东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 77-92.DOI: 10.12068/j.issn.1005-3026.2025.20250006

易红亮, 赵明辉, 王睿婷, 马彦琦

收稿日期:2025-01-16

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

易红亮

作者简介:易红亮(1981—),男,重庆人,东北大学教授,博士生导师.

基金资助:Hong-liang YI, Ming-hui ZHAO, Rui-ting WANG, Yan-qi MA

Received:2025-01-16

Online:2025-08-15

Published:2025-11-24

Contact:

Hong-liang YI

摘要:

高强钢因其性能优势与成本效益,在现代工业中占据重要地位.聚焦其发展趋势与技术挑战,重点分析低合金马氏体钢、淬火-配分(Q&P)马氏体钢和马氏体时效钢这3类抗拉强度超1 800 MPa、塑韧性优异的马氏体基结构钢.低合金马氏体钢经热处理后得到回火马氏体钢,通过调整合金成分和工艺实现强韧性平衡.淬火-配分马氏体钢含富碳奥氏体,变形时通过相变提升强度和塑性.马氏体时效钢碳含量极低,依赖时效析出强化,韧性优于同强度碳强化钢.系统总结了上述高强钢在成分设计、制造工艺以及力学性能等方面的研究进展.

中图分类号:

易红亮, 赵明辉, 王睿婷, 马彦琦. 1 800 MPa级以上高强钢的研究现状[J]. 东北大学学报(自然科学版), 2025, 46(8): 77-92.

Hong-liang YI, Ming-hui ZHAO, Rui-ting WANG, Yan-qi MA. Current Status of Research on High-Strength Steel Above 1 800 MPa Grade[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 77-92.

| 钢号 | 合金成分 | 工艺 | 屈服强度/MPa | 抗拉强度/MPa | 延伸率/% |

|---|---|---|---|---|---|

| 30CrMnSiNi2A | 0.26~0.33C-0.9~1.2Si-1.0~1.3Mn- 0.9~1.2Cr-1.4~1.8Ni | 900 ℃油淬+ 250 ℃回火 | / | ≥1 600 | ≥9 |

| 35Si2Mn2MoVA | 0.32~0.38C-1.4~1.7Si-1.6~1.9Mn- 0.35~0.45Mo-0.1~0.2V | 920 ℃油淬+ 250 ℃回火 | / | ≥1 700 | ≥9 |

| 4130 | 0.28~0.33C-0.2~0.35Si-0.4~0.6Mn- 0.8~1.1Cr-0.15~0.25Mo | 860 ℃油淬+ 205 ℃回火 | 1 340 | 1 550 | 11 |

| 4140 | 0.38~0.43C-0.2~0.35Si-0.75~1.0Mn- 0.8~1.1Cr-0.15~0.25Mo | 845 ℃油淬+ 205 ℃回火 | 1 740 | 1 965 | 11 |

| 4340 | 0.38C~0.43C-0.2~0.35Si-0.6~0.8Mn- 0.7~0.9Cr-1.65~2.0Ni-0.2~0.3Mo | 845 ℃油淬+ 205 ℃回火 | 1 860 | 1 980 | 11 |

| 300M | 0.41~0.46C-1.45~1.8Si-0.65~0.9Mn- 0.65~0.95Cr-1.6~2.0Ni-0.3~0.4Mo-≥0.05V | 860 ℃油淬+ 260 ℃回火 | 1 670 | 2 050 | 8 |

| D6AC | 0.42~0.48C-0.15~0.3Si-0.6~0.9Mn- 0.8~1.05Cr-0.4~0.7Ni-0.9~1.1Mo-0.05~0.1V | 880 ℃油淬+ 315 ℃回火 | 1 760 | 2 000 | 8 |

| 6150 | 0.48~0.53C-0.2~0.35Si-0.7~0.9Mn- 0.8~1.1Cr | 860 ℃油淬+ 205 ℃回火 | 1 810 | 2 050 | 10 |

| 8640 | 0.38~0.43C-0.2~0.35Si-0.75~1.0Mn- 0.4~0.6Cr-0.4~0.7Ni-0.15~0.25Mo | 820 ℃油淬+ 205 ℃回火 | 1 670 | 1 810 | 8 |

表1 常见低合金超高强度钢的成分和力学性能[16-17]

Table 1 Composition and mechanical properties of common low-alloyed ultra-high strength steel [16-17]

| 钢号 | 合金成分 | 工艺 | 屈服强度/MPa | 抗拉强度/MPa | 延伸率/% |

|---|---|---|---|---|---|

| 30CrMnSiNi2A | 0.26~0.33C-0.9~1.2Si-1.0~1.3Mn- 0.9~1.2Cr-1.4~1.8Ni | 900 ℃油淬+ 250 ℃回火 | / | ≥1 600 | ≥9 |

| 35Si2Mn2MoVA | 0.32~0.38C-1.4~1.7Si-1.6~1.9Mn- 0.35~0.45Mo-0.1~0.2V | 920 ℃油淬+ 250 ℃回火 | / | ≥1 700 | ≥9 |

| 4130 | 0.28~0.33C-0.2~0.35Si-0.4~0.6Mn- 0.8~1.1Cr-0.15~0.25Mo | 860 ℃油淬+ 205 ℃回火 | 1 340 | 1 550 | 11 |

| 4140 | 0.38~0.43C-0.2~0.35Si-0.75~1.0Mn- 0.8~1.1Cr-0.15~0.25Mo | 845 ℃油淬+ 205 ℃回火 | 1 740 | 1 965 | 11 |

| 4340 | 0.38C~0.43C-0.2~0.35Si-0.6~0.8Mn- 0.7~0.9Cr-1.65~2.0Ni-0.2~0.3Mo | 845 ℃油淬+ 205 ℃回火 | 1 860 | 1 980 | 11 |

| 300M | 0.41~0.46C-1.45~1.8Si-0.65~0.9Mn- 0.65~0.95Cr-1.6~2.0Ni-0.3~0.4Mo-≥0.05V | 860 ℃油淬+ 260 ℃回火 | 1 670 | 2 050 | 8 |

| D6AC | 0.42~0.48C-0.15~0.3Si-0.6~0.9Mn- 0.8~1.05Cr-0.4~0.7Ni-0.9~1.1Mo-0.05~0.1V | 880 ℃油淬+ 315 ℃回火 | 1 760 | 2 000 | 8 |

| 6150 | 0.48~0.53C-0.2~0.35Si-0.7~0.9Mn- 0.8~1.1Cr | 860 ℃油淬+ 205 ℃回火 | 1 810 | 2 050 | 10 |

| 8640 | 0.38~0.43C-0.2~0.35Si-0.75~1.0Mn- 0.4~0.6Cr-0.4~0.7Ni-0.15~0.25Mo | 820 ℃油淬+ 205 ℃回火 | 1 670 | 1 810 | 8 |

| 序号 | 合金成分 | 屈服强度/MPa | 抗拉强度/MPa | 延伸率/% | 参考 文献 |

|---|---|---|---|---|---|

| 1 | 0.34C-0.25Si-1.34Mn-0.04Al-0.21V-0.04Ti-0.002B-0.24Cr | 1 353 | 2 018 | 7.5 | [ |

| 2 | 0.36C-0.22Si-1.31Mn-0.298Cr-0.005B-0.157Mo | 1 421 | 2 061 | 7 | [ |

| 3 | 0.31C-0.3Si-1.5Mn-0.03Al-1.0Cr-0.002B-0.07Ti-0.046Nb | 1 321 | 2 183 | 5.7 | [ |

| 4 | 0.38C-1.48Si-1.58Mn-0.035Al-0.91Cr-0.003 7B-0.07Ti-0.048Nb | 1 119 | 2 121 | 8.86 | [ |

| 5 | 0.354C-0.32Si-1.48Mn-0.05Al-0.042Ti-0.002 5B | 1 301 | 2 046 | 6.6 | [ |

| 6 | 0.38C-0.19Si-1.2Mn-0.28Cr-0.005Mo-0.005Ni-0.003B-0.024Ti | 1 424 | 2 045 | 5.9 | [ |

| 7 | 0.61C-1.5Cr-0.08Ni-0.05Ti-0.07Nb | 1 940 | 2 400 | 10 | [ |

| 8 | 0.66C-1.42Cr-0.4Si-0.42Mn-0.07V | 2 367 | 2 613 | 7 | [ |

| 9 | 0.46C-1.99Mn-1.53Si-1.27Cr-0.76Al-0.45Ni-0.3Mo-0.28V | 1 809 | 2 590 | 12.6 | [ |

| 10 | 0.28C-1.76Mn-0.35Si-4.4Ni-1.88Mo-0.02Al-0.06Ti-0.08Nb | 1 487 | 2 032 | 6.53 | [ |

| 11 | 0.38C-1.48Si-1.58Mn-0.035Al-0.9~1.0Cr-0.003~0.004 B-0.06~0.08Ti-0.04~0.05Nb | 1 500 | 2 080 | 8.8 | [ |

| 12 | 0.42C-0.19Si-0.80Mn-0.02Ni-1.16Cr-0.16Mo | 1 540 | 2 068 | 12.1 | [ |

| 13 | 0.56C-2.3Si-0.69Mn-0.89Cr-0.02Mo-0.1V-0.03Ti-0.2Ni-0.15Cu | 2 038 | 2 382 | 8.8 | [ |

| 14 | 0.4C-1.6Si-1.5Mn-1.4Cr-0.4Mo-0.3No-0.1W | 1 520 | 2 100 | / | [ |

| 15 | 0.48C-0.85Si-0.24Mn-0.63Cr-2.0Ni-0.42Mo-0.2V | 1 720 | 2 441 | 10 | [ |

| 16 | 0.34C-0.32Si-1.39Mn-0.03Ti-0.0025B-0.11~0.3V | 1 508 | 2 121 | 8 | [ |

表2 1 800 MPa级以上热冲压钢的成分和力学性能[22-38]

Table 2 Composition and mechanical properties of hot stamping steel above 1 800 MPa grade [22-38]

| 序号 | 合金成分 | 屈服强度/MPa | 抗拉强度/MPa | 延伸率/% | 参考 文献 |

|---|---|---|---|---|---|

| 1 | 0.34C-0.25Si-1.34Mn-0.04Al-0.21V-0.04Ti-0.002B-0.24Cr | 1 353 | 2 018 | 7.5 | [ |

| 2 | 0.36C-0.22Si-1.31Mn-0.298Cr-0.005B-0.157Mo | 1 421 | 2 061 | 7 | [ |

| 3 | 0.31C-0.3Si-1.5Mn-0.03Al-1.0Cr-0.002B-0.07Ti-0.046Nb | 1 321 | 2 183 | 5.7 | [ |

| 4 | 0.38C-1.48Si-1.58Mn-0.035Al-0.91Cr-0.003 7B-0.07Ti-0.048Nb | 1 119 | 2 121 | 8.86 | [ |

| 5 | 0.354C-0.32Si-1.48Mn-0.05Al-0.042Ti-0.002 5B | 1 301 | 2 046 | 6.6 | [ |

| 6 | 0.38C-0.19Si-1.2Mn-0.28Cr-0.005Mo-0.005Ni-0.003B-0.024Ti | 1 424 | 2 045 | 5.9 | [ |

| 7 | 0.61C-1.5Cr-0.08Ni-0.05Ti-0.07Nb | 1 940 | 2 400 | 10 | [ |

| 8 | 0.66C-1.42Cr-0.4Si-0.42Mn-0.07V | 2 367 | 2 613 | 7 | [ |

| 9 | 0.46C-1.99Mn-1.53Si-1.27Cr-0.76Al-0.45Ni-0.3Mo-0.28V | 1 809 | 2 590 | 12.6 | [ |

| 10 | 0.28C-1.76Mn-0.35Si-4.4Ni-1.88Mo-0.02Al-0.06Ti-0.08Nb | 1 487 | 2 032 | 6.53 | [ |

| 11 | 0.38C-1.48Si-1.58Mn-0.035Al-0.9~1.0Cr-0.003~0.004 B-0.06~0.08Ti-0.04~0.05Nb | 1 500 | 2 080 | 8.8 | [ |

| 12 | 0.42C-0.19Si-0.80Mn-0.02Ni-1.16Cr-0.16Mo | 1 540 | 2 068 | 12.1 | [ |

| 13 | 0.56C-2.3Si-0.69Mn-0.89Cr-0.02Mo-0.1V-0.03Ti-0.2Ni-0.15Cu | 2 038 | 2 382 | 8.8 | [ |

| 14 | 0.4C-1.6Si-1.5Mn-1.4Cr-0.4Mo-0.3No-0.1W | 1 520 | 2 100 | / | [ |

| 15 | 0.48C-0.85Si-0.24Mn-0.63Cr-2.0Ni-0.42Mo-0.2V | 1 720 | 2 441 | 10 | [ |

| 16 | 0.34C-0.32Si-1.39Mn-0.03Ti-0.0025B-0.11~0.3V | 1 508 | 2 121 | 8 | [ |

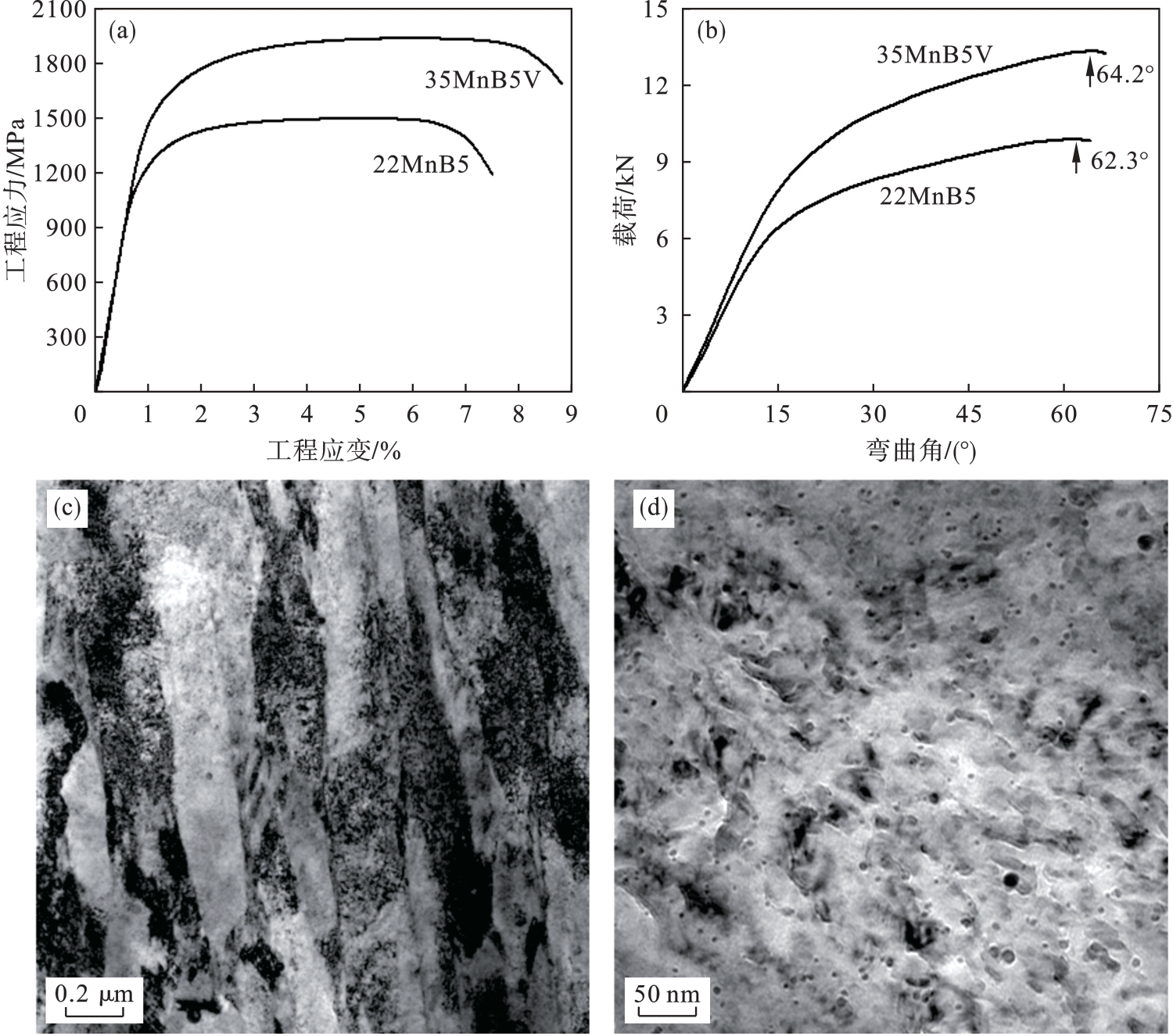

图1 2 000 MPa级纳米析出韧化热冲压钢的微观组织和力学性能[37-38](a)—22MnB5和35MnB5V的工程应力-应变曲线; (b)—22MnB5和35MnB5V的三点弯曲载荷-角度曲线;(c)—35MnB5V板条马氏体透射电镜图像; (d)—35MnB5V纳米碳化物析出.

Fig.1 Microstructure and mechanical properties of 2 000 MPa nano-precipitated toughened hot stamping steel [37-38]

| 编号 | 合金成分的质量分数/% | 工艺 | 力学性能 | 参考 文献 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | Al | Cr | Ni | Nb | Mo | V | 抗拉强度/MPa | 延伸率/% | |||

| 1 | 0.41 | 1.3 | 1.27 | — | 0.56 | 1.01 | — | — | — | Q&P | 2 468 | 11.6 | [ |

| 2 | 0.43 | 0.59 | 2.03 | 0.008 | 1.33 | 0.07 | 0.03 | 0.03 | — | Q&P | 1 810~2 096 | 12~20 | [ |

| 3 | 0.43 | 0.59 | 2.6 | 0.008 | 1.33 | 0.01 | 0.03 | 0.03 | — | Q&P | 1 965~1 975 | 12~17 | [ |

| 4 | 0.43 | 1.17 | 2.6 | 0.008 | 1.33 | 0.07 | 0.03 | 0.03 | — | Q&P | 1 837~2 218 | 14~22 | [ |

| 5 | 0.42 | 0.59 | 2.6 | — | 1.33 | — | 0.03 | 0.03 | — | Q&P | 1 810~2 096 | 12~20 | [ |

| 6 | 0.56 | 0.62 | 1.95 | — | 0.75 | — | 0.04 | 0.03 | — | Q&P | 2 100~2 251 | 16~22 | [ |

| 7 | 0.56 | 1.36 | 1.88 | — | 1.36 | — | 0.04 | 0.03 | — | Q&P | 2 168~2 377 | 8~13 | [ |

| 8 | 0.32 | 0.23 | 1.78 | — | 1.08 | — | — | 0.45 | 0.21 | Q&FP | 1 942 | ~10 | [ |

表3 1 800 MPa级别及以上高碳Q&P钢的成分、工艺及力学性能[37,53-55] (grade[37,53-55])

Table 3 Composition, processes, and mechanical properties of high-carbon Q&P steel above 1 800 MPa

| 编号 | 合金成分的质量分数/% | 工艺 | 力学性能 | 参考 文献 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | Al | Cr | Ni | Nb | Mo | V | 抗拉强度/MPa | 延伸率/% | |||

| 1 | 0.41 | 1.3 | 1.27 | — | 0.56 | 1.01 | — | — | — | Q&P | 2 468 | 11.6 | [ |

| 2 | 0.43 | 0.59 | 2.03 | 0.008 | 1.33 | 0.07 | 0.03 | 0.03 | — | Q&P | 1 810~2 096 | 12~20 | [ |

| 3 | 0.43 | 0.59 | 2.6 | 0.008 | 1.33 | 0.01 | 0.03 | 0.03 | — | Q&P | 1 965~1 975 | 12~17 | [ |

| 4 | 0.43 | 1.17 | 2.6 | 0.008 | 1.33 | 0.07 | 0.03 | 0.03 | — | Q&P | 1 837~2 218 | 14~22 | [ |

| 5 | 0.42 | 0.59 | 2.6 | — | 1.33 | — | 0.03 | 0.03 | — | Q&P | 1 810~2 096 | 12~20 | [ |

| 6 | 0.56 | 0.62 | 1.95 | — | 0.75 | — | 0.04 | 0.03 | — | Q&P | 2 100~2 251 | 16~22 | [ |

| 7 | 0.56 | 1.36 | 1.88 | — | 1.36 | — | 0.04 | 0.03 | — | Q&P | 2 168~2 377 | 8~13 | [ |

| 8 | 0.32 | 0.23 | 1.78 | — | 1.08 | — | — | 0.45 | 0.21 | Q&FP | 1 942 | ~10 | [ |

| 编号 | 合金成分的质量分数/% | 工艺 | 力学性能 | 参考 文献 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | Al | Ni | Nb | Cr | 抗拉强度/MPa | 延伸率/% | |||

| 1 | 0.485 | 1.195 | 1.185 | — | 0.98 | 0.21 | — | Q-P-T(400 ℃) | 2 160 | 11 | [ |

| 2 | 0.63 | 1.52 | 1.49 | — | — | 0.036 | 0.62 | Q-P-T(400 ℃) | 1 860 | 28.9 | [ |

表4 1 800 MPa级别及以上Q-P-T钢的成分、工艺及力学性能[57,61]

Table 4 Composition, processes, and mechanical properties of Q-P-T steel above 1 800 MPa grade [57,61]

| 编号 | 合金成分的质量分数/% | 工艺 | 力学性能 | 参考 文献 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | Al | Ni | Nb | Cr | 抗拉强度/MPa | 延伸率/% | |||

| 1 | 0.485 | 1.195 | 1.185 | — | 0.98 | 0.21 | — | Q-P-T(400 ℃) | 2 160 | 11 | [ |

| 2 | 0.63 | 1.52 | 1.49 | — | — | 0.036 | 0.62 | Q-P-T(400 ℃) | 1 860 | 28.9 | [ |

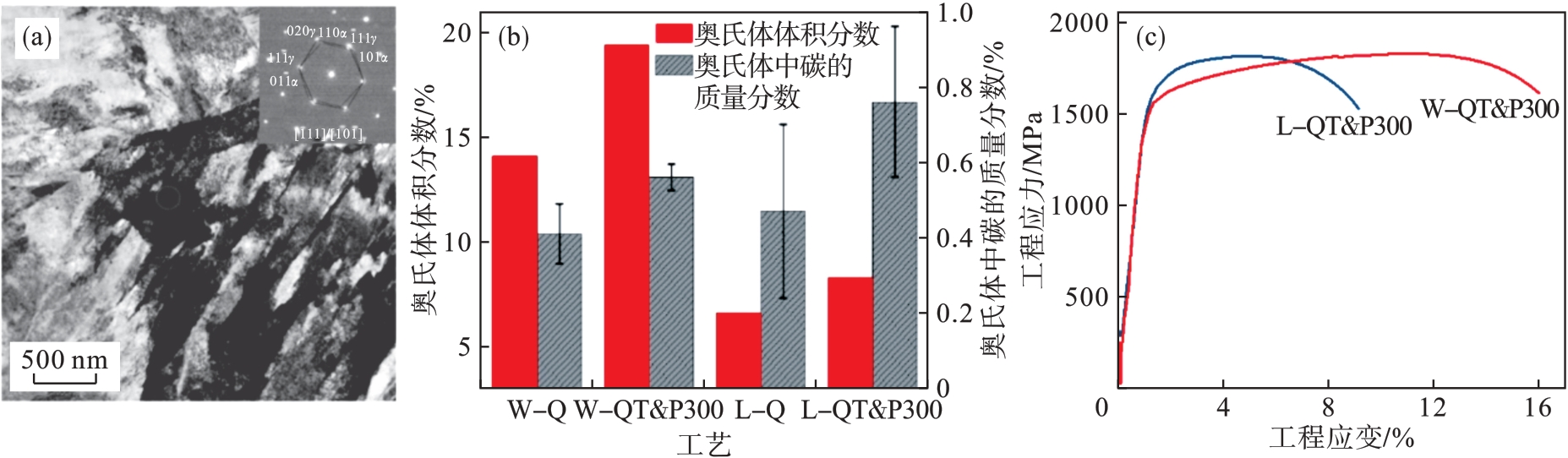

图4 中锰钢低温回火材料微观组织及力学性能[63](a)—淬火后板条马氏体与残余奥氏体组织; (b)—残余奥氏体的体积分数以及W-QT&P300和L-QT&P300过程不同阶段奥氏体中碳的质量分数; (c)—拉伸工程应力-应变曲线.

Fig.4 Microstructure and mechanical properties of low-temperature tempered medium-manganese steel[63]

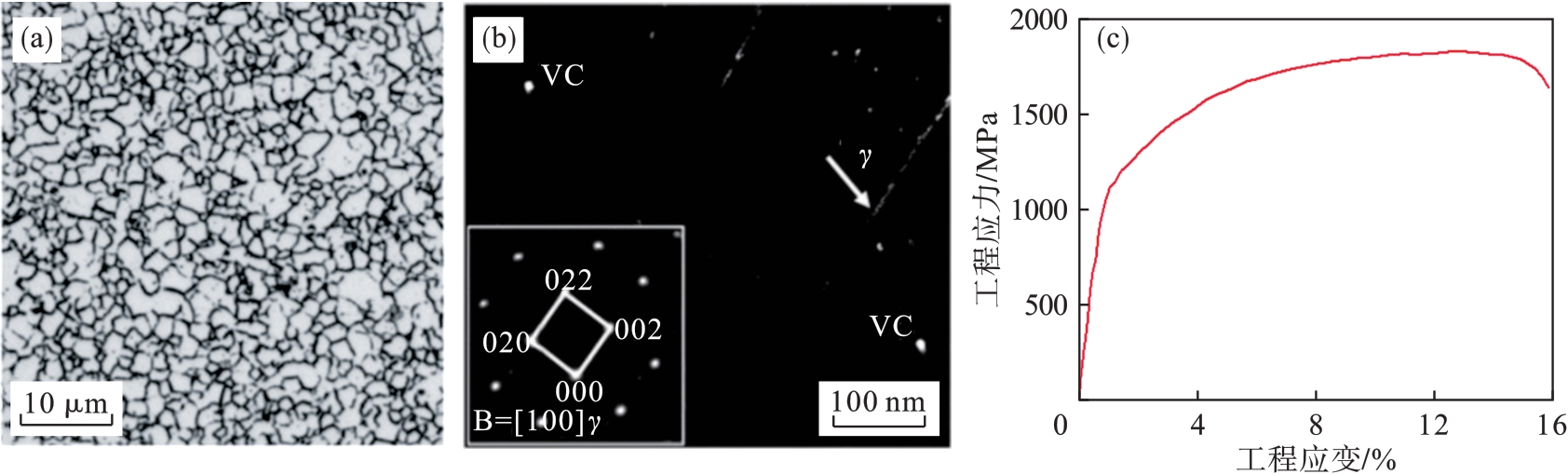

图5 B-P钢微观组织及力学性能[68](a)—晶界刻蚀得到原始奥氏体晶粒大小的光学显微镜图像; (b)—透射电镜暗场图像显示了B-P钢中厚度约为5 nm的薄膜状残余奥氏体和面心立方结构VC析出; (c)—拉伸工程应力-应变曲线.

Fig.5 Microstructure and mechanical properties of B-P steel[68]

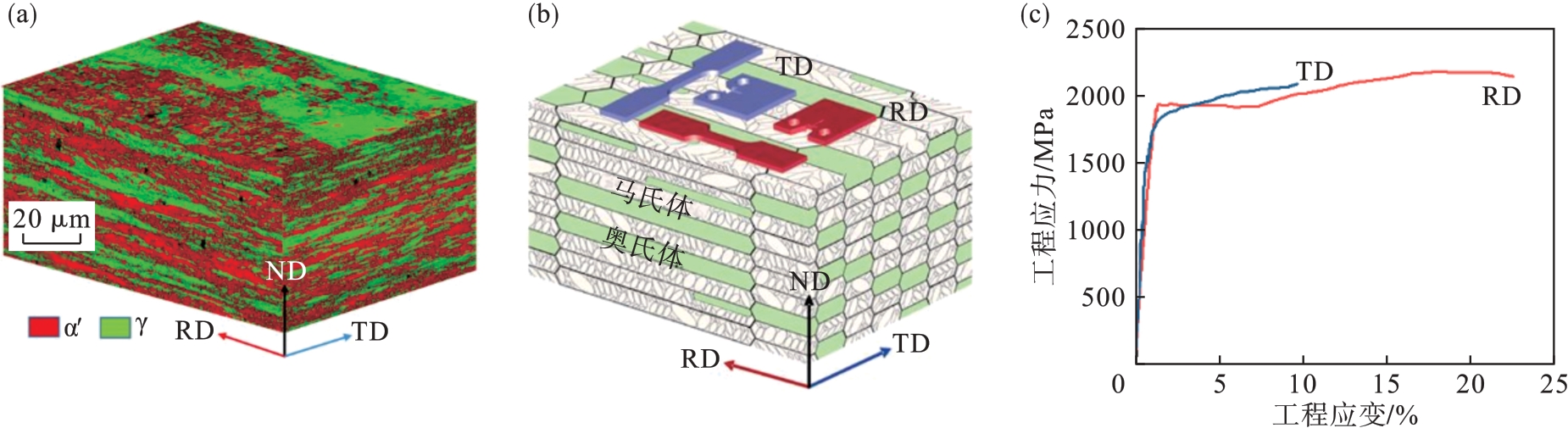

图6 D&P钢微观组织及力学性能[70]注:ND为法向;RD为轧制方向;TD为横向.(a)—高位错密度的亚稳奥氏体-马氏体异质片层双相组织的三维电子背散射衍射图; (b)—组织结构特征及试样相对方向示意图; (c)—拉伸作用下沿RD和TD方向变形的工程应力-应变曲线.

Fig.6 Microstructure and mechanical properties of D&P steel[70]

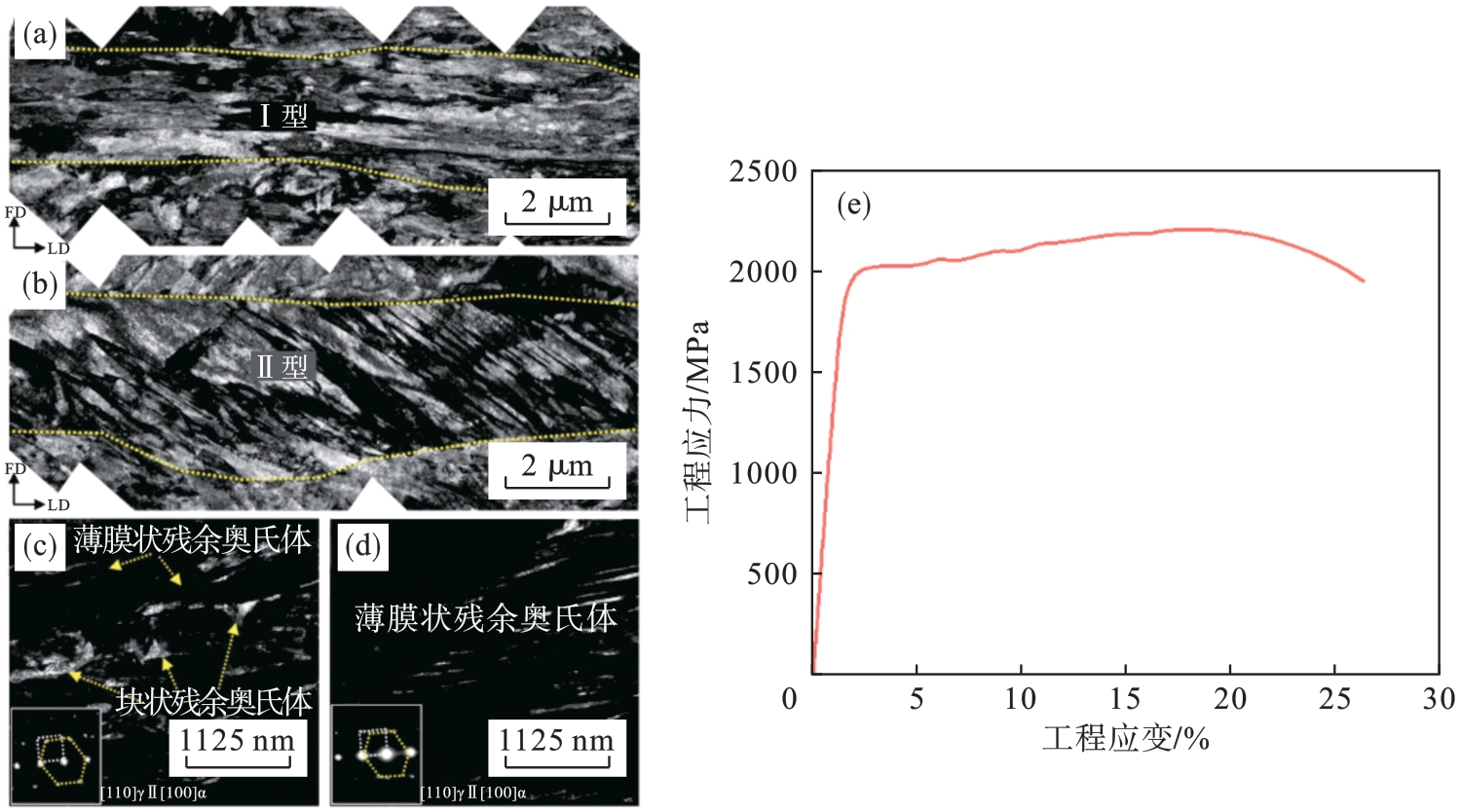

图7 具有分级微观结构的2 GPa韧性钢微观组织及力学性能[71](a)—母体奥氏体的局部区域,显示I型马氏体与纵向平行; (b)—母体奥氏体的局部区域,显示Ⅱ型马氏体与纵向倾斜45°; (c)和(d)—超细残余奥氏体的暗场成像; (e)—工程应力-应变曲线.

Fig.7 Microstructure and mechanical properties of 2 GPa ductile steel with hierarchical substructure[71]

| 钢种 | w(Ni)/% | w(Mo)/% | w(Co)/% | w(Ti)/% | w(Al)/% | 屈服强度/MPa |

|---|---|---|---|---|---|---|

| 18Ni(200) | 18 | 3.3 | 8.5 | 0.2 | 0.1 | 1 400 |

| 18Ni(250) | 18 | 5.0 | 8.5 | 0.4 | 0.1 | 1 700 |

| 18Ni(300) | 18 | 5.0 | 9.0 | 0.7 | 0.1 | 2 000 |

| 18Ni(350) | 18 | 4.2 | 12.5 | 1.6 | 0.1 | 2 400 |

| 18Ni(铸态) | 17 | 4.6 | 10.0 | 0.3 | 0.1 | 1 650 |

表5 早期开发的18Ni系马氏体时效钢成分的质量分数和屈服强度[77]

Table 5 Composition mass fraction and yield strength of early developed 18Ni martensitic aging steel[77]

| 钢种 | w(Ni)/% | w(Mo)/% | w(Co)/% | w(Ti)/% | w(Al)/% | 屈服强度/MPa |

|---|---|---|---|---|---|---|

| 18Ni(200) | 18 | 3.3 | 8.5 | 0.2 | 0.1 | 1 400 |

| 18Ni(250) | 18 | 5.0 | 8.5 | 0.4 | 0.1 | 1 700 |

| 18Ni(300) | 18 | 5.0 | 9.0 | 0.7 | 0.1 | 2 000 |

| 18Ni(350) | 18 | 4.2 | 12.5 | 1.6 | 0.1 | 2 400 |

| 18Ni(铸态) | 17 | 4.6 | 10.0 | 0.3 | 0.1 | 1 650 |

图8 Ni(Al,Fe)B2相析出强化钢的力学性能和析出相与基体间的共格界面 [108](a)—工程应力-应变曲线; (b)—Ni(Al,Fe) B2相与基体的共格关系.

Fig.8 Mechanical properties of Ni(Al,Fe) B2 precipitation strengthened steel and coherent interface between precipitates and matrix [108]

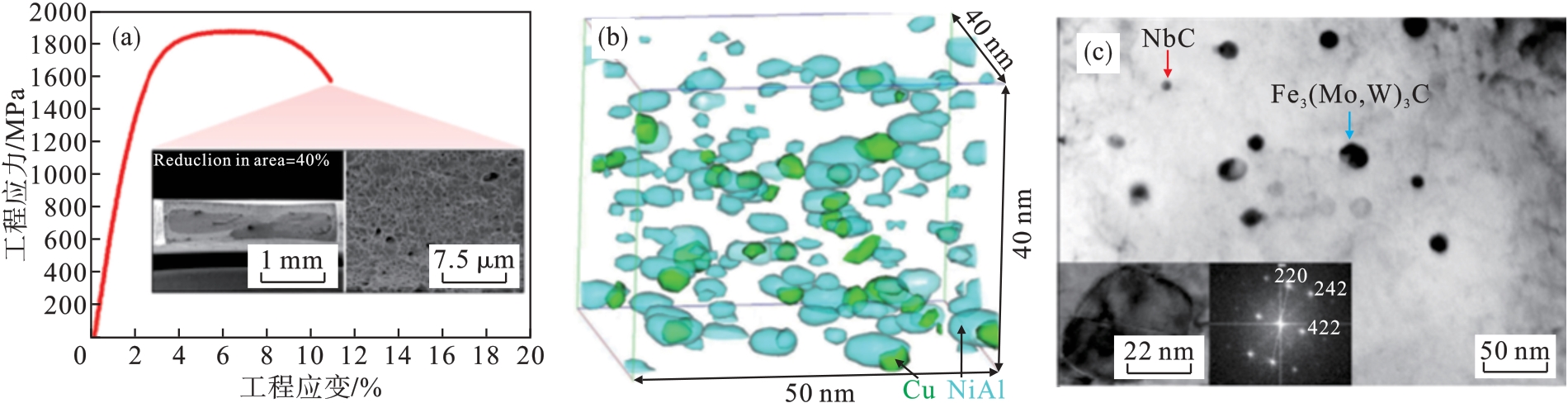

图9 Cu-NiAl复合析出强化钢的力学性能与不同析出的表征[114](a)—应力-应变曲线及拉伸断口形貌; (b)—Cu-NiAl共析出的分布; (c)—碳化物分布.

Fig.9 Mechanical properties and characterization of different precipitates in Cu-NiAl composite precipitation-strengthened steel[114]

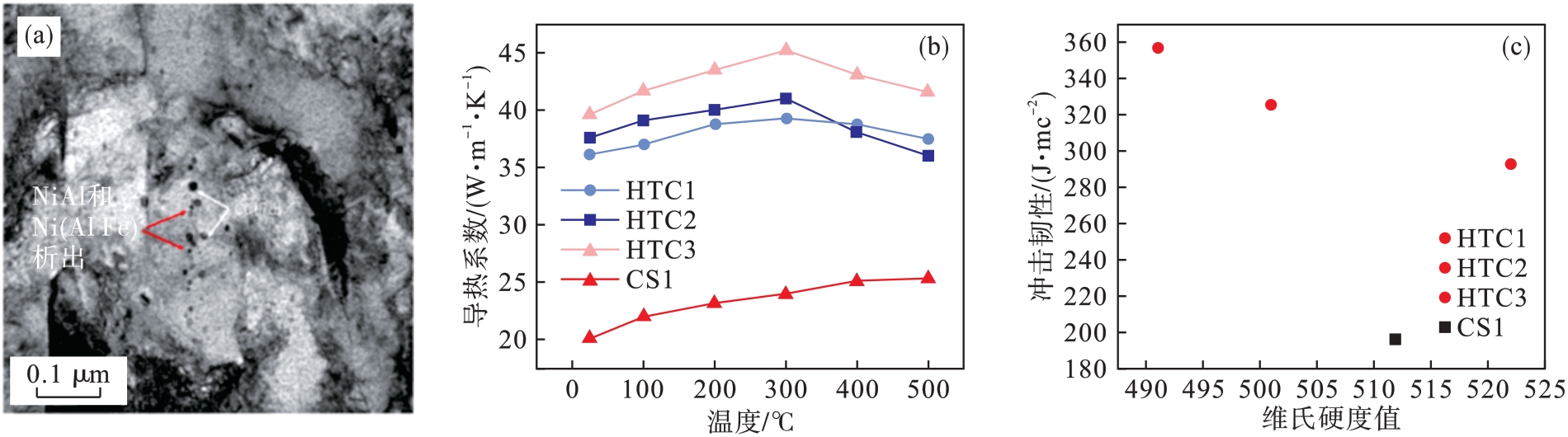

图10 Cu-NiAl系高导热模具钢与由碳化物析出和回火马氏体模具钢的导热性能和力学性能比较[118-119]注:HTCi(i=1,2,3)为不同配比的Cu-NiAl系高导热模具钢,CS1为普通回火马氏体模具钢对照组.(a)—TEM观察的组织形貌; (b)—导热系数对比; (c)—冲击韧性与维氏硬度值.

Fig.10 Comparison of thermal conductivity and mechanical properties of Cu-NiAl high thermal conductivity die steel and tempered martensitic die steel by carbide precipitation[118-119]

| [1] | 常智渊. 2 000 MPa级热冲压成形钢的组织调控及强韧化机理研究[D]. 沈阳: 东北大学, 2020. |

| Chang Zhi-yuan. Study on microstructure control and strengthening-toughening mechanism of 2 000 MPa grade press hardening steel [D].Shenyang: Northeastern University, 2020. | |

| [2] | Tümer M, Schneider-Bröskamp C, Enzinger N.Fusion welding of ultra-high strength structural steels: a review[J]. Journal of Manufacturing Processes, 2022, 82: 203-229. |

| [3] | Bouaziz O, Zurob H, Huang M X. Driving force and logic of development of advanced high strength steels for automotive applications[J]. Steel Research International, 2013, 84(10): 937-947. |

| [4] | Malakondaiah G, Srinivas M, Rao P R. Ultrahigh-strength low-alloy steels with enhanced fracture toughness[J]. Progress in Materials Science, 1997, 42(1/2/3/4): 209-242. |

| [5] | 师昌绪.材料大辞典[M].北京:化学工业出版社,1994. |

| Shi Chang-xu. Materials comprehensive dictionary [M]. Beijing: Chemical Industry Press, 1994. | |

| [6] | 王鹏飞.真空感应冶炼AerMet100超高强度钢工艺研究[D].沈阳:东北大学,2021. |

| Wang Peng-fei. Research on smelting process of AerMet100 ultra-high strength steel by vacuum induction furnace [D]. Shenyang: Northeastern University, 2021. | |

| [7] | Shao Y, Liu C X, Yan Z S, et al. Formation mechanism and control methods of acicular ferrite in HSLA steels: a review[J]. Journal of Materials Science & Technology, 2018, 34(5): 737-744. |

| [8] | Speer J, Matlock D K, De Cooman B C, et al. Carbon partitioning into austenite after martensite transformation[J]. Acta Materialia, 2003, 51(9): 2611-2622. |

| [9] | Yin W J, Briffod F, Hu H Y, et al. Role of prior austenite grain boundary and retained austenite in strain localization of medium-carbon high-strength steels[J]. Acta Materialia, 2024, 281: 120422. |

| [10] | 诸汇涛,王建勇,杨辉,等.马氏体时效钢的研究现状[J].机械制造,2023, 61(8): 41-46. |

| Zhu Hui-tao, Wang Jian-yong, Yang Hui, et al. Research status of martensitic aging steel [J]. Machinery, 2023, 61(8): 41-46. | |

| [11] | Tomita Y. Low-temperature improvement of mechanical properties of AISI 4340 steel through high-temperature thermomechanical treatment[J]. Metallurgical Transactions A, 1991, 22(5): 1093-1102. |

| [12] | Dilipkumar D, Wbod W E. Acoustic-emission analysis of fracture-toughness tests[J]. Experimental Mechanics, 1979, 19(11): 416-420. |

| [13] | Ryder J T, Pickel F M. Effect of temperature on stress corrosion cracking of 300M steel[J]. Joumal of Testing and Evaluation, 1978, 6(2): 129-133. |

| [14] | Bakhshi S, Mirak A. The effect of low temperature transformation time on microstructural & textural evolution, mechanical properties and fracture behavior of a low alloy, medium carbon, super strength AISI 4340 steel[J]. Materials Science and Engineering: A, 2022, 831: 142247. |

| [15] | Cheng X, Gao G H, Fu C, et al. Mechanistic understanding of banded microstructure and its effect on anisotropy of toughness in low carbon-low alloy steel[J]. Materials Science and Engineering: A, 2025, 919: 147507. |

| [16] | 万翛如,许昌淦.高强度及超高强度钢[M].北京:机械工业出版社,1988:25-71. |

| Wan Xiao-ru, Xu Chang-gan. High strength and ultra-high strength steel[M]. Beijing: China Machine Press, 1988: 25-71. | |

| [17] | 王瑞.超高强度钢制备工艺的关键技术研究[D].沈阳:东北大学,2017. |

| Wang Rui. Key process technologies for manufacture of ultra high strength steels [D]. Shenyang: Northeastern University, 2017. | |

| [18] | 张国英.新型无钴高强高韧钢的微观结构与强韧性机理研究[D].沈阳:东北大学,2000. |

| Zhang Guo-ying. Investigation on microstructure and strength-toughening mechanism of a noval cobalt-free ultra-high tensile steel with high fracture toughness [D]. Shenyang: Northeastern University, 2000. | |

| [19] | Taylor T, Clough A. Critical review of automotive hot-stamped sheet steel from an industrial perspective[J]. Materials Science and Technology, 2018, 34(7): 809-861. |

| [20] | Karbasian H, Tekkaya A E. A review on hot stamping[J]. Journal of Materials Processing Technology, 2010, 210(15): 2103-2118. |

| [21] | Honeycombe R W K, Arnold E. Steels: microstructure and properties[M]. London: Butterworth-Heinemann, 1981. |

| [22] | 田秀刚,王朝,孙旭,等.加热温度对34MnB5热成形钢组织性能的影响[J].金属热处理,2023, 48(3): 135-139. |

| Tian Xiu-gang, Wang Chao, Sun Xu, et al. Effect of heating temperature on microstructure and properties of 34MnB5 hot forming steel[J]. Heat Treatment of Metals, 2023, 48(3): 135-139. | |

| [23] | 郝亮,朱国明,闻玉辉,等.超高强度硼钢38MnB5的热冲压工艺研究[J].中南大学学报(自然科学版), 2018, 49(4): 817-823. |

| Hao Liang, Zhu Guo-ming, Wen Yu-hui, et al. Study on hot stamping process of 38MnB5 ultra high strength boron steel [J]. Journal of Central South University (Science and Technology), 2018, 49(4): 817-823. | |

| [24] | Chen W J, Gao P F, Wang S, et al. Strengthening mechanisms of Nb and V microalloying high strength hot-stamped steel[J]. Materials Science and Engineering A, 2020, 797: 140115. |

| [25] | Liang J T, Zhao Z Z, Sun B H, et al.A novel ultra-strong hot stamping steel treated by quenching and partitioning process[J]. Materials Science and Technology, 2018, 34(18): 2241-2249. |

| [26] | Chang Z Y, Liu Z Y, Yu Q, et al. Microstructure and mechanical properties of a 2000 MPa grade ultrahigh strength boron steel[J]. IOP Conference Series: Materials Science and Engineering, 2022, 1270: 012055. |

| [27] | Taylor T, Fourlaris G, Evans P, et al. New generation ultrahigh strength boron steel for automotive hot stamping technologies[J]. Materials Science and Technology, 2014, 30(7): 818-826. |

| [28] | Sun J J, Liu Y N, Zhu Y T, et al. Super-strong dislocation-structured high-carbon martensite steel[J]. Scientific Reports, 2017, 7: 6596. |

| [29] | Wang Y J, Sun J J, Jiang T, et al. A low-alloy high-carbon martensite steel with 2.6 GPa tensile strength and good ductility[J]. Acta Materialia, 2018, 158: 247-256. |

| [30] | Li J K, Yang Z N, Ma H, et al. A medium-C martensite steel with 2.6 GPa tensile strength and large ductility[J]. Scripta Materialia, 2023, 228: 115327. |

| [31] | Mandal G, Roy C, Ghosh S K, et al. Structure-property relationship in a 2 GPa grade micro-alloyed ultrahigh strength steel[J]. Journal of Alloys and Compounds, 2017, 705: 817-827. |

| [32] | Liang J T, Lu H Z, Zhang L L, et al. A 2000 MPa grade Nb bearing hot stamping steel with ultra-high yield strength[J]. Materials Science and Engineering: A, 2021, 801: 140419. |

| [33] | Furuya Y, Matsuoka S. Improvement of gigacycle fatigue properties by modified ausforming in 1600 and 2000 MPA-class low-alloy steels[J]. Metallurgical and Materials Transactions A, 2002, 33(11): 3421-3431. |

| [34] | Kim B, Boucard E, Sourmail T, et al. The influence of silicon in tempered martensite: understanding the microstructure-properties relationship in 0.5~0.6wt% C steels[J]. Acta Materialia, 2014, 68: 169-178. |

| [35] | 于林然,杨卓越,苏杰,等.一种新型2 GPa级低合金超高强度钢及热处理工艺[J].金属热处理,2024, 49(3): 164-168. |

| Yu Lin-ran, Yang Zhuo-yue, Su Jie, et al. A novel 2 GPa grade low alloy ultra-high strength steel and heat treatment process[J]. Heat Treatment of Metals, 2024, 49(3): 164-168. | |

| [36] | 谢地荣,薛彦均,尉文超,等.回火温度对2 300 MPa 级低合金超高强度钢组织及力学性能的影响[J].钢铁研究学报,2024, 36(5): 660-668. |

| Xie Di-rong, Xue Yan-jun, Wei Wen-chao, et al. Effect of tempering temperature on microstructure and mechanical properties of 2 300 MPa grade low alloy ultra-high strength steel [J]. Journal of Iron and Steel Research, 2024, 36(5): 660-668. | |

| [37] | 易红亮,常智渊,才贺龙,等.热冲压成形钢的强度与塑性及断裂应变[J].金属学报,2020, 56(4): 429-443. |

| Yi Hong-liang, Chang Zhi-yuan, Cai He-long, et al. Strength, ductility and fracture strain of press-hardening steels [J]. Acta Metallica Sinica, 2020, 56(4): 429-443. | |

| [38] | 易红亮,刘宏亮,常智渊,等.热冲压成形用钢材、热冲压成形工艺及热冲压成形构件:201610535069.3[P]. 2017-02-15. |

| Yi Hong-liang, Liu Hong-liang, Chang Zhi-yuan, et al. Steel for hot stamping forming, hot stamping forming process and hot stamping forming member: 201610535069.3[P]. 2017-02-15. | |

| [39] | Jimenez-Melero E, van Dijk N H, Zhao L, et al. In situ synchrotron study on the interplay between martensite formation, texture evolution and load partitioning in low-alloyed TRIP steels[J]. Materials Science and Engineering: A, 2011, 528(21): 6407-6416. |

| [40] | Yang D P, Wang T, Miao Z T, et al. Effect of grain size on the intrinsic mechanical stability of austenite in transformation-induced plasticity steels: the competition between martensite transformation and dislocation slip[J]. Journal of Materials Science & Technology, 2023, 162: 38-43. |

| [41] | An X L, Zhang R M, Wu Y X, et al. The role of retained austenite on the stress-strain behaviour of chemically patterned steels[J]. Materials Science and Engineering: A, 2022, 831: 142286. |

| [42] | Seo E J, Cho L, Estrin Y, et al. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel[J]. Acta Materialia, 2016, 113: 124-139. |

| [43] | Soleimani M, Kalhor A, Mirzadeh H. Transformation-induced plasticity (TRIP) in advanced steels: a review[J]. Materials Science and Engineering: A, 2020, 795: 140023. |

| [44] | Clarke A J, Speer J G, Miller M K, et al. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: a critical assessment[J]. Acta Materialia, 2008, 56(1): 16-22. |

| [45] | Santofimia M J, Zhao L, Petrov R, et al. Characterization of the microstructure obtained by the quenching and partitioning process in a low-carbon steel[J]. Materials Characterization, 2008, 59(12): 1758-1764. |

| [46] | Yan S, Liu X H, Liu W J, et al. Comparison on mechanical properties and microstructure of a C-Mn-Si steel treated by quenching and partitioning (Q&P) and quenching and tempering (Q&T) processes[J]. Materials Science and Engineering: A, 2015, 620: 58-66. |

| [47] | HajyAkbary F, Sietsma J, Miyamoto G, et al. Analysis of the mechanical behavior of a 0.3C-1.6Si-3.5Mn(wt%) quenching and partitioning steel[J]. Materials Science and Engineering: A, 2016, 677: 505-514. |

| [48] | Thomas G A, Speer J G. Interface migration during partitioning of Q&P steel[J]. Materials Science and Technology, 2014, 30(9): 998-1007. |

| [49] | Wang H S, Shen F H, Wang Y, et al. Effect of tempering temperature on the microstructure, deformation and fracture properties of an ultrahigh strength medium-Mn steel processed by quenching and tempering[J]. Steel Research International, 2023, 94(11): 2200902. |

| [50] | Kim B, Celada C, San Martín D, et al. The effect of silicon on the nanoprecipitation of cementite[J]. Acta Materialia, 2013, 61(18): 6983-6992. |

| [51] | Yi H L, Lee K Y, Bhadeshia H K D H. Mechanical stabilisation of retained austenite in δ-TRIP steel[J]. Materials Science and Engineering: A, 2011, 528: 5900-5903. |

| [52] | Yi H L, Ryu J H, Bhadeshia H K D H, et al. Low-alloy duplex, directly quenched transformation-induced plasticity steel[J]. Scripta Materialia, 2011, 65(7): 604-607. |

| [53] | Li H Y, Lu X W, Li W J, et al. Microstructure and mechanical properties of an ultrahigh-strength 40SiMnNiCr steel during the one-step quenching and partitioning process[J]. Metallurgical and Materials Transactions A, 2010, 41(5): 1284-1300. |

| [54] | Jirková H, Kučerová L, Mašek B. Effect of quenching and partitioning temperatures in the Q-P process on the properties of AHSS with various amounts of manganese and silicon[J]. Materials Science Forum, 2012, 706-709: 2734-2739. |

| [55] | Jirkova H, Kucerova L. Q-P process on steels with various carbon and chromium contents[C]// Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing. Cham: Springer International Publishing, 2013: 819-824. |

| [56] | Hsu T Y, Xu Z Y. Design of structure, composition and heat treatment process for high strength steel[J]. Materials Science Forum, 2007, 561/565: 2283-2286. |

| [57] | Wang X D, Zhong N, Rong Y H, et al. Novel ultrahigh-strength nanolath martensitic steel by quenching-partitioning-tempering process[J]. Journal of Materials Research, 2009, 24(1): 260-267. |

| [58] | Zhong N, Wang X D, Wang L, et al. Enhancement of the mechanical properties of a Nb-microalloyed advanced high-strength steel treated by quenching-partitioning-tempering process[J]. Materials Science and Engineering: A, 2009, 506(1/2): 111-116. |

| [59] | Peng F, Xu Y B, Gu X L, et al. The relationships of microstructure-mechanical properties in quenching and partitioning (Q&P) steel accompanied with microalloyed carbide precipitation[J]. Materials Science and Engineering: A, 2018, 723: 247-258. |

| [60] | Krauss G. Deformation and fracture in martensitic carbon steels tempered at low temperatures[J]. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 2001, 32(2): 205-221. |

| [61] | Wang Y, Li R B, Zuo X W, et al. The twice softening of martensitic matrix in Q-P-T steels and its effect on ductility[J]. Heat Treatment and Surface Engineering, 2019, 1(1/2): 2-10. |

| [62] | Yi H L, Chen P, Hou Z Y, et al. A novel design: Partitioning achieved by quenching and tempering (Q-T & P) in an aluminium-added low-density steel[J]. Scripta Materialia, 2013, 68(6): 370-374. |

| [63] | Du P J, Chen P, Misra D K, et al. Transformation-induced ductility of reverse austenite evolved by low-temperature tempering of martensite[J]. Metals, 2020, 10(10): 1343. |

| [64] | He B B, Pan S, Huang M X. Extra work hardening in room-temperature quenching and partitioning medium Mn steel enabled by intercritical annealing[J]. Materials Science and Engineering: A, 2020, 797: 140106. |

| [65] | He B B, Liu L, Huang M X. Room-temperature quenching and partitioning steel[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2018, 49(8): 3167-3172. |

| [66] | Li S S, Wen P Y, Li S L, et al. A novel medium-Mn steel with superior mechanical properties and marginal oxidization after press hardening[J]. Acta Materialia, 2021, 205: 116567. |

| [67] | Gu G Y, Kim J H, Lee H H, et al. Room temperature quenching and partitioning (RT-Q&P) processed steel with chemically heterogeneous initial microstructure[J]. Materials Science and Engineering: A, 2022, 851: 143651. |

| [68] | Hou Z R, Opitz T, Xiong X C, et al. Bake-partitioning in a press-hardening steel[J]. Scripta Materialia, 2019, 162: 492-496. |

| [69] | He B B, Hu B, Yen H W, et al. High dislocation density-induced large ductility in deformed and partitioned steels[J]. Science, 2017, 357(6355): 1029-1032. |

| [70] | Liu L, Yu Q, Wang Z, et al. Making ultrastrong steel tough by grain-boundary delamination[J]. Science, 2020, 368(6497): 1347-1352. |

| [71] | Li Y J, Yuan G, Li L L, et al. Ductile 2-GPa steels with hierarchical substructure[J]. Science, 2023, 379(6628): 168-173. |

| [72] | Xu Y S, Gong Y, Du H, et al. A newly-designed hot stamping plus non-isothermal Q&P process to improve mechanical properties of commercial QP980 steel[J]. International Journal of Lightweight Materials and Manufacture, 2020, 3(1): 26-35. |

| [73] | Sun W W, Wu Y X, Yang S C, et al. Advanced high strength steel (AHSS) development through chemical patterning of austenite[J]. Scripta Materialia, 2018, 146: 60-63. |

| [74] | Zhang C, Xiong Z P, Yang D Z, et al. Heterogeneous quenching and partitioning from manganese-partitioned pearlite: retained austenite modification and formability improvement[J]. Acta Materialia, 2022, 235: 118060. |

| [75] | Gao G H, Zhang H, Gui X L, et al. Enhanced ductility and toughness in an ultrahigh-strength Mn-Si-Cr-C steel: the great potential of ultrafine filmy retained austenite[J]. Acta Materialia, 2014, 76: 425-433. |

| [76] | Rao M N. Progress in understanding the metallurgy of 18% Nickel-Maraging Steel[J]. International Journal of Materials Research, 2006, 97(11): 1594-1607. |

| [77] | Sha W, Guo Z L. Maraging steels modelling of microstructure, properties and applications[M]. Cambridge: Woodhead Publishing Limited, 2009. |

| [78] | Lombardo S, Ferreira N R, de Souza Santos L A, et al. Microstructural characterization of joints of maraging 300 steel welded by laser and subjected to plasma nitriding treatment [J]. Materials Science Forum, 2016, 869: 479-483. |

| [79] | Fanton L, Abdalla A J, de Lima M S F. Heat treatment and Yb-fiber laser welding of a maraging steel[J]. Welding Journal, 2014, 93(9): 362-368. |

| [80] | Rajkumar V, Arivazhagan N, Ramkumar K D. Studies on welding of maraging steels [J]. Procedia Engineering, 2014, 75: 83-87. |

| [81] | Raabe D, Ponge D, Dmitrieva O. Designing ultrahigh strength steels with good ductility by combining transformation induced plasticity and martensite aging [J]. Advanced Engineering Materials, 2009, 11(7): 547-555. |

| [82] | Seede R, Shoukr D, Zhang B, et al. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: densification, microstructure, and mechanical properties [J]. Acta Materialia, 2020, 186: 199-214. |

| [83] | Anil Kumar V, Karthikeyan M K, Gupta R K, et al. Aging behavior in 15-5 pH precipitation hardening martensitic stainless steel [J]. Materials Science Forum, 2012, 710: 483-488. |

| [84] | Zou X D, Niu B, Pan L L, et al. Wire+arc additive manufacturing and heat treatment of super martensitic stainless steel with a refined microstructure and excellent mechanical properties [J]. Materials, 2022, 15(7): 2624. |

| [85] | Samei J, Asgari H, Pelligra C, et al. A hybrid additively manufactured martensitic-maraging stainless steel with superior strength and corrosion resistance for plastic injection molding dies [J]. Additive Manufacturing, 2021, 45: 102068. |

| [86] | Karabeyoglu S S, Yaman P. An experimental investigation of martensitic stainless steel in aircraft and aerospace industry for thermal wear performance and corrosion potential [J]. Practical Metallography, 2022, 59(4): 199-215. |

| [87] | Li X D, Yin Z D. A computer-simulated electron diffraction analysis of precipitates in 18Ni(350) maraging steel [J]. Materials Letters, 1995, 23(4/6): 269-272. |

| [88] | Pardal J M, Tavares S S M, Terra V F, et al. Modeling of precipitation hardening during the aging and overaging of 18Ni-Co-Mo-Ti maraging 300 steel [J]. Journal of Alloys and Compounds, 2005, 393(1/2): 109-113. |

| [89] | Viswanathan U K, Dey G K, Asundi M K. Precipitation hardening in 350 grade maraging steel [J]. Metallurgical Transactions A, 1993, 24(11): 2429-2442. |

| [90] | Li X D, Yin Z D, Li H B, et al. Mössbauer study of the early stages of aging in 18Ni(350) maraging steel [J]. Materials Chemistry and Physics, 1993, 33(3/4): 277-280. |

| [91] | Cerra F M A, Pereira Ú C, Cardoso J L, et al. Microstructural characterization of grade 300 and grade 350 maraging steels and electrochemical study in hydrofluoric solution [J]. Journal of Fluorine Chemistry, 2021, 243: 109738. |

| [92] | Marcisz J, Adamczyk M, Garbarz B. Optimisation of mechanical properties of 18%Ni350 grade maraging steel using novel heat treatment [J]. Archives of Metallurgy and Materials, 2017, 62(1): 73-84. |

| [93] | Ahmed M, Salam I, Nasim I, et al. Reclamation and additional alloying of 18Ni(350) maraging steel [J]. Journal of Materials Engineering and Performance, 1994, 3(3): 386-392. |

| [94] | Kalish D, Rack H J. Thermal embrittlement of 18 Ni(350) maraging steel [J]. Metallurgical Transactions, 1971, 2(9): 2665-2672. |

| [95] | Rack H J, Kalish D. The strength and fracture toughness of 18 Ni (350) maraging steel[J]. Metallurgical Transactions, 1971, 11(2): 3011-3020. |

| [96] | Becker T H, Dimitrov D. The achievable mechanical properties of SLM produced maraging steel 300 components[J]. Rapid Prototyping Journal, 2016, 22(3): 487-494. |

| [97] | Song J, Tang Q, Feng Q X, et al. Effect of heat treatment on microstructure and mechanical behaviors of 18Ni-300 maraging steel manufactured by selective laser melting[J]. Optics & Laser Technology, 2019, 120: 105725. |

| [98] | Kempen K, Yasa E, Thijs L, et al. Microstructure and mechanical properties of selective laser melted 18Ni-300 steel [J]. Physics Procedia, 2011, 12: 255-263. |

| [99] | Wu W P, Wang X, Wang Q, et al. Microstructure and mechanical properties of maraging 18Ni-300 steel obtained by powder bed based selective laser melting process[J]. Rapid Prototyping Journal, 2020, 26(8): 1379-1387. |

| [100] | Yin S, Chen C Y, Yan X C, et al. The influence of aging temperature and aging time on the mechanical and tribological properties of selective laser melted maraging 18Ni-300 steel[J]. Additive Manufacturing, 2018, 22: 592-600. |

| [101] | He Y, Yang K, Sha W. Microstructure and mechanical properties of a 2000 MPa grade Co-free maraging steel after aging at 753K[J]. Metallurgical and Materials Transactions A, 2005, 36(9): 2273-2287. |

| [102] | He Y, Yang K, Sha W, et al. Microstructure and mechanical properties of a 2000 MPa Co-free maraging steel after aging at 753 K[J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2747-2755. |

| [103] | Niu M C, Yin L C, Yang K, et al. Synergistic alloying effects on nanoscale precipitation and mechanical properties of ultrahigh-strength steels strengthened by Ni3Ti, Mo-enriched, and Cr-rich co-precipitates[J]. Acta Materialia, 2021, 209: 116788. |

| [104] | 尹炎祺,伍翠兰,谢盼,等.冷轧及退火制备的超细晶粒双相Mn12Ni2MoTi(Al)[J].金属学报,2016, 52(12): 1527-1535. |

| Yin Yan-qi, Wu Cui-lan, Xie Pan, et al. An ultrafine grained duplex Mn12Ni2MoTi(Al) steel fabricated by cold rolling and annealing [J]. Acta Metallica Sinica, 2016, 52(12): 1527-1535. | |

| [105] | Stallybrass C, Schneider A, Sauthoff G. The strengthening effect of (Ni,Fe)Al precipitates on the mechanical properties at high temperatures of ferritic Fe-Al-Ni-Cr alloys[J]. Intermetallics, 2005, 13(12): 1263-1268. |

| [106] | Sun L, Simm T H, Martin T L, et al. A novel ultra-high strength maraging steel with balanced ductility and creep resistance achieved by nanoscale β-NiAl and Laves phase precipitates[J]. Acta Materialia, 2018, 149: 285-301. |

| [107] | Simm T H, Sun L, Galvin D R, et al. A SANS and APT study of precipitate evolution and strengthening in a maraging steel[J]. Materials Science and Engineering: A, 2017, 702: 414–424. |

| [108] | Jiang S H, Wang H, Wu Y, et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation[J]. Nature, 2017, 544(7651): 460-464. |

| [109] | Galindo N E I, Rainforth W M, Rivera P E J. Predicting microstructure and strength of maraging steels: elemental optimization[J]. Acta Materialia, 2016, 117: 270-285. |

| [110] | Wang J, Wu D J, Zhu C Y, et al. Thermal stability enhancement of hybrid Ni2Al3/Ni coatings on creep-resistant ferritic steels by a mechanism of thermodynamically constrained interdiffusion[J]. Surface and Coatings Technology, 2013, 232: 489-496. |

| [111] | Wang M, Sun H Y, Zheng W Y, et al. Creep behavior of an alumina-forming austenitic steel with simple alloy design[J]. Materials Today Communications, 2020, 25: 101303. |

| [112] | Yamamoto Y, Santella M L, Brady M P, et al. Effect of alloying additions on phase equilibria and creep resistance of alumina-forming austenitic stainless steels[J]. Metallurgical and Materials Transactions A, 2009, 40(8): 1868-1880. |

| [113] | Jiao Z B, Luan J H, Miller M K, et al. Co-precipitation of nanoscale particles in steels with ultra-high strength for a new era[J]. Materials Today, 2017, 20(3): 142-154. |

| [114] | Jiao Z B, Luan J H, Miller M K, et al. Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles[J]. Acta Materialia, 2015, 97: 58-67. |

| [115] | Liu Z K, Jie X H, Wu H S, et al. The preparation and properties of Ni2Al3 intermetallic compound coating[J]. Coatings, 2023, 13(11): 1900. |

| [116] | Polvani R S, Tzeng W S, Strutt P R. High temperature creep in a semi-coherent NiAl-Ni2AlTi alloy[J]. Metallurgical Transactions A, 1976, 7: 33-40. |

| [117] | Baik S, Wang S Y, Liaw P K, et al. Increasing the creep resistance of Fe-Ni-Al-Cr superalloys via Ti additions by optimizing the B2/L21 ratio in composite nano-precipitates[J]. Acta Materialia, 2018, 157(15): 142-154. |

| [118] | 易红亮,刘连骞,芦富敏,等.热作模具钢、其热处理方法及热作模具: 202210703843.2[P]. 2022-07-29. |

| Yi Hong-liang, Liu Lian-qian, Lu Fu-min, et al. Hot work die steel, heat treatment method thereof and hot work die: 202210703843.2[P]. 2022-07-29. | |

| [119] | 易红亮,刘连骞,王国栋,等.热作模具钢、其热处理方法及热作模具: 201910156108.2[P]. 2020-09-18. |

| Yi Hong-liang, Liu Lian-qian, Wang Guo-dong, et al. Hot work die steel, heat treatment method thereof and hot work die: 201910156108.2[P]. 2020-09-18. |

| [1] | 李艳艳, 潘进, 岳圆圆, 张亚龙. HRB600E高强钢筋混凝土柱抗震性能及恢复力特性[J]. 东北大学学报(自然科学版), 2023, 44(1): 130-137. |

| [2] | 杨森宇, 付天亮, 朱美君, 王昭东. Q960E超高强钢板控温淬火试验研究与应用[J]. 东北大学学报(自然科学版), 2022, 43(11): 1570-1574. |

| [3] | 李美莹, 肖乃友, 周剑华, 贾涛. 合金设计对贝氏体相变动力学影响的建模研究[J]. 东北大学学报(自然科学版), 2022, 43(11): 1561-1569. |

| [4] | 王皓, 曹光明, 汤军舰, 刘振宇. 700MPa级高强钢水蒸气条件下的高温氧化行为[J]. 东北大学学报(自然科学版), 2021, 42(7): 920-926. |

| [5] | 王斌, 宁新禹, 李方坡, 李海军. 差温轧制连铸钢坯芯部孔洞压合过程数值模拟[J]. 东北大学学报(自然科学版), 2021, 42(7): 939-946. |

| [6] | 张健新, 张标, 戎贤, 丁传林. 钢纤维增强高强钢筋混凝土梁柱节点抗震性能试验研究[J]. 东北大学学报:自然科学版, 2020, 41(10): 1465-1475. |

| [7] | 张大征, 高秀华, 杜林秀, 王鸿轩. 多级热处理对柔性立管用高强钢组织性能影响[J]. 东北大学学报:自然科学版, 2020, 41(1): 49-54. |

| [8] | 温长飞, 邓想涛, 王昭东, 王国栋. 超高强钢Q1100的SH-CCT曲线及粗晶热影响区组织和性能[J]. 东北大学学报:自然科学版, 2017, 38(6): 809-813. |

| [9] | 王贵桥, 李建平, 孙涛, 赵安石. 超高强钢管气压热成形设备的研究开发[J]. 东北大学学报:自然科学版, 2017, 38(2): 234-239. |

| [10] | 孙茜, 邸洪双, 李峻臣. 780MPa级微合金钢的激光相变硬化工艺及组织性能[J]. 东北大学学报:自然科学版, 2016, 37(6): 785-789. |

| [11] | 谢辉,杜林秀,胡军. 冷却工艺对低碳Ti微合金化热轧超高强钢组织性能的影响[J]. 东北大学学报:自然科学版, 2014, 35(4): 508-511. |

| [12] | 曹光明,孙彬,刘小江,张琳. 热轧高强钢氧化动力学和氧化铁皮结构控制[J]. 东北大学学报:自然科学版, 2013, 34(1): 71-75. |

| [13] | 张明亚;朱伏先;马世成;张自成;. 冷轧Q345钢退火工艺的实验研究[J]. 东北大学学报(自然科学版), 2011, 32(8): 1111-1114+1123. |

| [14] | 康健;卢峰;王昭东;王国栋;. 工程机械用960 MPa级调质钢板的淬火工艺研究[J]. 东北大学学报(自然科学版), 2011, 32(1): 52-55. |

| [15] | 衣海龙;王晓南;杜林秀;王国栋;. 710MPa级热轧高强钢的组织性能[J]. 东北大学学报(自然科学版), 2009, 30(10): 1421-1424+1428. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||