东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (11): 1629-1637.DOI: 10.12068/j.issn.1005-3026.2024.11.014

收稿日期:2023-06-07

出版日期:2024-11-15

发布日期:2025-02-24

通讯作者:

柳静献

作者简介:柳静献(1966-),男,河北元氏人,东北大学教授,博士生导师.

基金资助:

Jing-xian LIU1( ), Ya-fei LI1, Chao LYU1, Han-peng ZHAO2

), Ya-fei LI1, Chao LYU1, Han-peng ZHAO2

Received:2023-06-07

Online:2024-11-15

Published:2025-02-24

Contact:

Jing-xian LIU

About author:LIU Jing-xian, E-mail: liujingxian@mail.neu.edu.cn摘要:

为探究袋式除尘滤料孔径特征及其对过滤性能的影响,分别选用针刺毡、水刺毡和覆膜类纤维滤袋共13种样品,采用泡点法对其最大孔径及平均孔径进行测试,利用场发射分析扫描电镜-Image-pro plus 6.0计算机图像软件联用分析针刺毡和水刺毡类纤维滤袋的孔径分布.结果表明:针刺毡最大孔径及平均孔径均大于水刺毡,覆膜类滤料的最大孔径及平均孔径最小;内部孔喉最大孔径及平均孔径会影响到透气度、过滤效率和过滤阻力的大小,随着孔径的增大,透气度逐渐增加;孔径越小则过滤效率越大.此外,水刺毡滤料的表观孔径分布较针刺毡滤料更加集中,分布更加均匀,这对提高滤料的过滤效率有一定程度的影响.

中图分类号:

柳静献, 李亚霏, 吕超, 赵翰鹏. 纤维滤袋孔径特征对过滤性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(11): 1629-1637.

Jing-xian LIU, Ya-fei LI, Chao LYU, Han-peng ZHAO. Effect of Pore Characteristics on Filtration Performance of Filter Bag[J]. Journal of Northeastern University(Natural Science), 2024, 45(11): 1629-1637.

| 编号 | 生产厂家 | 样品类型 | 面密度/(g·m-2) | 厚度/mm |

|---|---|---|---|---|

| 1# | ZJHS | 针刺毡 | 687.85 | 1.64 |

| 2# | EEDS | 针刺毡 | 539.56 | 1.52 |

| 3# | FSXDF | 针刺毡 | 597.78 | 1.43 |

| 4# | HHHT | 针刺毡 | 594.07 | 1.46 |

| 5# | ZZYB | 超细海岛纤维+针刺毡 | 535.85 | 2.11 |

| 6# | JH | 水刺毡 | 543.56 | 1.79 |

| 7# | JH | 水刺毡 | 705.48 | 1.35 |

| 8# | JH | 水刺毡 | 741.93 | 1.40 |

| 9# | HSWX | PTFE覆膜针刺毡 | 814.67 | 1.05 |

| 10# | HSWX | PTFE覆膜针刺毡 | 568.00 | 1.93 |

| 11# | HSWX | PTFE覆膜针刺毡 | 628.67 | 2.03 |

| 12# | JSFS | 覆膜玻纤机织布 | 814.67 | 0.93 |

| 13# | YSRD | PTFE覆膜针刺毡 | 573.78 | 1.66 |

表1 实验样品参数特性

Table 1 Parameter characteristics of experimental samples

| 编号 | 生产厂家 | 样品类型 | 面密度/(g·m-2) | 厚度/mm |

|---|---|---|---|---|

| 1# | ZJHS | 针刺毡 | 687.85 | 1.64 |

| 2# | EEDS | 针刺毡 | 539.56 | 1.52 |

| 3# | FSXDF | 针刺毡 | 597.78 | 1.43 |

| 4# | HHHT | 针刺毡 | 594.07 | 1.46 |

| 5# | ZZYB | 超细海岛纤维+针刺毡 | 535.85 | 2.11 |

| 6# | JH | 水刺毡 | 543.56 | 1.79 |

| 7# | JH | 水刺毡 | 705.48 | 1.35 |

| 8# | JH | 水刺毡 | 741.93 | 1.40 |

| 9# | HSWX | PTFE覆膜针刺毡 | 814.67 | 1.05 |

| 10# | HSWX | PTFE覆膜针刺毡 | 568.00 | 1.93 |

| 11# | HSWX | PTFE覆膜针刺毡 | 628.67 | 2.03 |

| 12# | JSFS | 覆膜玻纤机织布 | 814.67 | 0.93 |

| 13# | YSRD | PTFE覆膜针刺毡 | 573.78 | 1.66 |

样品 编号 | 第1冒泡点压力 | 最大孔径 | 群泡点压力 | 平均孔径 |

|---|---|---|---|---|

| kPa | μm | kPa | μm | |

| 1# | 0.82 | 109.03 | 0.89 | 95.79 |

| 2# | 0.78 | 113.43 | 0.92 | 96.53 |

| 3# | 1.02 | 86.67 | 1.08 | 82.03 |

| 4# | 0.86 | 104.07 | 1.05 | 84.98 |

| 5# | 0.71 | 124.49 | 0.89 | 99.50 |

| 6# | 0.85 | 104.99 | 0.93 | 96.37 |

| 7# | 1.00 | 89.47 | 1.10 | 81.18 |

| 8# | 1.07 | 83.14 | 1.19 | 74.80 |

| 9# | 1.19 | 72.85 | 1.70 | 50.76 |

| 10# | 0.91 | 95.13 | 1.20 | 72.05 |

| 11# | 0.79 | 109.30 | 1.68 | 51.61 |

| 12# | 0.79 | 112.78 | 1.05 | 84.43 |

| 13# | 1.17 | 74.61 | 1.38 | 62.75 |

表2 滤料内部孔喉直径

Table 2 Pore size of the filter materials

样品 编号 | 第1冒泡点压力 | 最大孔径 | 群泡点压力 | 平均孔径 |

|---|---|---|---|---|

| kPa | μm | kPa | μm | |

| 1# | 0.82 | 109.03 | 0.89 | 95.79 |

| 2# | 0.78 | 113.43 | 0.92 | 96.53 |

| 3# | 1.02 | 86.67 | 1.08 | 82.03 |

| 4# | 0.86 | 104.07 | 1.05 | 84.98 |

| 5# | 0.71 | 124.49 | 0.89 | 99.50 |

| 6# | 0.85 | 104.99 | 0.93 | 96.37 |

| 7# | 1.00 | 89.47 | 1.10 | 81.18 |

| 8# | 1.07 | 83.14 | 1.19 | 74.80 |

| 9# | 1.19 | 72.85 | 1.70 | 50.76 |

| 10# | 0.91 | 95.13 | 1.20 | 72.05 |

| 11# | 0.79 | 109.30 | 1.68 | 51.61 |

| 12# | 0.79 | 112.78 | 1.05 | 84.43 |

| 13# | 1.17 | 74.61 | 1.38 | 62.75 |

| 编号 | 斜率 | 标准误差 |

|---|---|---|

| 1# | 18.42 | 0.02 |

| 2# | 18.46 | 0.18 |

| 3# | 35.92 | 0.35 |

| 4# | 20.93 | 0.20 |

| 5# | 11.54 | 0.68 |

| 6# | 12.15 | 0.14 |

| 7# | 22.82 | 0.14 |

| 8# | 25.03 | 0.17 |

| 9# | 131.94 | 0.74 |

| 10# | 68.86 | 0.36 |

| 11# | 71.26 | 0.50 |

| 12# | 62.46 | 0.42 |

| 13# | 72.51 | 1.18 |

表3 实验滤料阻力拟合曲线数据

Table 3 Pressure drop fitted curve of the samples

| 编号 | 斜率 | 标准误差 |

|---|---|---|

| 1# | 18.42 | 0.02 |

| 2# | 18.46 | 0.18 |

| 3# | 35.92 | 0.35 |

| 4# | 20.93 | 0.20 |

| 5# | 11.54 | 0.68 |

| 6# | 12.15 | 0.14 |

| 7# | 22.82 | 0.14 |

| 8# | 25.03 | 0.17 |

| 9# | 131.94 | 0.74 |

| 10# | 68.86 | 0.36 |

| 11# | 71.26 | 0.50 |

| 12# | 62.46 | 0.42 |

| 13# | 72.51 | 1.18 |

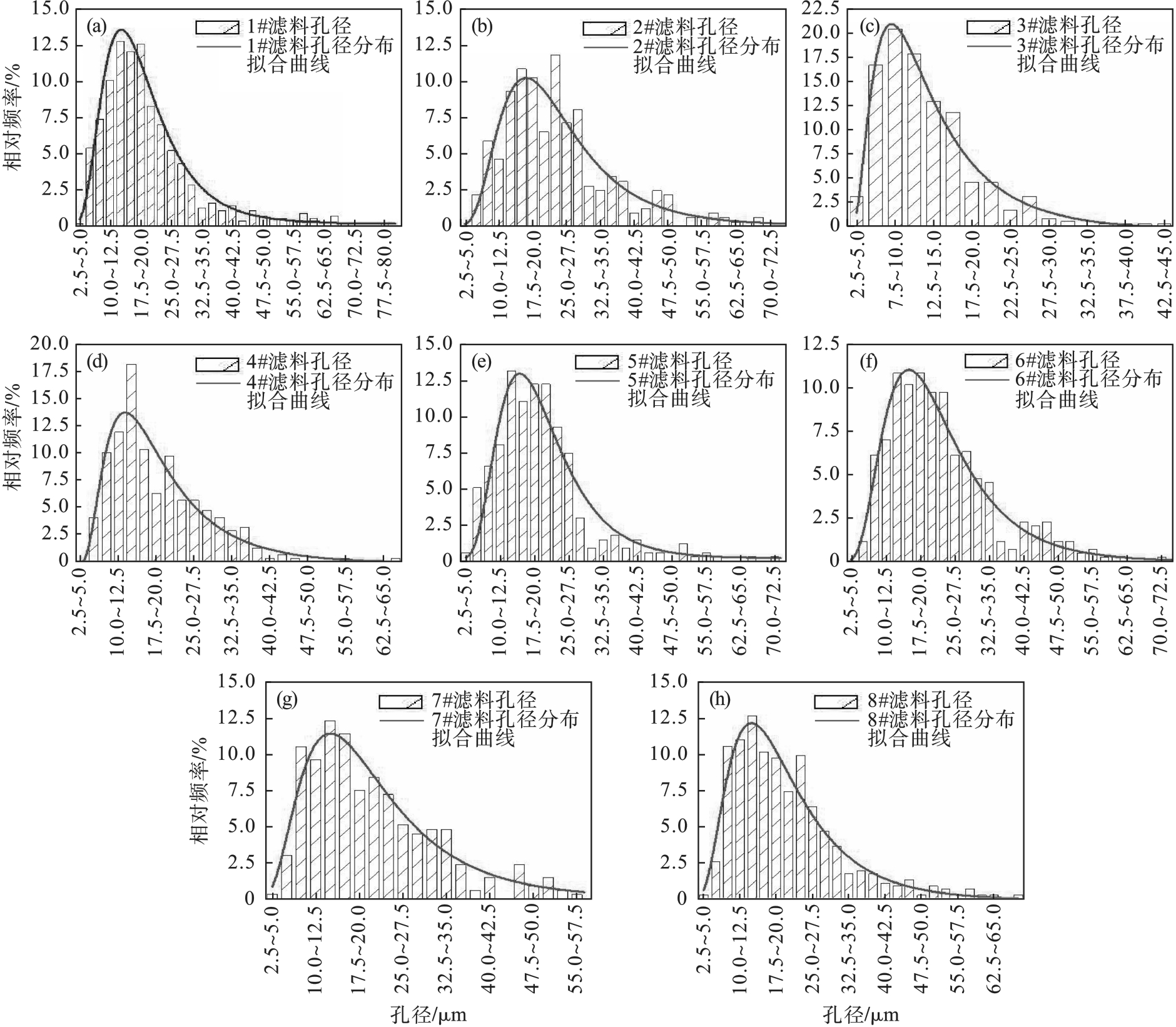

图9 1#~8#滤料孔径分布(a)—1#滤料; (b)—2#滤料; (c)—3#滤料; (d)—4#滤料; (e)—5#滤料; (f)—6#滤料; (g)—7#滤料; (h)—8#滤料.

Fig.9 Pore size distribution of the samples from 1# to 8#

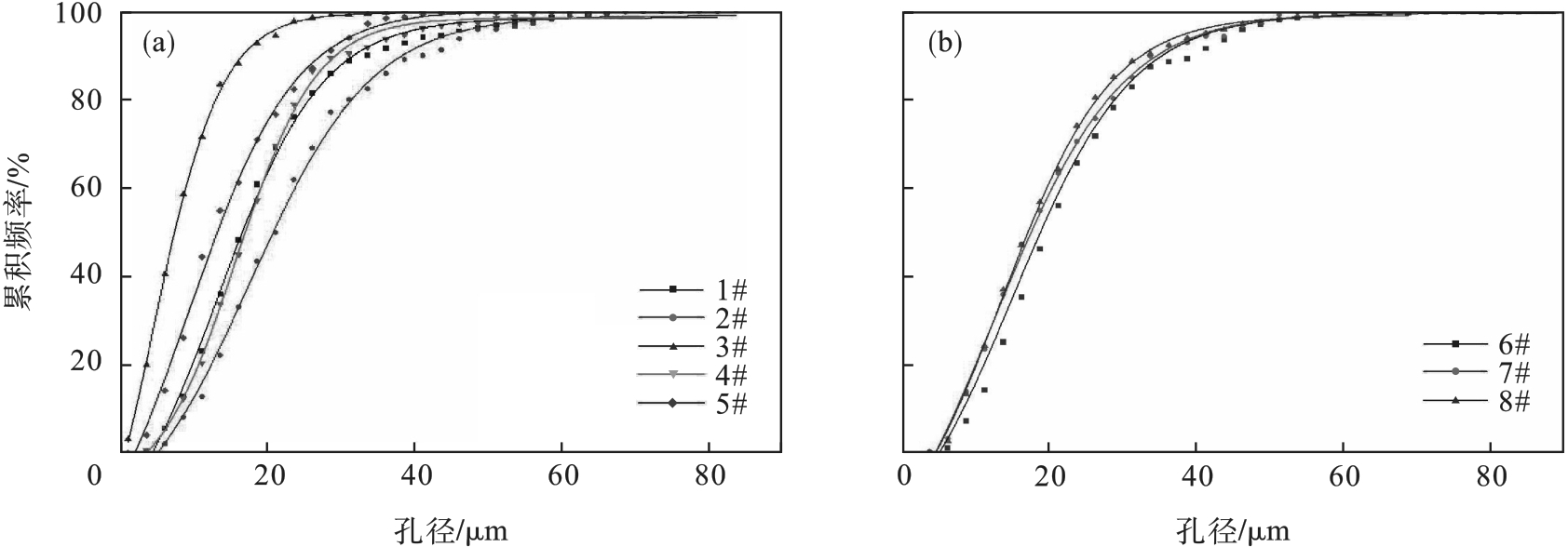

图11 1#~8#滤料孔径分布累积频率及其拟合曲线(a)—1#~5#滤料; (b)—6#~8#滤料.

Fig.11 Cumulative frequency of the pore size distribution with its fitted curve of the samples from 1# to 8#

| 1 | 陈芳.我国城市环境污染现状及治理措施[J].皮革制作与环保科技,2022,3(9):117-119. |

| Chen Fang.Current situation and treatment measures of urban environmental pollution in China[J].Leather Manufacture and Environmental Technology,2022,3(9):117-119. | |

| 2 | Neidell M J.Air pollution,health,and socio‑economic status:the effect of outdoor air quality on childhood asthma[J].Journal of Health Economics,2004,23(6):1209-1236. |

| 3 | Vlachokostas C, Achillas C, Ν Moussiopoulos,et al.Health effects and social costs of particulate and photochemical urban air pollution:a case study for Thessaloniki,Greece[J].Air Quality Atmosphere and Health,2010,5(3):325-334. |

| 4 | 刘造芳,张得昆,张星.芳纶针刺毡在高温下的孔径分布变化[J].西安工程大学学报,2017,31(3):315-321. |

| Liu Zao‑fang, Zhang De‑kun, Zhang Xing.Pore size distribution changes of aramid needle‑punched felt in hight temperature[J].Journal of Xi'an Polytechnic University,2017,31(3):315-321. | |

| 5 | 赖艳,张得昆.纤维混合比对针刺滤材孔径及透气性的影响[J].现代纺织技术,2020,28(4):14-18. |

| Lai Yan, Zhang De‑kun.Effect of fiber mixing ratio on pore size and air permeability of needled filter material[J].Advanced Textile Technology,2020,28(4):14-18. | |

| 6 | Bao L, Musadiq M, Kijima T,et al.Influence of fibers on the dust dislodgement efficiency of bag filters[J].Textile Research Journal,2014,84(7):764-771. |

| 7 | Niedziela M, Sąsiadek M, Woźniak W.Pore size,shape and orientation analysis with respect to tensile tests in nonwoven spun‑lace textiles using image processing[J].Journal of the Textile Institute,2022,114:420-432. |

| 8 | Rawal A.Structural analysis of pore size distribution of nonwovens[J].Journal of the Textile Institute,2010,101:350-359. |

| 9 | Li X W, Kong H Y, He J H.Study on highly filtration efficiency of electrospun polyvinyl alcohol micro‑porous webs[J].Indian Journal of Physics,2014,89(2):175-179. |

| 10 | Nakamura K, Suda T, Matsumoto K.Characterization of pore size distribution of non‑woven fibrous filter by inscribed sphere within 3D filter model[J].Separation and Purification Technology,2018,197:289-294. |

| 11 | Seok J, Chun K M, Song S,et al.Study on the filtration behavior of a metal fiber filter as a function of filter pore size and fiber diameter[J].Journal of Aerosol Science,2015,81:47-61. |

| 12 | Nakao S I.Determination of pore size and pore size distribution[J].Journal of Membrane Science,1994,96(1/2):131-165. |

| 13 | Cabasso I, Robert K Q, Klein E,et al.Porosity and pore size determination in polysulfone hollow fibers[J].Journal of Applied Polymer Science,1977,21(7):1883-1900. |

| 14 | Germic L, Ebert K, Bouma R H B,et al.Characterization of polyacrylonitrile ultrafiltration membranes[J].Journal of Membrane Science,1997,132(1):131-145. |

| 15 | Zhao C S, Zhou X S, Yue Y L.Determination of pore size and pore size distribution on the surface of hollow‑fiber filtration membranes:a review of methods[J].Desalination,2000,129(2):107-123. |

| 16 | Chung T S, Qin J J, Huan A,et al.Visualization of the effect of die shear rate on the outer surface morphology of ultrafiltration membranes by AFM[J].Journal of Membrane Science,2002,196(2):251-266. |

| 17 | Calvo J I, Bottino A, Capannelli G,et al.Comparison of liquid‑liquid displacement porosimetry and scanning electron microscopy image analysis to characterise ultrafiltration track‑etched membranes[J].Journal of Membrane Science,2004,239(2):189-197. |

| 18 | Hernández A, Calvo J I, Prádanos P,et al.Pore size distributions of track‑etched membranes;comparison of surface and bulk porosities[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,1998,138(2):391-401. |

| 19 | Jena A, Gupta K.An innovative technique for pore structure analysis of fuel cell and battery components using flow porometry[J].Journal of Power Sources,2001,96(1):214-219. |

| 20 | Hung C H, Leung W W F.Filtration of nano‑aerosol using nanofiber filter under low Peclet number and transitional flow regime[J].Separation and Purification Technology,2011,79(1):34-42. |

| 21 | Chen F, Ji Z L, Qi Q Q.Effect of pore size and layers on filtration performance of coalescing filters with different wettabilities[J].Separation and Purification Technology,2018,201:71-78. |

| 22 | Liu X C, Shen H G, Nie X L.Study on the filtration performance of the baghouse filters for ultra‑low emission as a function of filter pore size and fiber diameter[J].International Journal of Environmental Research and Public Health,2019,16(2):247-265. |

| 23 | Soo J C, Monaghan K, Lee T,et al.Air sampling filtration media:collection efficiency for respirable size‑selective sampling[J].Aerosol Science and Technology,2016,50(1):76-87. |

| 24 | 周荣菲,张文阁,许潇.滤膜孔径分析常用方法[J].中国计量,2019(6):64-68. |

| Zhou Rong‑fei, Zhang Wen‑ge, Xu Xiao.Common analysis methods of filter membrane pore size[J].China Metrology,2019(6):64-68. | |

| 25 | 李杨.低比例海岛纤维与棉混纺对棉织物服用性能影响的研究[D].西安:西安工程大学,2011. |

| Li Yang.Study on the influence of low proportion of sea‑island fiber blended with cotton on the wearability of cotton fabric[D].Xi’an:Xi’an Polytechnic University,2011. | |

| 26 | 蔡伟龙.滤料的孔径及分布对过滤性能的影响[J].中国环保产业,2017(6):55-57. |

| Cai Wei‑long.Effect of pore size and distribution of filter materials on filtration performance[J].China Environmental Protection Industry,2017 (6):55-57. | |

| 27 | 武松梅,袁传刚.非织造材料孔径与过滤性能关系的研究[J].产业用纺织品,2010,28(1):12-14. |

| Wu Song‑mei, Yuan Chuan‑gang.Study on relation between pore size of nonwovens and filtration characteristic[J].Technical Textiles,2010,28(1):12-14. |

| [1] | 李珉, 曹卓坤, 于洋, 姚广春. Mg对碳纤维稳定泡沫铝发泡过程和胞孔结构的影响[J]. 东北大学学报:自然科学版, 2017, 38(12): 1712-1715. |

| [2] | 霍汉鑫,林海,董颖博,刘泉利. 焙烧改造对沸石特征及其去除氨氮性能的影响[J]. 东北大学学报(自然科学版), 2013, 34(12): 1778-1782. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||