analysis of mechanical properties of hot-rolled strip steel based on an interpretable machine learning[J]. Materials Today Communications, 2024, 40: 109997. |

| [27] | Song K, Yan F, Ding T, et al. A steel property optimization model based on the XGBoost algorithm and improved PSO[J]. Computational Materials Science, 2020, 174: 109472. |

| [28] | Diao Y P, Yan L C, Gao K W. A strategy assisted machine learning to process multi-objective optimization for improving mechanical properties of carbon steels[J]. Journal of Materials Science & Technology, 2022, 109: 86-93. |

| [29] | Jiang X, Jia B R, Zhang G F, et al. A strategy combining machine learning and multiscale calculation to predict tensile strength for pearlitic steel wires with industrial data[J]. Scripta Materialia, 2020, 186: 272-277. |

| [30] | Li H W, Li Y, Huang J, et al. Physical metallurgy guided industrial big data analysis system with data classification and property prediction[J]. Steel Research International, 2022, 93(8): 2100820. |

| [31] | 任鹏帆, 王振华, 贾燚, 等. 机理和数据融合的304不锈钢极薄带轧制力模型[J]. 钢铁, 2024, 59(10): 64-76. |

| Ren Peng-fan, Wang Zhen-hua, Jia Yi, et al. Rolling force model for 304 stainless steel ultra-thin strip based on mechanism and data fusion[J]. Iron & Steel, 2024, 59(10): 64-76. | |

| [32] | 李鑫, 周晓光, 曹光明, 等.融合物理冶金学与机器学习的组织性能预测及热轧工艺优化[J]. 冶金自动化, 2023, 47(2): 16-26. |

| Li Xin, Zhou Xiao-guang, Cao Guang-ming, et al. Microstructure and properties prediction and optimization of hot rolling process based on physical metallurgy and machine learning[J]. Metallurgical Industry Automation, 2023, 47(2): 16-26. | |

| [33] | 吴思炜. 基于工业大数据的热轧带钢组织性能预测与优化技术研究[D]. 沈阳: 东北大学, 2018. |

| Wu Si-wei. Research on microstructure and property prediction and optimization technology of hot rolled strips based on industrial big data[D]. Shenyang: Northeastern University, 2018. | |

| [34] | Li X, Zhou X G, Cao G M, et al. Machine learning hot deformation behavior of Nb micro-alloyed steels and its extrapolation to dynamic recrystallization kinetics[J]. Metallurgical and Materials Transactions A, 2021, 52(7): 3171-3181. |

| [35] | Jiang L, Fu H D, Zhang H T, et al. Physical mechanism interpretation of polycrystalline metals’ yield strength via a data-driven method: a novel Hall-Petch relationship[J]. Acta Materialia, 2022, 231: 117868. |

| [36] | Zhang X C, Gong J G, Xuan F Z. A physics-informed neural network for creep-fatigue life prediction of components at elevated temperatures[J]. Engineering Fracture Mechanics, 2021, 258: 108130. |

| [37] | 王毅, 李高楠, 刘哲, 等. 材料基因工程与智能科学:AI+时代无尽前沿[J]. 科技导报, 2025, 43(12): 93-109. |

| Wang Yi, Li Gao-nan, Liu Zhe, et al. Materials genome engineering and intelligent science: the endless frontier in AI+ era [J]. Science & Technology Review, 2025, 43(12): 93-109. | |

| [38] | Li Y F, Wang Z H, Zhang L Y, et al. Arrhenius-type constitutive model and dynamic recrystallization behavior of V-5Cr-5Ti alloy during hot compression[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1889-1900. |

| [39] | Maccagno T M, Jonas J J, Hodgson P D. Spreadsheet modelling of grain size evolution during rod rolling[J]. ISIJ International, 1996, 36(6): 720-728. |

| [40] | Gao Z W, Wu S W, Li X, et al. Modelling strain-induced precipitation kinetics of Nb (C, N) by symbolic regression machine learning[J]. Journal of Materials Research and Technology, 2025, 35: 1712-1721. |

| [41] | Cui C Y, Wang H, Gao X Y, et al. Machine learning model for thickness evolution of oxide scale during hot strip rolling of steels[J]. Metallurgical and Materials Transactions A, 2021, 52(9): 4112-4124. |

| [42] | Cao Y, Cao G M, Cui C Y, et al. Modeling continuous cooling transformations for HSLA steels with physical metallurgy guided hereditary machine learning[J]. Metallurgical and Materials Transactions A, 2023, 54(12): 4891-4904. |

| [43] | Cao Y, Wu S W, Tang S, et al. Dynamic deep learning to predict mechanical properties of high-strength low-alloy steels[J]. Metallurgical and Materials Transactions A, 2025, 56(1): 168-179. |

| [44] | Choudhary A, Kumar M, Unune D R. Experimental investigation and optimization of weld bead characteristics during submerged arc welding of AISI 1023 steel [J]. Defence Technology, 2019, 15(1): 72-82. |

| [45] | Rao V D P, Ali S R S M, Ali S M Z M S, et al. Multi-objective optimization of cutting parameters in CNC turning of stainless steel 304 with TiAlN nano coated tool [J]. Materials Today: Proceedings, 2018, 5(12): 25789-25797. |

| [46] | Wu S W, Cao G M, Zhou X G, et al. High dimensional data-driven optimal design for hot strip rolling of C-Mn steels[J]. ISIJ International, 2017, 57(7): 1213-1220. |

| [47] | 崔春圆. 热轧板带材集成机器学习模型开发与应用[D]. 沈阳: 东北大学, 2023. |

| Cui Chun-yuan. The development and application of integrated machine learning models for hot rolled plate and strip [D]. Shenyang: Northeastern University, 2023. | |

| [48] | Cao Y, Zhang C D, Tang S, et al. Machine learning to predict phase transformation products and their morphologies-application in design of lean high strength steel[J]. Materials & Design, 2025, 258: 114642. |

| [1] | 朱庆丰, 闫渤, 冯志鑫, 左玉波. 2195铝合金不同速度热轧过程数值模拟及实验研究[J]. 东北大学学报(自然科学版), 2023, 44(4): 502-509. |

| [2] | 彭文, 辛洪伞, 李旭东, 孙杰. 基于因子分析的板带热轧产品质量缺陷诊断[J]. 东北大学学报(自然科学版), 2022, 43(6): 809-814. |

| [3] | 李天祥, 李海军, 王昭东, 王国栋. 热芯大压下轧制厚板坯缩孔及表面开裂的数值模拟[J]. 东北大学学报(自然科学版), 2021, 42(7): 913-919. |

| [4] | 何彧, 宋克臣, 张德富, 颜云辉. 融合多层级特征的弱监督钢板表面缺陷检测算法[J]. 东北大学学报(自然科学版), 2021, 42(5): 687-692. |

| [5] | 祖国胤, 张影, 魏振雄, 满婷. Fe-Al微叠层复合材料的制备及界面表征[J]. 东北大学学报(自然科学版), 2021, 42(11): 1554-1561. |

| [6] | 彭良贵, 邢俊芳, 陈国涛, 龚殿尧. 传热与相变耦合的卷取温度模型自适应方法[J]. 东北大学学报:自然科学版, 2020, 41(1): 62-67. |

| [7] | 任家宽, 阎冬, 陈俊, 刘振宇. QT工艺对一种B-Nb低碳贝氏体钢组织及强韧性的影响[J]. 东北大学学报:自然科学版, 2019, 40(11): 1561-1567. |

| [8] | 彭文, 姬亚锋, 陈小睿, 张殿华. 热轧非稳态过程轧制力自学习模型优化[J]. 东北大学学报:自然科学版, 2019, 40(10): 1408-1412. |

| [9] | 李振垒, 陈冬, 袁国, 王国栋. 变速轧制下超快冷系统工艺温度在线实时修正策略[J]. 东北大学学报:自然科学版, 2019, 40(1): 37-42. |

| [10] | 纪英俊, 勇晓玥, 刘英林, 刘士新. 基于随机森林的热轧带钢质量分析与预测方法[J]. 东北大学学报:自然科学版, 2019, 40(1): 11-15. |

| [11] | 陈其源, 周晓光, 刘振宇, 吴思炜. Ti微合金化汽车大梁钢510L的组织性能[J]. 东北大学学报:自然科学版, 2018, 39(3): 339-344. |

| [12] | 王振华, 龚殿尧, 李广焘, 张殿华. 遗传算法优化神经网络的热轧带钢弯辊力预报模型[J]. 东北大学学报:自然科学版, 2018, 39(12): 1717-1722. |

| [13] | 李振垒, 陈冬, 康健, 袁国. 在线控冷对热轧L360管线管组织和性能的影响[J]. 东北大学学报:自然科学版, 2018, 39(11): 1588-1592. |

| [14] | 韩怀宾, 赵宪明, 王维, 万长杰. 穿水冷却对GCr15轴承钢组织和力学性能的影响[J]. 东北大学学报:自然科学版, 2018, 39(10): 1390-1395. |

| [15] | 利成宁, 袁国, 康健, 王国栋. 异步热轧对低合金钢显微组织及力学性能的影响[J]. 东北大学学报:自然科学版, 2017, 38(7): 941-945. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||