东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (2): 42-49.DOI: 10.12068/j.issn.1005-3026.2025.20230264

收稿日期:2023-09-08

出版日期:2025-02-15

发布日期:2025-05-20

通讯作者:

董辉

作者简介:于珂凡(1998—),女,辽宁大连人,东北大学硕士研究生基金资助:

Ke-fan YU1, Liang ZHAO1, Hui DONG1( ), Yong-qing HE2

), Yong-qing HE2

Received:2023-09-08

Online:2025-02-15

Published:2025-05-20

Contact:

Hui DONG

摘要:

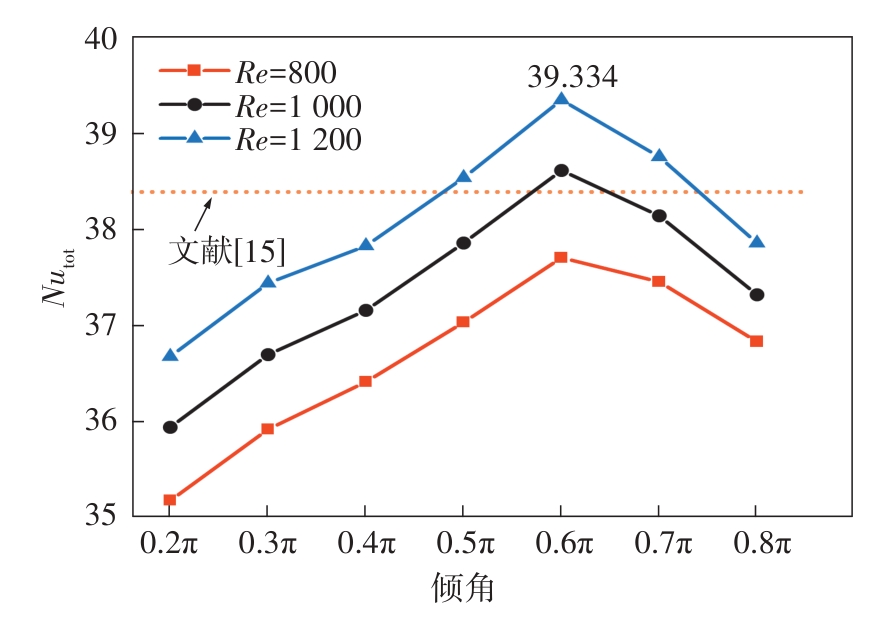

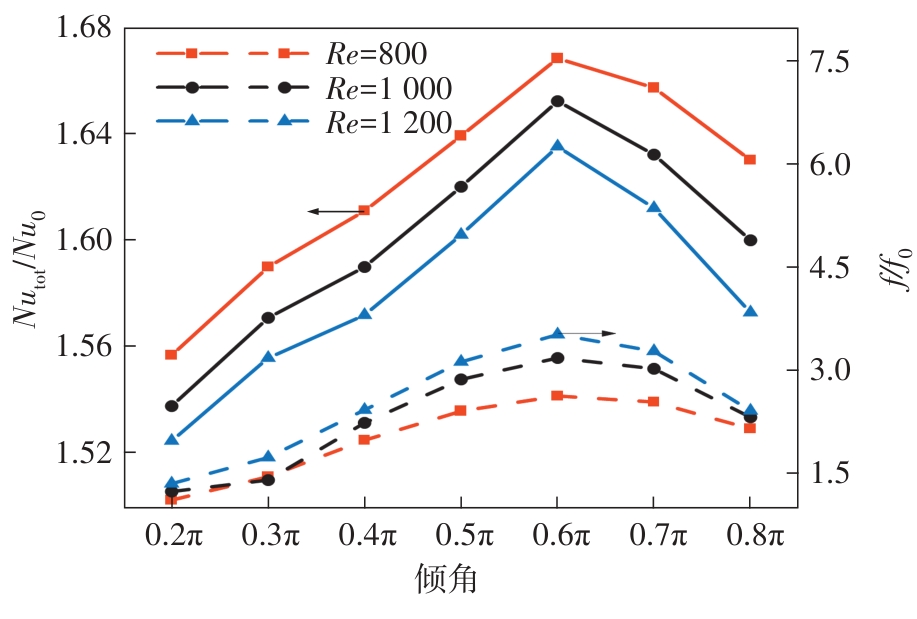

为解决电子器件的散热问题,对具有不同初始倾角的柔性柱微通道内的流动与传热特性进行了数值研究.此外,还探讨了柔性柱的动态特性和倾角对流体传热性能、水动力摩擦系数和总水热效率的影响.结果表明,柔性柱倾角为0.2π时,产生1.25 μm的小振幅,不利于涡流的产生,而在完全扑动模式下的柔性柱可以产生周期性涡流,更有利于边界层的扰动和冷热流体的混合,从而强化传热.在雷诺数Re为800 ~ 1 200的范围内,柔性柱存在最佳的倾角0.6π,在最佳工况下,以较高的机械损失为代价,可以使流体传热性能(Nutot)提高63.5%,总水热效率(η)提高7.5%.

中图分类号:

于珂凡, 赵亮, 董辉, 何永清. 柔性柱初始倾角对微通道传热增强的影响[J]. 东北大学学报(自然科学版), 2025, 46(2): 42-49.

Ke-fan YU, Liang ZHAO, Hui DONG, Yong-qing HE. Effect of Initial Inclination Angle of Elastic Pillars on Heat Transfer Enhancement in Microchannel[J]. Journal of Northeastern University(Natural Science), 2025, 46(2): 42-49.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 微通道宽度H/μm | 35w | 圆柱障碍物离壁面B的距离b/μm | 17.5w |

| 微通道长度L/μm | 150w | 圆柱障碍物直径d/μm | 3w |

| 柔性柱离流动入口的距离l/μm | 42w | 柔性柱宽度w/μm | 14 |

| 圆柱障碍物离流动入口的距离c/μm | 11w | 柔性柱高度h/μm | 13w |

| 柔性柱倾角θ | 0.2π ~ 0.8π |

表1 二维微通道几何参数

Table 1 Geometric parameters for two-dimensional microchannels

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 微通道宽度H/μm | 35w | 圆柱障碍物离壁面B的距离b/μm | 17.5w |

| 微通道长度L/μm | 150w | 圆柱障碍物直径d/μm | 3w |

| 柔性柱离流动入口的距离l/μm | 42w | 柔性柱宽度w/μm | 14 |

| 圆柱障碍物离流动入口的距离c/μm | 11w | 柔性柱高度h/μm | 13w |

| 柔性柱倾角θ | 0.2π ~ 0.8π |

| 物性参数 | 数值 | 物性参数 | 数值 |

|---|---|---|---|

| 密度/(kg·m-3) | 2 500 | 泊松比 | 0.48 |

| 弹性模量/MPa | 7 | 导热系数/(W·m-1·K-1) | 2.5 |

| 比热容/(J·kg-1·K-1) | 1 200 |

表2 柔性柱材料物性

Table 2 Physical properties of elastic pillar material

| 物性参数 | 数值 | 物性参数 | 数值 |

|---|---|---|---|

| 密度/(kg·m-3) | 2 500 | 泊松比 | 0.48 |

| 弹性模量/MPa | 7 | 导热系数/(W·m-1·K-1) | 2.5 |

| 比热容/(J·kg-1·K-1) | 1 200 |

| 网格数 | Nutot | 误差/% | 计算时间/h |

|---|---|---|---|

| 579 59 | 33.199 | 12.3 | 8.65 |

| 103 348 | 33.441 | 11.7 | 22.47 |

| 128 000 | 37.555 | 0.8 | 34.43 |

| 148 102 | 37.867 | 0.0 | 48.98 |

表3 倾角0.5π的柔性柱的网格无关性验证

Table 3 Verification of grid independence for elastic pillar with an inclination angle of 0.5π

| 网格数 | Nutot | 误差/% | 计算时间/h |

|---|---|---|---|

| 579 59 | 33.199 | 12.3 | 8.65 |

| 103 348 | 33.441 | 11.7 | 22.47 |

| 128 000 | 37.555 | 0.8 | 34.43 |

| 148 102 | 37.867 | 0.0 | 48.98 |

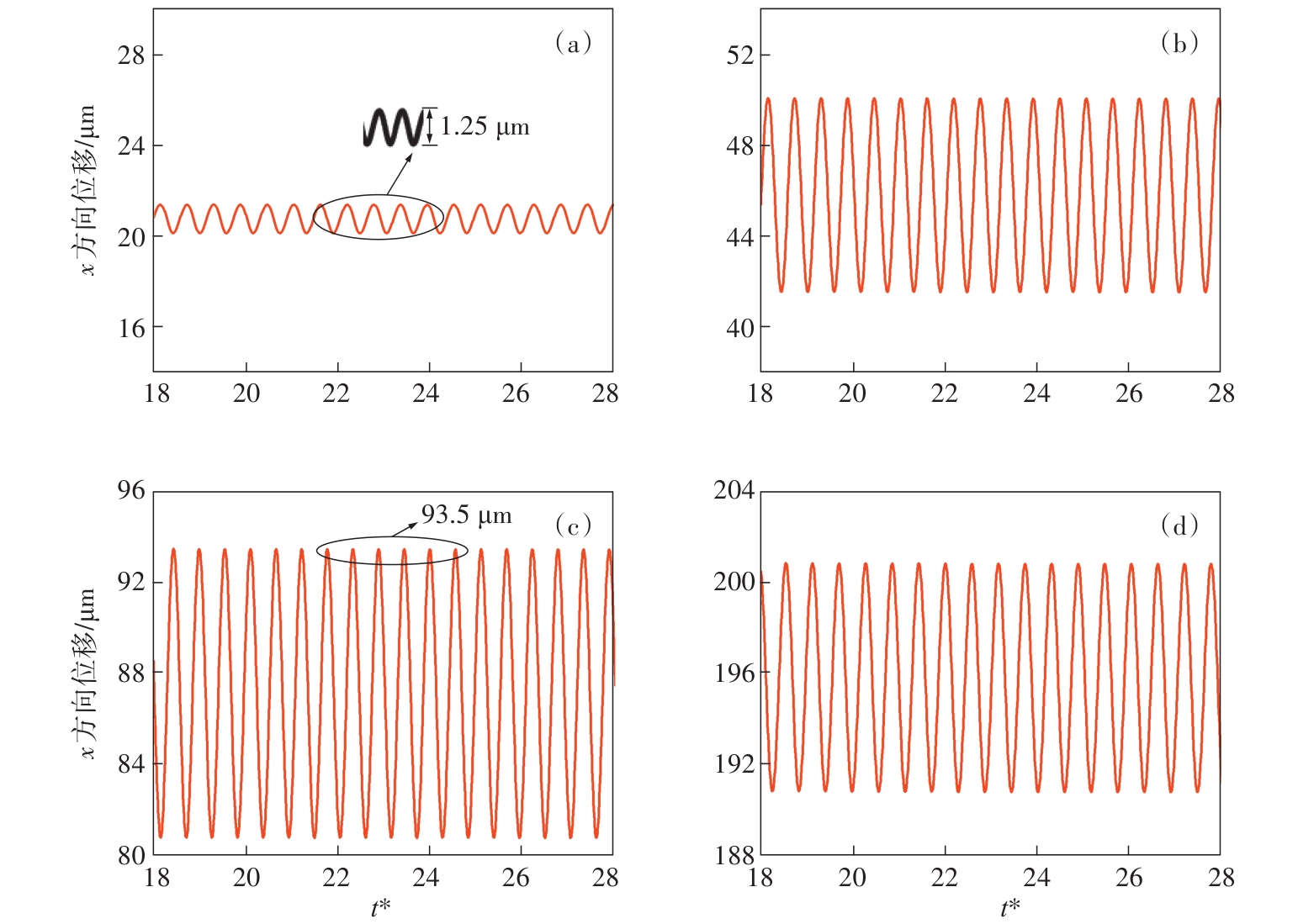

图8 不同倾角下柔性柱自由端x方向的尖端位移(a)—θ=0.2π;(b)—θ=0.4π;(c)—θ=0.6π;(d)—θ=0.8π.

Fig.8 Tip displacement of the x-component at the end of an elastic pillar with different inclination angles

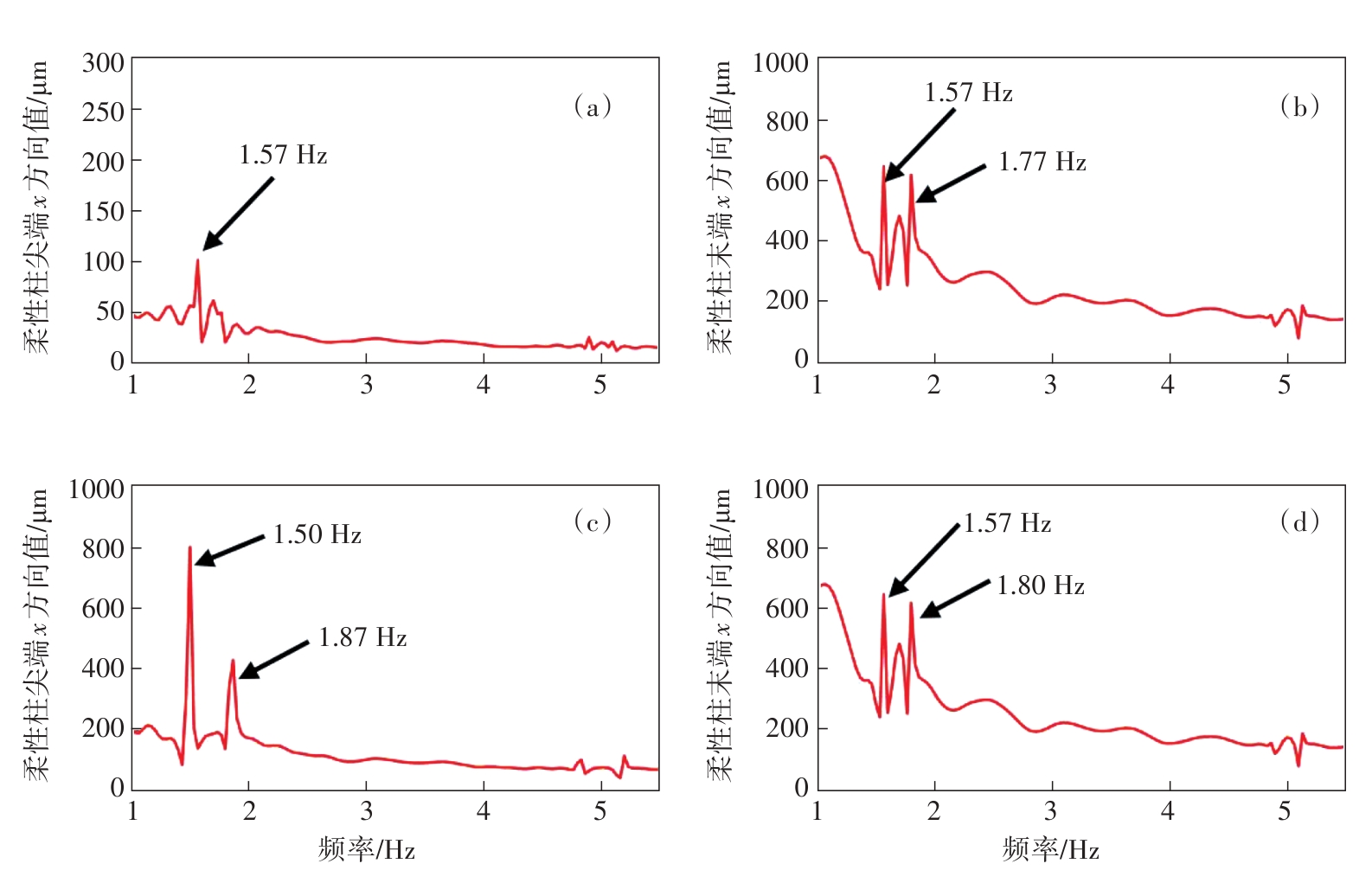

图9 不同倾角下柔性柱自由端x方向的频谱(a)—θ=0.2π;(b)—θ=0.4π;(c)—θ=0.6π;(d)—θ=0.8π.

Fig.9 Frequency of the x-component at the end of an elastic pillar with different inclination angles

图10 不同柔性柱倾角下微通道两侧壁面的总努塞尔数

Fig.10 The total Nusselt number of the walls on both sides of microchannel under different inclination angles of elastic pillar

图11 不同柔性柱倾角下微通道的总努塞尔数比和摩擦系数比

Fig.11 The total Nusselt number ratio and friction coefficient ratio of microchannels under different inclination angles of elastic pillar

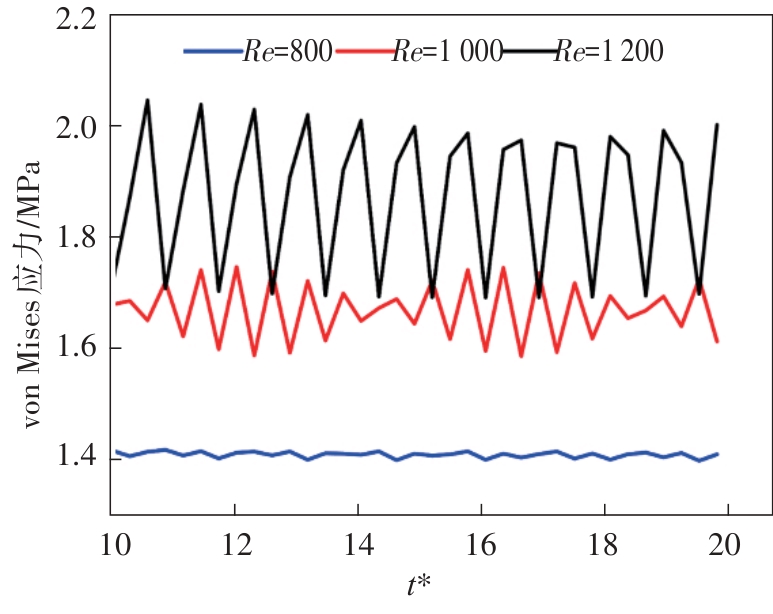

图15 不同Re下倾角0.8π的柔性柱E点的最大von Mises应力

Fig.15 Maximum von Mises stress at point E of an elastic pillar with an inclination angle of 0.8 π under different Re

| 1 | Fu C J, Wang J G, Zhao T L, et al. Experimental study on the influence factors of flow velocity structure and turbulent characteristics in open channel with biomimetic grass[J]. Advances in Civil Engineering, 2021(1): 5512536. |

| 2 | Ali S, Habchi C, Menanteau S, et al. Heat transfer and mixing enhancement by free elastic flaps oscillation[J]. International Journal of Heat and Mass Transfer, 2015, 85: 250-264. |

| 3 | Kurzthaler C, Brandão R, Schnitzer O, et al. Shape of a tethered filament in various low-Reynolds-number flows[J]. Physical Review Fluids, 2023(8): 014101. |

| 4 | Gallegos R K B, Sharma R N. Heat transfer performance of flag vortex generators in rectangular channels[J]. International Journal of Thermal Sciences, 2019, 137: 26-44. |

| 5 | Gallegos R K B, Sharma R N. Small flags in rectangular channels: dynamics and mean wake characteristics[J]. International Journal of Mechanical Sciences, 2019, 155: 518-535. |

| 6 | Mirzaee H, Dadvand A, Mirzaee I, et al. Heat transfer enhancement in microchannels using an elastic vortex generator[J]. Journal of Enhanced Heat Transfer, 2012, 19(3): 199-211. |

| 7 | Ghalambaz M, Jamesahar E, Ismael M A, et al. Fluid-structure interaction study of natural convection heat transfer over a flexible oscillating fin in a square cavity[J]. International Journal of Thermal Sciences, 2017, 111: 256-273. |

| 8 | Wang J S, Wang X, Liu X L. Numerical investigation on flow behavior and heat transfer feature of flexible wings located at the bottom of a two-dimensional channel[J]. Applied Thermal Engineering, 2022, 206: 118112. |

| 9 | Lee J B, Park S G, Kim B, et al. Heat transfer enhancement by flexible flags clamped vertically in a Poiseuille channel flow[J]. International Journal of Heat and Mass Transfer, 2017, 107: 391-402. |

| 10 | Chen Y J, Yang J, Liu Y Z, et al. Heat transfer enhancement in a poiseuille channel flow by using multiple wall-mounted flexible flags[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120447. |

| 11 | Ali S, Menanteau S, Habchi C, et al. Heat transfer and mixing enhancement by using multiple freely oscillating flexible vortex generators[J]. Applied Thermal Engineering, 2016, 105: 276-289. |

| 12 | Park S G. Heat transfer enhancement by a wall-mounted flexible vortex generator with an inclination angle[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119053. |

| 13 | Lee J B, Park S G, Sung H J. Heat transfer enhancement by asymmetrically clamped flexible flags in a channel flow[J]. International Journal of Heat and Mass Transfer, 2018, 116: 1003-1015. |

| 14 | Kang M S, Park S G, Dinh C T. Heat transfer enhancement by a pair of asymmetric flexible vortex generators and thermal performance prediction using machine learning algorithms[J]. International Journal of Heat and Mass Transfer, 2023, 200: 123518. |

| 15 | Dadvand A, Hosseini S, Aghebatandish S, et al. Enhancement of heat and mass transfer in a microchannel via passive oscillation of a flexible vortex generator[J]. Chemical Engineering Science, 2019, 207: 556-580. |

| 16 | Hosseini S, Aghebatandish S, Dadvand A, et al. An immersed boundary-lattice Boltzmann method with multi relaxation time for solving flow-induced vibrations of an elastic vortex generator and its effect on heat transfer and mixing[J]. Chemical Engineering Journal, 2021, 405: 126652. |

| 17 | Jing D L, Zhan X K. Numerical studies on the hydraulic and mixing performances of fluid flow around a cylinder in microchannel with vertical flexible flag[J]. Chemical Engineering Journal, 2022, 430: 133009. |

| 18 | Karniadakis G, Beskok A, Aluru N R. Microflows and nanoflows: fundamentals and simulation[C]// Interdisciplinary Applied Mathematics Series. Berlin: Springer Science Business Media, 2005: 1-61. |

| 19 | Hirt C W, Amsden A A, Cook J L. An arbitrary Lagrangian-Eulerian computing method for all flow speeds[J]. Journal of Computational Physics, 1974, 14(3): 227-253. |

| 20 | Done J, Huerta A, Rodrguez-Ferran A. Chapter 14: arbitrary Lagrangian-Eulerian methods[M]//Encyclopedia of Computational Mechanics. [S. l.]:John Wiley & Son, 2004: 1-25. |

| 21 | Tuković Ž, Jasak H. Updated Lagrangian finite volume solver for large deformation dynamic response of elastic body[J].Transactions of Famena, 2017, 31: 55-70. |

| 22 | Attard M M. Finite strain– isotropic hyperelasticity[J]. International Journal of Solids and Structures, 2003, 40(17): 4353-4378. |

| 23 | Celik I B, Ghia U, Roache P J, et al. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications[J]. Journal of Fluids Engineering, 2008, 130(7): 078001. |

| 24 | Amini Y, Habibi S E. Effects of multiple flexible vortex generators on the hydrothermal characteristics of a rectangular channel[J]. International Journal of Thermal Sciences, 2022, 175: 107454. |

| 25 | Turek S, Hron J. Proposal for numerical benchmarking of fluid-structure interaction between an elastic object and laminar incompressible flow[C]// Fluid-Structure Interaction. Berlin, Heidelberg: Springer, 2006: 371-385. |

| [1] | 王述红, 任明珠, 李世宇, 董福瑞. 近距离穿越既有车站不等强度注浆变形的控制[J]. 东北大学学报(自然科学版), 2025, 46(2): 126-135. |

| [2] | 李中正, 吴朝霞, 王金杨, 康增鑫. 铁矿石烧结过程传质传热数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(1): 35-43. |

| [3] | 袁熙, 马明旭, 陈杰, 王哲英. 无油涡旋真空泵主轴冷却装置数值模拟研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 92-98. |

| [4] | 董辉, 于珂凡, 赵亮, 王进. 复合纳米流体在歧管微通道内的流动传热数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(7): 960-966. |

| [5] | 郑智群, 黄贤振, 姜智元, 苗兴琳. 基于Kriging模型的螺旋波纹管流动换热特性及结构优化[J]. 东北大学学报(自然科学版), 2024, 45(7): 992-1001. |

| [6] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [7] | 张晋瑞, 姚锡文, 许开立, 孙修. 矿井智能巡检车CO传感器搭载位置优化[J]. 东北大学学报(自然科学版), 2024, 45(5): 721-728. |

| [8] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| [9] | 王雨萌, 关凯, 朱万成, 刘洪磊. 基于现场监测与数值模拟结合的采动诱发围岩失稳与地表沉降研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 234-243. |

| [10] | 李刚, 周雷, 张晓宇, 张凯. 连通设备粉尘爆炸泄压面积确定方法[J]. 东北大学学报(自然科学版), 2024, 45(2): 276-281. |

| [11] | 陈百玲, 殷悦, 高海洋, 王连广. 预制钢板夹心混凝土组合板与柱连接及其有限元分析[J]. 东北大学学报(自然科学版), 2024, 45(10): 1476-1484. |

| [12] | 侯俊旭, 杨天鸿, 马凯, 赵永. “亿级”自由度数值模拟技术及其工程应用[J]. 东北大学学报(自然科学版), 2023, 44(9): 1298-1308. |

| [13] | 孟庆有, 袁致涛, 杨建超. 微细粒黑钨矿疏水絮凝浮选中聚团形成机制[J]. 东北大学学报(自然科学版), 2023, 44(7): 1002-1008. |

| [14] | 段少陪, 李宝宽, 穆永鸿, 荣文杰. 预热竖窑气固传热与水分蒸发数值模拟[J]. 东北大学学报(自然科学版), 2023, 44(5): 626-634. |

| [15] | 朱庆丰, 闫渤, 冯志鑫, 左玉波. 2195铝合金不同速度热轧过程数值模拟及实验研究[J]. 东北大学学报(自然科学版), 2023, 44(4): 502-509. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||