东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (8): 1096-1106.DOI: 10.12068/j.issn.1005-3026.2024.08.005

宋翰生, 马辉, 刘子濛, 黄文康

收稿日期:2023-03-24

出版日期:2024-08-15

发布日期:2024-11-12

作者简介:宋翰生(1999-),男,黑龙江哈尔滨人,东北大学硕士研究生基金资助:Han-sheng SONG, Hui MA, Zi-meng LIU, Wen-kang HUANG

Received:2023-03-24

Online:2024-08-15

Published:2024-11-12

摘要:

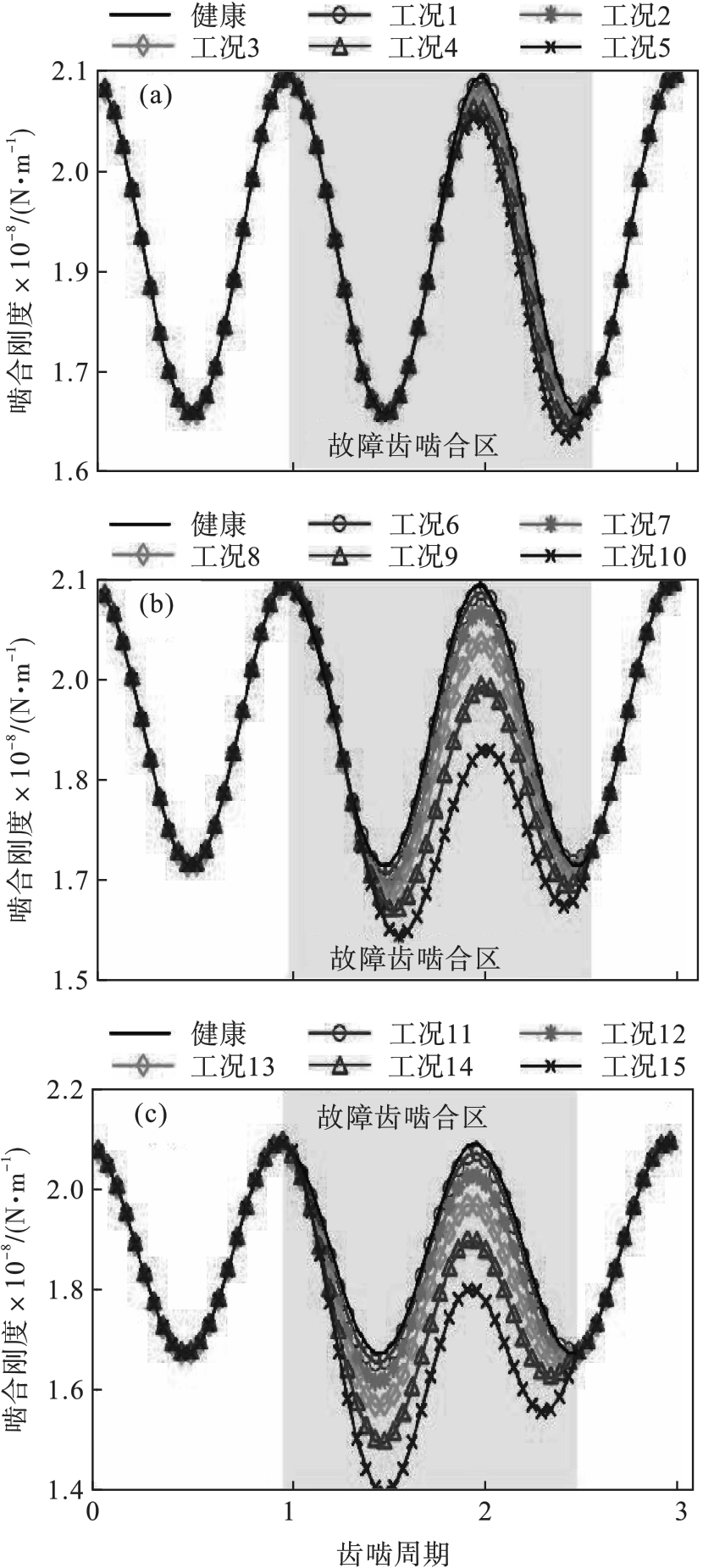

在重载和交变载荷工况下,弧齿锥齿轮易产生齿根裂纹导致轮齿断裂,需明晰裂纹对啮合特性的影响机理,为故障诊断提供理论基础.利用ANSYS软件对弧齿锥齿轮齿副进行静态接触仿真分析.通过单元节点替换的方法设置了多种裂纹类型的故障模型,探讨了裂纹对弧齿锥齿轮副啮合特性的影响.研究结果表明:当轮齿接触椭圆移动到轮齿裂纹区域,啮合刚度随着裂纹的严重程度增加而逐渐下降,平面裂纹工况、空间裂纹工况和断齿工况的刚度最大下降量分别为27.58%,14.12%,32.82%.轮齿啮合的接触椭圆位置、裂纹位置以及深度会使齿面接触应力以及齿根弯曲应力产生不同的增减趋势.

中图分类号:

宋翰生, 马辉, 刘子濛, 黄文康. 含有不同裂纹类型的弧齿锥齿轮副啮合特性分析[J]. 东北大学学报(自然科学版), 2024, 45(8): 1096-1106.

Han-sheng SONG, Hui MA, Zi-meng LIU, Wen-kang HUANG. Meshing Characteristics Analysis of Spiral Bevel Gear Pairs with Different Crack Types[J]. Journal of Northeastern University(Natural Science), 2024, 45(8): 1096-1106.

| 工况 | 弧长 | |

|---|---|---|

| 齿宽方向 | 齿厚方向 | |

| 工况1 | W/3 | P/6 |

| 工况2 | W/3 | P/3 |

| 工况3 | W/3 | P/2 |

| 工况4 | W/3 | 2P/3 |

| 工况5 | W/3 | 5P/6 |

| 工况6 | 2W/3 | P/6 |

| 工况7 | 2W/3 | P/3 |

| 工况8 | 2W/3 | P/2 |

| 工况9 | 2W/3 | 2P/3 |

| 工况10 | 2W/3 | 5P/6 |

| 工况11 | W | P/6 |

| 工况12 | W | P/3 |

| 工况13 | W | P/2 |

| 工况14 | W | 2P/3 |

| 工况15 | W | 5P/6 |

表1 平面裂纹工况参数

Table 1 Parameters of plane crack working conditions

| 工况 | 弧长 | |

|---|---|---|

| 齿宽方向 | 齿厚方向 | |

| 工况1 | W/3 | P/6 |

| 工况2 | W/3 | P/3 |

| 工况3 | W/3 | P/2 |

| 工况4 | W/3 | 2P/3 |

| 工况5 | W/3 | 5P/6 |

| 工况6 | 2W/3 | P/6 |

| 工况7 | 2W/3 | P/3 |

| 工况8 | 2W/3 | P/2 |

| 工况9 | 2W/3 | 2P/3 |

| 工况10 | 2W/3 | 5P/6 |

| 工况11 | W | P/6 |

| 工况12 | W | P/3 |

| 工况13 | W | P/2 |

| 工况14 | W | 2P/3 |

| 工况15 | W | 5P/6 |

| 工况 | 角度方向角/(°) | 齿厚方向弧长 |

|---|---|---|

| 工况1 | α1 | S/6 |

| 工况2 | α1 | S/3 |

| 工况3 | α1 | S/2 |

| 工况4 | α1 | 2S/3 |

| 工况5 | α1 | 5S/6 |

| 工况6 | α2 | S/6 |

| 工况7 | α2 | S/3 |

| 工况8 | α2 | S/2 |

| 工况9 | α2 | 2S/3 |

| 工况10 | α2 | 5S/6 |

| 工况11 | α3 | S/6 |

| 工况12 | α3 | S/3 |

| 工况13 | α3 | S/2 |

| 工况14 | α3 | 2S/3 |

| 工况15 | α3 | 5S/6 |

| 工况16 | α1 | 断齿 |

| 工况17 | α2 | 断齿 |

| 工况18 | α3 | 断齿 |

表2 空间裂纹工况参数

Table 2 Parameters of space crack working conditions

| 工况 | 角度方向角/(°) | 齿厚方向弧长 |

|---|---|---|

| 工况1 | α1 | S/6 |

| 工况2 | α1 | S/3 |

| 工况3 | α1 | S/2 |

| 工况4 | α1 | 2S/3 |

| 工况5 | α1 | 5S/6 |

| 工况6 | α2 | S/6 |

| 工况7 | α2 | S/3 |

| 工况8 | α2 | S/2 |

| 工况9 | α2 | 2S/3 |

| 工况10 | α2 | 5S/6 |

| 工况11 | α3 | S/6 |

| 工况12 | α3 | S/3 |

| 工况13 | α3 | S/2 |

| 工况14 | α3 | 2S/3 |

| 工况15 | α3 | 5S/6 |

| 工况16 | α1 | 断齿 |

| 工况17 | α2 | 断齿 |

| 工况18 | α3 | 断齿 |

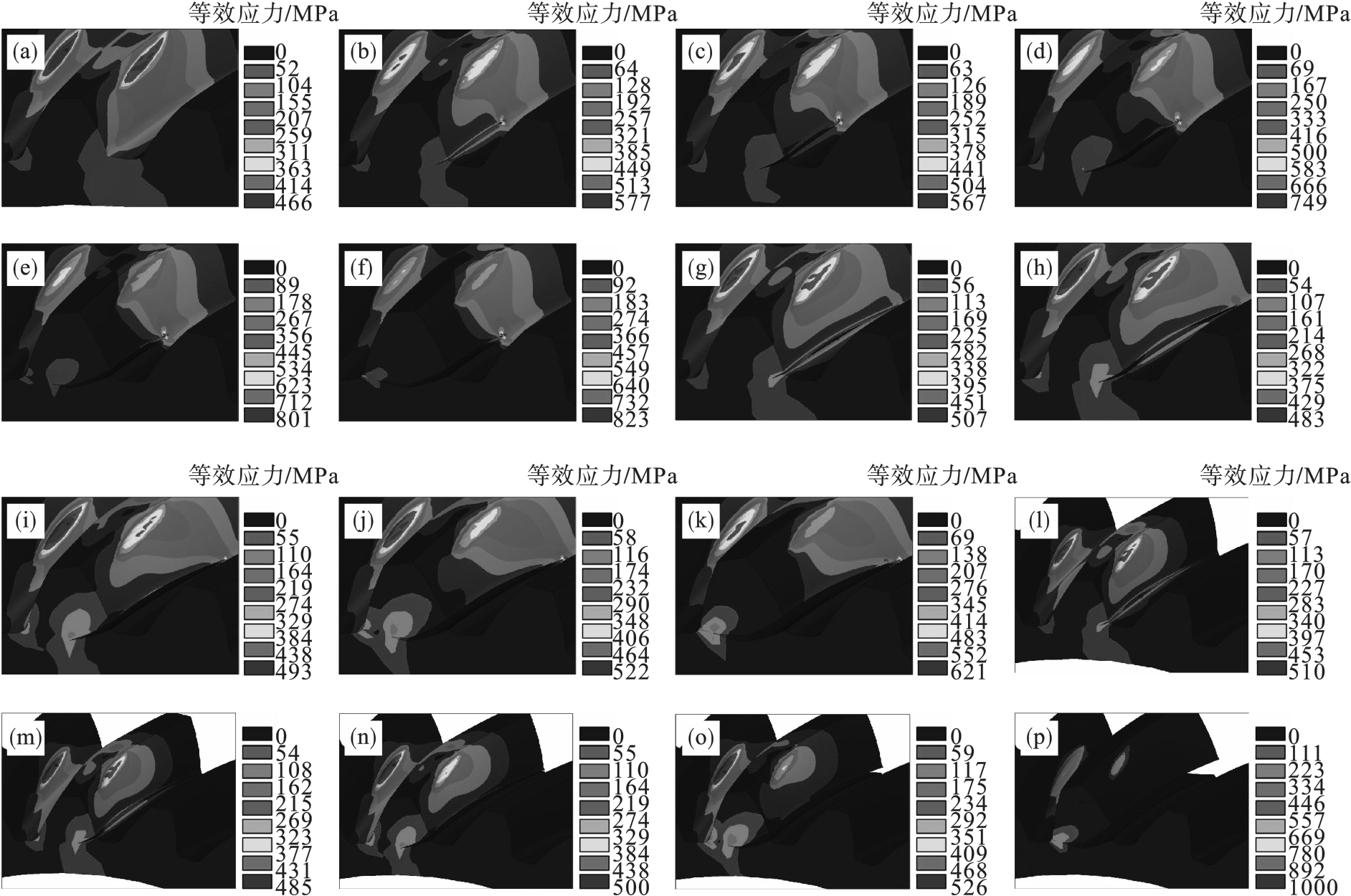

图9 健康状态以及平面裂纹工况下轮齿等效应力云图(a)—健康; (b)—工况1; (c)—工况2; (d)—工况3; (e)—工况4; (f)—工况5; (g)—工况6; (h)—工况7; (i)—工况8;(j)—工况9; (k)—工况10; (l)—工况11; (m)—工况12; (n)—工况13; (o)—工况14; (p)—工况15.

Fig. 9 Equivalent stress nephogram of gear teeth under the good and plane crack working conditions

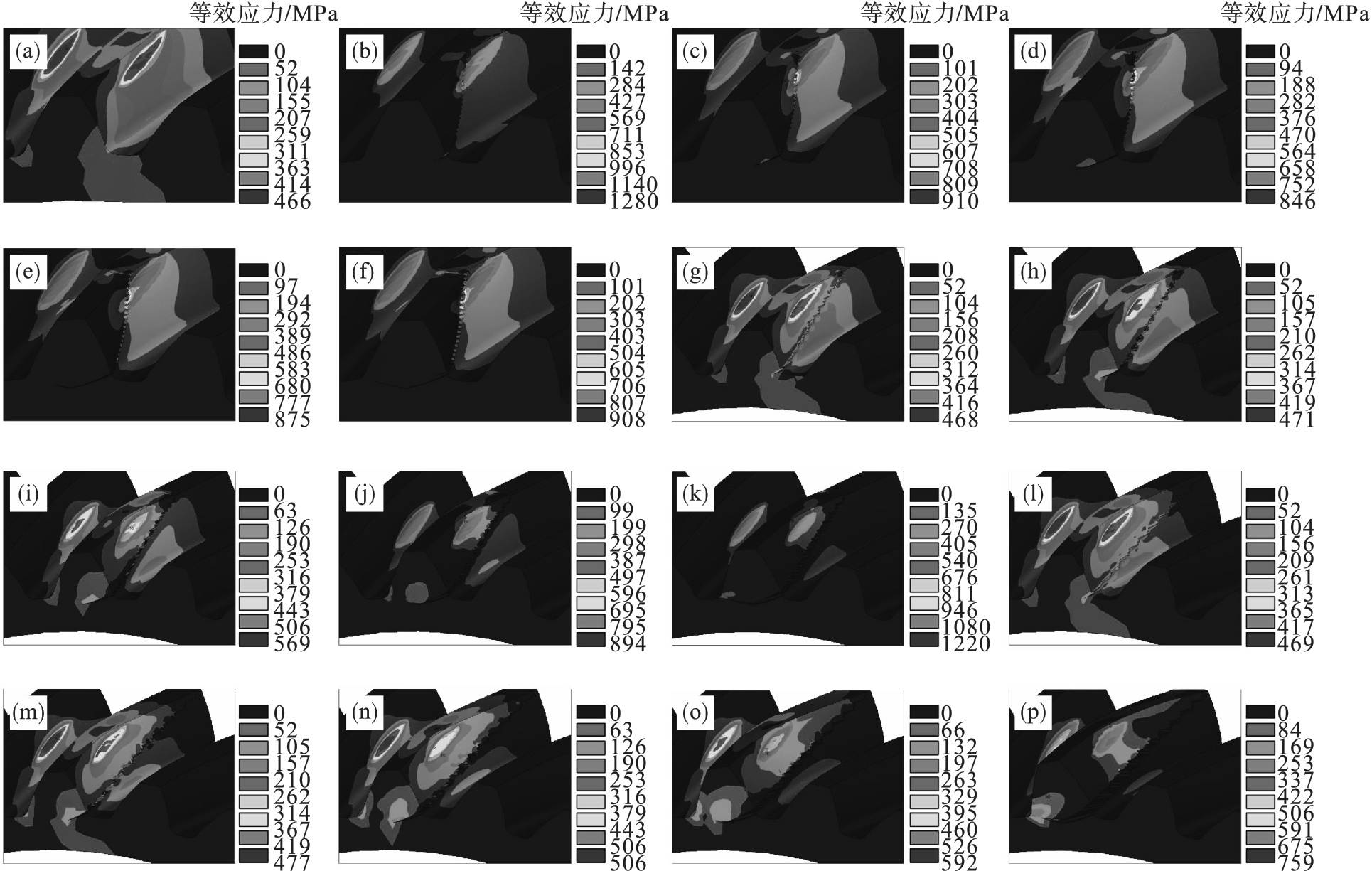

图10 健康状态以及空间裂纹工况下轮齿等效应力云图(a)—健康; (b)—工况1; (c)—工况2; (d)—工况3; (e)—工况4; (f)—工况5; (g)—工况6; (h)—工况7; (i)—工况8;(j)—工况9; (k)—工况10; (l)—工况11; (m)—工况12; (n)—工况13; (o)—工况14; (p)—工况15.

Fig. 10 Equivalent stress nephogram of gear teeth under the good and spatial crack working conditions

图13 健康状态以及不同空间裂纹工况下轮齿啮合刚度(a)—工况1~5; (b)—工况6~10; (c)—工况11~15.

Fig. 13 Gear tooth meshing stiffness under the good and different space crack working conditions

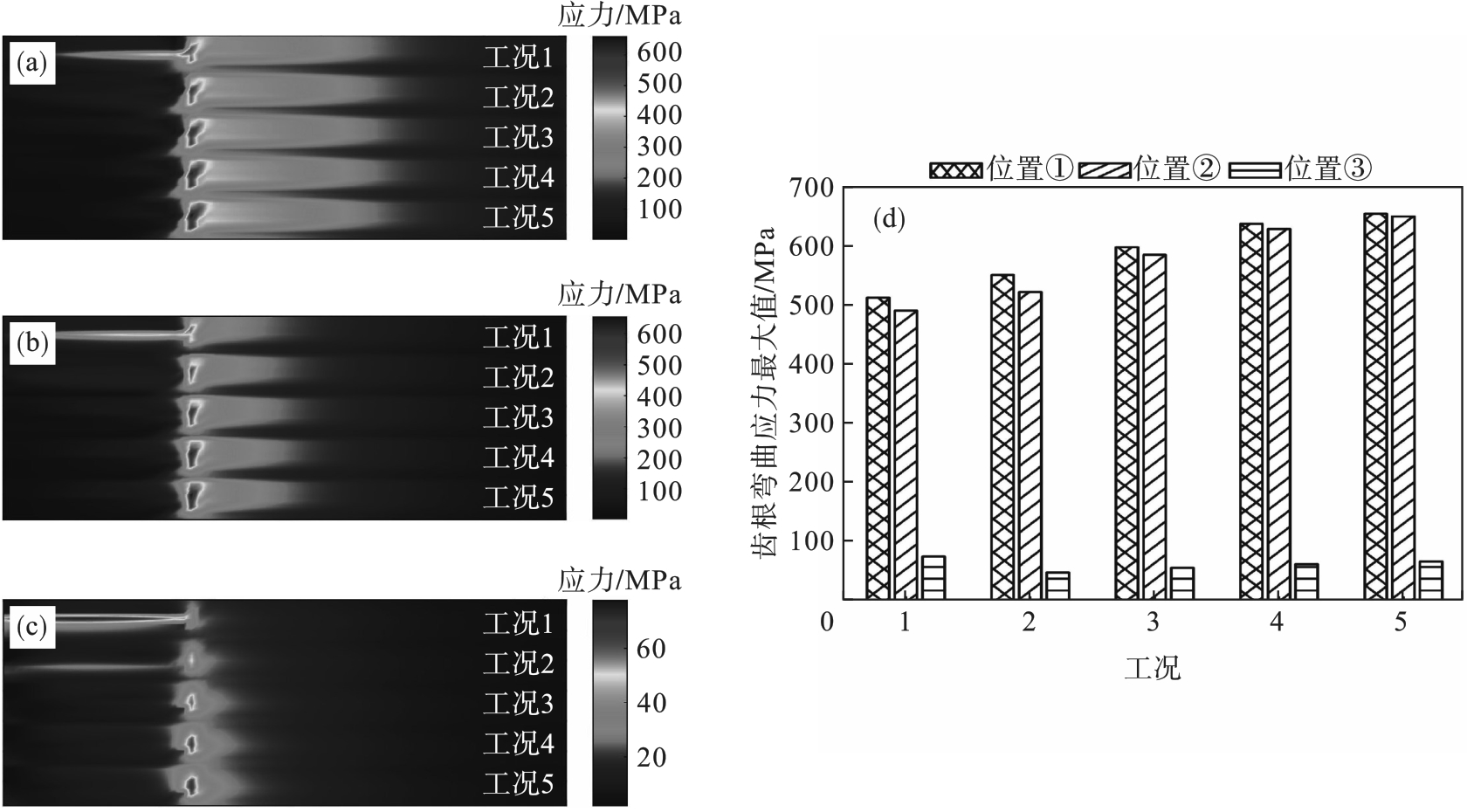

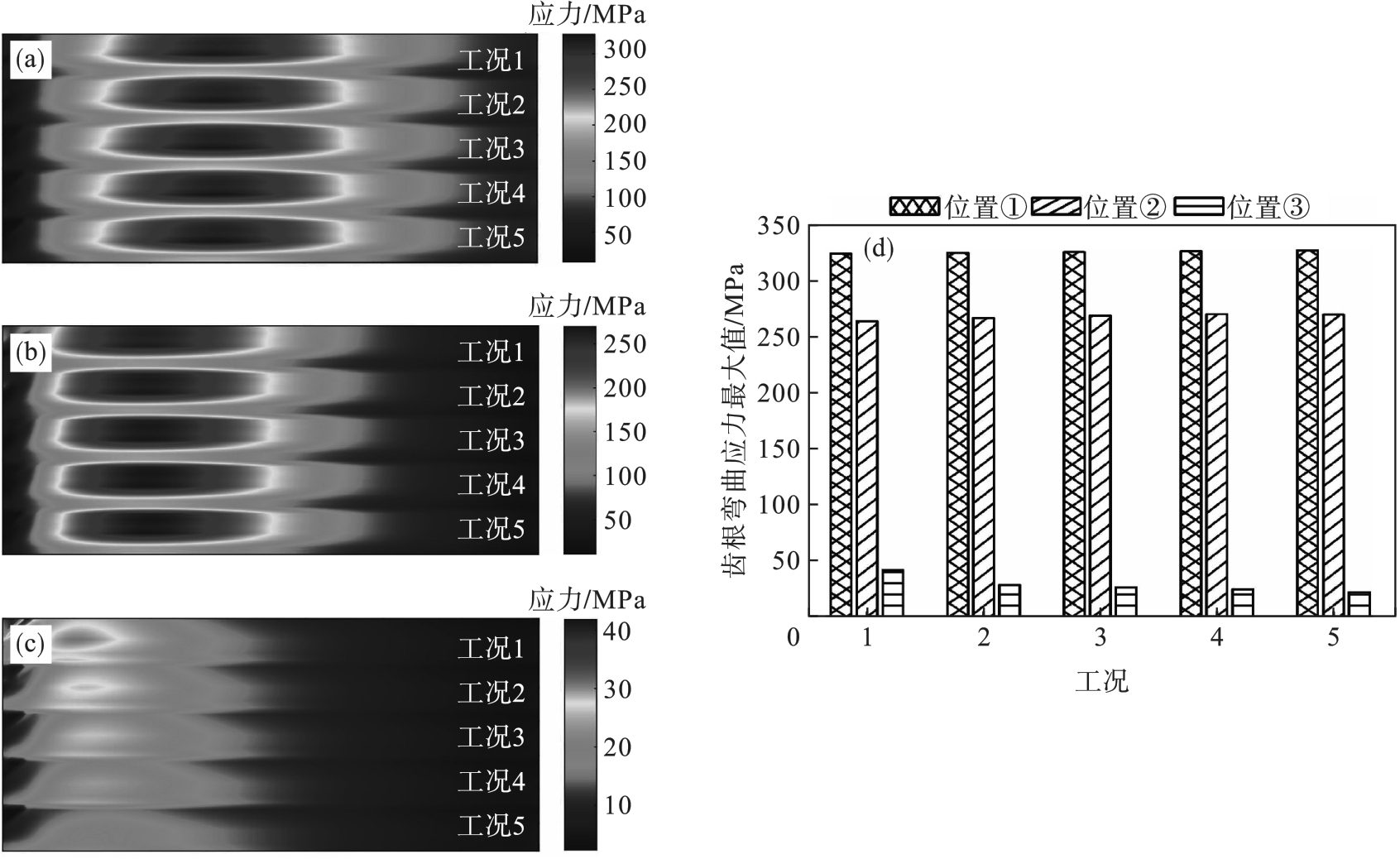

图17 平面裂纹工况1~5各位置齿根弯曲应力(a)—位置①应力云图; (b)—位置②应力云图; (c)—位置③应力云图; (d)—应力最大值.

Fig. 17 Bending stress at tooth root of every position under plane crack working conditions 1~5

图19 空间裂纹工况1~5各位置齿根弯曲应力(a)—位置①应力云图; (b)—位置②应力云图; (c)—位置③应力云图; (d)—应力最大值.

Fig. 19 Bending stress at the tooth root of every position under spatial crack working conditions 1~5

| 1 | Zhou C J, Li Z D, Hu B,et al.Analytical solution to bending and contact strength of spiral bevel gears in consideration of friction[J].International Journal of Mechanical Sciences,2017,128/129:475-485. |

| 2 | Hou X Y, Fang Z D, Zhang X J.Static contact analysis of spiral bevel gear based on modified VFIFE (vector form intrinsic finite element) method[J].Applied Mathematical Modelling,2018,60:192-207. |

| 3 | Mu Y M, Li W L, Fang Z D.Tooth surface modification method of face.milling spiral bevel gears with high contact ratio based on cutter blade profile correction[J].The International Journal of Advanced Manufacturing Technology,2020,106(7):3229-3237. |

| 4 | Pei X, Pu W, Wang Z Z.Contact stiffness and dynamic behavior caused by surface defects of spiral bevel gear in mixed lubrication[J].Engineering Failure Analysis,2021,121:105129. |

| 5 | Wang Z Z, Pu W, Pei X,et al.Nonlinear dynamical behaviors of spiral bevel gears in transient mixed lubrication[J].Tribology International,2021,160:107022. |

| 6 | Hu Z H, Ding H, Peng S D,et al.Numerical determination to loaded tooth contact performances in consideration of misalignment for the spiral bevel gears[J].International Journal of Mechanical Sciences,2019,151:343-355. |

| 7 | Spievak L E, Wawrzynek P A, Ingraffea A R,et al.Simulating fatigue crack growth in spiral bevel gears[J].Engineering Fracture Mechanics,2000,68(1):53-76. |

| 8 | Ural A, Heber G, Wawrzynek P A,et al.Three dimensional,parallel,finite element simulation of fatigue crack growth in a spiral bevel pinion gear[J].Engineering Fracture Mechanics,2005,72(8):1148-1170. |

| 9 | Lewicki D G, Handschuh R F, Spievak L E,et al.Consideration of moving tooth load in gear crack propagation predictions[J].Journal of Mechanical Design,2001,123(1):118-124. |

| 10 | Park M.Failure analysis of an accessory bevel gear installed on a J69 turbojet engine[J].Engineering Failure Analysis,2003,10(3):371-382. |

| 11 | Böhme S A, Keski‑Rahkonen J, Komssi T.A standardizable approach for tooth flank fracture[J].Forschung Im Ingenieurwesen,2022,86(4):693-708. |

| 12 | 栾孝驰,沙云东,郭小鹏,等.航空发动机高速锥齿轮瞬态动力学分析与试验研究[J].推进技术,2019,40(12):2806-2815. |

| Luan Xiao‑chi, Sha Yun‑dong, Guo Xiao‑peng,et al.Transient dynamic analysis and experimental study on high‑speed bevel gear of aero‑engine[J].Journal of Propulsion Technology,2019,40(12):2806-2815. | |

| 13 | 栾孝驰,沙云东,郭小鹏,等.装配参数对附件机匣锥齿轮破裂故障的影响[J].中国机械工程,2020,31(4):438-444. |

| Luan Xiao‑chi, Sha Yun‑dong, Guo Xiao‑peng,et al.Influence of assembly parameters on fracture failure of bevel gear of accessory casing[J].Chinese Journal of Mechanical Engineering,2020,31(4):438-444. | |

| 14 | Litvin F L.Gear geometry and applied theory[M].Englewood Cliffs:Prentice‑Hall,1994:634-645. |

| 15 | Vukelic G, Pastorcic D, Vizentin G,et al.Failure investigation of a crane gear damage[J].Engineering Failure Analysis,2020,115:104613. |

| 16 | Han H Z, Ma H, Wang H X,et al.Dynamic simulation of cracked spiral bevel gear pair considering assembly errors[J].Machines,2022,10(10):929-953. |

| 17 | Yang D L, Chen L M, Jiang L L,et al.Research on the influence of time‑varying excitation on vibration characteristics of the spiral bevel geared transmission system with broken teeth[J].Shock and Vibration,2021,2021:8880851. |

| 18 | 冯刚,李彦彬,高虹霓,等.裂纹对弧齿锥齿轮接触应力影响研究[J].机械强度,2014,36(4):631-635. |

| Feng Gang, Li Yan‑bin, Gao Hong‑ni,et al.Research on influence of cracks on contact stress of spiral bevel gears [J].Journal of Mechanical Strength,2014,36(4):631-635. |

| [1] | 马辉, 高昂, 杨天瑞, 官宏. 止口及螺栓对法兰盘结构静力学特性的影响[J]. 东北大学学报(自然科学版), 2022, 43(10): 1438-1445. |

| [2] | 马辉, 赵百顺, 皇甫一樊, 韩晨怡. 不对中工况下的修形齿轮副啮合特性分析[J]. 东北大学学报:自然科学版, 2020, 41(11): 1609-1614. |

| [3] | 马辉, 段田堂, 孙衍宁, 陈康康. 齿顶修形行星轮系啮合刚度分析[J]. 东北大学学报:自然科学版, 2019, 40(3): 380-385. |

| [4] | 秦大同, 任菲, 吴晓铃. 太阳轮偏心误差对人字齿行星传动动态特性影响[J]. 东北大学学报:自然科学版, 2015, 36(5): 709-714. |

| [5] | 马辉, 王迪, 能海强, 太兴宇. 压气机盘片榫连结构接触特性分析[J]. 东北大学学报:自然科学版, 2015, 36(1): 109-113. |

| [6] | 马辉,逄旭,宋溶泽,杨健. 基于改进能量法的直齿轮时变啮合刚度计算[J]. 东北大学学报:自然科学版, 2014, 35(6): 863-867. |

| [7] | 马辉,能海强,宋溶泽,唐玉生. 两种工况下锻压组合机架的接触特性分析[J]. 东北大学学报(自然科学版), 2013, 34(9): 1300-1304. |

| [8] | 薛建华,李威. 齿廓修形机理及其对温度场的影响[J]. 东北大学学报(自然科学版), 2013, 34(12): 1763-1767. |

| [9] | 戴继双;马辉;李朝峰;闻邦椿;. 含增速齿轮的转子系统固有特性研究[J]. 东北大学学报(自然科学版), 2011, 32(9): 1299-1303. |

| [10] | 宋雪萍;于涛;李国平;闻邦椿. 齿轮轴系弯扭耦合振动特性[J]. 东北大学学报(自然科学版), 2005, 26(10): 990-993. |

| [11] | 王若玲. 我校弧齿锥齿轮研究达到国际先进水平[J]. 东北大学学报:自然科学版, 1994, 15(3): 1--. |

| [12] | -. 《东北工学院学报》第14卷(1993年)总目次[J]. 东北大学学报:自然科学版, 1993, 14(6): 627-636. |

| [13] | 陈良玉;鄂中凯;郭星辉;王延忠. 弧齿锥齿轮离心应力和变形[J]. 东北大学学报:自然科学版, 1993, 14(6): 543-545. |

| [14] | 陈良玉;鄂中凯;郭星辉;王延忠;林基恕;常春江. 弧齿锥齿轮离心应力分析[J]. 东北大学学报:自然科学版, 1993, 14(5): 536--. |

| [15] | 陈良玉;鄂中凯;顾群;王延忠. 弧齿锥齿轮齿面和过渡曲面的方程与数值计算[J]. 东北大学学报:自然科学版, 1993, 14(5): 455-459. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||