东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (1): 93-100.DOI: 10.12068/j.issn.1005-3026.2024.01.012

郭俊1, 印万忠1, 杨斌2, 朱张磊3

收稿日期:2022-08-02

出版日期:2024-01-15

发布日期:2024-04-02

作者简介:郭 俊(1993-),男,内蒙古包头人,东北大学硕士研究生基金资助:Jun GUO1, Wan-zhong YIN1, Bin YANG2, Zhang-lei ZHU3

Received:2022-08-02

Online:2024-01-15

Published:2024-04-02

摘要:

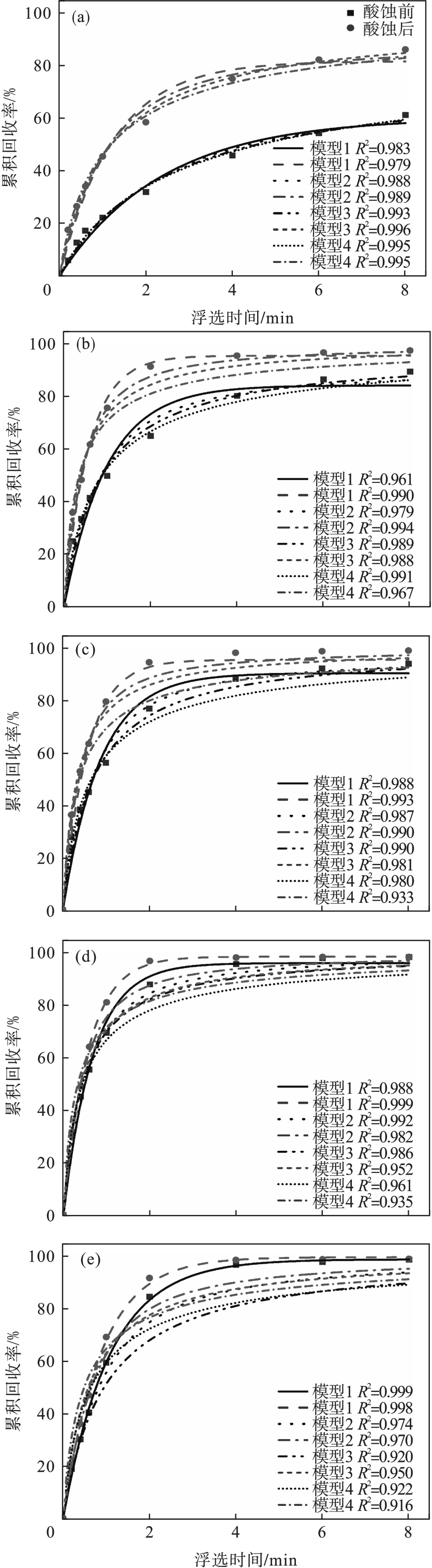

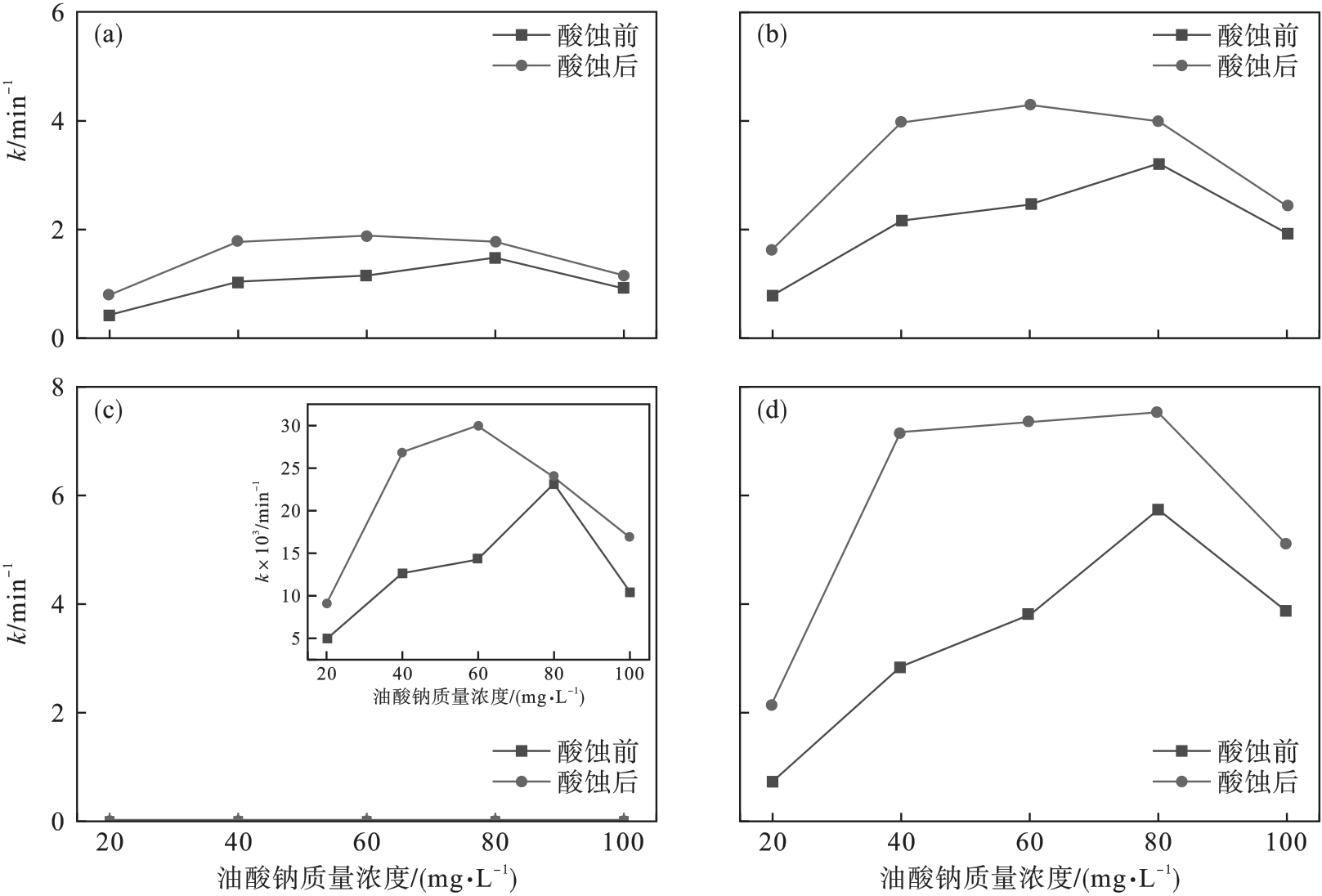

在油酸钠体系下,通过浮选试验、浮选动力学拟合、表面粗糙度表征、比表面积分析、XPS分析、吸附性能分析和润湿性分析,研究了酸蚀对白云石可浮性的影响及其作用机理.研究结果表明:酸蚀后,白云石表面粗糙度和比表面积增大,这暴露出更多的活性位点,强化了与油酸钠的吸附,增强了白云石的疏水性,进而改善了白云石的浮选性能.此外,在浮选动力学拟合中,经典一级动力学模型、一级矩阵分布模型、二级动力学模型的R2均高于95%.相比于其他模型,经典一级动力学拟合效果较好.其中在油酸钠质量浓度为60 mg/L时,酸蚀后白云石经典一级动力学k最大值为1.88 min-1,与此同时,酸蚀前白云石经典一级动力学k=1.15 min-1,表明酸蚀可以提高白云石浮选速率.本研究为白云石浮选提供了新的研究方向,具有一定的理论和现实意义.

中图分类号:

郭俊, 印万忠, 杨斌, 朱张磊. 酸蚀对白云石可浮性的影响及其作用机理[J]. 东北大学学报(自然科学版), 2024, 45(1): 93-100.

Jun GUO, Wan-zhong YIN, Bin YANG, Zhang-lei ZHU. Effect of Acid Etching on the Floatability of Dolomite and Its Mechanism of Action[J]. Journal of Northeastern University(Natural Science), 2024, 45(1): 93-100.

| 序号 | 浮选动力学模型 | 公式 |

|---|---|---|

| 模型1 | 经典一级 模型[ | |

| 模型2 | 一级矩阵分布模型[ | |

| 模型3 | 二级动力学 模型[ | |

| 模型4 | 二级矩阵分布模型[ |

表1 浮选动力学模型

Table 1 Flotation kinetic models

| 序号 | 浮选动力学模型 | 公式 |

|---|---|---|

| 模型1 | 经典一级 模型[ | |

| 模型2 | 一级矩阵分布模型[ | |

| 模型3 | 二级动力学 模型[ | |

| 模型4 | 二级矩阵分布模型[ |

图6 酸蚀前后白云石浮选动力学非线性拟合(a)—20 mg/L; (b)—40 mg/L; (c)—60 mg/L;(d)—80 mg/L; (e)—100 mg/L.

Fig. 6 Non‐linear fitting of flotation kinetics before and after acid etching

图7 油酸钠质量浓度对酸蚀前后白云石浮选速率常数的影响(a)—模型1; (b)—模型2; (c)—模型3; (d)—模型4.

Fig. 7 Effect of sodium oleate concentrations on the flotation rate constant of dolomite before and after acid etching

| 试样 | Ra/nm | Rq/nm | 粗糙度 | 比表面积 |

|---|---|---|---|---|

| nm | m2·g-1 | |||

| 酸蚀前 | 0.163 | 0.268 | 0.2~1.3 | 0.324 |

| 酸蚀后 | 0.216 | 0.370 | 0.5~2.2 | 0.386 |

表2 酸蚀前后白云石的表面粗糙度以及比表面积

Table 2 Surface roughness and specific surface area of dolomite before and after acid etching

| 试样 | Ra/nm | Rq/nm | 粗糙度 | 比表面积 |

|---|---|---|---|---|

| nm | m2·g-1 | |||

| 酸蚀前 | 0.163 | 0.268 | 0.2~1.3 | 0.324 |

| 酸蚀后 | 0.216 | 0.370 | 0.5~2.2 | 0.386 |

| 试样 | Ca2p | Mg1s | C1s | O1s |

|---|---|---|---|---|

| 酸蚀前 | 6.71 | 1.97 | 36.61 | 54.71 |

| 酸蚀后 | 9.60 | 4.22 | 38.24 | 47.94 |

表3 白云石的XPS分析结果 (%)

Table 3 XPS analysis results of dolomite

| 试样 | Ca2p | Mg1s | C1s | O1s |

|---|---|---|---|---|

| 酸蚀前 | 6.71 | 1.97 | 36.61 | 54.71 |

| 酸蚀后 | 9.60 | 4.22 | 38.24 | 47.94 |

| 酸蚀前 | 酸蚀后 | 酸蚀前+油酸钠 | 酸蚀后+油酸钠 |

|---|---|---|---|

| 32.18 | 25.71 | 72.67 | 88.35 |

表4 酸蚀前后白云石的接触角 (°)

Table 4 Contact angle of dolomite before and after acid etching

| 酸蚀前 | 酸蚀后 | 酸蚀前+油酸钠 | 酸蚀后+油酸钠 |

|---|---|---|---|

| 32.18 | 25.71 | 72.67 | 88.35 |

| 1 | Yekeler M, Ulusoy U.Characterisation of surface roughness and wettability of salt‐type minerals:calcite and barite[J].Mineral Processing and Extractive Metallurgy,2004,113(3):145-152. |

| 2 | Ulusoy U, Yekeler M.Correlation of the surface roughness of some industrial minerals with their wettability parameters[J].Chemical Engineering and Processing:Process Intensification,2005,44(5):555-563. |

| 3 | Yekeler M, Ulusoy U, Hiçyılmaz C.Effect of particle shape and roughness of talc mineral ground by different mills on the wettability and floatability[J].Powder Technology,2004,140(1/2):68-78. |

| 4 | Xia W C, Ni C, Xie G Y.The influence of surface roughness on wettability of natural/gold‐coated ultra‐low ash coal particles[J].Powder Technology,2016,288:286-290. |

| 5 | Xing Y W, Zhang Y F, Ding S H,et al.Effect of surface roughness on the detachment between bubble and glass beads with different contact angles[J].Powder Technology,2020,361:812-816. |

| 6 | Hassas V B, Caliskan H, Guven O,et al.Effect of roughness and shape factor on flotation characteristics of glass beads[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2016,492:88-99. |

| 7 | Tong Z Y, Liu L, Yuan Z T,et al.The effect of comminution on surface roughness and wettability of graphite particles and their relation with flotation[J].Minerals Engineering,2021,169:106959. |

| 8 | Wu H Q, Fang S, Shu K Q,et al.Selective flotation and adsorption of ilmenite from titanaugite by a novel method:ultrasonic treatment[J].Powder Technology,2020,363:38-47. |

| 9 | Zhang N N, Ejtemaei M, Nguyen A V,et al.XPS analysis of the surface chemistry of sulfuric acid‐treated kaolinite and diaspore minerals with flotation reagents[J].Minerals Engineering,2019,136:1-7. |

| 10 | Li H X, Chai W C, Cao Y J,et al.Flotation enhancement of low‐grade bauxite using oxalic acid as surface pretreatment agent[J].Applied Surface Science,2022,577:151964. |

| 11 | Zhu G L, Zhao Y H, Zheng X Y,et al.Surface features and flotation behaviors of spodumene as influenced by acid and alkali treatments[J].Applied Surface Science,2020,507:145058. |

| 12 | Cao S H, Yin W Z, Yang B,et al.Insights into the influence of temperature on the adsorption behavior of sodium oleate and its response to flotation of quartz[J].International Journal of Mining Science and Technology,2022,32(2):399-409. |

| 13 | 付亚峰,杨晓峰,印万忠,等.木质素磺酸钙对水镁石浮选中蛇纹石的抑制机理[J].中南大学学报(自然科学版),2022,53(2):371-378. |

| Fu Ya‑feng, Yang Xiao‑feng, Yin Wan‑zhong,et al.Inhibitory role of calcium lignosulfonate on serpentine during brucite flotation[J].Journal of Central South University (Science and Technology),2022,53(2):371-378. | |

| 14 | 姚金,印万忠,王余莲,等.油酸钠浮选体系中菱镁矿与白云石和石英的交互影响[J].东北大学学报(自然科学版),2013,34(9):1330-1334. |

| Yao Jin, Yin Wan‑zhong, Wang Yu‑lian,et al.Interactive effect of dolomite and quartz on the floatability of magnesite in sodium oleate flotation system[J].Journal of Northeastern University (Natural Science),2013,34(9):1330-1334. | |

| 15 | Hassanzadeh A, Huu H D, Brockmann M.Assessment of flotation kinetics modeling using information criteria; case studies of elevated‐pyritic copper sulfide and high‐grade carbonaceous sedimentary apatite ores[J].Journal of Dispersion Science and Technology,2020,41(7):1083-1094. |

| 16 | Zhang H J, Liu J T, Cao Y J,et al.Effects of particle size on lignite reverse flotation kinetics in the presence of sodium chloride[J].Powder Technology,2013,246:658-663. |

| 17 | Stanojlović R D, Sokolović J M.A study of the optimal model of the flotation kinetics of copper slag from copper mine BOR[J].Archives of Mining Sciences,2014,59(3):821-834. |

| 18 | Ruiz‑Cabello F M, Trefalt G, Csendes Z,et al.Predicting aggregation rates of colloidal particles from direct force measurements[J].The Journal of Physical Chemistry B,2013,117(39):11853-11862. |

| 19 | Xu M Q.Modified flotation rate constant and selectivity index[J].Minerals Engineering,1998,11(3):271-278. |

| 20 | Polat M, Chander S.First‐order flotation kinetics models and methods for estimation of the true distribution of flotation rate constants[J].International Journal of Mineral Processing,2000,58(1/2/3/4):145-166. |

| 21 | Azizi A.A study on the modified flotation parameters and selectivity index in copper flotation[J].Particulate Science and Technology,2017,35(1):38-44. |

| 22 | Zhu Z L, Wang D H, Yang B,et al.Water droplets and air bubbles at magnesite nano‐rough surfaces:analysis of induction time,adhesion and detachment using a dynamic microbalance[J].Minerals Engineering,2020,155:106449. |

| 23 | Zhu Z L, Yin W Z, Wang D H,et al.The role of surface roughness in the wettability and floatability of quartz particles[J].Applied Surface Science,2020,527:146799. |

| [1] | 赵旭, 印万忠, 姚金, 朱张磊. 油酸钠体系下粗糙度对白云石可浮性的影响及其机理[J]. 东北大学学报(自然科学版), 2023, 44(8): 1188-1194. |

| [2] | 张家豪, 邹平, 魏事宇, 梁付强. 单激励三维超声车削加工技术的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1152-1159. |

| [3] | 杨金金, 王者超, 乔丽苹, 李崴. 粗糙裂隙内涡旋结构演化特征及影响因素分析[J]. 东北大学学报(自然科学版), 2023, 44(5): 697-704. |

| [4] | 方锐, 邹平, 段经伟, 魏事宇. 三维超声振动辅助车削减摩特性与表面质量的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(2): 233-241. |

| [5] | 孙瑶, 唐本甲, 巩亚东, 李思慧. 镍基单晶高温合金表面微阵列孔的制备方法及其实验研究[J]. 东北大学学报(自然科学版), 2023, 44(12): 1719-1725. |

| [6] | 周孝洪, 高淑玲, 孟令国, 赵强. 壁面粗糙度对螺旋溜槽中矿浆流动及颗粒分离行为的影响[J]. 东北大学学报(自然科学版), 2023, 44(12): 1769-1777. |

| [7] | 姜世杰, 胡科, 陈丕峰, 战明. 熔丝成型制品三维表面粗糙度的理论与实验研究[J]. 东北大学学报(自然科学版), 2022, 43(9): 1290-1297. |

| [8] | 温雪龙, 韩凤兵, 巩亚东, 黄雄俊. 沉积时间对真空离子镀TiC涂层微磨具表面性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(6): 857-863. |

| [9] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [10] | 温雪龙, 李佳育, 李欣妍. TiC涂层微磨具磨削表面质量影响因素[J]. 东北大学学报(自然科学版), 2022, 43(4): 534-540. |

| [11] | 周云光, 田川川, 马廉洁, 毕长波. 氧化锆陶瓷微尺度磨削表面质量试验研究[J]. 东北大学学报(自然科学版), 2022, 43(1): 83-88. |

| [12] | 赵春雨, 程大众, 耿浩博. 车削工件2-D表面形貌检测方法研究[J]. 东北大学学报(自然科学版), 2021, 42(9): 1299-1306. |

| [13] | 姜世杰, 胡科, 陈丕峰, SIYAJEU Yannick. 熔丝成型薄板表面粗糙度理论模型与实验验证[J]. 东北大学学报(自然科学版), 2021, 42(7): 980-986. |

| [14] | 孙文瀚, 刘文刚, 杨婷, 代淑娟. TX-100对油酸钠体系下菱镁矿与白云石浮选分离的影响[J]. 东北大学学报(自然科学版), 2021, 42(2): 226-231. |

| [15] | 焦安源, 张国富, 丁浩东, 刘伟军. TC4钛合金孔的磁粒研磨试验[J]. 东北大学学报:自然科学版, 2020, 41(9): 1304-1310. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||