Journal of Northeastern University(Natural Science) ›› 2025, Vol. 46 ›› Issue (4): 33-42.DOI: 10.12068/j.issn.1005-3026.2025.20230286

• Mechanical Engineering • Previous Articles Next Articles

Xing-long LIU1,2, Chen LI1, Zeng LIN1

Received:2023-10-09

Online:2025-04-15

Published:2025-07-01

CLC Number:

Xing-long LIU, Chen LI, Zeng LIN. Effect of TiAlSiN Coating Structure on Its Mechanical Properties[J]. Journal of Northeastern University(Natural Science), 2025, 46(4): 33-42.

| WC | Co | C | 其他 |

|---|---|---|---|

| 9.85 | 6.0 | 5.57 | 0.15 |

Table 1 Chemical composition of the sample

| WC | Co | C | 其他 |

|---|---|---|---|

| 9.85 | 6.0 | 5.57 | 0.15 |

| 步骤 | 偏置 电压/V | Ar cm3·min-1 | H2 cm3·min-1 | N2稳 压/ Pa | 弧电流/ A | 沉积温度/℃ | 沉积时间/min | ||

|---|---|---|---|---|---|---|---|---|---|

| Ti | AlTi | TiSi | |||||||

| a-1 | 50 | 100 | 0 | — | 80 | 0 | 0 | 480 | 15 |

| a-2 | 140 | 100 | 100 | — | 80 | 0 | 0 | 480 | 15 |

| a-3 | 140 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| a-4 | 150 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| a-5 | 40 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 60 |

| a-6 | 80 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 20 |

| a-7 | 80 | 0 | 0 | 3.5 | 0 | 0 | 140 | 480 | 70 |

| b-1 | 50 | 100 | 0 | — | 80 | 0 | 0 | 480 | 15 |

| b-2 | 140 | 100 | 100 | — | 80 | 0 | 0 | 480 | 15 |

| b-3 | 140 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| b-4 | 150 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| b-5 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 60 |

| b-6 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 2 |

| b-7 | 60 | 0 | 0 | 3.5 | 0 | 140 | 480 | 2 | |

| b-(8~21) | b-6与b-7往复叠层 | ||||||||

| b-22 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 30 |

Table 2 Deposition parameters of the coatings

| 步骤 | 偏置 电压/V | Ar cm3·min-1 | H2 cm3·min-1 | N2稳 压/ Pa | 弧电流/ A | 沉积温度/℃ | 沉积时间/min | ||

|---|---|---|---|---|---|---|---|---|---|

| Ti | AlTi | TiSi | |||||||

| a-1 | 50 | 100 | 0 | — | 80 | 0 | 0 | 480 | 15 |

| a-2 | 140 | 100 | 100 | — | 80 | 0 | 0 | 480 | 15 |

| a-3 | 140 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| a-4 | 150 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| a-5 | 40 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 60 |

| a-6 | 80 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 20 |

| a-7 | 80 | 0 | 0 | 3.5 | 0 | 0 | 140 | 480 | 70 |

| b-1 | 50 | 100 | 0 | — | 80 | 0 | 0 | 480 | 15 |

| b-2 | 140 | 100 | 100 | — | 80 | 0 | 0 | 480 | 15 |

| b-3 | 140 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| b-4 | 150 | 100 | 0 | — | 100 | 0 | 0 | 480 | 30 |

| b-5 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 60 |

| b-6 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 2 |

| b-7 | 60 | 0 | 0 | 3.5 | 0 | 140 | 480 | 2 | |

| b-(8~21) | b-6与b-7往复叠层 | ||||||||

| b-22 | 60 | 0 | 0 | 3.5 | 0 | 140 | 0 | 480 | 30 |

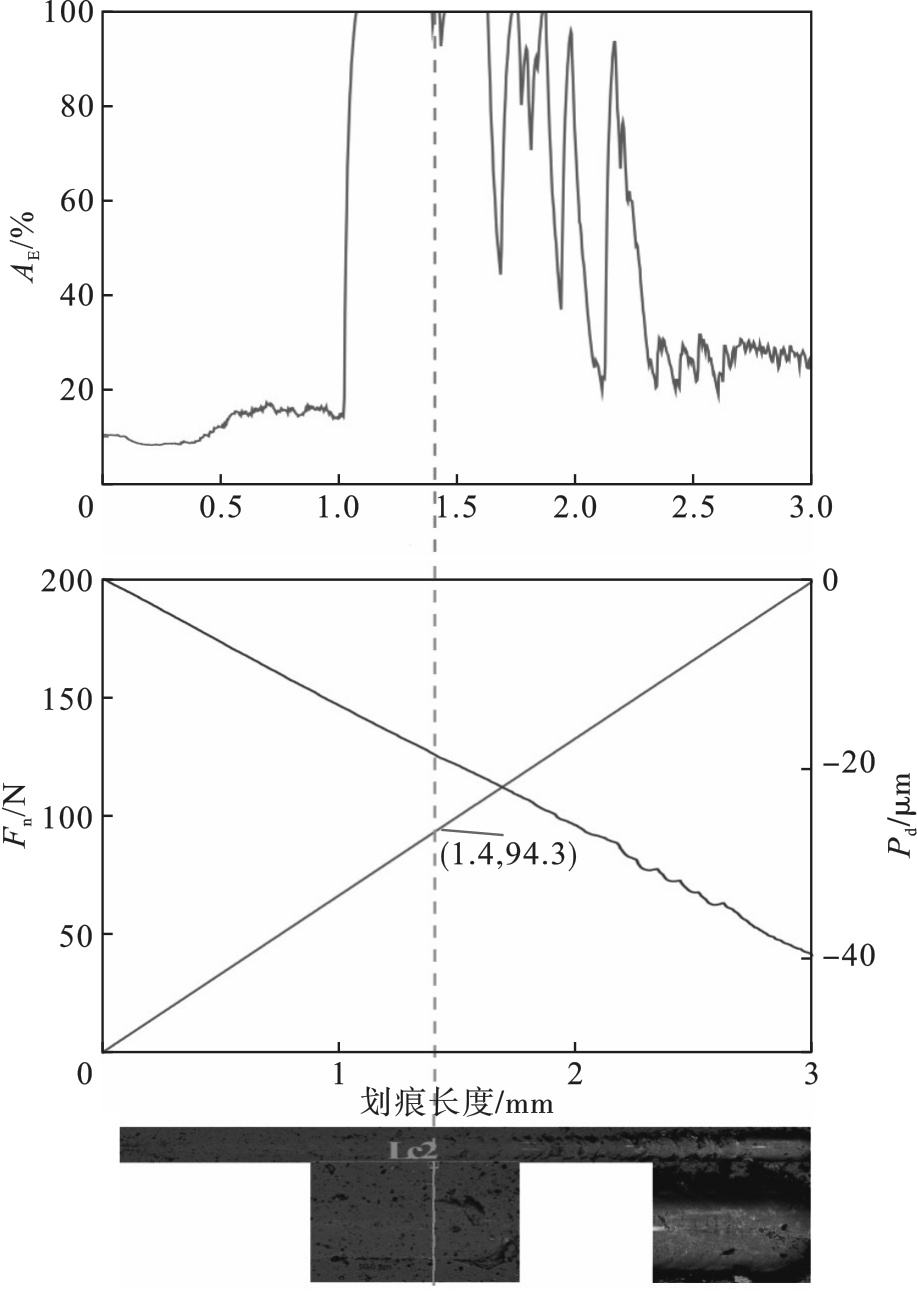

Fig.10 AE signal (AE), loading force (Fn), penetration depth (Pd), and scratch morphology of the multi-layer structured coating measured in the scratch test

| 1 | Makabe R, Nakajima S, Tabata O, et al. Dependence of the hardness of titanium nitride prepared by plasma chemical vapour deposition on the gas flow rate and the r.f. power[J]. Thin Solid Films, 1986, 137(1): 49-50. |

| 2 | Chang C L, Chen W C, Tsai P C, et al. Characteristics and performance of TiSiN/TiAlN multilayers coating synthesized by cathodic arc plasma evaporation[J]. Surface and Coatings Technology, 2007, 202(4/5/6/7): 987-992. |

| 3 | Boelens S, Veltrop H. Hard coatings of TiN, (TiHf)N and (TiNb)N deposited by random and steered arc evaporation[J]. Surface and Coatings Technology, 1987, 33: 63-71. |

| 4 | Cho C W, Lee Y Z. Effects of the oxide layer formed on TiN coated silicon wafer on the friction and wear characteristics in dry sliding[J]. Surface & Coatings Technology,2003,168(1):84-90. |

| 5 | Rebouta L, Vaz F, Andritschky M, et al. Oxidation resistance of (Ti, Al, Zr, Si)N coatings in air[J]. Surface and Coatings Technology, 1995, 76: 70-74. |

| 6 | Palmier S, Rullier J L, Capoulade J, et al. Effect of laser irradiation on silica substrate contaminated by aluminum particles[J]. Applied Optics, 2008, 47(8): 1164-1170. |

| 7 | Artur R S, Evgenii D K, Yuriy A G, et al. Improvement of mechanical properties and adhesion of Ti-Al-Si-N coatings by alloying with Ta[J]. Lubricants,2020,10(178):178. |

| 8 | Ramazanov K N, Vardanyan E L, Mukhamadeev V R, et al. Change in the chemical composition of a carbide tool with TI-Al-N coating surface layers during machining[J]. Journal of Surface Investigation: X-Ray, Synchrotron and Neutron Techniques, 2022, 16(3): 412-415. |

| 9 | Kehal A, Saoula N, Abaidia S E H, et al. Effect of Ar/N2 flow ratio on the microstructure and mechanical properties of Ti-Cr-N coatings deposited by DC magnetron sputtering on AISI D2 tool steels[J]. Surface and Coatings Technology, 2021, 421: 127444. |

| 10 | Kiryukhantsev-Korneev P V, Shtansky D V, Petrzhik M I, et al. Thermal stability and oxidation resistance of Ti-B-N, Ti-Cr-B-N, Ti-Si-B-N and Ti-Al-Si-B-N films[J]. Surface and Coatings Technology, 2007, 201(13): 6143-6147. |

| 11 | Zhang C, Qiu J T, Kong F, et al. Plasma surface treatment of Cu by nanosecond-pulse diffuse discharges in atmospheric air[J]. Plasma Science and Technology, 2018, 20(1): 014011. |

| 12 | Tanaka Y, Ichimiya N, Onishi Y, et al. Structure and properties of Al-Ti-Si-N coatings prepared by the cathodic arc ion plating method for high speed cutting applications[J]. Surface and Coatings Technology, 2001, 146: 215-221. |

| 13 | Hörling A, Hultman L, Odén M, et al. Mechanical properties and machining performance of Ti1- x Al x N-coated cutting tools[J]. Surface and Coatings Technology, 2005, 191(2/3): 384-392. |

| 14 | Yu D H, Wang C Y, Cheng X L, et al. Microstructure and properties of TiAlSiN coatings prepared by hybrid PVD technology[J]. Thin Solid Films, 2009, 517(17): 4950-4955. |

| 15 | Liu A H, Deng J X, Cui H B. Friction and wear properties of TiN, AlTiN, AlTiN and CrAlN PVD nitride coatings[J]. International Journal of Refractory Metals and Hard Materials,2012,31:82-88. |

| 16 | Fukumoto N, Ezura H, Suzuki T. Synthesis and oxidation resistance of TiAlSiN and multilayer TiAlSiN/CrAlN coating[J]. Surface and Coatings Technology, 2009, 204(6/7): 902-906. |

| 17 | Li W Z, Yuan Z W, Zhu Y B, et al. Influence of nitrogen partial pressure on structure, mechanical and tribological properties of TaCN coatings[J]. Ceramics International, 2021, 47(18): 26233-26241. |

| 18 | Xia B, Zhou S G, Wang Y X, et al. Multilayer architecture design to enhance load-bearing capacity and tribological behavior of CrAlN coatings in seawater[J]. Ceramics International, 2021, 47(19): 27430-27440. |

| 19 | Geng D S, Zeng R K, Wu Z T, et al. An investigation on microstructure and milling performance of arc-evaporated TiSin/AlTiN film[J]. Thin Solid Films, 2020, 709: 138243. |

| 20 | Wan Q, Yang B, Chen Y M, et al. Effect of bilayer period on microstructure and mechanical properties of TiSiN/TiN coatings[J]. Materialia, 2018,3:260-264. |

| 21 | Yao Y R, Li J L, Wang Y X, et al. Influence of the negative bias in ion plating on the microstructural and tribological performances of Ti-Si-N coatings in seawater[J]. Surface and Coatings Technology, 2015, 280: 154-162. |

| 22 | Kowalski S, Cygnar M. The application of TiSiN/TiAlN coatings in the mitigation of fretting wear in push fit joints[J]. Wear, 2019, 426: 725-734. |

| 23 | 费加喜. 电弧离子镀TiAlN基涂层的制备及其性能研究[D]. 广州: 广东工业大学, 2018. |

| Fei Jia-xi. Preparation and properties of TiAlN-based coating by arc ion plating[D]. Guangzhou: Guangdong University of Technology, 2018. | |

| 24 | Shtansky D V, Kiryukhantsev-Korneev P V, Bashkova I A, et al. Multicomponent nanostructured films for various tribological applications[J]. International Journal of Refractory Metals and Hard Materials, 2010, 28(1): 32-39. |

| 25 | 查旭明. 双层与纳米多层结构TiSiN/TiAlN涂层的力学及切削性能研究[D]. 泉州: 华侨大学, 2020. |

| Zha Xu-ming. Study on mechanical and cutting properties of TiSiN/TiAlN coatings with double-layer and nano-multilayer structures[D]. Quanzhou: Huaqiao University, 2020. | |

| 26 | 程正. Ti6Al4V切削过程热力耦合作用下刀具磨损研究[D]. 昆明: 昆明理工大学, 2019. |

| Cheng Zheng. Study on tool wear under thermal-mechanical coupling in Ti6Al4V cutting process[D]. Kunming: Kunming University of Science and Technology, 2019. | |

| 27 | Stewart V A, Brown R H. The interrelationship of shear and friction processes in machining under regenerative chatter conditions[M]//Proceedings of the Thirteenth International Machine Tool Design and Research Conference. London: Macmillan Education UK, 1973: 13-18. |

| 28 | Pu R, Yu Z G, Hao X Q, et al. Effect of Si content on microstructure, mechanical properties, and cutting performance of TiSiN/AlTiN dual-layer coating[J]. Journal of Manufacturing Processes,2020,88:134-144. |

| 29 | Zhang H D, Mei F S, Yu Y, et al. Improvement on the mechanical, tribological properties and cutting performance of AlTiN-based coatings by compositional and structural design[J]. Surface and Coatings Technology, 2021, 422: 127503. |

| [1] | Shang-wu YANG, Hai-xia QU, Heng-jun LI, Chang-sheng LIU. Properties of (Ti,W)C Particles Reinforced Ni-based Coating by Laser Cladding [J]. Journal of Northeastern University(Natural Science), 2024, 45(7): 953-959. |

| [2] | Hang SUN, Wei CHEN, Chang LUO, Chang-sheng LIU. Microstructure and Properties of Tempered High Vanadium Semi High Speed Steel Alloy Cladding Layer [J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 636-642. |

| [3] | Jiu-xin ZHANG, Xiao-jian REN, Dong-zheng JIN, Yong TIAN. Effect of Austenite Grain Refinement on Microstructure and Properties of Ultra‑Heavy EH47 Crack Arrest Steel [J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 643-651. |

| [4] | Da-zeng SUN, Wen ZHAO, Xing-liang XU, Xin WANG. Microscopic Failure Characteristics of Sandstones with Different Composition and Microstructures [J]. Journal of Northeastern University(Natural Science), 2024, 45(4): 584-591. |

| [5] | Wen-bo YAO, Chen LIU, Shuo SHANG, Chang-sheng LIU. Microstructure and Properties of Laser Cladding Fe‐Al Alloy at Different Scanning Speeds [J]. Journal of Northeastern University(Natural Science), 2024, 45(2): 170-178. |

| [6] | Ying WANG, Xiao-wei GU, Qing WANG, Xiao-chuan XU. Properties and Hydration Mechanism of Lime-Based Slag‑Steel Slag Composite Cementitious Materials [J]. Journal of Northeastern University(Natural Science), 2024, 45(10): 1459-1468. |

| [7] | LIU Jun-ru, ZHANG Guo-hua, ZHOU Guo-zhi. Effect of w(Fe)/w(Ni) Ratio on Mo2FeB2 Based Cermet [J]. Journal of Northeastern University(Natural Science), 2023, 44(9): 1269-1278. |

| [8] | ZHANG Ya-jing, WANG Jin-peng, CHEN Xin, WU Hang-yu. Preparation and Properties of Biodegradable Zn-3Cu-xMn Alloys [J]. Journal of Northeastern University(Natural Science), 2023, 44(8): 1104-1110. |

| [9] | WANG Ming-kun, LUO Zong-an, ZENG Zhou-yu, XIE Guang-ming. Effect of Heat Treatment on Microstructure and Mechanical Properties of Super Austenitic Stainless Steel Clad Plate [J]. Journal of Northeastern University(Natural Science), 2023, 44(6): 777-783. |

| [10] | MAO Ning, NIU Hui-rong, LIU Jing-xian. Experimental Study on Acid Resistance Characteristics of Polyaromatic Oxadiazole Fiber [J]. Journal of Northeastern University(Natural Science), 2023, 44(5): 719-725. |

| [11] | REN Zhao-hui, LI Zhu-hong, WANG Yun-he, ZHANG Zi-ting. Surface Mechanical Properties of Ultrasonic Rolling Micro-forging Additive Manufactured Parts [J]. Journal of Northeastern University(Natural Science), 2023, 44(5): 634-641. |

| [12] | WANG Hai-tao, LI Jia-dong, DENG Xiang-tao, WANG Zhao-dong. Effect of Solution Temperature on Microstructure and Mechanical Properties of Fe-20Mn-9Al-1.2C Low-Density Steel [J]. Journal of Northeastern University(Natural Science), 2023, 44(5): 609-616. |

| [13] | WEN Xue-long, WANG Cheng-bao, LIU Wen-bo, REN Hai-yang. Experimental Study on the Microstructure of FeCoNiCr High-Entropy Alloys by Selective Laser Melting [J]. Journal of Northeastern University(Natural Science), 2023, 44(4): 536-543. |

| [14] | WANG Zhen, JIANG Mao-fa, LIU Cheng-jun, MIN Yi. Microstructure Analysis of Mold Flux of Cao-SiO2-Al2O3-Na2O-MgO System for Ingot Casting [J]. Journal of Northeastern University(Natural Science), 2023, 44(4): 517-523. |

| [15] | JIA Peng, ZHU Peng-cheng, LI Bo, MAO Song-ze. Experimental Study on Wave Characteristics and Acoustic Emission Characteristics of Thermal Damaged Marble [J]. Journal of Northeastern University(Natural Science), 2023, 44(2): 279-288. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||