东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (4): 523-529.DOI: 10.12068/j.issn.1005-3026.2024.04.009

• 材料与冶金 • 上一篇

傅大学1,2,3, 狄跃忠1,2, 王耀武1,2

收稿日期:2022-11-08

出版日期:2024-04-15

发布日期:2024-06-26

作者简介:傅大学(1986-),男,辽宁沈阳人,东北大学副教授.

基金资助:Da-xue FU1,2,3, Yue-zhong DI1,2, Yao-wu WANG1,2

Received:2022-11-08

Online:2024-04-15

Published:2024-06-26

摘要:

球团在还原罐内传热导致的温度梯度是限制皮江法还原反应的关键因素.本文采用数值方法研究了球团尺寸、装料方式、还原罐外壁温度等因素对床层温度分布、还原率分布的影响.结果表明:在球团直径为22.3 mm、还原时间相同时能够获得最大的还原率;生产过程中应尽量提高还原罐外壁温度;床层中心区域温度低,还原反应速率慢,反应滞后;通过中心留空的方法能够有效缩短还原周期,提高原料利用率;以单位体积、单位时间镁的产量为依据,对于内径为270 mm的还原罐,当中心留空区域的直径小于27 mm时,可获得最大生产效率.

中图分类号:

傅大学, 狄跃忠, 王耀武. 基于床层传热的皮江法炼镁过程优化[J]. 东北大学学报(自然科学版), 2024, 45(4): 523-529.

Da-xue FU, Yue-zhong DI, Yao-wu WANG. Optimization of Mg Production by Pidgeon Process Based on Heat Transfer in the Bed[J]. Journal of Northeastern University(Natural Science), 2024, 45(4): 523-529.

| 相关参数 | 数值 |

|---|---|

| 球团密度ρ/(kg·m-3) | 2 100-420α |

| 球团比定压热容cp /(J·kg-1·K-1) | 955.02+0.1T |

| 球团导热系数λs/(W·m-1·K-1) | 0.14+0.000 288T |

| 反应(1)焓变ΔH/(J·mol-1) | 249 023.4-21.2T |

| 球团中镁的初始浓度c/(mol·m-3) | 17 500 |

表1 物理性质参数

Table 1 Physical parameters

| 相关参数 | 数值 |

|---|---|

| 球团密度ρ/(kg·m-3) | 2 100-420α |

| 球团比定压热容cp /(J·kg-1·K-1) | 955.02+0.1T |

| 球团导热系数λs/(W·m-1·K-1) | 0.14+0.000 288T |

| 反应(1)焓变ΔH/(J·mol-1) | 249 023.4-21.2T |

| 球团中镁的初始浓度c/(mol·m-3) | 17 500 |

| 参数 | 时间/min | |||||||

|---|---|---|---|---|---|---|---|---|

| ≤15 | ≤12 | ≤10 | ≤8 | >15 | >12 | >10 | >8 | |

| 温度/℃ | 1 050 | 1 100 | 1 150 | 1 200 | 1 050 | 1 100 | 1 150 | 1 200 |

| 动力学常数k/min-1 | 0.025 13 | 0.051 74 | 0.079 42 | 0.110 55 | 9.98×10-4 | 3.03×10-3 | 5.32×10-3 | 9.65×10-3 |

| 还原反应速率/min-1 | ||||||||

表2 反应速率方程及相关动力学参数[19]

Table 2 Reaction rate equations and related kinetic parameters

| 参数 | 时间/min | |||||||

|---|---|---|---|---|---|---|---|---|

| ≤15 | ≤12 | ≤10 | ≤8 | >15 | >12 | >10 | >8 | |

| 温度/℃ | 1 050 | 1 100 | 1 150 | 1 200 | 1 050 | 1 100 | 1 150 | 1 200 |

| 动力学常数k/min-1 | 0.025 13 | 0.051 74 | 0.079 42 | 0.110 55 | 9.98×10-4 | 3.03×10-3 | 5.32×10-3 | 9.65×10-3 |

| 还原反应速率/min-1 | ||||||||

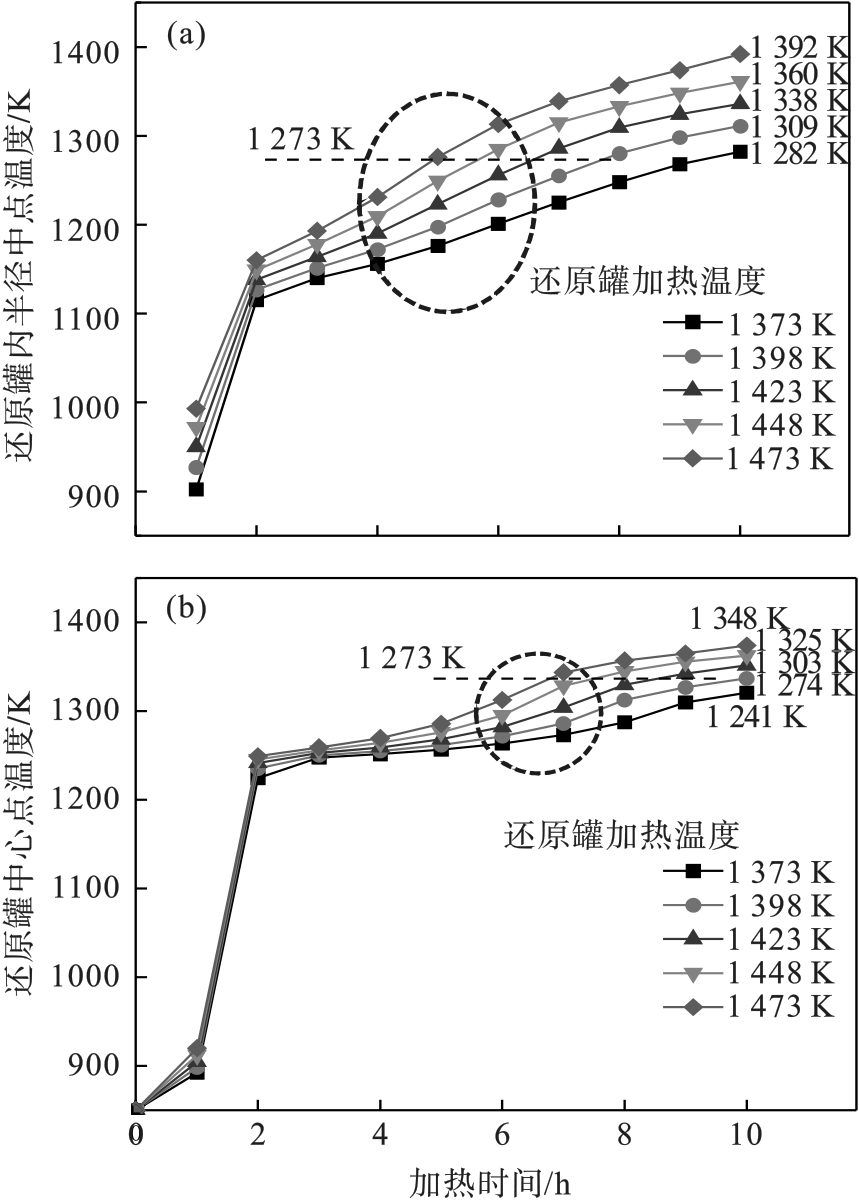

图6 还原罐在不同加热温度下内半径中点和还原罐中心点的温度与加热时间的关系(a)—内半径中点; (b)—还原罐中心点.

Fig.6 Relationship between temperature and heating time at inner radius midpoint and center point of the retort at different heating temperatures

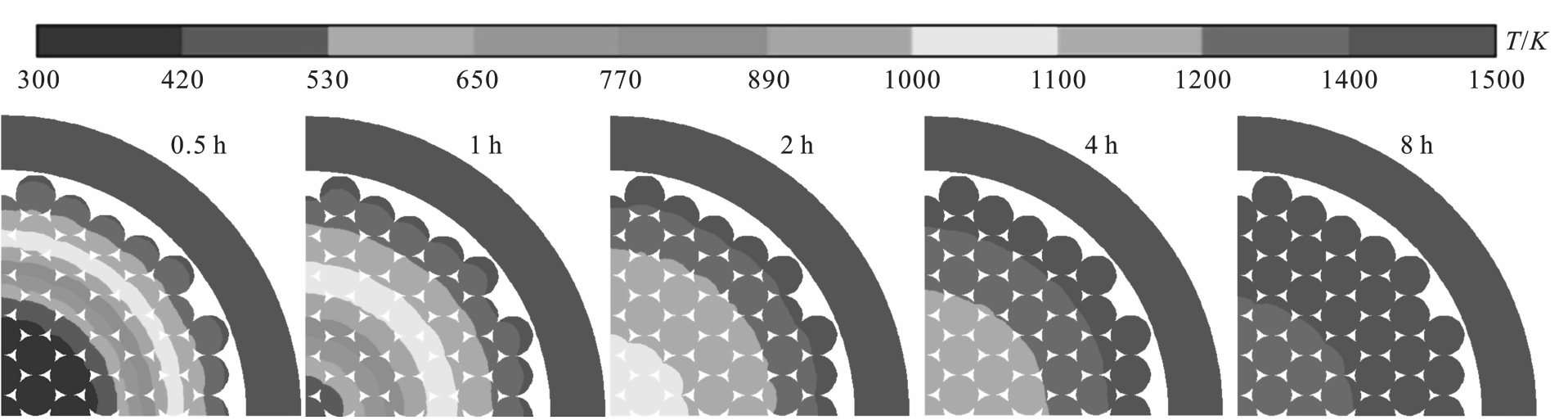

图7 球团床层的温度分布(球团直径22.3 mm,还原罐加热温度T=1 473 K)

Fig.7 Temperature distribution in the pellets bed (pellet diameter 22.3 mm,heating temperature of retort T=1 473 K)

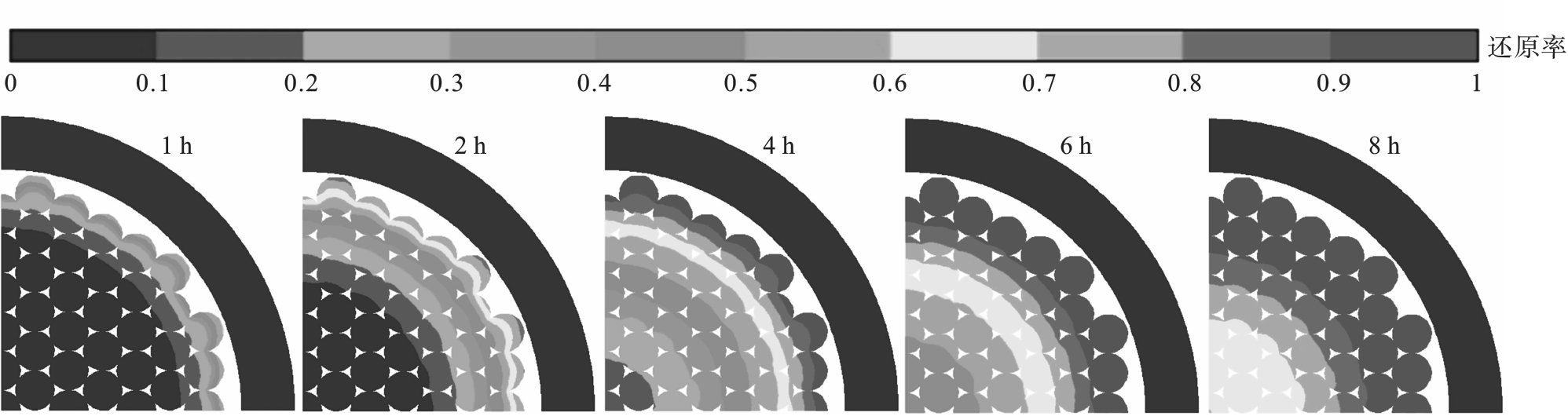

图8 球团床层的还原率分布(球团直径22.3 mm,还原罐加热温度T=1 473 K)

Fig.8 Reduction ratio distribution in the pellets bed (pellet diameter 22.3 mm,heating temperature of retort T=1 473 K)

| 体积 | 还原时间/h | 还原率/% | 最大生产效率 | ||

|---|---|---|---|---|---|

| kg·m-3·h-1 | |||||

| V10+ | 2 | 73.53 | 5.42 | ||

| V9+ | 2.69 | 71.88 | 16.47 | ||

| V8+ | 2.94 | 66.29 | 23.72 | ||

| V7+ | 3.32 | 65.23 | 28.39 | ||

| V6+ | 3.74 | 65.00 | 31.91 | ||

| V5+ | 4.09 | 64.74 | 34.23 | ||

| V4+ | 4.36 | 64.61 | 35.73 | ||

| V3+ | 4.55 | 64.59 | 36.51 | ||

| V2+ | 4.68 | 64.45 | 37.15 | ||

| V1+ | 4.72 | 64.45 | 37.14 | ||

表3 不同床层体积的最大生产效率

Table 3 Maximum production efficiency of different bed volumes

| 体积 | 还原时间/h | 还原率/% | 最大生产效率 | ||

|---|---|---|---|---|---|

| kg·m-3·h-1 | |||||

| V10+ | 2 | 73.53 | 5.42 | ||

| V9+ | 2.69 | 71.88 | 16.47 | ||

| V8+ | 2.94 | 66.29 | 23.72 | ||

| V7+ | 3.32 | 65.23 | 28.39 | ||

| V6+ | 3.74 | 65.00 | 31.91 | ||

| V5+ | 4.09 | 64.74 | 34.23 | ||

| V4+ | 4.36 | 64.61 | 35.73 | ||

| V3+ | 4.55 | 64.59 | 36.51 | ||

| V2+ | 4.68 | 64.45 | 37.15 | ||

| V1+ | 4.72 | 64.45 | 37.14 | ||

| 1 | Jayasathyakawin S, Ravichandran M, Baskar N,et al.Magnesium matrix composite for biomedical applications through powder metallurgy‐review[J].Materials Today:Proceedings,2020,27:736-741. |

| 2 | Hornberger H, Virtanen S, Boccaccini A R.Biomedical coatings on magnesium alloys:a review[J].Acta Biomaterialia,2012,8(7):2442-2455. |

| 3 | Xiong N, Tian Y, Yang B,et al.Results of recent investigations of magnesia carbothermal reduction in vacuum[J].Vacuum,2019,160:213-225. |

| 4 | Tian Y, Wang L P, Yang B,et al.Comparative evaluation of energy and resource consumption for vacuum carbothermal reduction and Pidgeon process used in magnesium production[J].Journal of Magnesium and Alloys,2022,10(3):697-706. |

| 5 | Hua J, He L L, Yan K D,et al.Robotic slag offloading and process improvement of magnesium smelting in Pidgeon process with faster region‑based convolutional neural network[J].International Journal of Heat and Technology,2019,37(1):345-350. |

| 6 | Fu D X, Ji Z H, Guo J H,et al.Diffusion and phase transformations during the reaction between ferrosilicon and CaO·MgO under vacuum[J].Journal of Materials Research and Technology,2020,9(3):4379-4385. |

| 7 | Wynnyckyj J R, Tackie E, Chen G.The problem of limited recoveries in the Pidgeon process for magnesium production[J].Canadian Metallurgical Quarterly,1991,30(3):139-143. |

| 8 | Toguri J M, Pidgeon L M.High‐temperature studies of metallurgical processes.part Ⅱ: the thermal reduction of calcined dolomite with silicon[J].Canadian Journal of Chemistry,1962,40(9):1769-1776. |

| 9 | Zhang C, Wang C, Zhang S J,et al.The effects of hydration activity of calcined dolomite (HCD) on the silicothermic reduction process[J].International Journal of Mineral Processing,2015,142:154-160. |

| 10 | Li R B, Zhang S J, Guo L J,et al.Numerical study of magnesium (Mg) production by the Pidgeon process:impact of heat transfer on Mg reduction process[J].International Journal of Heat and Mass Transfer,2013,59:328-337. |

| 11 | Li R B, Zhang C, Zhang S J,et al.Experimental and numerical modeling studies on production of Mg by vacuum silicothermic reduction of CaO·MgO[J].Metallurgical and Materials Transactions B,2014,45:236-250. |

| 12 | 吴永.皮江法炼镁工艺的一种改良技术及其宏观动力学模型分析[J].轻金属,2016(7):39-47. |

| Wu Yong.An improved shrinking core model synthesis method of Pidgeon magnesium smelting process and its macro kinetic model analysis[J].Light Metals,2016(7):39-47. | |

| 13 | 冯俊小,张志远.镁还原罐内强化换热研究[J].北京科技大学学报,2012,34(7):830-835. |

| Feng Jun‑xiao, Zhang Zhi‑yuan.Enhancement of heat transfer in a magnesium reduction retort[J].Journal of University of Science and Technology Beijing,2012,34(7):830-835. | |

| 14 | 夏德宏,张刚,郭梁.金属镁还原罐径向传热强化器的研究[J].工业加热,2005,34(6):39-42. |

| Xia De‐hong, Zhang Gang, Guo Liang.Study of the radial conductive intensifier for magnesium reduction jar[J].Industrial Heating,2005,34(6):39-42. | |

| 15 | Yu A, Hu H, Li N Y.Mathematical modelling of magnesium reduction in a novel vertical Pidgeon process[J].Modelling and Simulation in Materials Science and Engineering,2002,10(4):413-423. |

| 16 | 傅大学,张廷安,豆志河,等.球团预制-硅热还原炼镁还原罐内传热[J].东北大学学报(自然科学版),2018,39(5):643-648. |

| Fu Da‐xue, Zhang Ting‐an, Dou Zhi‐he,et al.Heat transfer in a retort for Mg‑extraction by pre‑prepared pellet silicothermic process[J].Journal of Northeastern University (Natural Science),2018,39(5):643-648. | |

| 17 | 傅大学,关录奎,豆志河,等.球团预制-硅热还原炼镁的球团传热性研究[J].东北大学学报(自然科学版),2017,38(9):1274-1279. |

| Fu Da‐xue, Guan Lu‐kui, Dou Zhi‐he,et al.Study on heat transfer of pre‑prepared pellets for Mg extraction by silicothermic process[J].Journal of Northeastern University (Natural Science),2017,38(9):1274-1279. | |

| 18 | Fu D X, Zhang T A, Dou Z H,et al.Numerical study of magnesium production by Pidgeon process and pre‐prepared pellets silicothermic process:comparison of heat transfer[C]//TMS 2017 Magnesium Technology.San Diego,2017:107-111. |

| 19 | 张超,付瑾.硅热法炼镁动力学的数学模型分析及数值模拟[J].化工进展,2019,38(9):4155-4163. |

| Zhang Chao, Fu Jin.Analysis of the kinetic models of the silicothermic reduction process and their numerical simulation[J].Chemical Industry and Engineering Progress,2019,38(9):4155-4163. | |

| 20 | Zhang C, Chu H Q, Gu M Y,et al.Experimental and numerical investigation of silicothermic reduction process with detailed chemical kinetics and thermal radiation[J].Applied Thermal Engineering,2018,135:454-462. |

| [1] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| [2] | 余犇, 王冬晓, 刘禹, 李建平. AZ31镁合金薄板热油恒温成形数值模拟与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 179-186. |

| [3] | 郑立春, 彭博, 娄健, 姜周华. 含铈镁H13模具钢电渣重熔渣系的研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1111-1118. |

| [4] | 郭丽莉, 涂赣峰, 冯乃祥, 狄跃忠. 以电解法氢氧化镁为原料制备纳米氧化镁[J]. 东北大学学报(自然科学版), 2023, 44(6): 783-789. |

| [5] | 黄菲, 王鑫宇, 闻昕宇, 常卓雅. 低铁赤泥混熔体系中镁铁尖晶石生长的研究[J]. 东北大学学报(自然科学版), 2023, 44(6): 849-856. |

| [6] | 陈洋洋, 孟凡一, 蔡景治, 苑春苗. 金属氧化物对镁粉尘层火蔓延的增强机制[J]. 东北大学学报(自然科学版), 2023, 44(12): 1778-1784. |

| [7] | 闫基森, 豆志河, 张廷安. 多级深度还原法制备Ti6Al4V粉体中镁热自蔓延产物浸出动力学[J]. 东北大学学报(自然科学版), 2023, 44(10): 1416-1423. |

| [8] | 郭荣荣, 李宗辉, 黄萧. 鞍本地区晚太古宙高镁安山岩的成因解释[J]. 东北大学学报(自然科学版), 2022, 43(5): 740-747. |

| [9] | 张晓虎, 张晟, 赵亮, 董辉. 烧结镁砂煅烧竖炉内气固传热特性数值分析[J]. 东北大学学报(自然科学版), 2022, 43(1): 40-47. |

| [10] | 王长军, 于洋, 李宝宽, 刘雪林. 钢带烧结料层的干燥氧化过程仿真[J]. 东北大学学报(自然科学版), 2021, 42(9): 1282-1289. |

| [11] | 周素莹, 丁学勇, 薛向欣, 杨合. 磷酸铵镁结晶法高效回收提钒废水中的高浓度氨氮[J]. 东北大学学报(自然科学版), 2021, 42(6): 789-794. |

| [12] | 张晟, 张晓虎, 赵亮, 董辉. 基于Ergun方程的菱镁球团填充床层阻力特性实验[J]. 东北大学学报(自然科学版), 2021, 42(3): 347-352. |

| [13] | 孙文瀚, 刘文刚, 杨婷, 代淑娟. TX-100对油酸钠体系下菱镁矿与白云石浮选分离的影响[J]. 东北大学学报(自然科学版), 2021, 42(2): 226-231. |

| [14] | 袁杰, 王姝, 王福利, 孙晓辉. 基于改进主观贝叶斯方法识别电熔镁炉异常工况[J]. 东北大学学报(自然科学版), 2021, 42(2): 153-159. |

| [15] | 苏建铭, 豆志河, 张廷安, 刘燕. 氧质量分数对于镁蒸气铁水脱硫的影响[J]. 东北大学学报:自然科学版, 2020, 41(6): 824-827. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||