东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (7): 992-1001.DOI: 10.12068/j.issn.1005-3026.2024.07.011

收稿日期:2023-03-17

出版日期:2024-07-15

发布日期:2024-10-29

通讯作者:

黄贤振

作者简介:郑智群(1996-),男,山东济南人,东北大学博士研究生

基金资助:

Zhi-qun ZHENG, Xian-zhen HUANG( ), Zhi-yuan JIANG, Xing-lin MIAO

), Zhi-yuan JIANG, Xing-lin MIAO

Received:2023-03-17

Online:2024-07-15

Published:2024-10-29

Contact:

Xian-zhen HUANG

About author:HUANG Xian-zhen professor, E-mail: xzhhuang@mail.neu.edu.cn摘要:

在螺旋管式换热器的基础上结合波纹结构,设计出一种新型的螺旋波纹管换热器.通过数值计算研究了不同波纹深度和波纹节距对其流动换热的影响.以数值计算结果训练Kriging模型,训练后的Kriging模型可预测大量不同螺旋波纹结构特征样本的流动换热特性.通过筛选摩擦系数较低且换热效率较高的结构参数以实现螺旋波纹管换热特性优化.结果表明,波纹结构产生的流速突变和螺旋结构产生的二次流提高了换热效率和流动阻力.通过与数值计算结果的对比,Kriging模型预测换热特性具有较高的效率和精度.在所选定的参数范围内,当波纹深度、波纹节距、螺旋中径、螺旋节距分别为1.32,27.99,86.49,57.85 mm时,螺旋波纹管具有较低的摩擦系数和较高的换热效率.

中图分类号:

郑智群, 黄贤振, 姜智元, 苗兴琳. 基于Kriging模型的螺旋波纹管流动换热特性及结构优化[J]. 东北大学学报(自然科学版), 2024, 45(7): 992-1001.

Zhi-qun ZHENG, Xian-zhen HUANG, Zhi-yuan JIANG, Xing-lin MIAO. Flow and Heat Transfer Characteristics and Structure Optimization of Helically Corrugated Tubes Based on Kriging Model[J]. Journal of Northeastern University(Natural Science), 2024, 45(7): 992-1001.

| 变量 | 分布 | 分布下限/mm | 分布上限/mm |

|---|---|---|---|

| e | 均匀 | 1 | 2 |

| P | 均匀 | 25 | 35 |

| D | 均匀 | 85 | 115 |

| L | 均匀 | 40 | 60 |

表1 特征参数分布及变化范围

Table 1 Characteristic parameter distribution and variation range

| 变量 | 分布 | 分布下限/mm | 分布上限/mm |

|---|---|---|---|

| e | 均匀 | 1 | 2 |

| P | 均匀 | 25 | 35 |

| D | 均匀 | 85 | 115 |

| L | 均匀 | 40 | 60 |

| f | Ea(Nu) | Er(Nu)/% | Ea(f )/% | Er(f )/% | |

|---|---|---|---|---|---|

| Kriging | 数值计算 | ||||

| 0.107 49 | 0.117 31 | -7.857 | -1.87 | -0.98 | -8.37 |

| 0.078 22 | 0.078 96 | 20.727 | 5.55 | -0.07 | -0.93 |

| 0.099 26 | 0.099 53 | 2.700 | 0.67 | -0.02 | -0.26 |

| 0.104 44 | 0.104 85 | 1.232 | 0.30 | -0.04 | -0.38 |

| 0.120 37 | 0.124 21 | -4.525 | -1.06 | -0.38 | -3.09 |

| 0.084 02 | 0.082 98 | -11.82 | -2.96 | 0.10 | 1.26 |

| 0.120 48 | 0.122 95 | -14.23 | -3.25 | -0.24 | -2.01 |

| 0.092 99 | 0.095 98 | -7.410 | -1.77 | -0.29 | -3.11 |

| 0.077 67 | 0.077 51 | -1.002 | -0.25 | 0.01 | 0.21 |

| 0.100 45 | 0.099 75 | 13.982 | 3.58 | 0.07 | 0.70 |

表2 Kriging模型验证

Table 2 Kriging model validation

| f | Ea(Nu) | Er(Nu)/% | Ea(f )/% | Er(f )/% | |

|---|---|---|---|---|---|

| Kriging | 数值计算 | ||||

| 0.107 49 | 0.117 31 | -7.857 | -1.87 | -0.98 | -8.37 |

| 0.078 22 | 0.078 96 | 20.727 | 5.55 | -0.07 | -0.93 |

| 0.099 26 | 0.099 53 | 2.700 | 0.67 | -0.02 | -0.26 |

| 0.104 44 | 0.104 85 | 1.232 | 0.30 | -0.04 | -0.38 |

| 0.120 37 | 0.124 21 | -4.525 | -1.06 | -0.38 | -3.09 |

| 0.084 02 | 0.082 98 | -11.82 | -2.96 | 0.10 | 1.26 |

| 0.120 48 | 0.122 95 | -14.23 | -3.25 | -0.24 | -2.01 |

| 0.092 99 | 0.095 98 | -7.410 | -1.77 | -0.29 | -3.11 |

| 0.077 67 | 0.077 51 | -1.002 | -0.25 | 0.01 | 0.21 |

| 0.100 45 | 0.099 75 | 13.982 | 3.58 | 0.07 | 0.70 |

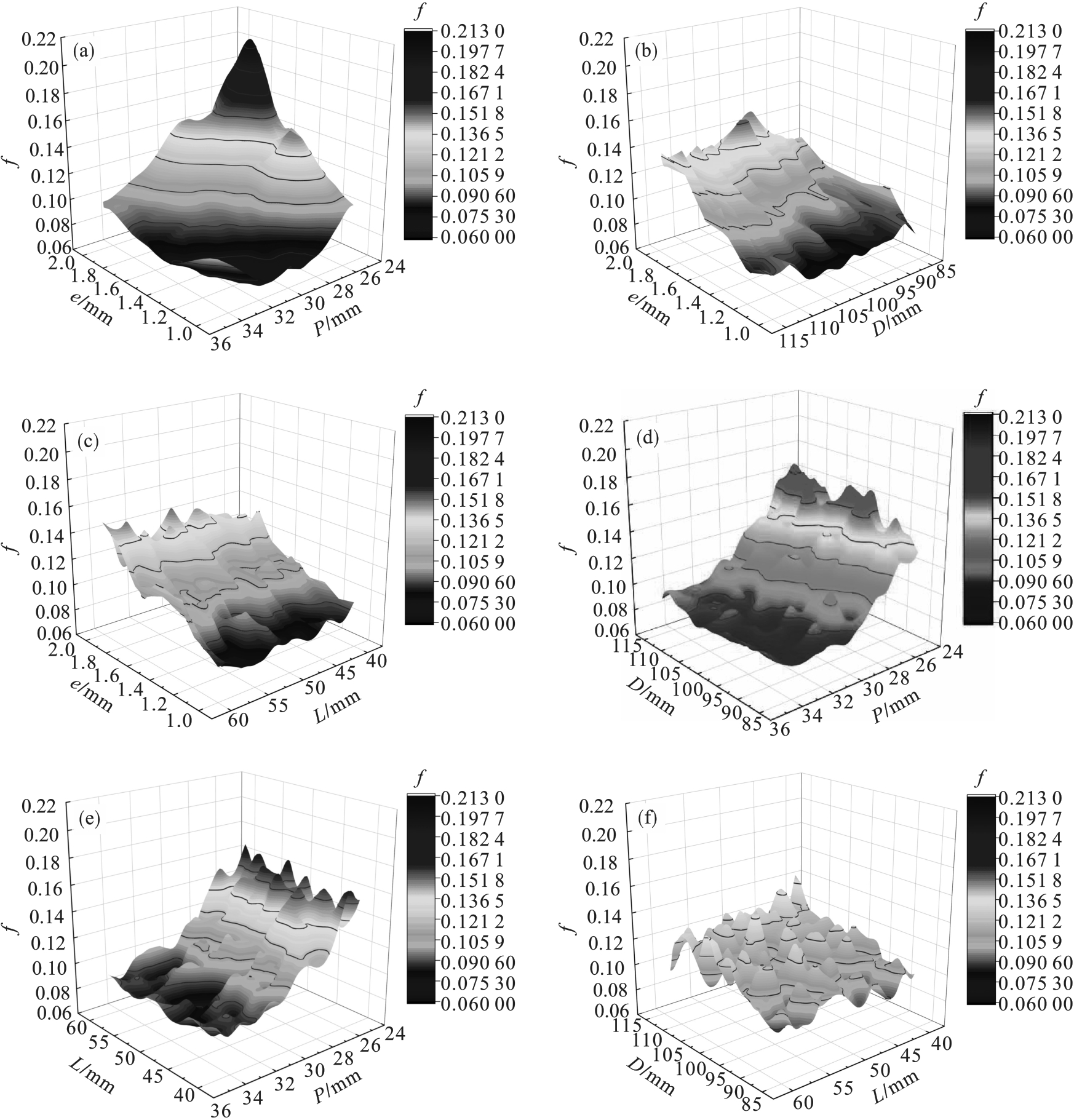

图10 Kriging模型拟合计算响应面(摩擦系数)(a)—e-P; (b)—e-D; (c)—e-L; (d)—D-P; (e)—L-P; (f)—D-L.

Fig.10 Response surface fitted by Kriging model (friction coefficient)

| 名称 | e/mm | P/mm | D/mm | L/mm | Nu | f |

|---|---|---|---|---|---|---|

| Kriging模型优化结果 | 1.32 | 27.99 | 86.49 | 57.85 | 427.66 | 0.109 1 |

| 优化结果的数值计算值 | 1.32 | 27.99 | 86.49 | 57.85 | 421.45 | 0.106 6 |

表3 优化结果对比

Table 3 Optimization results comparison

| 名称 | e/mm | P/mm | D/mm | L/mm | Nu | f |

|---|---|---|---|---|---|---|

| Kriging模型优化结果 | 1.32 | 27.99 | 86.49 | 57.85 | 427.66 | 0.109 1 |

| 优化结果的数值计算值 | 1.32 | 27.99 | 86.49 | 57.85 | 421.45 | 0.106 6 |

| 1 | 于庆波,彭家燕,任慧来,等.颗粒绕流圆管传热的数值模拟研究[J].东北大学学报(自然科学版),2016,37(5):663-667. |

| Yu Qing‑bo, Peng Jia‑yan, Ren Hui‑lai,et al.Numerical simulation research on heat transfer in particle flow round tubes[J].Journal of Northeastern University(Natural Science),2016,37(5):663-667. | |

| 2 | Liu S L, Sakr M.A comprehensive review on passive heat transfer enhancements in pipe exchangers[J].Renewable and Sustainable Energy Reviews,2013,19:64-81. |

| 3 | 马鹏程,唐志国,刘轻轻,等.新型单圆锥体热沉单孔射流散热数值模拟[J].机械工程学报,2016,52(24):136-141. |

| Ma Peng‑cheng, Tang Zhi‑guo, Liu Qing‑qing,et al.Numerical simulation of characteristic of heat transfer for jet impingement with new single cone heat sink through single spray nozzle[J].Journal of Mechanical Engineering,2016,52(24):136-141. | |

| 4 | Zheng Z Q, Yan F Y, Shi L.Numerical study on heat transfer and flow resistance characteristics of multi‑head twisted spiral tube[J].Thermal Science(Part C),2022,26:1880-1895. |

| 5 | Gokulnathan E, Pradeep S, Jayan N,et al.Review of heat transfer enhancement on helical coil heat exchanger by additive passive method[J].Materials Today:Proceedings,2021,37:3024-3027. |

| 6 | Wang M L, Zheng M G, Chao M K,et al.Experimental and CFD estimation of single‑phase heat transfer in helically coiled tubes[J].Progress in Nuclear Energy,2019,112:185-190. |

| 7 | 陈迁乔,钟秦.螺旋管内对流传质场协同强化模拟[J].化工学报,2012,63(12):3764-3770. |

| Chen Qian‑qiao, Zhong Qin.Simulation on field synergy enhancement for convective mass transfer in helical tube[J].CIESC Journal,2012,63(12):3764-3770. | |

| 8 | Cioncolini A, Santini L.On the laminar to turbulent flow transition in diabatic helically coiled pipe flow[J].Experimental Thermal and Fluid Science,2006,30(7):653-661. |

| 9 | Moulin P, Rouch J C, Serra C,et al.Mass transfer improvement by secondary flows:Dean vortices in coiled tubular membranes[J].Journal of Membrane Science,1996,114(2):235-244. |

| 10 | Moulin P, Veyret D, Charbit F.Dean vortices:comparison of numerical simulation of shear stress and improvement of mass transfer in membrane processes at low permeation fluxes[J].Journal of Membrane Science,2001,183(2):149-162. |

| 11 | Seban R A, McLaughlin E F.Heat transfer in tube coils with laminar and turbulent flow[J].International Journal of Heat and Mass Transfer,1963,6(5):387-395. |

| 12 | Pawar S S, Sunnapwar V K.Experimental studies on heat transfer to Newtonian and non‑Newtonian fluids in helical coils with laminar and turbulent flow[J].Experimental Thermal and Fluid Science,2013,44:792-804. |

| 13 | Gee D L, Webb R L.Forced convection heat transfer in helically rib‑roughened tubes[J].International Journal of Heat and Mass Transfer,1980,23(8):1127-1136. |

| 14 | Mimura K, Isozaki A.Heat transfer and pressure drop of corrugated tubes[J].Desalination,1977,22(1):131-139. |

| 15 | Kareem Z S, Mohd Jaafar M N, Lazim T M,et al.Passive heat transfer enhancement review in corrugation[J].Experimental Thermal and Fluid Science,2015,68:22-38. |

| 16 | Córcoles‑Tendero J I, Belmonte J F, Molina A E,et al.Numerical simulation of the heat transfer process in a corrugated tube[J].International Journal of Thermal Sciences,2018,126:125-136. |

| 17 | Zachár A.Analysis of coiled‑tube heat exchangers to improve heat transfer rate with spirally corrugated wall[J].International Journal of Heat and Mass Transfer,2010,53:3928-3939. |

| 18 | Andrade F, Moita A S, Nikulin A,et al.Experimental investigation on heat transfer and pressure drop of internal flow in corrugated tubes[J].International Journal of Heat and Mass Transfer,2019,140:940-955. |

| 19 | Rainieri S, Bozzoli F, Cattani L,et al.Compound convective heat transfer enhancement in helically coiled wall corrugated tubes[J].International Journal of Heat and Mass Transfer,2013,59:353-362. |

| 20 | Rainieri S, Bozzoli F, Pagliarini G.Experimental investigation on the convective heat transfer in straight and coiled corrugated tubes for highly viscous fluids:preliminary results[J].International Journal of Heat and Mass Transfer,2012,55:498-504. |

| 21 | Bozzoli F, Cattani L, Rainieri S.Effect of wall corrugation on local convective heat transfer in coiled tubes[J].International Journal of Heat and Mass Transfer,2016,101:76-90. |

| 22 | Zaboli M, Nourbakhsh M, Ajarostaghi S S M.Numerical evaluation of the heat transfer and fluid flow in a corrugated coil tube with lobe‑shaped cross‑section and two types of spiral twisted tape as swirl generator[J].Journal of Thermal Analysis and Calorimetry,2020,147:999-1015. |

| 23 | Fouda A, Nada S A, Elattar H F,et al.Thermal performance modeling of turbulent flow in multi tube in tube helically coiled heat exchangers[J].International Journal of Mechanical Sciences,2018,135:621-638. |

| 24 | Zhang C C, Wang D B, Xiang S,et al.Numerical investigation of heat transfer and pressure drop in helically coiled tube with spherical corrugation[J].International Journal of Heat and Mass Transfer,2017,113:332-341. |

| 25 | Vicente P G, Garcı́a A, Viedma A.Experimental investigation on heat transfer and frictional characteristics of spirally corrugated tubes in turbulent flow at different Prandtl numbers[J].International Journal of Heat and Mass Transfer,2004,47(4):671-681. |

| 26 | Echard B, Gayton N, Lemaire M,et al.A combined importance sampling and Kriging reliability method for small failure probabilities with time‑demanding numerical models[J].Reliability Engineering & System Safety,2013,111:232-240. |

| 27 | Helton J C, Davis F J.Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems[J].Reliability Engineering & System Safety,2003,81:23-69. |

| [1] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [2] | 黄贤振, 于瑞, 姜智元, 荣治明. 考虑热误差的电主轴建模与可靠性全局灵敏度分析[J]. 东北大学学报(自然科学版), 2024, 45(5): 675-682. |

| [3] | 张晋瑞, 姚锡文, 许开立, 孙修. 矿井智能巡检车CO传感器搭载位置优化[J]. 东北大学学报(自然科学版), 2024, 45(5): 721-728. |

| [4] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| [5] | 王雨萌, 关凯, 朱万成, 刘洪磊. 基于现场监测与数值模拟结合的采动诱发围岩失稳与地表沉降研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 234-243. |

| [6] | 李刚, 周雷, 张晓宇, 张凯. 连通设备粉尘爆炸泄压面积确定方法[J]. 东北大学学报(自然科学版), 2024, 45(2): 276-281. |

| [7] | 库尔班江·乌丝曼, 戴晓业, 史琳. 相变材料对储热系统换热速率的影响[J]. 东北大学学报(自然科学版), 2023, 44(9): 1292-1298. |

| [8] | 侯俊旭, 杨天鸿, 马凯, 赵永. “亿级”自由度数值模拟技术及其工程应用[J]. 东北大学学报(自然科学版), 2023, 44(9): 1298-1308. |

| [9] | 孟庆有, 袁致涛, 杨建超. 微细粒黑钨矿疏水絮凝浮选中聚团形成机制[J]. 东北大学学报(自然科学版), 2023, 44(7): 1002-1008. |

| [10] | 段少陪, 李宝宽, 穆永鸿, 荣文杰. 预热竖窑气固传热与水分蒸发数值模拟[J]. 东北大学学报(自然科学版), 2023, 44(5): 626-634. |

| [11] | 朱庆丰, 闫渤, 冯志鑫, 左玉波. 2195铝合金不同速度热轧过程数值模拟及实验研究[J]. 东北大学学报(自然科学版), 2023, 44(4): 502-509. |

| [12] | 赵文, 孙远, 柏谦, 夏云朋. 小直径管幕工法横导洞施工现场试验及参数优化[J]. 东北大学学报(自然科学版), 2023, 44(3): 432-439. |

| [13] | 黄贤振, 张安星, 孙楷铂. 打磨机器人的打磨头螺栓组系统可靠性分析[J]. 东北大学学报(自然科学版), 2023, 44(12): 1712-1719. |

| [14] | 焦石岩, 廖相巍, 闵义, 刘承军. 25%K2O-30%Na2O-45%SiO2熔渣中超声空化行为的数值模拟[J]. 东北大学学报(自然科学版), 2023, 44(11): 1584-1590. |

| [15] | 赵文, 王志国, 王昭鹏, 王鑫. 带翼缘板圆钢管顶进过程土体变形数值模拟[J]. 东北大学学报(自然科学版), 2023, 44(10): 1490-1498. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||