东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (1): 52-60.DOI: 10.12068/j.issn.1005-3026.2025.20230206

巩亚东, 李远峰, 温泉, 任启震

收稿日期:2023-07-17

出版日期:2025-01-15

发布日期:2025-03-25

作者简介:巩亚东(1958—),男,辽宁本溪人,东北大学教授,博士生导师.

基金资助:Ya-dong GONG, Yuan-feng LI, Quan WEN, Qi-zhen REN

Received:2023-07-17

Online:2025-01-15

Published:2025-03-25

摘要:

为探究2.5D Cf/SiC复合材料与SiC陶瓷的微尺度磨削过程,对比2种材料在同一工艺参数下表面显微形貌、表面粗糙度与磨削力的差异,并分析工艺参数变化对磨削性能评价参数的影响;采用直径为0.9 mm的500 #电镀金刚石微磨具对2种材料分别进行单因素微磨削试验.结果表明,2.5D Cf/SiC复合材料去除过程不同于SiC陶瓷,这是因为复合材料增强纤维的存在,有效抑制了微磨削过程中裂纹的扩展;在同一工艺参数下,2.5D Cf/SiC复合材料表面微观形貌较好、缺陷少、表面粗糙度小,而无纤维增强的SiC陶瓷表面微观形貌较差、缺陷多、表面粗糙度大;SiC陶瓷的平均磨削力大于2.5D Cf/SiC,并且在微磨削过程中,2.5D Cf/SiC的实时磨削力信号较平稳,而SiC陶瓷的实时磨削力信号存在尖刺.

中图分类号:

巩亚东, 李远峰, 温泉, 任启震. 2.5D Cf/SiC复合材料与SiC陶瓷微磨削性能对比试验研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 52-60.

Ya-dong GONG, Yuan-feng LI, Quan WEN, Qi-zhen REN. Comparative Experimental Study on Micro-grinding Performance of 2.5D Cf/SiC Composites and SiC Ceramics[J]. Journal of Northeastern University(Natural Science), 2025, 46(1): 52-60.

| 参数 | 2.5D Cf/SiC | SiC陶瓷 |

|---|---|---|

| 抗拉强度/MPa | 280 | 441 |

| 抗弯强度/MPa | 220 | 500 |

| 断裂韧性/(MPa·m1/2) | 20.2~31.0 | 3.0~3.5 |

| 密度/(g·cm-3) | 2.0 | 3.1 |

| 纤维直径/μm | 7 | — |

| 纤维体积分数/% | 37 | — |

表1 2.5D Cf/SiC复合材料与SiC陶瓷性能参数 (composites and SiC ceramics)

Table 1 Performance parameters of 2.5D Cf/SiC

| 参数 | 2.5D Cf/SiC | SiC陶瓷 |

|---|---|---|

| 抗拉强度/MPa | 280 | 441 |

| 抗弯强度/MPa | 220 | 500 |

| 断裂韧性/(MPa·m1/2) | 20.2~31.0 | 3.0~3.5 |

| 密度/(g·cm-3) | 2.0 | 3.1 |

| 纤维直径/μm | 7 | — |

| 纤维体积分数/% | 37 | — |

| 因素 | 水平 | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| 磨削速度vs/(m·s-1) | 0.471,0.942,1.414,1.885,2.356 | 1.414 | 1.414 |

| 磨削深度ap/μm | 9 | 3,6,9,12,15 | 9 |

| 进给速度vw/(μm·s-1) | 120 | 120 | 20,70,120,170,220 |

表2 单因素微磨削试验方案

Table 2 Process parameters in the single‑factor experiment

| 因素 | 水平 | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| 磨削速度vs/(m·s-1) | 0.471,0.942,1.414,1.885,2.356 | 1.414 | 1.414 |

| 磨削深度ap/μm | 9 | 3,6,9,12,15 | 9 |

| 进给速度vw/(μm·s-1) | 120 | 120 | 20,70,120,170,220 |

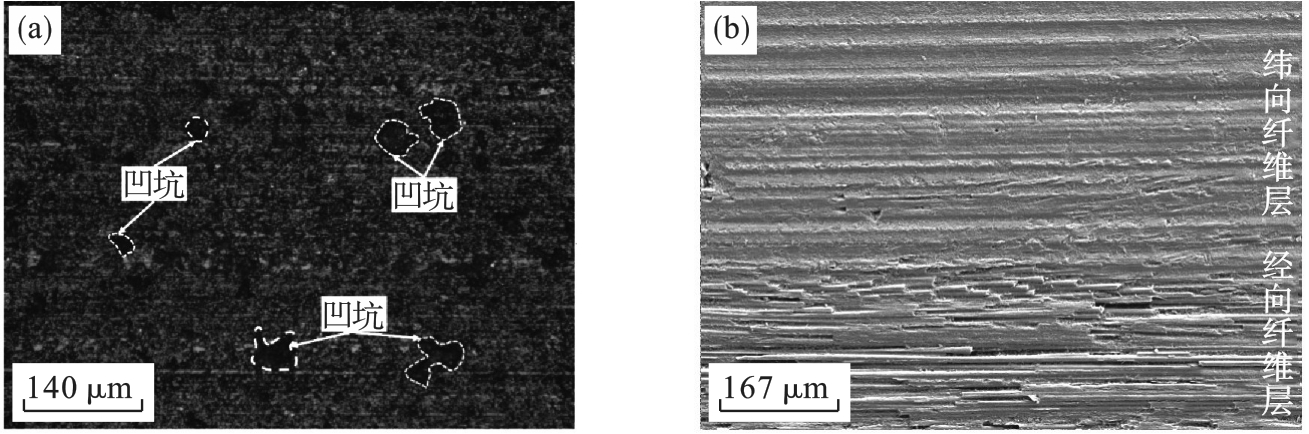

图3 SiC陶瓷与2.5D Cf/SiC复合材料微磨削后表面微观形貌(a)—SiC陶瓷; (b)—2.5D Cf/SiC复合材料.

Fig.3 Micro‑morphology of 2.5D Cf/SiC composites and SiC ceramics after micro‑grinding

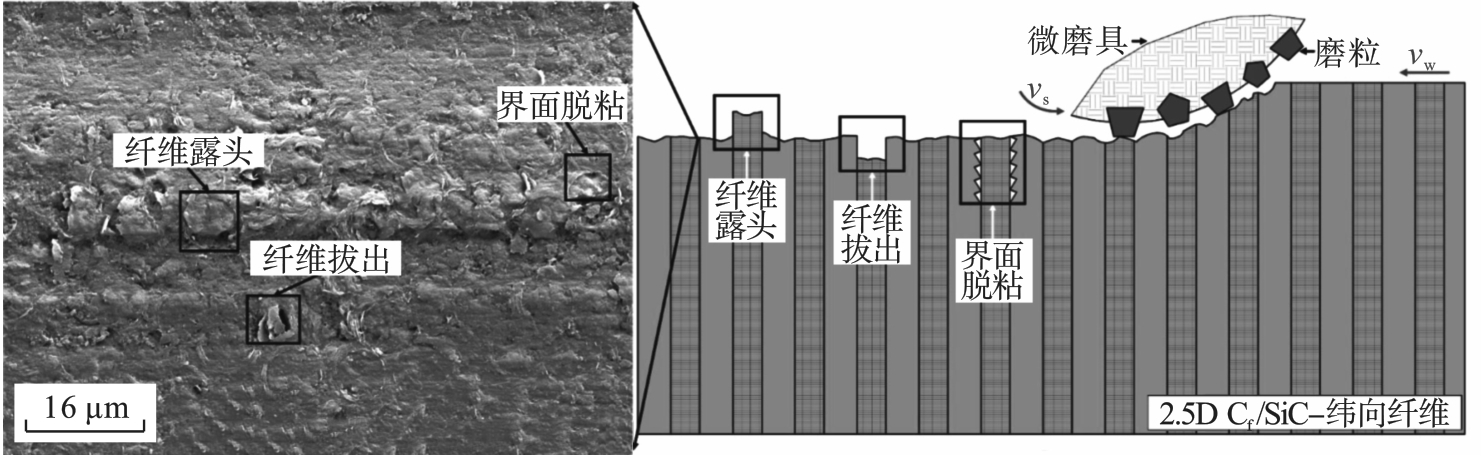

图5 2.5D Cf/SiC复合材料纬向纤维层微磨削后表面显微形貌与去除过程原理图

Fig.5 Surface morphology of weft fiber layer of 2.5D Cf/SiC composites and schematic diagram of the removal process

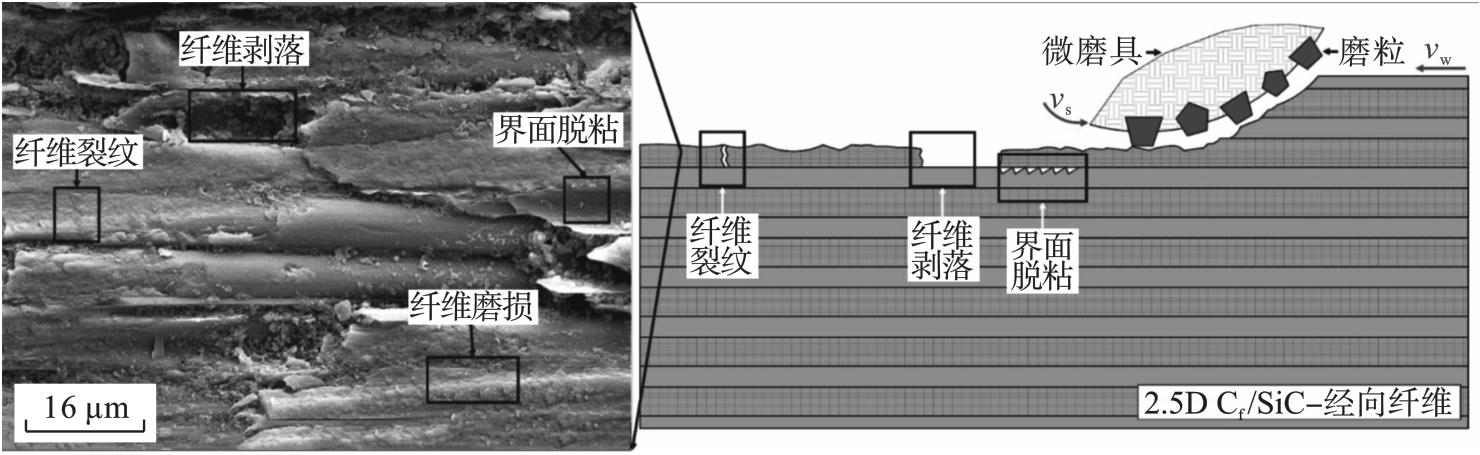

图6 2.5D Cf/SiC复合材料经向纤维层微磨削后表面显微形貌与去除过程原理图

Fig.6 Surface morphology of warp fiber layer of 2.5D Cf/SiC composites and schematic diagram of the removal process

| 试验序号 | 工艺参数 | 2.5D Cf/SiC | SiC陶瓷 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| vs/(m·s-1) | ap/μm | vw/(μm·s-1) | Fn/N | Ft/N | Ra/μm | Fn/N | Ft/N | Ra/μm | |

| 1 | 0.471 | 9 | 120 | 1.223 | 0.980 | 1.004 | 1.407 | 1.146 | 1.235 |

| 2 | 0.942 | 9 | 120 | 0.958 | 0.778 | 0.921 | 1.219 | 0.967 | 1.074 |

| 3 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 4 | 1.885 | 9 | 120 | 0.496 | 0.366 | 0.663 | 0.767 | 0.657 | 0.846 |

| 5 | 2.356 | 9 | 120 | 0.385 | 0.294 | 0.587 | 0.619 | 0.526 | 0.690 |

| 6 | 1.414 | 3 | 120 | 0.293 | 0.222 | 0.501 | 0.525 | 0.411 | 0.638 |

| 7 | 1.414 | 6 | 120 | 0.394 | 0.303 | 0.622 | 0.748 | 0.634 | 0.792 |

| 8 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 9 | 1.414 | 12 | 120 | 0.873 | 0.657 | 0.916 | 1.289 | 1.046 | 1.106 |

| 10 | 1.414 | 15 | 120 | 1.122 | 0.888 | 1.102 | 1.513 | 1.206 | 1.356 |

| 11 | 1.414 | 9 | 20 | 0.337 | 0.269 | 0.632 | 0.594 | 0.475 | 0.747 |

| 12 | 1.414 | 9 | 70 | 0.428 | 0.382 | 0.729 | 0.767 | 0.642 | 0.852 |

| 13 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 14 | 1.414 | 9 | 170 | 0.756 | 0.597 | 0.922 | 1.094 | 0.956 | 0.989 |

| 15 | 1.414 | 9 | 220 | 0.852 | 0.685 | 0.985 | 1.209 | 1.035 | 1.020 |

表3 单因素微磨削实验结果

Table 3 Experimental results of single‑factor micro‑grinding

| 试验序号 | 工艺参数 | 2.5D Cf/SiC | SiC陶瓷 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| vs/(m·s-1) | ap/μm | vw/(μm·s-1) | Fn/N | Ft/N | Ra/μm | Fn/N | Ft/N | Ra/μm | |

| 1 | 0.471 | 9 | 120 | 1.223 | 0.980 | 1.004 | 1.407 | 1.146 | 1.235 |

| 2 | 0.942 | 9 | 120 | 0.958 | 0.778 | 0.921 | 1.219 | 0.967 | 1.074 |

| 3 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 4 | 1.885 | 9 | 120 | 0.496 | 0.366 | 0.663 | 0.767 | 0.657 | 0.846 |

| 5 | 2.356 | 9 | 120 | 0.385 | 0.294 | 0.587 | 0.619 | 0.526 | 0.690 |

| 6 | 1.414 | 3 | 120 | 0.293 | 0.222 | 0.501 | 0.525 | 0.411 | 0.638 |

| 7 | 1.414 | 6 | 120 | 0.394 | 0.303 | 0.622 | 0.748 | 0.634 | 0.792 |

| 8 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 9 | 1.414 | 12 | 120 | 0.873 | 0.657 | 0.916 | 1.289 | 1.046 | 1.106 |

| 10 | 1.414 | 15 | 120 | 1.122 | 0.888 | 1.102 | 1.513 | 1.206 | 1.356 |

| 11 | 1.414 | 9 | 20 | 0.337 | 0.269 | 0.632 | 0.594 | 0.475 | 0.747 |

| 12 | 1.414 | 9 | 70 | 0.428 | 0.382 | 0.729 | 0.767 | 0.642 | 0.852 |

| 13 | 1.414 | 9 | 120 | 0.627 | 0.511 | 0.805 | 0.984 | 0.839 | 0.927 |

| 14 | 1.414 | 9 | 170 | 0.756 | 0.597 | 0.922 | 1.094 | 0.956 | 0.989 |

| 15 | 1.414 | 9 | 220 | 0.852 | 0.685 | 0.985 | 1.209 | 1.035 | 1.020 |

| 1 | Fu H, Jiang L P, Song Q H,et al.Grinding surface roughness prediction for silicon nitride ceramics:a dynamic grinding force and frequency domain approach[J].Ceramics International,2023,49(22):35239-35253. |

| 2 | Zhang X H, Wang X, Jiao W L,et al.Evolution from microfibers to nanofibers toward next‑generation ceramic matrix composites:a review[J].Journal of the European Ceramic Society,2023,43(4):1255-1269. |

| 3 | An Q L, Chen J, Ming W W,et al.Machining of SiC ceramic matrix composites:a review[J].Chinese Journal of Aeronautics,2021,34(4):540-567. |

| 4 | Du J G, Ming W Y, Ma J,et al.New observations of the fiber orientations effect on machinability in grinding of C/SiC ceramic matrix composite[J].Ceramics International,2018,44(12):13916-13928. |

| 5 | Zhou K, Xiao G J, Xu J Y,et al.Material removal behavior of Cf/SiC ceramic matrix composites as a function of abrasive wear during diamond abrasive belt grinding[J].Wear,2021,486:43-59. |

| 6 | Guo M X, Tao J B, Wu C J,et al.High‑speed grinding fracture mechanism of Cf/SiC composite considering interfacial strength and anisotropy[J].Ceramics International,2023,49(2):2600-2612. |

| 7 | Chen J, Ming W W, Chen M,et al.Investigation on machined surface quality in ultrasonic‑assisted grinding of Cf/SiC composites based on fracture mechanism of carbon fibers[J].The International Journal of Advanced Manufacturing Technology,2020,109(5):1583-1599. |

| 8 | 屈硕硕,巩亚东,杨玉莹,等.单向碳纤维增强陶瓷基复合材料磨削表面质量研究[J].东北大学学报(自然科学版),2019,40(9):1310-1315. |

| Qu Shuo‑shuo, Gong Ya‑dong, Yang Yu‑ying,et al.Study on grinding surface quality of unidirectional carbon fiber reinforced ceramic matrix composites[J].Journal of Northeastern University(Natural Science),2019,40(9):1310-1315. | |

| 9 | Liu Q, Huang G Q, Xu X P,et al.Influence of grinding fiber angles on grinding of the 2D-Cf /C-SiC composites[J].Ceramics International,2018,44(11):12774-12782. |

| 10 | Sun Z G, Kong C Y, Niu X M,et al.Optimization and reliability analysis of 2.5D C/SiC composites turbine stator vane[J].Applied Composite Materials,2014,21(5):789-803. |

| 11 | 黄水泉,高尚,黄传真,等.脆性材料磨粒加工的纳米尺度去除机理[J].金刚石与磨料磨具工程,2022,42(3):257-267. |

| Huang Shui‑quan, Gao Shang, Huang Chuan‑zhen,et al.Nano‑scale removal mechanism of abrasive grain processing of brittle materials[J].Diamond and Abrasive Engineering,2022,42(3):257-267. | |

| 12 | Li W, Long C J, Ma W Q,et al.Key technologies for laser‑assisted precision grinding of 3D C/C-SiC composites[J].Journal of the European Ceramic Society,2023,43(10):4322-4335. |

| 13 | 任敬心,华定安.磨削原理[M].北京:电子工业出版社,2011:356-361. |

| Ren Jing‑xin, Hua Ding‑an.Grinding principle[M]. Beijing:Electronic Industry Press,2011:356-361. |

| [1] | 李远峰, 温泉, 巩亚东, 唐本甲. 2.5D Cf /SiC复合材料微尺度磨削试验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1143-1149. |

| [2] | 马廉洁, 孙立业, 邱喆, 李红双. 二维超声振动辅助磨削的磨削力建模[J]. 东北大学学报(自然科学版), 2024, 45(8): 1135-1142. |

| [3] | 周云光, 田川川, 王书海, 陈晗. SiC陶瓷的磨削去除机理及参数对磨削力影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 548-554. |

| [4] | 温雪龙, 桂宏泽, 巩亚东, 王蒙山. 高熵合金微尺度磨削力实验研究[J]. 东北大学学报(自然科学版), 2024, 45(12): 1734-1743. |

| [5] | 张家豪, 邹平, 魏事宇, 梁付强. 单激励三维超声车削加工技术的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1152-1159. |

| [6] | 方锐, 邹平, 段经伟, 魏事宇. 三维超声振动辅助车削减摩特性与表面质量的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(2): 233-241. |

| [7] | 孙瑶, 唐本甲, 巩亚东, 李思慧. 镍基单晶高温合金表面微阵列孔的制备方法及其实验研究[J]. 东北大学学报(自然科学版), 2023, 44(12): 1719-1725. |

| [8] | 姜世杰, 胡科, 陈丕峰, 战明. 熔丝成型制品三维表面粗糙度的理论与实验研究[J]. 东北大学学报(自然科学版), 2022, 43(9): 1290-1297. |

| [9] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [10] | 温雪龙, 李佳育, 李欣妍. TiC涂层微磨具磨削表面质量影响因素[J]. 东北大学学报(自然科学版), 2022, 43(4): 534-540. |

| [11] | 周云光, 田川川, 马廉洁, 毕长波. 氧化锆陶瓷微尺度磨削表面质量试验研究[J]. 东北大学学报(自然科学版), 2022, 43(1): 83-88. |

| [12] | 赵春雨, 程大众, 耿浩博. 车削工件2-D表面形貌检测方法研究[J]. 东北大学学报(自然科学版), 2021, 42(9): 1299-1306. |

| [13] | 姜世杰, 胡科, 陈丕峰, SIYAJEU Yannick. 熔丝成型薄板表面粗糙度理论模型与实验验证[J]. 东北大学学报(自然科学版), 2021, 42(7): 980-986. |

| [14] | 修世超, 卢跃, 孙聪, 李清良. 端面磨削动态热力耦合效应及对表面去除过程影响[J]. 东北大学学报(自然科学版), 2021, 42(3): 389-395. |

| [15] | 焦安源, 张国富, 丁浩东, 刘伟军. TC4钛合金孔的磁粒研磨试验[J]. 东北大学学报:自然科学版, 2020, 41(9): 1304-1310. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||