东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (7): 131-138.DOI: 10.12068/j.issn.1005-3026.2025.20250081

• 绿色冶金 • 上一篇

收稿日期:2025-07-02

出版日期:2025-07-15

发布日期:2025-09-24

通讯作者:

乐启炽

作者简介:王 强(1971—),男,山东烟台人,东北大学教授,博士生导师

Qiang WANG, Qi-chi LE( ), Xiang-jie WANG

), Xiang-jie WANG

Received:2025-07-02

Online:2025-07-15

Published:2025-09-24

Contact:

Qi-chi LE

摘要:

大型高性能金属产品是高端装备制造业发展的基础和先导,但我国大型铸坯传统制备方法普遍存在夹杂、偏析、晶粒粗大以及裂纹等铸造缺陷,导致坯料冶金质量和成材率低等问题,无法满足大规格高端金属产品加工制造要求.因此,研发大型铸坯冶金质量调控新技术,攻克坯料洁净化、均质化、细晶化和低应力铸造难题是突破困境的有效途径.东北大学历经二十余年产学研用协同攻关,在大型坯料制备过程中利用电磁场独特效应,精准调控坯料制备过程凝固行为,完成了电磁调控技术全链条创新,构建了大型金属坯料制备电磁调控理论,研发出了电磁调控核心技术和装备,成功制备了系列大型高品质钢、镁合金和铝合金坯料,推动了高端材料制备技术的进步.

中图分类号:

王强, 乐启炽, 王向杰. 大型金属坯料制备电磁调控关键共性技术开发和应用[J]. 东北大学学报(自然科学版), 2025, 46(7): 131-138.

Qiang WANG, Qi-chi LE, Xiang-jie WANG. Development and Application of Key Generic Technologies for Electromagnetic Regulation in Large-Sized Metal Billet Preparation[J]. Journal of Northeastern University(Natural Science), 2025, 46(7): 131-138.

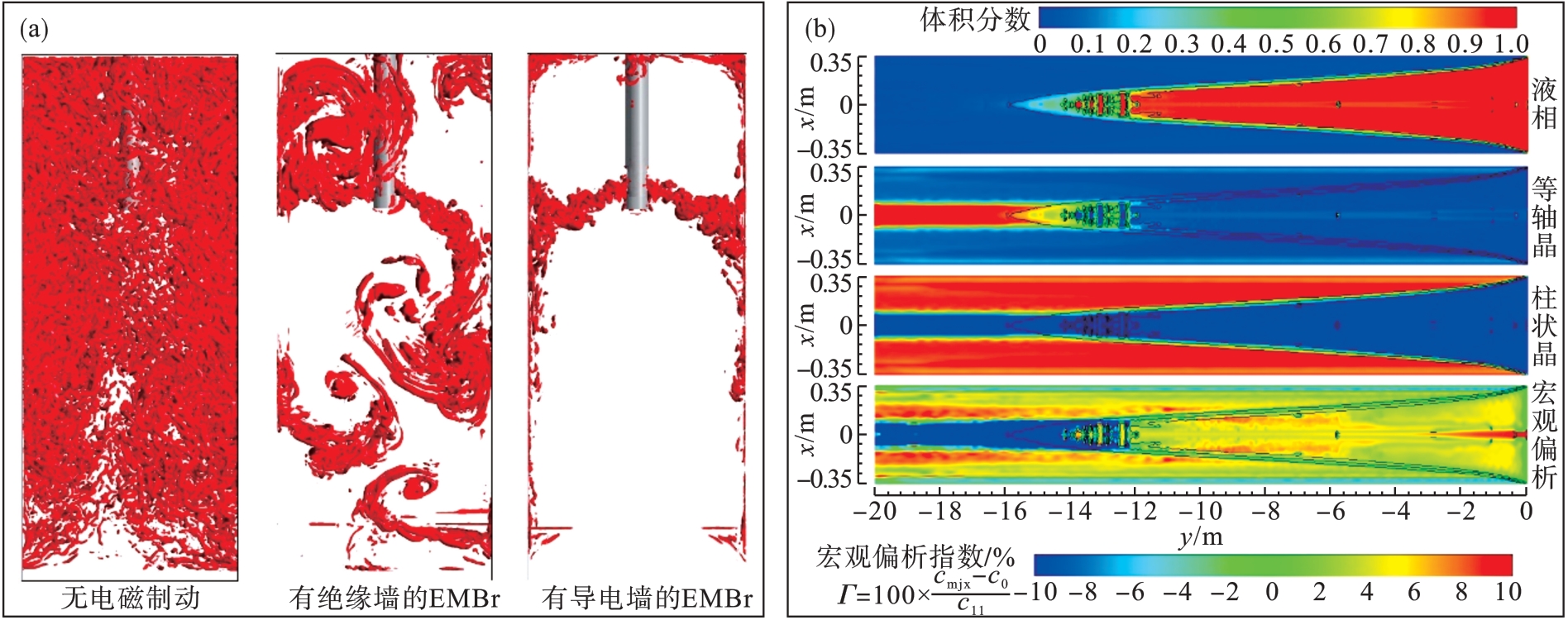

图1 大型坯料多相多尺度多场耦合三维数值模拟[16-17](a)—Q准则瞬时等值面(500 s-2); (b)—相体积分数及宏观偏析指数.

Fig.1 Three-dimensional numerical simulation of multiphase,multiscale,and multifield coupling for large-sized billets [16-17]

| [1] | Guo S J, Le Q C, Zhao Z H, et al. Microstructural refinement of DC cast AZ80 Mg billets by low frequency electromagnetic vibration[J]. Materials Science and Engineering: A, 2005, 404(1/2): 323-329. |

| [2] | 冯士超, 王艳红, 丁瑞锋. 国内外电磁连铸技术应用研究进展[J]. 上海金属, 2014, 36(3): 47-50,55. |

| Feng Shi-chao, Wang Yan-hong, Ding Rui-feng. Progress in investigation of electromagnetic technology application in continuous casting both at home and abroad [J]. Shanghai Metals, 2014, 36(3): 47-50,55. | |

| [3] | Vives C. Electromagnetic refining of aluminum alloys by the CREM process: part II. specific practical problems and their solutions[J]. Metallurgical Transactions B, 1989, 20(5): 631-643. |

| [4] | Le Q C, Zhang Z Q, Cui J Z. Effects of electromagnetic field and lubricate condition on the surface quality of magnesium alloy billet during LFEC processing[J]. Science in China Series E: Technological Sciences, 2009, 52(1): 180-185. |

| [5] | 和玉晓, 张志强, 宝磊, 等. 低频电磁半连续铸造AC52锭坯[J]. 特种铸造及有色合金, 2013, 33(4):357-360. |

| He Yu-xiao, Zhang Zhi-qiang, Bao Lei, et al. Low frequency electromagnetic semi-continuous casting AC52 magnesium alloy billets[J]. Special Casting & Nonferrous Alloys, 2013, 33(4): 357-360. | |

| [6] | 吴春雷, 刘晓明, 李德伟, 等. 电磁旋流水口连铸技术研究进展[J]. 连铸, 2022, 47(4): 8-15. |

| Wu Chun-lei, Liu Xiao-ming, Li De-wei, et al. Study and development on electromagnetic nozzle swirling flow technology in continuous casting[J]. Continuous Casting, 2022, 47(4): 8-15. | |

| [7] | 贾永辉. 镁合金新型电磁半连铸的瞬态耦合数值模拟及大扁坯制备研究[D]. 沈阳:东北大学, 2022. |

| Jia Yong-hui. Transient coupled numerical simulation of novel electromagnetic semi-continuous casting for magnesium alloy and research on large flat billet preparation [D]. Shenyang: Northeastern University, 2022. | |

| [8] | Liao Q Y, Le Q C, Zhao D Z, et al. Research progress on semi-continuous casting of magnesium alloys under external field[J]. China Foundry, 2024, 21(5): 516-524. |

| [9] | Jia Y H, Chen X R, Le Q C, et al. Numerical study on action of HMF, PMF, DHMF, and DPMF on molten metal during electromagnetic casting[J]. The International Journal of Advanced Manufacturing Technology, 2019, 103(1): 201-217. |

| [10] | Jia Y H, Hou J, Wang H, et al. Effects of an oscillation electromagnetic field on grain refinement and Al8Mn5 phase formation during direct-chill casting of AZ31B magnesium alloy[J]. Journal of Materials Processing Technology, 2020, 278: 116542. |

| [11] | 孙延文, 刘晓明, 牟望重, 等. 应用电磁旋流水口技术调控连铸板坯流场的研究[C]//第十二届中国金属学会青年学术年会暨首届“碳中和”冶金青年科学家沙龙论文集(一). 赣州, 2024: 219. |

| Sun Yan-wen, Liu Xiao-ming, Mu Wang-zhong, et al. Research on regulating the flow field of continuous casting slabs by applying electromagnetic rotary water inlet technology[C]// Proceedings of the 12th China Metallurgical Society Youth Academic Annual Conference and the First “Carbon Neutrality” Metallurgical Young Scientists’ Salon (1). Ganzhou, 2024: 219.) | |

| [12] | Li G J, Wang H M, Wang Q, et al. Structure and properties of Co-doped ZnO films prepared by thermal oxidization under a high magnetic field[J]. Nanoscale Research Letters, 2015, 10(1): 112. |

| [13] | 刘晓明, 刘泽熠, 张思远, 等. 电磁旋流及其多级耦合电磁驱动技术研发与应用[C]//第十二届中国金属学会青年学术年会暨首届“碳中和”冶金青年科学家沙龙论文集(一). 赣州, 2024: 220. |

| Liu Xiao-ming, Liu Ze-yi, Zhang Si-yuan, et al. Research and application of electromagnetic swirl and its multi-stage coupled electromagnetic drive technology[C]// Proceedings of the 12th China Metallurgical Society Youth Academic Annual Conference and the First “Carbon Neutrality” Metallurgical Young Scientists’ Salon (1). Ganzhou, 2024: 220.) | |

| [14] | Wu C L, Li D W, Zhu X W, et al. Experimental study of macrostructure and segregation by a novel electromagnetic nozzle swirling flow combined with electromagnetic stirring in continuous casting[J]. Metallurgical and Materials Transactions B, 2021, 52(3): 1207-1212. |

| [15] | Yuan S, Zhao Y, Chen W B, et al. Self-assembled 3D hierarchical porous Bi2MoO6 microspheres toward high capacity and ultra-long-life anode material for Li-ion batteries[J]. ACS Applied Materials & Interfaces, 2017, 9(26): 21781-21790. |

| [16] | Liu Z Q, Vakhrushev A, Wu M H, et al. Effect of an electrically-conducting wall on transient magnetohydrodynamic flow in a continuous-casting mold with an electromagnetic brake [J]. Metals, 2018, 8(8): 609. |

| [17] | 姚毓超,刘中秋,荣文杰,等. 喂钢带碳浓度对连铸大圆坯宏观偏析的影响[J]. 东北大学学报(自然科学版). 2024, 45(4): 499-506. |

| Yao Yu-chao, Liu Zhong-qiu, Rong Wen-jie, et al. Effect of feeding steel strip carbon content on macrosegregation distribution in large continuous casting round bloom [J]. Journal of Northeastern University (Natural Science) 2024, 45(4): 499-506. | |

| [18] | Hou J, Le Q C, Chen L, et al. Domination and effect of multi-parameters in direct chill casting based on establishment of thermo model by numerical simulation and experiment[J]. Journal of Materials Research and Technology, 2023, 27: 6619-6644. |

| [19] | 徐大召, 孟令刚, 杨春峰, 等. 高性能铝合金外场辅助半连续铸造研究进展[J]. 中国材料进展,2022,41(11):880-890. |

| Xu Da-zhao, Meng Ling-gang, Yang Chun-feng, et al. Research progress of external field assisted semi-continuous casting for high performance aluminum alloys[J]. Materials China, 2022, 41(11): 880-890. | |

| [20] | Liu T, Wang Q, Gao A, et al. Fabrication of functionally graded materials by a semi-solid forming process under magnetic field gradients[J]. Scripta Materialia, 2007, 57(11): 992-995. |

| [21] | Jia Y H, Le Q C, Liao Q Y, et al. The effect of frequency on solidification characteristics of AZ80 alloy during electromagnetic DC casting[J]. Materials Research Express, 2019, 6(12): 126549. |

| [22] | Wang Q, Liu Y, Liu T, et al. Magnetostriction of TbFe2-based alloy treated in a semi-solid state with a high magnetic field[J]. Applied Physics Letters, 2012, 101(13): 132406. |

| [23] | Li D W, Su Z J, Chen J, et al. Effects of electromagnetic swirling flow in submerged entry nozzle on square billet continuous casting of steel process[J]. ISIJ International, 2013, 53(7): 1187-1194. |

| [24] | 石红燕, 吴春雷, 刘利, 等. 电磁旋流水口对圆坯结晶器液面波动的控制[J]. 连铸, 2021, 46(6): 24-28. |

| Shi Hong-yan, Wu Chun-lei, Liu Li, et al. Liquid level fluctuation in mold controlled by electromagnetic nozzle swirling flow in continuous casting of round bloom[J].Continuous Casting, 2021, 46(6): 24-28. | |

| [25] | Zhu Q F, Zhao Z H, Zuo Y B, et al. The effect of grain refiner and combined electro-magnetic field on grain evolution of horizontal direct chill casting 7075 aluminum alloy[J]. International Journal of Materials Research, 2010, 101(3): 380-385. |

| [26] | Jia Y H, Chen X R, Le Q C, et al. Macro-physical field of large diameter magnesium alloy billet electromagnetic direct-chill casting: a comparative study[J]. Journal of Magnesium and Alloys, 2020, 8(3): 716-730. |

| [27] | Jia Y H, Wang H, Le Q C. Transient coupling simulation of multi-physical field during pulse electromagnetic direct-chill casting of AZ80 magnesium alloy[J]. International Journal of Heat and Mass Transfer, 2019, 143: 118524. |

| [1] | 杨酉坚, 齐俊峰, 庞小娟, 王兆文. 冶金级氧化铝颗粒磨损指数分析[J]. 东北大学学报(自然科学版), 2021, 42(6): 801-806. |

| [2] | 王宁, 李宝宽, 齐凤升, 张晓明. 蝶式感应加热中间包流场与升温特性[J]. 东北大学学报(自然科学版), 2021, 42(12): 1724-1730. |

| [3] | 杨酉坚, 李有才, 王兆文, 石忠宁. 铝电解中氧化铝溶解过程及结壳行为[J]. 东北大学学报(自然科学版), 2021, 42(1): 55-61. |

| [4] | 郝国成, 锅娟, 谭淞元, 曾佐勋5. 混沌参数优化RBF算法的震前ENPEMF信号强度趋势预测[J]. 东北大学学报:自然科学版, 2020, 41(12): 1692-1698. |

| [5] | 牛大鹏, 臧雅丽, 贾明兴. 基于案例推理的湿法冶金全流程优化设定[J]. 东北大学学报:自然科学版, 2020, 41(1): 1-6. |

| [6] | 翟莹莹, 厉英, 敖志广. 基于改进多目标遗传算法的连铸二冷过程优化[J]. 东北大学学报:自然科学版, 2019, 40(5): 658-662. |

| [7] | 傅大学, 张廷安, 豆志河, 关录奎. 球团预制-硅热还原炼镁还原罐内传热[J]. 东北大学学报:自然科学版, 2018, 39(5): 643-648. |

| [8] | 郑迪, 王大志, 李硕, 于林鑫. 基于电磁-温度耦合方法的永磁驱动器温度场分析[J]. 东北大学学报:自然科学版, 2018, 39(4): 457-461. |

| [9] | 傅大学, 关录奎, 豆志河, 张廷安. 球团预制-硅热还原炼镁的球团传热性研究[J]. 东北大学学报:自然科学版, 2017, 38(9): 1274-1279. |

| [10] | 李阳, 李亮, 陈圆圆, 邓安元. 侧壁式感应加热中间包磁/热/流耦合模拟[J]. 东北大学学报:自然科学版, 2017, 38(7): 966-971. |

| [11] | 余嘉, 刘福斌, 姜周华, 陈奎. 工业规模电渣重熔过程电磁场的数值模拟[J]. 东北大学学报:自然科学版, 2017, 38(5): 655-660. |

| [12] | 任兵芝, 陈登福, 王宏丹 , 漆锐. 大圆坯连铸结晶器电磁偏心搅拌的数值模拟[J]. 东北大学学报:自然科学版, 2016, 37(6): 820-824. |

| [13] | 储满生, 冯聪, 唐珏, 柳政根. 中性气氛下钒钛磁铁矿高炉渣系研究[J]. 东北大学学报:自然科学版, 2015, 36(9): 1283-1287. |

| [14] | 付小佼, 赵嘉琦, 陈双印, 储满生. 硼铁矿应用于高铬型钒钛矿烧结优化的实验研究[J]. 东北大学学报:自然科学版, 2015, 36(8): 1115-1119. |

| [15] | 王芳, 王强, 刘中秋, 李宝宽. 利用高炉出铁重力势能的旋流反应器冶金特性[J]. 东北大学学报:自然科学版, 2015, 36(8): 1120-1125. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||