东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 1-10.DOI: 10.12068/j.issn.1005-3026.2025.20250060

• 综述 •

袁国, 王超, 李振垒, 王国栋

收稿日期:2025-05-26

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

王超

作者简介:袁 国(1979—),男,山东泰安人,东北大学教授,博士生导师Guo YUAN, Chao WANG, Zhen-lei LI, Guo-dong WANG

Received:2025-05-26

Online:2025-08-15

Published:2025-11-24

Contact:

Chao WANG

摘要:

双辊薄带铸轧作为材料与冶金领域重要的铸轧一体化短流程工艺技术,在薄规格板带钢、特殊钢和特殊合金制备领域具有重大应用价值.针对双辊薄带铸轧过程高温熔体流动与传热过程中存在的多元、多相、多变量、强耦合的复杂理论及技术难题,本文综述了双辊薄带铸轧关键技术、工艺控制策略及产品技术相关研究进展,基于理论研究与技术开发实践,重点介绍了高温熔体布流、铸辊冷却、侧封技术以及铸轧工艺控制等方面的自主创新成果与技术应用情况,并指出需要深入研究的理论与技术难题,以推动该技术在高端高质钢铁材料研发生产中的应用.

中图分类号:

袁国, 王超, 李振垒, 王国栋. 双辊薄带铸轧工业化关键技术研究进展[J]. 东北大学学报(自然科学版), 2025, 46(8): 1-10.

Guo YUAN, Chao WANG, Zhen-lei LI, Guo-dong WANG. Research Progress in Key Technologies of Twin-Roll Strip Casting for Industrialization[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 1-10.

| 项目 | 浇铸速度/(m·min-1) | 产品厚度/mm | 浇铸钢种 | 铸辊辊径/mm | 发展情况 |

|---|---|---|---|---|---|

| DSC | ≤90 | 1.6~5 | 不锈钢 | 1 200 | 终止生产 |

| Eurostrip | 40~90 ≤150 | 1.4~3.5 | 不锈钢 | 1 500 | 工业化进程 |

| Postrip | 30~130 ≤160 | 1.6~4 | 不锈钢 | 1 200 | 工业化进程 |

| CASTRIP | 40~120 | 0.7~2.0 | 碳钢 | 500 | 商业化进程 |

| Baostrip | 30~130 | 0.8~3.6 | 碳钢 | 800 | 工业化进程 |

| E2Strip | 30~75 | 1.0~2.2 | 碳钢、硅钢 | 500 | 工业化进程 |

表1 国内外双辊薄带铸轧产线发展状态

Table 1 Development status of domestic and foreign twin-roll strip casting production lines

| 项目 | 浇铸速度/(m·min-1) | 产品厚度/mm | 浇铸钢种 | 铸辊辊径/mm | 发展情况 |

|---|---|---|---|---|---|

| DSC | ≤90 | 1.6~5 | 不锈钢 | 1 200 | 终止生产 |

| Eurostrip | 40~90 ≤150 | 1.4~3.5 | 不锈钢 | 1 500 | 工业化进程 |

| Postrip | 30~130 ≤160 | 1.6~4 | 不锈钢 | 1 200 | 工业化进程 |

| CASTRIP | 40~120 | 0.7~2.0 | 碳钢 | 500 | 商业化进程 |

| Baostrip | 30~130 | 0.8~3.6 | 碳钢 | 800 | 工业化进程 |

| E2Strip | 30~75 | 1.0~2.2 | 碳钢、硅钢 | 500 | 工业化进程 |

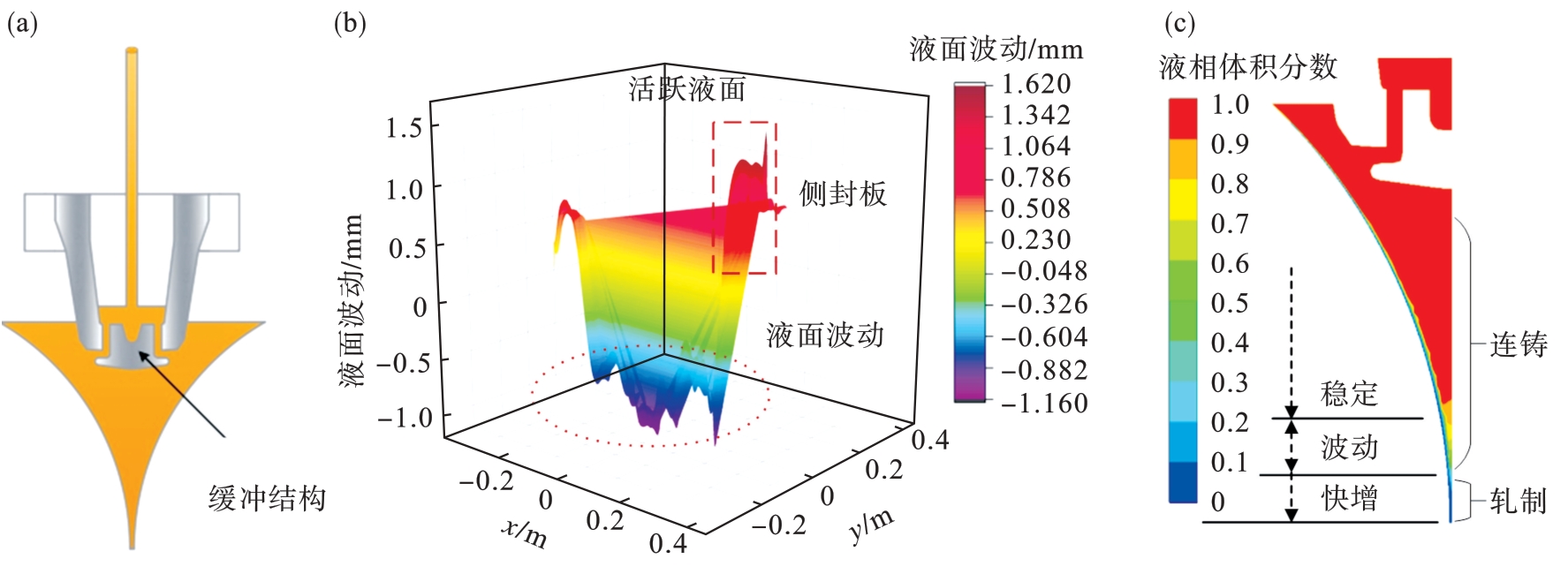

图5 布流工艺对双辊薄带铸轧过程熔池液位波动及金属液凝固特性的影响(a)—典型布流器结构; (b)—熔池液面波动; (c)—金属液凝固特性.

Fig.5 Influence of flow distribution process on molten pool level fluctuation and solidification characteristics of metal liquid during twin-roll strip casting process

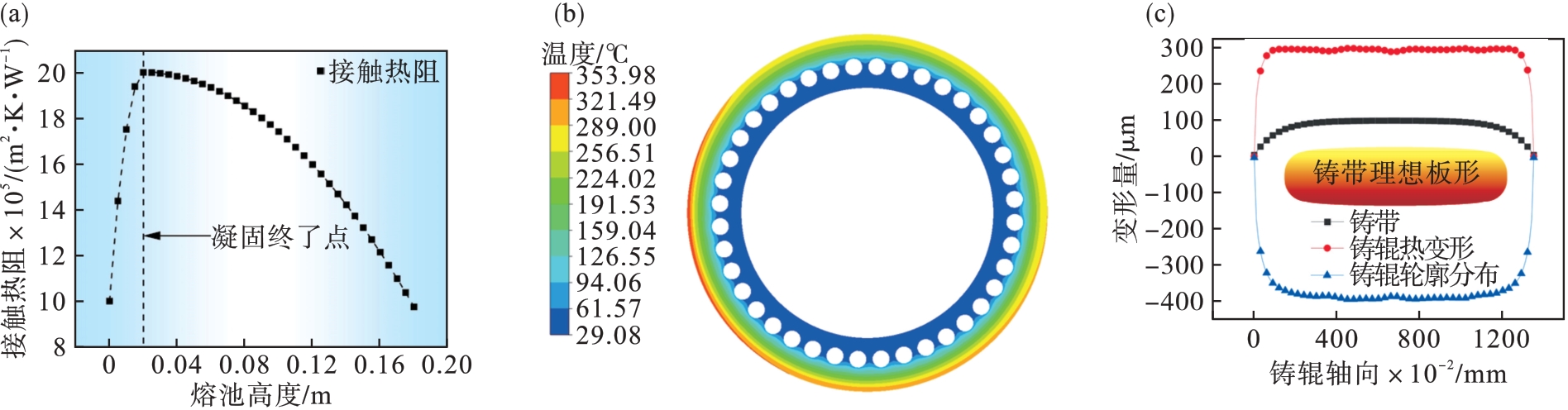

图6 基于熔池与铸辊接触界面非线性热阻分布的铸辊温度与热变形特性(a)—界面接触热阻分布; (b)—铸辊圆周方向温度; (c)—基于理想铸带板形与铸辊热变形的铸辊轮廓分布.

Fig.6 Temperature and thermal deformation characteristics of casting roller based on the nonlinear thermal resistance distribution at the contact interface between the molten pool and the casting roller

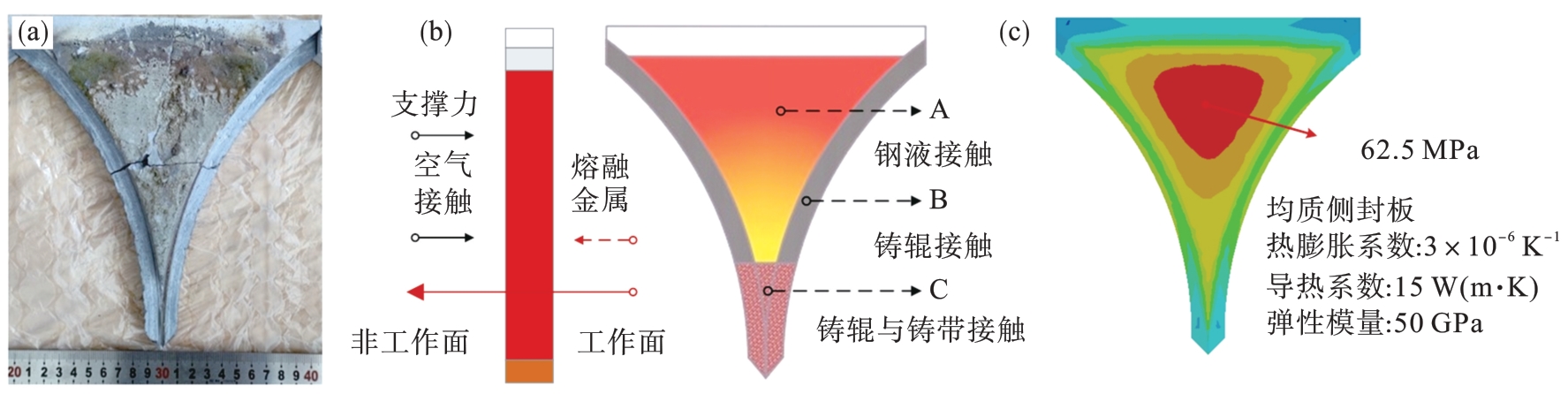

图7 基于实际服役性能的侧封板热力特性研究(a)—侧封板服役效果; (b)—侧封板功能性分区; (c)—侧封板应力分布.

Fig.7 Research on the thermal characteristics of side dams based on actual service performance

| [1] | Guthrie R I L, Isac M M. Continuous casting practices for steel: past, present and future[J]. Metals, 2022, 12(5): 862. |

| [2] | Campbell P, Mahapatra R, Blejde W, et al. The CASTRIP® process: progress towards commercial strip casting at Nucor Crawfordsville[J]. Revue De Métallurgie-Cahiers D:Informations Techniques, 2006, 103(1): 25-31. |

| [3] | 方园, 张健. 双辊薄带连铸连轧技术的发展现状及未来[J]. 宝钢技术, 2018(4): 2-6. |

| Fang Yuan, Zhang Jian. Development status and future of twin roll strip casting & rolling [J]. Baosteel Technology, 2018 (4): 2-6. | |

| [4] | 史华跃, 冯庆晓, 董瀚, 等. 沙钢超薄带双辊铸轧工艺及超薄带耐候钢的发展现状[J]. 上海金属, 2020, 42(6): 51-57. |

| Shi Hua-yue, Feng Qing-xiao, Dong Han, et al. Development status of shasteel’s ultra-thin cast strip twin-roll casting and rolling process and weatherproof steel for ultra-thin cast strip [J]. Shanghai Metals, 2020, 42(6): 51-57. | |

| [5] | 蔡常青. 双辊薄带连铸连轧技术的现状与展望[J]. 福建冶金, 2022, 51(1): 50-54. |

| Cai Chang-qing. Present situation and prospect of twin-roll strip continuous casting and rolling technology [J]. Fujian Metallurgy, 2022, 51(1): 50-54. | |

| [6] | 杨泽曦, 王子铭, 李跃, 等. 双辊薄带连铸熔池内流动、传热与凝固的模拟研究[J]. 炼钢, 2023, 39(4): 48-54. |

| Yang Ze-xi, Wang Zi-ming, Li Yue, et al. Modelling of flow, heat transfer and solidification in the bath of twin roll strip continuous casting[J]. Steelmaking, 2023, 39(4): 48-54. | |

| [7] | 任三兵, 朱苗勇, 樊俊飞. 薄带连铸新型布流系统的数学物理模拟[J]. 东北大学学报(自然科学版), 2014, 35(1): 60-63. |

| Ren San-bing, Zhu Miao-yong, Fan Jun-fei. Mathematical and physical simulations of the new type feeding system in strip casting [J]. Journal of Northeastern University (Natural Science), 2014, 35(1): 60-63. | |

| [8] | 钟勇. 双辊薄带连铸熔池布流系统的数值模拟研究[D]. 重庆: 重庆大学, 2020. |

| Zhong Yong. Numerical simulation of distribution system in molten pool of twin roll strip continuous casting[D]. Chongqing: Chongqing University, 2020. | |

| [9] | Xu M G, Zhu M Y. Physical and computational study of a novel submerged entry nozzle design for twin-roll casting process[J]. Journal of Iron and Steel Research International, 2021, 28(11): 1390-1399. |

| [10] | Bai C F, Wang B, Ma J, et al. Modeling effect of cooling conditions on solidification process during thermal cycle of rollers in twin-roll strip casting[J]. Journal of Iron and Steel Research International, 2023, 30(1): 64-73. |

| [11] | 蒋恩, 刘刚. 双辊薄带连铸铸辊水冷系统数值模拟[J]. 一重技术, 2020(1): 1-4, 48. |

| Jiang En, Liu Gang. Numerical simulation to water cooling system of casting rolls in twin roll strip casters [J]. CFHI Technology, 2020(1): 1-4, 48. | |

| [12] | 朱光明, 方园. 双辊薄带连铸结晶辊辊形优化[J]. 钢铁研究学报, 2007, 19 (4): 28-30. |

| Zhu Guang-ming, Fang Yuan. Roll profile optimization of twin-roll strip casting rolls [J]. Journal of Iron and Steel Research, 2007, 19 (4): 28-30. | |

| [13] | Wang W L, Cai D W, Lu C, et al. Formation of deposited oxide film during the sub-rapid solidification of silicon steel droplet and its effect on interfacial heat transfer behavior[J]. Metallurgical and Materials Transactions B, 2022, 53(1): 198-207. |

| [14] | 刘孟, 宋仪杰, 徐晓虹, 等. 薄带连铸用BN基侧封板材料的性能研究及应用[J]. 耐火材料, 2015, 49(5): 357-360. |

| Liu Meng, Song Yi-jie, Xu Xiao-hong, et al. Properties and application of BN based side dam materials for thin strip continuous casting [J]. Refractories, 2015, 49(5): 357-360. | |

| [15] | 郭海荣, 李鑫, 李化龙, 等. 薄带连铸用侧封板服役过程中热应力分析[J]. 中国冶金, 2022, 32(4): 27-33. |

| Guo Hai-rong, Li Xin, Li Hua-long, et al.Thermal stress analysis during service of side sealing plate for thin strip continuous casting [J]. China Metallurgy, 2022, 32(4): 27-33. | |

| [16] | 张晓明, 张军锋, 刘相华, 等. 双辊铸轧薄带过程中铸速对熔池内温度场的影响[J]. 东北大学学报(自然科学版), 2006, 27(7): 759-762. |

| Zhang Xiao-ming, Zhang Jun-feng, Liu Xiang-hua, et al. Influence of casting speed on temperature field in molten pool during twin-roll strip casting [J]. Journal of Northeastern University (Natural Science), 2006, 27(7): 759-762. | |

| [17] | 张文宇, 马宇翔, 巨东英, 等. 双辊铸轧过程金属熔池液面的优化控制[J]. 辽宁科技大学学报, 2016, 39(2): 98-103. |

| Zhang Wen-yu, Ma Yu-xiang, Ju Dong-ying, et al. Optimal control of molten metal level in twin-roll casting process[J]. Journal of University of Science and Technology Liaoning, 2016, 39(2): 98-103. | |

| [18] | 齐春雨, 邸洪双, 张晓明, 等. 双辊铸轧薄带钢铸轧力计算公式及控制模型[J]. 黄金学报, 2001, 3(3): 168-170. |

| Qi Chun-yu, Di Hong-shuang, Zhang Xiao-ming, et al. Establishment of rolling force formula and process control model for twin-roll strip casting of thin steel strips [J]. Gold Journal, 2001,3 (3): 168-170. | |

| [19] | Browne F, Rees B, Chiu G T C, et al. Iterative learning control with time-delay compensation: an application to twin-roll strip casting[J]. IEEE Transactions on Control Systems Technology, 2021, 29(1): 140-149. |

| [20] | Chen D, Tang Y, Dou W X, et al. Detecting height of liquid level with computer vision for twin-roll strip casting[J]. ISIJ International, 2023, 63(7): 1226-1232. |

| [21] | Park Y, Cho H. A fuzzy logic controller for the molten steel level control of strip casting processes[J]. Control Engineering Practice, 2005, 13(7): 821-834. |

| [22] | 袁国, 张元祥, 王洋, 等. 薄带铸轧凝固组织的低能晶界及遗传效应[J]. 钢铁, 2023, 58(9): 157-166. |

| Yuan Guo, Zhang Yuan-xiang, Wang Yang, et al. Low-energy grain boundaries and their hereditary effects on microstructures in strip casting [J]. Iron and Steel, 2023, 58(9): 157-166. | |

| [23] | 杜锋, 方园. 影响薄带连铸低碳钢带表面微裂纹形成的主要因素[J]. 上海金属, 2012, 34(4): 48-53. |

| Du Feng, Fang Yuan. Main factors affecting surface micro crack on low carbon steel strip by strip casting [J]. Shanghai Metals, 2012, 34(4): 48-53. | |

| [24] | 王鹤松, 袁国, 曹光明, 等. 双辊薄带连铸低碳微合金钢的铸态组织[J]. 东北大学学报(自然科学版), 2018, 39(4): 497-500. |

| Wang He-song, Yuan Guo, Cao Guang-ming, et al. As-cast microstructures of low-carbon microalloyed steel produced by twin-roll strip casting [J]. Journal of Northeastern University (Natural Science), 2018, 39(4): 497-500. | |

| [25] | Zhang Y S, Li Z L, Tang Y, et al. Research on flow, heat transfer, and solidification characteristics of flow distribution process in the twin-roll casting[J]. International Journal of Thermal Sciences, 2024, 204: 109215. |

| [26] | Zhang Y S, Li Z L, Tang Y, et al. Research on temperature field and thermal deformation characteristics of casting rollers in twin-roll casting process[J]. Applied Thermal Engineering, 2024, 256: 124005. |

| [27] | Zhang Y S, Li Z L, Fang F, et al. Numerical analysis and experimental study on side dam temperature and stress field of two-roll casting[J]. Steel Research International, 2024, 95(5): 2300748. |

| [28] | Zhang Y X, Lan M F, Wang Y, et al. Microstructure and texture evolution of thin-gauge non-oriented silicon steel with high permeability produced by twin-roll strip casting[J]. Materials Characterization, 2019, 150: 118-127. |

| [1] | 代峰, 柳静献. 钢铁企业除尘用涤纶滤料在复杂烟气环境下的老化行为分析[J]. 东北大学学报(自然科学版), 2024, 45(6): 883-889. |

| [2] | 杨庭松, 黄敦亮, 孙文权, 何安瑞. 电磁调控轧辊的热力胀形行为及高效控制方法[J]. 东北大学学报(自然科学版), 2024, 45(5): 660-667. |

| [3] | 刘佳琪, 李小彭, 尹猛, 周赛男. 变长度柔性机械臂的双柔性伺服驱动系统振动抑制策略[J]. 东北大学学报(自然科学版), 2024, 45(4): 530-539. |

| [4] | 张朝, 张欣欣. 政府和钢铁企业间行为策略的演化博弈分析——有机朗肯循环技术推广[J]. 东北大学学报(自然科学版), 2022, 43(11): 1653-1661. |

| [5] | 胡悦嫣, 黄敏, 贾大宇, 高哲明. 基于区块链技术的钢铁企业全流程数据管理[J]. 东北大学学报(自然科学版), 2022, 43(11): 1552-1560. |

| [6] | 李小彭, 尚东阳, 李凡杰, 闻邦椿. 输电线巡检机器人位姿变化的柔性关节控制策略[J]. 东北大学学报:自然科学版, 2020, 41(11): 1577-1583. |

| [7] | 连静, 范悟明, 李琳辉, 袁鲁山. 基于道路工况分析的HEV控制策略优化方法[J]. 东北大学学报:自然科学版, 2017, 38(4): 551-556. |

| [8] | 顾晓薇, 秦宗琛, 王青, 王凤波. 我国铁矿消费强度与钢铁冶炼及加工业的关系[J]. 东北大学学报:自然科学版, 2017, 38(3): 410-413. |

| [9] | 李小玲, 孙文强, 赵亮, 蔡九菊. 典型钢铁企业物能消耗与烟粉尘排放分析[J]. 东北大学学报:自然科学版, 2016, 37(3): 352-356. |

| [10] | 杨靖辉, 蔡九菊, 刘精宇, 孙文强. 煤气系统供需预测及剩余煤气优化分配[J]. 东北大学学报:自然科学版, 2015, 36(8): 1125-1129. |

| [11] | 刘精宇, 柴少轩, 常勇. 钢铁企业自发电与外购国家电网电之间的经济利益[J]. 东北大学学报:自然科学版, 2015, 36(7): 980-984. |

| [12] | 刘精宇, 常勇. 拓扑结构在钢铁企业发电节点网络的应用[J]. 东北大学学报:自然科学版, 2015, 36(2): 241-244. |

| [13] | 杨靖辉, 蔡九菊, 黄健, 孙文强. 基于动态设计方法的钢铁企业煤气柜柜容研究[J]. 东北大学学报:自然科学版, 2015, 36(12): 1724-1728. |

| [14] | 李旭东, 袁国, 江潇, 王国栋. 热轧带钢X80超快冷出口温度高精度控制方法[J]. 东北大学学报:自然科学版, 2015, 36(10): 1431-1435. |

| [15] | 蓝海燕,戢守峰,唐金环,朱宝琳. 基于改进EOQ的碳约束条件下三级生产-库存控制策略[J]. 东北大学学报:自然科学版, 2014, 35(11): 1659-1663. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||