东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (12): 94-103.DOI: 10.12068/j.issn.1005-3026.2025.20240128

王乾, 高淑玲, 周孝洪, 刘春雨

收稿日期:2024-06-03

出版日期:2025-12-15

发布日期:2026-02-09

通讯作者:

高淑玲

作者简介:王 乾(1994—),男,甘肃张掖人,东北大学博士研究生

基金资助:Qian WANG, Shu-ling GAO, Xiao-hong ZHOU, Chun-yu LIU

Received:2024-06-03

Online:2025-12-15

Published:2026-02-09

Contact:

Shu-ling GAO

摘要:

流体力学特性是决定重选分离效果的关键因素.采用数值模拟方法研究了

中图分类号:

王乾, 高淑玲, 周孝洪, 刘春雨. 螺旋溜槽流场演变及不同粒度赤铁矿与石英分离指标预测[J]. 东北大学学报(自然科学版), 2025, 46(12): 94-103.

Qian WANG, Shu-ling GAO, Xiao-hong ZHOU, Chun-yu LIU. Flow Field Evolution in Spiral Concentrator and Separation Index Prediction of Hematite and Quartz with Different Particle Sizes[J]. Journal of Northeastern University(Natural Science), 2025, 46(12): 94-103.

| 直径 | 外半径R/mm | 内半径r0/mm | 下斜角γ/(°) | 螺距P/mm | 圈数N |

|---|---|---|---|---|---|

| 400 | 200 | 35 | 12 | 240 | 3.25 |

表 1 螺旋溜槽结构参数

Table 1 Structural parameters of spiral concentrator

| 直径 | 外半径R/mm | 内半径r0/mm | 下斜角γ/(°) | 螺距P/mm | 圈数N |

|---|---|---|---|---|---|

| 400 | 200 | 35 | 12 | 240 | 3.25 |

| 项目 | 气-液两相流 | 气-液-固多相流 |

|---|---|---|

| 梯度 | Least Squares Cell Based | Least Squares Cell Based |

| 压力 | PRESTO | — |

| 动量 | Second Order Upwind | QUICK |

| 体积分数 | Compressive | Compressive |

| 湍流动能 | Second Order Upwind | QUICK |

| 湍流耗散率 | Second Order Upwind | QUICK |

表2 不同求解模型的空间离散格式

Table 2 Spatial discretization patterns for different solving models

| 项目 | 气-液两相流 | 气-液-固多相流 |

|---|---|---|

| 梯度 | Least Squares Cell Based | Least Squares Cell Based |

| 压力 | PRESTO | — |

| 动量 | Second Order Upwind | QUICK |

| 体积分数 | Compressive | Compressive |

| 湍流动能 | Second Order Upwind | QUICK |

| 湍流耗散率 | Second Order Upwind | QUICK |

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -1.14 | 9.66 | 15.57 | 24.09 | -2.21 | -14.98 | -6.90 | -24.09 |

| 0.5→0.75 | 1.65 | 23.89 | -7.12 | 18.42 | -15.08 | -3.34 | 0.00 | -18.42 |

| 0.75→1.0 | 3.29 | 5.32 | 0.57 | 9.17 | -7.48 | -1.70 | 0.00 | -9.17 |

| 1.0→2.0 | 13.86 | 14.34 | -20.27 | 7.92 | -7.74 | -0.18 | 0.00 | -7.92 |

| 2.0→3.0 | 4.96 | -11.99 | 7.41 | 0.37 | -0.38 | 0.00 | 0.00 | -0.37 |

表3 不同径向微区中90 μm赤铁矿颗粒的产率变化值

Table 3 Yield variation of 90 μm hematite particles in different radial regions

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -1.14 | 9.66 | 15.57 | 24.09 | -2.21 | -14.98 | -6.90 | -24.09 |

| 0.5→0.75 | 1.65 | 23.89 | -7.12 | 18.42 | -15.08 | -3.34 | 0.00 | -18.42 |

| 0.75→1.0 | 3.29 | 5.32 | 0.57 | 9.17 | -7.48 | -1.70 | 0.00 | -9.17 |

| 1.0→2.0 | 13.86 | 14.34 | -20.27 | 7.92 | -7.74 | -0.18 | 0.00 | -7.92 |

| 2.0→3.0 | 4.96 | -11.99 | 7.41 | 0.37 | -0.38 | 0.00 | 0.00 | -0.37 |

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.60 | -2.80 | -3.26 | -6.67 | 3.49 | 32.49 | -29.31 | 6.67 |

| 0.5→0.75 | 0.15 | 36.37 | 33.60 | 70.12 | -12.02 | -51.99 | -6.11 | -70.12 |

| 0.75→1.0 | 0.35 | -30.84 | 24.35 | -6.14 | 10.79 | -4.57 | -0.08 | 6.14 |

| 1.0→2.0 | 1.83 | 33.27 | -27.81 | 7.29 | 1.72 | -8.82 | -0.19 | -7.29 |

| 2.0→3.0 | 0.84 | -14.40 | 24.01 | 10.46 | -10.03 | -0.32 | -0.11 | -10.46 |

表4 不同径向微区中59 μm赤铁矿颗粒的产率变化值

Table 4 Yield variation of 59 μm hematite particles in different radial regions

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.60 | -2.80 | -3.26 | -6.67 | 3.49 | 32.49 | -29.31 | 6.67 |

| 0.5→0.75 | 0.15 | 36.37 | 33.60 | 70.12 | -12.02 | -51.99 | -6.11 | -70.12 |

| 0.75→1.0 | 0.35 | -30.84 | 24.35 | -6.14 | 10.79 | -4.57 | -0.08 | 6.14 |

| 1.0→2.0 | 1.83 | 33.27 | -27.81 | 7.29 | 1.72 | -8.82 | -0.19 | -7.29 |

| 2.0→3.0 | 0.84 | -14.40 | 24.01 | 10.46 | -10.03 | -0.32 | -0.11 | -10.46 |

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.97 | -0.14 | -2.57 | -3.67 | -3.39 | 2.54 | 4.53 | 3.67 |

| 0.5→0.75 | 0.38 | 0.65 | 0.82 | 1.85 | -4.12 | -13.97 | 16.24 | -1.85 |

| 0.75→1.0 | 0.15 | -1.05 | 1.98 | 1.09 | -0.53 | -3.57 | 3.02 | -1.09 |

| 1.0→2.0 | -0.04 | 1.35 | -0.65 | 0.66 | 1.49 | -4.61 | 2.46 | -0.66 |

| 2.0→3.0 | -0.44 | 4.99 | 3.39 | 7.93 | -1.69 | -5.70 | -0.54 | -7.93 |

表5 不同径向微区中石英颗粒的产率变化值(90 μm赤铁矿与38 μm石英给料体系) (feeding system))

Table 5 Yield variation of quartz particles in different radial regions (90 μm hematite and 38 μm quartz

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.97 | -0.14 | -2.57 | -3.67 | -3.39 | 2.54 | 4.53 | 3.67 |

| 0.5→0.75 | 0.38 | 0.65 | 0.82 | 1.85 | -4.12 | -13.97 | 16.24 | -1.85 |

| 0.75→1.0 | 0.15 | -1.05 | 1.98 | 1.09 | -0.53 | -3.57 | 3.02 | -1.09 |

| 1.0→2.0 | -0.04 | 1.35 | -0.65 | 0.66 | 1.49 | -4.61 | 2.46 | -0.66 |

| 2.0→3.0 | -0.44 | 4.99 | 3.39 | 7.93 | -1.69 | -5.70 | -0.54 | -7.93 |

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.84 | -2.97 | -4.84 | -8.66 | -4.93 | -0.24 | 13.82 | 8.66 |

| 0.5→0.75 | -0.02 | 13.53 | 9.42 | 22.93 | -3.94 | -1.97 | -17.02 | -22.93 |

| 0.75→1.0 | 0.07 | -12.38 | 7.15 | -5.16 | 9.91 | -6.70 | 1.95 | 5.16 |

| 1.0→2.0 | 0.13 | 3.17 | -7.26 | -3.96 | -10.30 | -7.57 | 21.83 | 3.96 |

| 2.0→3.0 | 0.13 | -2.81 | 4.64 | 1.96 | 3.27 | -0.42 | -4.81 | -1.96 |

表6 不同径向微区中石英颗粒的产率变化值(59 μm赤铁矿与38 μm石英给料体系) (feeding system))

Table 6 Yield variation of quartz particles in different radial regions (59 μm hematite and 38 μm quartz

| 纵向行程/圈 | 内半槽产率变化/% | 外半槽产率变化/% | ||||||

|---|---|---|---|---|---|---|---|---|

| r1 | r2 | r3 | 总和 | r4 | r5 | r6 | 总和 | |

| 0.25→0.50 | -0.84 | -2.97 | -4.84 | -8.66 | -4.93 | -0.24 | 13.82 | 8.66 |

| 0.5→0.75 | -0.02 | 13.53 | 9.42 | 22.93 | -3.94 | -1.97 | -17.02 | -22.93 |

| 0.75→1.0 | 0.07 | -12.38 | 7.15 | -5.16 | 9.91 | -6.70 | 1.95 | 5.16 |

| 1.0→2.0 | 0.13 | 3.17 | -7.26 | -3.96 | -10.30 | -7.57 | 21.83 | 3.96 |

| 2.0→3.0 | 0.13 | -2.81 | 4.64 | 1.96 | 3.27 | -0.42 | -4.81 | -1.96 |

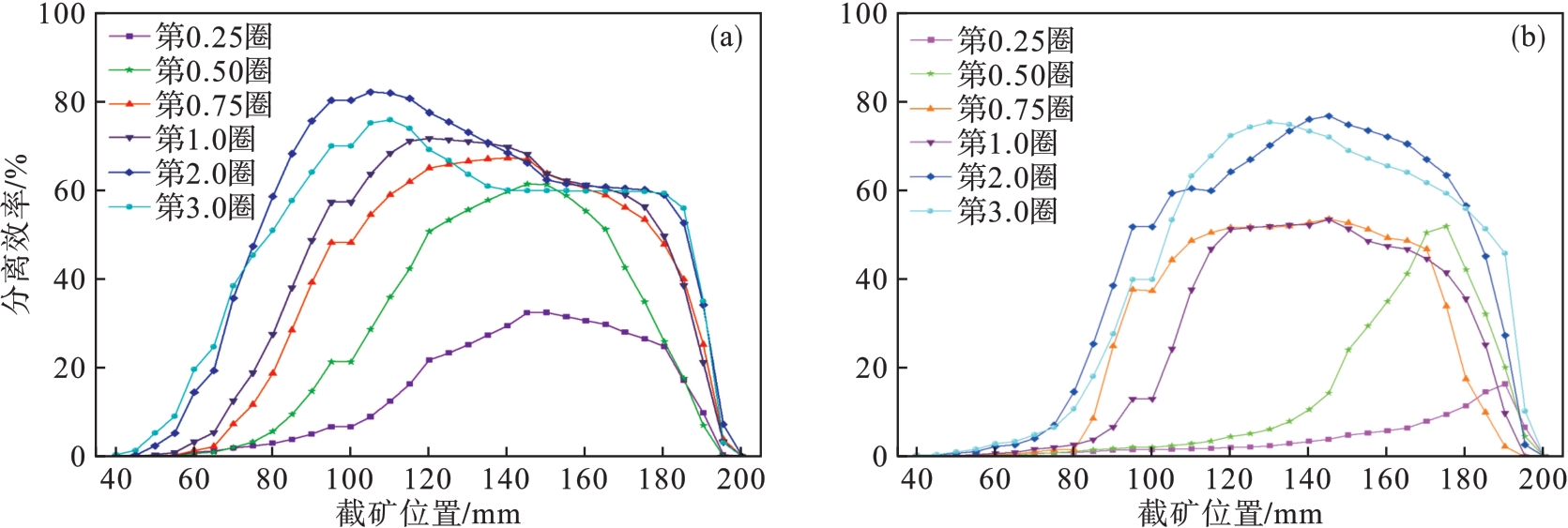

图11 不同圈数槽面中截矿位置对颗粒分离效率的影响(a)—90 μm赤铁矿与38 μm石英给料体系; (b)—59 μm赤铁矿与38 μm石英给料体系.

Fig.11 Influence of splitter position on particle separation efficiency across different turns in the trough

| [1] | Davies P O J, Goodman R H, Deschamps J A. Recent developments in spiral design, construction and application[J]. Minerals Engineering, 1991, 4 (3/4):437-456. |

| [2] | 高淑玲, 魏德洲, 崔宝玉, 等. 基于CFD的螺旋溜槽流场及颗粒运动行为数值模拟[J]. 金属矿山, 2014(11): 121-126. |

| Gao Shu-ling, Wei De-zhou, Cui Bao-yu, et al. CFD-based numerical simulation of flow field of and particles motion behavior in spiral[J]. Metal Mine, 2014(11): 121-126. | |

| [3] | Dixit P, Tiwari R, Mukherjee A K, et al. Application of response surface methodology for modeling and optimization of spiral separator for processing of iron ore slime [J]. Powder Technology, 2015, 275: 105-112. |

| [4] | Yu W, Zhang H L, Wang X B, et al. Enrichment of residual carbon from coal gasification fine slag by spiral separator[J]. Journal of Environmental Management, 2022, 315: 115149. |

| [5] | 张文杰, 叶晗晨, 杜云鹏, 等. 印尼某褐铁型红土镍矿工艺矿物学及选矿工艺的研究[J]. 有色金属工程, 2023, 13 (12): 90-99. |

| Zhang Wen-jie, Ye Han-chen, Du Yun-peng, et al. Research on process mineralogy and beneficiation technology of a limonite-type lateritic nickel ore in Indonesia[J]. Nonferrous Metals Engineering, 2023, 13 (12): 90-99. | |

| [6] | 骆洪振, 高春庆, 沈进杰. 某伴生钽铌锂辉石矿选矿试验研究[J]. 金属矿山, 2022(8): 101-107. |

| Luo Hong-zhen, Gao Chun-qing, Shen Jin-jie, et al. Study on mineral dressing of an associated tantalum niobium lithium pyroxene ore[J]. Metal Mine, 2022 (8): 101-107. | |

| [7] | 孙小乐, 南凯, 睢月婷, 等. 螺旋溜槽摇床联选对气化渣提碳行为研究[J]. 中国矿业, 2023, 32 (12): 235-241. |

| Sun Xiao-le, Kai Nan, Sui Yue-ting, et al. Study on carbon extraction from gasification slag by spiral chute and table concentrator combined separation[J]. China Mining Magazine, 2023, 32 (12): 235-241. | |

| [8] | Ye G C, Huo Y Y, Li C F, et al. A comparative study of trough profile and operating parameters performance in spiral concentrator[J]. International Journal of Coal Preparation & Utilization, 2021, 41(9): 678-691. |

| [9] | 孟令国, 高淑玲, 周孝洪, 等. 入口流量对螺旋溜槽首圈流场演变及矿物颗粒分布的影响[J]. 东北大学学报(自然科学版), 2023, 44(6): 856-862. |

| Meng Ling-guo, Gao Shu-ling, Zhou Xiao-hong, et al. Influence of the inlet flow rate on flow field evolution and mineral particle distribution in the first turn of spiral separators[J]. Journal of Northeastern University (Natural Science), 2023, 44 (6): 856-862. | |

| [10] | Sudikondala P, Mangadoddy N, Kumar M, et al. CFD modelling of spiral concentrator—prediction of comprehensive fluid flow field and particle segregation[J]. Minerals Engineering, 2022, 183: 107570. |

| [11] | 高淑玲, 孟令国, 周孝洪, 等. 给料参数对螺旋溜槽内流层铺展及颗粒分离行为的影响[J]. 有色金属(选矿部分), 2022 (5): 137-143, 158. |

| Gao Shu-ling, Meng Ling-guo, Zhou Xiao-hong, et al. Effect of feed parameters on flow spreading and particle separation behavior in spirals[J]. Nonferrous Metals (Mineral Processing Section), 2022 (5): 137-143, 158. | |

| [12] | 高淑玲, 周孝洪, 王乾, 等. 粗糙壁面螺旋溜槽中矿浆流场参数及颗粒分离行为演变特性[J]. 矿产保护与利用, 2023, 43 (3): 127-136. |

| Gao Shu-ling, Zhou Xiao-hong, Wang Qian, et al. Evolution characteristic of slurry flow field parameters and particles separation behavior in spirals with rough wall[J]. Conservation and Utilization of Mineral Resources, 2023, 43 (3): 127-136. | |

| [13] | Ankireddy P R, Purushotham S, Narasimha M. Fluid flow modeling and analysis of low- and high-gravity spiral concentrators: experimental and analytical approaches[J]. Chemical Engineering & Technology, 2023, 46 (8): 1619-1629. |

| [14] | 袁俊, 高淑玲, 孟令国, 等. 螺旋溜槽内二次环流分布特性及其分选作用研究进展[J]. 有色金属(选矿部分), 2021 (2): 29-35, 43. |

| Yuan Jun, Gao Shu-ling, Meng Ling-guo, et al. Research progress on secondary circulation distribution and separation in spiral chute[J]. Nonferrous Metals (Mineral Processing Section), 2021 (2): 29-35, 43. | |

| [15] | Holtham P N. Flow visualisation of secondary currents on spiral separators[J]. Minerals Engineering, 1990, 3 (3/4): 279-286. |

| [16] | Jain P K, Rayasam V. An analytical approach to explain the generation of secondary circulation in spiral concentrators[J]. Powder Technology, 2017, 308: 165-177. |

| [17] | Holtham P N. Primary and secondary fluid velocities on spiral separators[J]. Minerals Engineering, 1992, 5 (1): 79-91. |

| [18] | Matthews B W, Fletcher C A J, Partridge A C. Computational simulation of fluid and dilute particulate flows on spiral concentrators[J]. Applied Mathematical Modelling, 1998, 22 (12): 965-979. |

| [19] | Ye G C, Liu Q X, Ma L Q, et al. CFD-DEM investigation of fluid and particle motion behaviors in initial stage of spiral separation process at low solids concentration[J]. Mineral Processing and Extractive Metallurgy Review, 2023, 44 (7): 475-480. |

| [20] | Boisvert L, Sadeghi M, Bazin C. Investigation of residence time and fluid volume in spiral concentrators [J]. Minerals Engineering, 2023, 202: 108272. |

| [21] | Kapur P C, Meloy T P. Industrial modeling of spirals for optimal configuration and design: spiral geometry, fluid flow and forces on particles[J]. Powder Technology, 1999, 102 (3): 244-252. |

| [22] | Arnold D J, Stokes Y M, Green J E F. Particle-laden thin-film flow in helical channels with arbitrary shallow cross-sectional shape[J]. Physics of Fluids, 2019, 31 (7): 073305. |

| [23] | Gao S L, Meng L G, Zhou X H, et al. Design of partial cross-sectional geometry and prediction of separation performance in the spiral separator[J]. Separation Science and Technology, 2022, 57 (13): 2127-2144. |

| [24] | Meng L G, Gao S L, Wei D Z, et al. Effects of cross-sectional geometry on flow characteristics in spiral separators[J]. Separation Science and Technology, 2021, 56 (17): 2967-2977. |

| [25] | Doheim M A, Abdel G A F, Mahran G M A, et al. Computational prediction of water-flow characteristics in spiral separators: part I, flow depth and turbulence intensity[J]. JES Journal of Engineering Sciences, 2008, 36 (4): 935-950. |

| [26] | Doheim M A, Abdel G A F, Mahran G M A, et al. Computational prediction of water-flow characteristics in spiral separators: part Ⅱ, the primary and secondary flows[J]. JES Journal of Engineering Sciences, 2008, 36 (4): 951-961. |

| [27] | Wang J H, Luo J, Huang S X, et al. Numerical simulation of single aluminum droplet evaporation based on VOF method[J]. Case Studies in Thermal Engineering, 2022, 34: 102008. |

| [28] | 高淑玲, 孟令国, 魏德洲, 等. 螺旋溜槽流场特性与分离性能研究进展[J]. 矿产保护与利用, 2020, 40 (1): 166-171. |

| Gao Shu-ling, Meng Ling-guo, Wei De-zhou, et al. Research advance of flow characteristics in spirals and its separation performance[J]. Conservation and Utilization of Mineral Resources, 2020, 40 (1): 166-171. | |

| [29] | Meng L G, Gao S L, Wei D Z, et al. Particulate flow modelling in a spiral separator by using the Eulerian multi-fluid VOF approach[J]. International Journal of Mining Science and Technology, 2023,33 (2): 251-263. |

| [30] | Meng L G, Gao S L, Wei D Z, et al. Investigation on the evolution of flow field stability in a spiral separator[J]. Minerals Engineering, 2021, 174: 107224. |

| [31] | 周孝洪, 高淑玲, 孟令国, 等.壁面粗糙度对螺旋溜槽中矿浆流动及颗粒分离行为的影响[J]. 东北大学学报(自然科学版), 2023, 44 (12): 1769-1777. |

| Zhou Xiao-hong, Gao Shu-ling, Meng Ling-guo, et al. Influence of wall roughness on slurry flow and particles separation behaviors in spirals[J]. Journal of Northeastern University (Natural Science), 2023, 44 (12): 1769-1777. | |

| [32] | Gao S L, Zhou X H, Meng L G, et al. Variation of flow hydrodynamic parameters and prediction of particle separation indices in the spiral concentrator with the regulation of pitch-diameter ratio[J]. Separations, 2023, 10 (7): 410. |

| [33] | 叶贵川. 螺旋分选机流场特征及分选密度调控研究[D]. 北京: 中国矿业大学(北京), 2019. |

| Ye Gui-chuan. Study on flow field characteristics and control mechanism of separation density in coal spiral separator[D]. Beijing: China University of Mining & Technology, Beijing, 2019. |

| [1] | 杨帅厚, 靳建平, 祝昕冉, 周振亚. 石煤钒矿工艺矿物学特性及预富集技术研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 135-142. |

| [2] | 武亚军, 吴明灿, 陆逸天, 吴锦津. 真空预压中排水板参数对处理效果的影响[J]. 东北大学学报(自然科学版), 2025, 46(3): 138-144. |

| [3] | 孟令国, 高淑玲, 周孝洪, 魏德洲. 入口流量对螺旋溜槽首圈流场演变及矿物颗粒分布的影响[J]. 东北大学学报(自然科学版), 2023, 44(6): 856-862. |

| [4] | 周孝洪, 高淑玲, 孟令国, 赵强. 壁面粗糙度对螺旋溜槽中矿浆流动及颗粒分离行为的影响[J]. 东北大学学报(自然科学版), 2023, 44(12): 1769-1777. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||