东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (9): 73-80.DOI: 10.12068/j.issn.1005-3026.2025.20240046

收稿日期:2024-03-04

出版日期:2025-09-15

发布日期:2025-12-03

通讯作者:

厉英

作者简介:郝云龙(1997—),男,甘肃兰州人,东北大学硕士研究生基金资助:

Yun-long HAO, Qing-hua XIE, Pei-yuan NI, Ying LI( )

)

Received:2024-03-04

Online:2025-09-15

Published:2025-12-03

Contact:

Ying LI

摘要:

为研究精炼过程中钢包底吹氩对熔池传质和混匀行为.以某钢厂150 t钢包为原型,建立了钢渣-钢液-氩气三相流的LES-DPM-VOF耦合数值模型,并通过该模型研究了不同吹氩量对渣-钢-气多相流行为及钢液混匀现象的影响.结果表明,数值模拟预测的渣眼形状与实验吻合良好;当吹气量为50 L/min时,钢包内钢液最大速度约为0.7 m/s,渣-钢界面波动较小,未形成明显渣眼;随着吹气量由50 L/min增至100 L/min,气泡对钢水提升作用增强,钢液上升流最大速度由0.7 m/s增至1.07 m/s,渣-钢界面波动增大.此外,混匀行为研究表明,合金混匀时间与氩气喷吹流量成反比.模拟合金块直径为20 cm,当吹气量为50 L/min时的混匀时间为245 s,当吹气量增至300 L/min时,混匀时间缩短为145 s.

中图分类号:

郝云龙, 谢清华, 倪培远, 厉英. 钢液稀土合金化过程多相流动及混匀行为研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 73-80.

Yun-long HAO, Qing-hua XIE, Pei-yuan NI, Ying LI. Study on Multiphase Flow and Homogenization Behavior During Rare Earth Alloying of Molten Steel[J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 73-80.

| 参数 | 值 |

|---|---|

| 钢液密度/(kg·m-3) | 7 020 |

| La-Fe液态合金密度/(kg·m-3) | 6 600 |

| La-Fe合金比热容/(J·(kg·K)-1) | 535.32 |

| 钢液黏度/(kg·m-1·s-1) | 0.005 5 |

| 渣的密度/(kg·m-3) | 3 500 |

| 渣的黏度/(kg·m-1·s-1) | 0.06 |

| 渣相顶部空气密度/(kg·m-3) | 0.5 |

| 渣相顶部空气黏度/(kg·m-1·s-1) | 0.000 089 |

| 氩气密度/(kg·m-3) | 1.623 |

| 吹气量/(L·min-1) | 50,100,300 |

| 渣-钢水界面张力/(N·m-1) | 1.15 |

| 渣-空气界面张力/(N·m-1) | 0.58 |

| 钢水-空气界面张力/(N·m-1) | 1.82 |

| La-Fe合金中La质量分数/% | 0.5 |

表1 数值模型所用物性参数和工艺条件 (used in numerical model)

Table 1 Physical parameters and process conditions

| 参数 | 值 |

|---|---|

| 钢液密度/(kg·m-3) | 7 020 |

| La-Fe液态合金密度/(kg·m-3) | 6 600 |

| La-Fe合金比热容/(J·(kg·K)-1) | 535.32 |

| 钢液黏度/(kg·m-1·s-1) | 0.005 5 |

| 渣的密度/(kg·m-3) | 3 500 |

| 渣的黏度/(kg·m-1·s-1) | 0.06 |

| 渣相顶部空气密度/(kg·m-3) | 0.5 |

| 渣相顶部空气黏度/(kg·m-1·s-1) | 0.000 089 |

| 氩气密度/(kg·m-3) | 1.623 |

| 吹气量/(L·min-1) | 50,100,300 |

| 渣-钢水界面张力/(N·m-1) | 1.15 |

| 渣-空气界面张力/(N·m-1) | 0.58 |

| 钢水-空气界面张力/(N·m-1) | 1.82 |

| La-Fe合金中La质量分数/% | 0.5 |

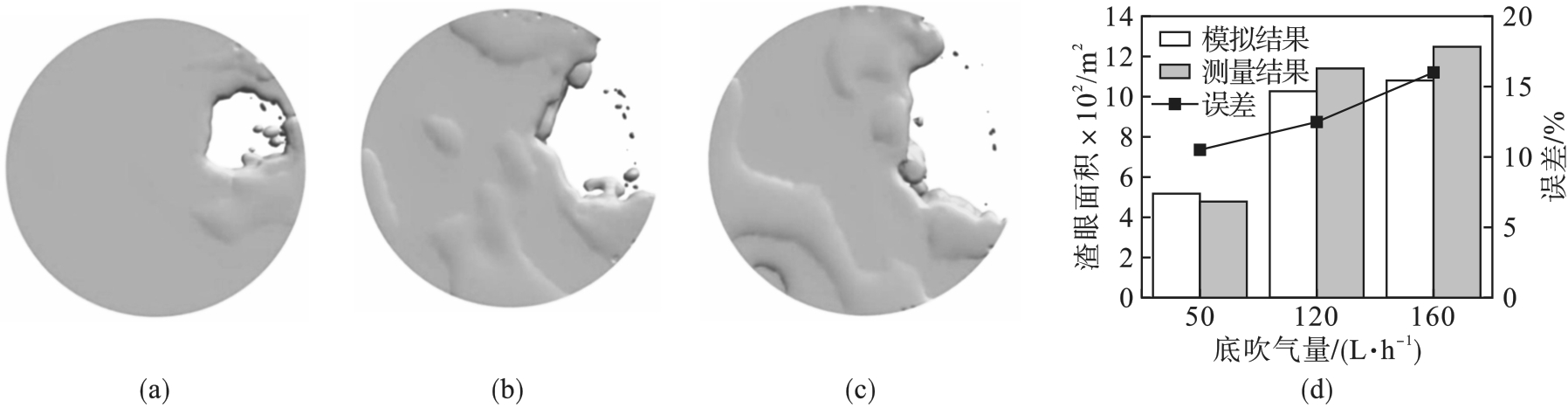

图2 水模型渣眼大小与数值模拟结果对比(a)—50 L/h; (b)—120 L/h; (c)—160 L/h; (d)—渣眼面积误差分析[14].

Fig.2 Comparison between size of slag holes in water model and results of numerical simulation

| [1] | 王乐, 刘浏, 王品. 轴承钢LF精炼深脱硫工艺的研究[J]. 炼钢, 2017, 33(4): 12-18. |

| Wang Le, Liu Liu, Wang Pin. The research on deep desulphurization process of bearing steel during LF refining[J]. Steelmaking, 2017, 33(4): 12-18. | |

| [2] | 陈鹏举, 朱诚意, 张志成, 等. GCr15轴承钢LF精炼过程脱硫能力的热力学评价[J]. 钢铁研究学报, 2016, 28(5): 30-35. |

| Chen Peng-ju, Zhu Cheng-yi, Zhang Zhi-cheng, et al. Thermodynamic evaluation of desulfurization ability of GCr15 bearing steels during LF refining process[J]. Journal of Iron and Steel Research, 2016, 28(5): 30-35. | |

| [3] | 李德军, 许孟春, 李晓伟, 等. 170~190 t LF精炼过程脱硫影响因素分析[J]. 特殊钢, 2018, 39(5): 32-35. |

| Li De-jun, Xu Meng-chun, Li Xiao-wei, et al. Study of affecting desulfurization factors in 170-190 t LF refining process[J]. Special Steel, 2018, 39(5): 32-35. | |

| [4] | 姜敏, 李凯轮, 王昆鹏, 等. 低氧高碳铬轴承钢LF-VD精炼时洁净度与夹杂物特征变化[J]. 炼钢, 2021, 37(1): 27-32, 43. |

| Jiang Min, Li Kai-lun, Wang Kun-peng, et al. Study on the variations of cleanliness and inclusions in low oxygen high-carbon-chromium bearing steel during LF-VD refining process[J]. Steelmaking, 2021, 37(1): 27-32, 43. | |

| [5] | Han J, Wang X D, Ba D C. Coordinated analysis of multiple factors of argon blowing parameters on the effect of circulation flow rate in RH vacuum refining process[J]. Vacuum, 2014, 109: 68-73. |

| [6] | 孔明姣. 钢包底吹氩工艺改进实践[J]. 宽厚板, 2020, 26(1): 15-17. |

| Kong Ming-jiao. Improvement practice of ladle bottom argon purging process[J]. Wide and Heavy Plate, 2020, 26(1): 15-17. | |

| [7] | 蒋星亮. 70 t钢包底吹氩工艺优化及钢-渣界面行为研究[D]. 武汉: 武汉科技大学, 2013. |

| Jiang Xing-liang. Optimization of argon blowing process at the bottom of 70 t ladle and study on interface behavior between steel and slag[D]. Wuhan: Wuhan University of Science and Technology, 2013. | |

| [8] | 张江山, 李京社, 杨静波, 等. 底吹钢包三相流的数值模拟[J]. 过程工程学报, 2012, 12(6): 946-951. |

| Zhang Jiang-shan, Li Jing-she, Yang Jing-bo, et al. Numerical simulation of three-phase fluid flow in a bottom-blown steelmaking ladle[J]. The Chinese Journal of Process Engineering, 2012, 12(6): 946-951. | |

| [9] | Li L M, Liu Z Q, Cao M X, et al. Large eddy simulation of bubbly flow and slag layer behavior in ladle with discrete phase model (DPM)-volume of fluid (VOF) coupled model[J]. JOM, 2015, 67(7): 1459-1467. |

| [10] | Kumar S, Dash S, Chandra S. Mixing evaluation in the RH process using mathematical modelling [J]. The Iron and Steel Institute of Japan, 2004,44(1): 82 - 90. |

| [11] | 蒋星亮, 倪红卫, 王社教, 等. 70 t钢包底吹氩工艺优化的数理模拟研究[J]. 材料与冶金学报, 2013, 12(2): 103-109. |

| Jiang Xing-liang, Ni Hong-wei, Wang She-jiao, et al. A mathematical simulation for optimization of 70 t ladle bottom argon blowing process[J]. Journal of Materials and Metallurgy, 2013, 12(2): 103-109. | |

| [12] | Liu W, Tang H Y, Yang S F, et al. Numerical simulation of slag eye formation and slag entrapment in a bottom-blown argon-stirred ladle[J]. Metallurgical and Materials Transactions B, 2018, 49(5): 2681-2691. |

| [13] | Llanos C A, Saul G H, Angel R B J, et al. Multiphase modeling of the fluidynamics of bottom argon bubbling during ladle operations[J]. ISIJ International, 2010, 50(3): 396-402. |

| [14] | Lou W T, Zhu M Y. Numerical simulation of gas and liquid two-phase flow in gas-stirred systems based on Euler-Euler approach[J]. Metallurgical and Materials Transactions B, 2013, 44(5):1251–1263. |

| [15] | Guo D, Irons G A. Modeling of gas-liquid plumes in metallurgical reactors with bottom gas injection[J]. Metallurgical and Materials Transactions B, 2000, 31(6): 1457-1464. |

| [16] | Olsen J E, Cloete S. Numerical modeling of bubble plume behavior in gas-stirred ladle systems[C]// Proceedings of the 7th International Conference on CFD in the Minerals and Process Industries. Melbourne: CSIRO, 2009: 1-6. |

| [17] | Liu H P, Qi Z Y, Xu M G. Numerical simulation of fluid flow and inclusion motion in continuous casting mold with electromagnetic brake[J]. Steel Research International, 2011, 82(4): 440-458. |

| [18] | Leitner J, Vomka P, Sedmidubsky D, et al. Heat capacity of MgB2 in the superconducting and normal state[J]. Thermochimica Acta, 2010, 497(1/2): 7-13. |

| [19] | 刘玉宝, 王举金, 杨文,等.LaFe合金在底吹氩钢包内熔化混匀的数值模拟研究[J].材料导报,2022, 36(21): 21050172-7. |

| Liu Yu-bao, Wang Ju-jin, Yang Wen, et al. Numerical simulation on melting and mixing of LaFe alloy in argon-stirred ladle[J]. Materials Reports, 2022, 36(21): 21050172-7. |

| [1] | 陈百玲, 牛金辉, 王连广, 许刚. 装配式钢管-拉森钢板桩围堰结构数值模拟分析[J]. 东北大学学报(自然科学版), 2025, 46(6): 102-112. |

| [2] | 林秀丽, 樊敏, 杨津硕, 柳静献. 90°弯头上下游风速及颗粒物质量浓度分布特征与测量[J]. 东北大学学报(自然科学版), 2025, 46(5): 113-125. |

| [3] | 王海艳, 冯岩, 王庆超, 于万春. 碳纤维增强复合材料螺栓连接力学特性分析[J]. 东北大学学报(自然科学版), 2025, 46(5): 71-79. |

| [4] | 韩宇超, 谢清华, 倪培远, 厉英. 旋流喷吹角度对RH精炼多相流及混匀行为的影响[J]. 东北大学学报(自然科学版), 2025, 46(4): 16-23. |

| [5] | 于珂凡, 赵亮, 董辉, 何永清. 柔性柱初始倾角对微通道传热增强的影响[J]. 东北大学学报(自然科学版), 2025, 46(2): 42-49. |

| [6] | 王述红, 任明珠, 李世宇, 董福瑞. 近距离穿越既有车站不等强度注浆变形的控制[J]. 东北大学学报(自然科学版), 2025, 46(2): 126-135. |

| [7] | 袁熙, 马明旭, 陈杰, 王哲英. 无油涡旋真空泵主轴冷却装置数值模拟研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 92-98. |

| [8] | 李中正, 吴朝霞, 王金杨, 康增鑫. 铁矿石烧结过程传质传热数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(1): 35-43. |

| [9] | 郑智群, 黄贤振, 姜智元, 苗兴琳. 基于Kriging模型的螺旋波纹管流动换热特性及结构优化[J]. 东北大学学报(自然科学版), 2024, 45(7): 992-1001. |

| [10] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [11] | 张晋瑞, 姚锡文, 许开立, 孙修. 矿井智能巡检车CO传感器搭载位置优化[J]. 东北大学学报(自然科学版), 2024, 45(5): 721-728. |

| [12] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| [13] | 王雨萌, 关凯, 朱万成, 刘洪磊. 基于现场监测与数值模拟结合的采动诱发围岩失稳与地表沉降研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 234-243. |

| [14] | 李刚, 周雷, 张晓宇, 张凯. 连通设备粉尘爆炸泄压面积确定方法[J]. 东北大学学报(自然科学版), 2024, 45(2): 276-281. |

| [15] | 陈百玲, 殷悦, 高海洋, 王连广. 预制钢板夹心混凝土组合板与柱连接及其有限元分析[J]. 东北大学学报(自然科学版), 2024, 45(10): 1476-1484. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||