东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (10): 104-112.DOI: 10.12068/j.issn.1005-3026.2025.20240013

• 材料与冶金 • 上一篇

姜世杰1,2, 王菲1, 李曙光1, 许子沼1

收稿日期:2024-01-12

出版日期:2025-10-15

发布日期:2026-01-13

作者简介:姜世杰(1985—),男,辽宁营口人,东北大学副教授.

基金资助:Shi-jie JIANG1,2, Fei WANG1, Shu-guang LI1, Zi-zhao XU1

Received:2024-01-12

Online:2025-10-15

Published:2026-01-13

摘要:

金属熔丝成型(metal fused filament fabrication, MFFF)样件尺寸在脱脂/烧结过程中会明显收缩,影响成型精度和实际应用.为明确收缩机理以提出有效的解决措施,首先建立了烧结样件尺寸收缩率的理论模型,完成尺寸变化过程的理论解析;然后,成型17-4PH不锈钢烧结样件并使用扫描电子显微镜确定其截面的微观结构;对比分析理论与实验结果,验证模型的正确性;最后,分析模型的敏感性,讨论了烧结升温速率、最高温度保持时间、生坯样件表观密度对MFFF样件尺寸收缩率的影响规律.结果表明,样件的尺寸收缩率呈各向异性特点(竖直方向略大于水平方向);生坯样件表观密度对烧结样件尺寸收缩率的影响最为显著,其次是烧结升温速率和最高温度保持时间.

中图分类号:

姜世杰, 王菲, 李曙光, 许子沼. 金属熔丝成型17-4PH制品尺寸收缩理论与实验研究[J]. 东北大学学报(自然科学版), 2025, 46(10): 104-112.

Shi-jie JIANG, Fei WANG, Shu-guang LI, Zi-zhao XU. Theoretical and Experimental Research on Dimensional Shrinkage of MFFF 17-4PH Products[J]. Journal of Northeastern University(Natural Science), 2025, 46(10): 104-112.

| C | O | Cr | Fe | Ni | Cu |

|---|---|---|---|---|---|

| 31.39 | 7.48 | 11.41 | 45.47 | 2.28 | 1.97 |

表1 BASF 17-4PH化学成分(质量分数) ((mass fraction) %)

Table 1 Chemical composition of BASF 17-4PH

| C | O | Cr | Fe | Ni | Cu |

|---|---|---|---|---|---|

| 31.39 | 7.48 | 11.41 | 45.47 | 2.28 | 1.97 |

| 参数 | 数值 |

|---|---|

| 喷嘴直径/mm | 0.4 |

| 挤出宽度/mm | 0.48 |

| 喷嘴温度/℃ | 240 |

| 成型速度/(mm∙s-1) | 15 |

| 层高/mm | 0.12 |

| 重叠/% | 15 |

| 填充率/% | 100 |

| 床温/℃ | 90 |

表2 主要过程参数设置

Table 2 Main process parameters setting

| 参数 | 数值 |

|---|---|

| 喷嘴直径/mm | 0.4 |

| 挤出宽度/mm | 0.48 |

| 喷嘴温度/℃ | 240 |

| 成型速度/(mm∙s-1) | 15 |

| 层高/mm | 0.12 |

| 重叠/% | 15 |

| 填充率/% | 100 |

| 床温/℃ | 90 |

| 过程 | 腔体温度 | 进酸温度 | 尾气温度 | 用气流量 | 风扇转速 | 进酸量 | 时间 |

|---|---|---|---|---|---|---|---|

| ℃ | ℃ | ℃ | cm3·min-1 | r∙min-1 | mL∙min-1 | min | |

| 加热 | 105 | 150 | 145 | 3 000 | 1 000 | 0 | 45 |

| 前冲洗 | 105 | 150 | 145 | 3 000 | 1 000 | 0 | 30 |

| 脱脂 | 105 | 150 | 145 | 3 000 | 1 000 | 0.5 | 600 |

| 后冲洗 | 120 | 150 | 145 | 3 000 | 1 000 | 0 | 90 |

表3 催化脱脂参数设置

Table 3 Catalytic debinding parameters setting

| 过程 | 腔体温度 | 进酸温度 | 尾气温度 | 用气流量 | 风扇转速 | 进酸量 | 时间 |

|---|---|---|---|---|---|---|---|

| ℃ | ℃ | ℃ | cm3·min-1 | r∙min-1 | mL∙min-1 | min | |

| 加热 | 105 | 150 | 145 | 3 000 | 1 000 | 0 | 45 |

| 前冲洗 | 105 | 150 | 145 | 3 000 | 1 000 | 0 | 30 |

| 脱脂 | 105 | 150 | 145 | 3 000 | 1 000 | 0.5 | 600 |

| 后冲洗 | 120 | 150 | 145 | 3 000 | 1 000 | 0 | 90 |

编 号 | 温度 | 时间 | 工艺类型 | 进气量 | 气体 |

|---|---|---|---|---|---|

| ℃ | min | cm3·min-1 | |||

| 1 | 600 | 300 | 负压脱脂 | 2 000 | Ar |

| 2 | 600 | 60 | 负压脱脂 | 2 000 | Ar |

| 3 | 1 100 | 200 | 真空内烧 | 0 | Ar |

| 4 | 1 100 | 60 | 真空内烧 | 0 | Ar |

| 5 | 1 300 | 120 | 分压烧结 | 2 500 | Ar |

| 6 | 80 | 300 | 冷却 | 500 | Ar |

表4 热脱脂和烧结参数设置 (setting)

Table 4 Thermal debinding and sintering parameters

编 号 | 温度 | 时间 | 工艺类型 | 进气量 | 气体 |

|---|---|---|---|---|---|

| ℃ | min | cm3·min-1 | |||

| 1 | 600 | 300 | 负压脱脂 | 2 000 | Ar |

| 2 | 600 | 60 | 负压脱脂 | 2 000 | Ar |

| 3 | 1 100 | 200 | 真空内烧 | 0 | Ar |

| 4 | 1 100 | 60 | 真空内烧 | 0 | Ar |

| 5 | 1 300 | 120 | 分压烧结 | 2 500 | Ar |

| 6 | 80 | 300 | 冷却 | 500 | Ar |

| 样件 | 生坯样件尺寸/mm | 烧结样件尺寸/mm | 实验收缩率/% | 理论 收缩率/% | 误差/% | ||||

|---|---|---|---|---|---|---|---|---|---|

x 方向 | y 方向 | x 方向 | y 方向 | x 方向 | y 方向 | x 方向 | y 方向 | ||

| S1-i | 15.02 | 15.12 | 12.52 | 12.37 | 16.64 | 18.19 | 17.25 | 3.51 | 5.44 |

| S2-i | 15.03 | 15.05 | 12.62 | 12.31 | 16.03 | 18.21 | 7.05 | 5.54 | |

| S3-i | 15.08 | 15.07 | 12.54 | 12.44 | 16.84 | 17.45 | 2.36 | 1.17 | |

| S4-i | 15.03 | 15.13 | 12.56 | 12.32 | 16.43 | 18.57 | 4.73 | 7.67 | |

| S5-i | 15.04 | 15.08 | 12.7 | 12.36 | 15.56 | 18.04 | 9.81 | 4.56 | |

表5 x,y方向尺寸收缩率的理论和实验结果

Table 5 Theoretical and experimental results of dimensional shrinkage rate in x, y directions

| 样件 | 生坯样件尺寸/mm | 烧结样件尺寸/mm | 实验收缩率/% | 理论 收缩率/% | 误差/% | ||||

|---|---|---|---|---|---|---|---|---|---|

x 方向 | y 方向 | x 方向 | y 方向 | x 方向 | y 方向 | x 方向 | y 方向 | ||

| S1-i | 15.02 | 15.12 | 12.52 | 12.37 | 16.64 | 18.19 | 17.25 | 3.51 | 5.44 |

| S2-i | 15.03 | 15.05 | 12.62 | 12.31 | 16.03 | 18.21 | 7.05 | 5.54 | |

| S3-i | 15.08 | 15.07 | 12.54 | 12.44 | 16.84 | 17.45 | 2.36 | 1.17 | |

| S4-i | 15.03 | 15.13 | 12.56 | 12.32 | 16.43 | 18.57 | 4.73 | 7.67 | |

| S5-i | 15.04 | 15.08 | 12.7 | 12.36 | 15.56 | 18.04 | 9.81 | 4.56 | |

样件 (i=5) | 生坯样件 | 烧结样件 | 实验 收缩率/% | 理论 收缩率/% | 误差/% |

|---|---|---|---|---|---|

| S1-i | 4.06 | 3.25 | 19.95 | 18.28 | 9.14 |

| S2-i | 4.12 | 3.28 | 20.39 | 11.53 | |

| S3-i | 4.05 | 3.23 | 20.25 | 10.76 | |

| S4-i | 4.11 | 3.31 | 19.46 | 6.48 | |

| S5-i | 4.09 | 3.29 | 19.56 | 7.00 |

表6 z方向尺寸收缩率的理论和实验结果

Table 6 Theoretical and experimental results of dimensional shrinkage rate in z direction

样件 (i=5) | 生坯样件 | 烧结样件 | 实验 收缩率/% | 理论 收缩率/% | 误差/% |

|---|---|---|---|---|---|

| S1-i | 4.06 | 3.25 | 19.95 | 18.28 | 9.14 |

| S2-i | 4.12 | 3.28 | 20.39 | 11.53 | |

| S3-i | 4.05 | 3.23 | 20.25 | 10.76 | |

| S4-i | 4.11 | 3.31 | 19.46 | 6.48 | |

| S5-i | 4.09 | 3.29 | 19.56 | 7.00 |

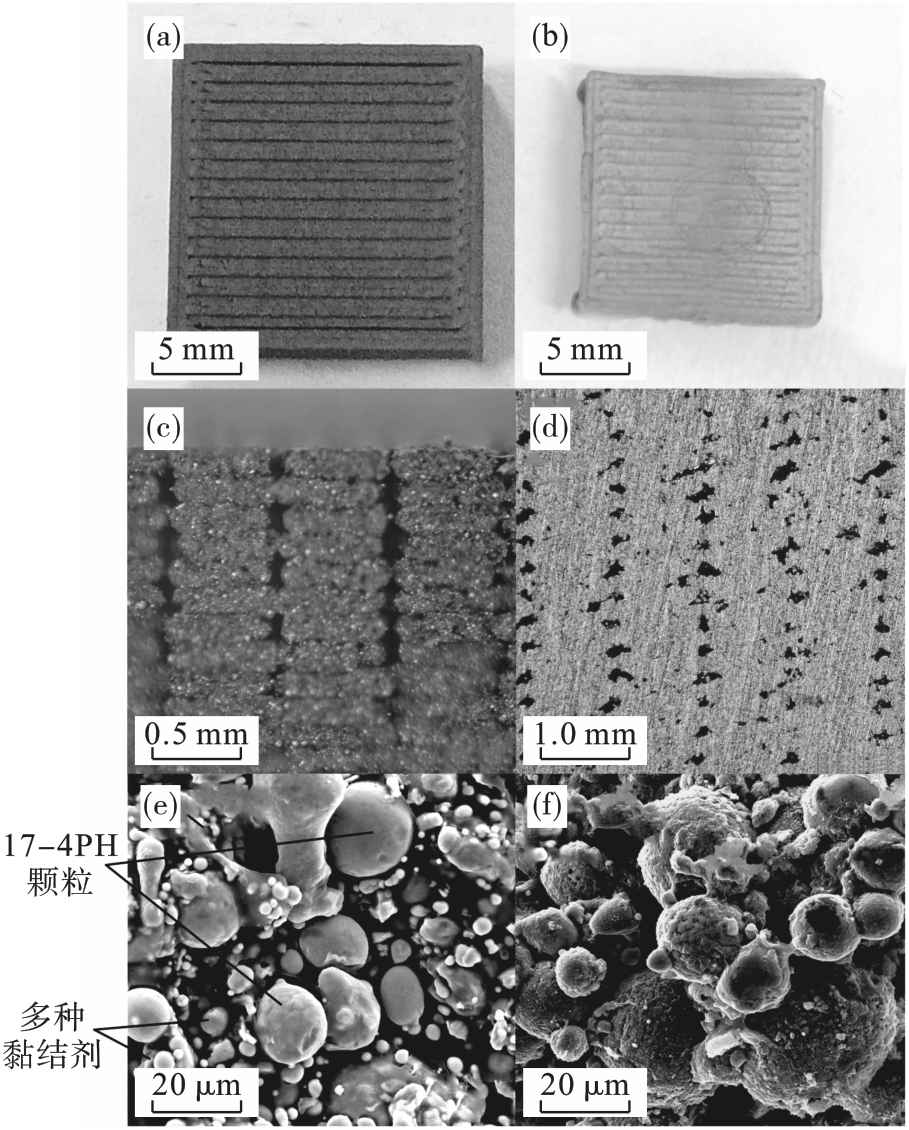

图5 MFFF样件外观、截面及显微结构(a)—生坯样件外观; (b)—烧结样件外观;(c)—生坯样件截面; (d)—烧结样件截面;(e)—生坯样件显微结构; (f)—烧结样件显微结构.

Fig.5 Appearance, cross-section, and microstrucure of MFFF samples

| 参数 | 最小值X1 | 默认值 | 最大值X2 |

|---|---|---|---|

| 烧结升温速率/(℃∙min-1) | 1 | 2 | 4 |

| 最高温度保持时间/h | 1 | 2 | 3 |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 3.9 | 4.9 |

表7 敏感性测试参数设置

Table 7 Sensitivity test parameters setting

| 参数 | 最小值X1 | 默认值 | 最大值X2 |

|---|---|---|---|

| 烧结升温速率/(℃∙min-1) | 1 | 2 | 4 |

| 最高温度保持时间/h | 1 | 2 | 3 |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 3.9 | 4.9 |

| 方向 | 参数 | 参数最小值 | 参数最大值 | 相对变化率 | ||

|---|---|---|---|---|---|---|

| x,y | 烧结升温速率/(℃∙min-1) | 1 | 27.69 | 4 | 11.53 | 19.45 |

| 最高温度保持时间/h | 1 | 15.29 | 3 | 19.08 | 12.39 | |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 19.51 | 4.9 | 14.86 | 35.75 | |

| z | 烧结升温速率/(℃∙min-1) | 1 | 29.24 | 4 | 12.19 | 19.44 |

| 最高温度保持时间/h | 1 | 16.15 | 3 | 20.15 | 12.38 | |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 20.76 | 4.9 | 15.66 | 36.85 |

表8 模型对不同参数的敏感性

Table 8 Sensitivity of model to different parameters

| 方向 | 参数 | 参数最小值 | 参数最大值 | 相对变化率 | ||

|---|---|---|---|---|---|---|

| x,y | 烧结升温速率/(℃∙min-1) | 1 | 27.69 | 4 | 11.53 | 19.45 |

| 最高温度保持时间/h | 1 | 15.29 | 3 | 19.08 | 12.39 | |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 19.51 | 4.9 | 14.86 | 35.75 | |

| z | 烧结升温速率/(℃∙min-1) | 1 | 29.24 | 4 | 12.19 | 19.44 |

| 最高温度保持时间/h | 1 | 16.15 | 3 | 20.15 | 12.38 | |

| 生坯样件表观密度/(g∙cm-3) | 2.9 | 20.76 | 4.9 | 15.66 | 36.85 |

| [1] | Singh P, Balla V K, Gokce A, et al. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): producing parts comparable to that of metal injection molding[J]. Progress in Additive Manufacturing, 2021, 6(4): 593-606. |

| [2] | Singh G, Missiaen J M, Bouvard D, et al. Additive manufacturing of 17-4 PH steel using metal injection molding feedstock: analysis of 3D extrusion printing, debinding and sintering[J]. Additive Manufacturing, 2021, 47: 102287. |

| [3] | German R M. Sintering: from empirical observations to scientific principles[M]. Oxford: Butterworth-Heinemann, 2014: 153-161. |

| [4] | Caminero M Á, Romero Gutiérrez A, Chacón J M, et al. Effects of fused filament fabrication parameters on the manufacturing of 316L stainless-steel components: geometric and mechanical properties[J]. Rapid Prototyping Journal, 2022, 28(10): 2004-2026. |

| [5] | Abe Y, Kurose T, Santos M V, et al. Effect of layer directions on internal structures and tensile properties of 17-4PH stainless steel parts fabricated by fused deposition of metals[J]. Materials, 2021, 14(2): 243-255. |

| [6] | Quarto M, Carminati M, D’Urso G. Density and shrinkage evaluation of AISI 316L parts printed via FDM process[J]. Materials and Manufacturing Processes, 2021, 36(13): 1535-1543. |

| [7] | Liu B, Wang Y X, Lin Z W, et al. Creating metal parts by fused deposition modeling and sintering[J]. Materials Letters, 2020, 263: 127252. |

| [8] | Olevsky E A. Theory of sintering: from discrete to continuum[J]. Materials Science and Engineering: R: Reports, 1998, 23(2): 41-100. |

| [9] | Braginsky M, Tikare V, Garino T J, et al. Three-dimensional simulation of sintering using a continuum modeling approach[R]. Albuquerque: Sandia National Laboratories, 2003. |

| [10] | Petersson A, Ågren J. Constitutive behaviour of WC-Co materials with different grain size sintered under load[J]. Acta Materialia, 2004, 52(7): 1847-1858. |

| [11] | Kuczynski G. The mechanism of densification during sintering of metallic particles[J]. Acta Metallurgica, 1956, 4(1): 58-61. |

| [12] | Scherer G W. Sintering inhomogeneous glasses: application to optical waveguides[J]. Journal of Non-Crystalline Solids, 1979, 34(2): 239-256. |

| [13] | De Jonghe L C, Chu M Y, Lin M K F. Pore size distribution, grain growth, and the sintering stress[J]. Journal of Materials Science, 1989, 24: 4403-4408. |

| [14] | German R M. Coarsening in sintering: grain shape distribution, grain size distribution, and grain growth kinetics in solid-pore systems[J]. Critical Reviews in Solid State and Materials Sciences, 2010, 35(4): 263-305. |

| [15] | Fukuyama H, Higashi H, Yamano H. Thermophysical properties of molten stainless steel containing 5% B4C[J]. Nuclear Technology, 2019, 205(9): 1154-1163. |

| [1] | 姜世杰, 李曙光, 许子沼, 王菲. 金属材料挤出成型生坯试件的静力学性能[J]. 东北大学学报(自然科学版), 2025, 46(9): 95-101. |

| [2] | 罗忠 , 石宝龙 , 张小霞 , 吴法勇. 拧紧工艺的螺栓连接结构预紧力变化规律[J]. 东北大学学报(自然科学版), 2023, 44(2): 215-222. |

| [3] | 姜世杰, 胡科, 陈丕峰, 战明. 熔丝成型制品三维表面粗糙度的理论与实验研究[J]. 东北大学学报(自然科学版), 2022, 43(9): 1290-1297. |

| [4] | 贠超群, 姜世杰, 战阳, 李常有. 过程参数对熔丝成型产品结合颈的影响[J]. 东北大学学报(自然科学版), 2022, 43(9): 1263-1269. |

| [5] | 姜世杰, 孙明宇, 董天阔, 陈丕峰. 熔丝加工成型薄板的动力学特性及响应[J]. 东北大学学报:自然科学版, 2020, 41(5): 673-678. |

| [6] | 王海英, 李亚宁, 周畅, 王琳. 反义标识的认知实验研究[J]. 东北大学学报:自然科学版, 2019, 40(7): 1056-1060. |

| [7] | 刘洋, 任凤玉, 何荣兴, 曹建立. 基于放矿下临界散体柱理论的地表塌陷范围预测[J]. 东北大学学报:自然科学版, 2018, 39(3): 416-420. |

| [8] | 王晓冬, 付强, 易舒, 李赫. 蒸汽喷射制冷系统喷射器工作特性的实验研究[J]. 东北大学学报:自然科学版, 2017, 38(12): 1744-1747. |

| [9] | 薛治家,于庆波,刘慧,史俊瑞. 过滤燃烧火焰锋面不稳定性的实验研究[J]. 东北大学学报(自然科学版), 2013, 34(9): 1273-1276. |

| [10] | 冯莹莹;骆宗安;张殿华;苏海龙;. 焊接热循环过程的在线模拟与应用[J]. 东北大学学报(自然科学版), 2012, 33(1): 86-89. |

| [11] | 孙红春;夏永发;崔雨;. 钢杆小裂纹最佳涡流检测参数的实验研究[J]. 东北大学学报(自然科学版), 2012, 33(1): 108-110+115. |

| [12] | 胡宇;龚殿尧;徐建忠;刘相华;. 四辊轧机热轧带钢板形的急停测量实验研究[J]. 东北大学学报(自然科学版), 2009, 30(4): 547-550. |

| [13] | 王忠堂;栾瑰馥;白光润;曹立;. 管材无模拉伸壁厚变化规律实验研究[J]. 东北大学学报:自然科学版, 1996, 17(2): 182-186. |

| [14] | 杜海传. 随机输入作用下线性随动系统的统计模拟实验研究[J]. 东北大学学报:自然科学版, 1978, -(2): 62-70. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||