东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (11): 1595-1603.DOI: 10.12068/j.issn.1005-3026.2024.11.010

收稿日期:2023-06-21

出版日期:2024-11-15

发布日期:2025-02-24

通讯作者:

徐新岩

作者简介:郝 博(1963-),男,辽宁沈阳人,东北大学教授,博士生导师.

基金资助:

Bo HAO1,2, Xin-yan XU1( ), Yu-xin ZHAO1, Jun-wei YAN1

), Yu-xin ZHAO1, Jun-wei YAN1

Received:2023-06-21

Online:2024-11-15

Published:2025-02-24

Contact:

Xin-yan XU

About author:XU Xin-yan, E-mail: 1035011108@qq.com摘要:

飞机蒙皮、尾翼等零件上的铆接孔表面质量关乎飞机整体装配性能,目前铆接孔缺陷检测大多为传统人工检测,易出现漏检现象.因此,提出一种具有创新性的改进YOLOv8的铆接孔表面缺陷检测方法.采用可变形卷积替换常规卷积,解决特征提取中感受野形状固定的问题.嵌入SimAM注意力机制,增强网络在背景和目标对比度较低状况下的辨识能力.使用WIoU边界框回归损失函数代替CIoU损失函数,降低低质量图像对模型训练的影响,提高模型的鲁棒性和泛化能力.为验证本文模型的性能,以带铆接孔的6061铝合金板代替飞机蒙皮进行检测.实验结果表明,本文模型在铆接孔测试集上mAP_0.5和准确率分别达到了0.918和0.920,较原始YOLOv8模型分别提高了24.1%和25.3%.

中图分类号:

郝博, 徐新岩, 赵玉欣, 闫俊伟. 基于改进YOLOv8的铆接孔表面缺陷检测[J]. 东北大学学报(自然科学版), 2024, 45(11): 1595-1603.

Bo HAO, Xin-yan XU, Yu-xin ZHAO, Jun-wei YAN. Surface Defect Detection of Riveting Holes Based on Improved YOLOv8[J]. Journal of Northeastern University(Natural Science), 2024, 45(11): 1595-1603.

| 型号 | MV-EM510M |

|---|---|

| 分辨率 | 2 456×2 058 |

| 外形尺寸/mm | 50×50×48 |

| 最大帧率/(帧 | 15 |

| 曝光方式 | 帧曝光 |

| 功耗/W | 2.5 |

表1 CCD相机参数

Table 1 Parameters of the CCD camera

| 型号 | MV-EM510M |

|---|---|

| 分辨率 | 2 456×2 058 |

| 外形尺寸/mm | 50×50×48 |

| 最大帧率/(帧 | 15 |

| 曝光方式 | 帧曝光 |

| 功耗/W | 2.5 |

| 型号 | BT-R23C144 |

|---|---|

| 放大倍率 | 0.061 |

| 视场尺寸/mm | 144.3×108.2 |

| 光圈 | 8 |

| 远心度/(°) | <0.05 |

| 景深/mm | 90 |

| 畸变/% | <0.08 |

表2 远心镜头参数

Table 2 Parameters of the telecentric lens

| 型号 | BT-R23C144 |

|---|---|

| 放大倍率 | 0.061 |

| 视场尺寸/mm | 144.3×108.2 |

| 光圈 | 8 |

| 远心度/(°) | <0.05 |

| 景深/mm | 90 |

| 畸变/% | <0.08 |

| 模型 | 缺陷 | P | R | F1值 | AP_0.5 |

|---|---|---|---|---|---|

| 本文模型 | 裂纹 | 0.919 | 0.938 | 0.928 | 0.912 |

| 凹陷 | 0.900 | 0.948 | 0.923 | 0.963 | |

| 毛刺 | 0.856 | 0.922 | 0.888 | 0.929 | |

| 划痕 | 0.890 | 0.759 | 0.819 | 0.869 | |

YOLOv8 模型 | 裂纹 | 0.791 | 0.812 | 0.801 | 0.723 |

| 凹陷 | 0.736 | 0.667 | 0.700 | 0.719 | |

| 毛刺 | 0.870 | 0.629 | 0.730 | 0.812 | |

| 划痕 | 0.575 | 0.487 | 0.527 | 0.453 |

表3 两种模型检测精度参数

Table 3 Test accuracy parameters of the two models

| 模型 | 缺陷 | P | R | F1值 | AP_0.5 |

|---|---|---|---|---|---|

| 本文模型 | 裂纹 | 0.919 | 0.938 | 0.928 | 0.912 |

| 凹陷 | 0.900 | 0.948 | 0.923 | 0.963 | |

| 毛刺 | 0.856 | 0.922 | 0.888 | 0.929 | |

| 划痕 | 0.890 | 0.759 | 0.819 | 0.869 | |

YOLOv8 模型 | 裂纹 | 0.791 | 0.812 | 0.801 | 0.723 |

| 凹陷 | 0.736 | 0.667 | 0.700 | 0.719 | |

| 毛刺 | 0.870 | 0.629 | 0.730 | 0.812 | |

| 划痕 | 0.575 | 0.487 | 0.527 | 0.453 |

| 组别 | 模型 | P | R | mAP_0.5 | mAP_0.5∶0.95 | 帧率/(帧· |

|---|---|---|---|---|---|---|

| 1 | YOLOv8 | 0.743 | 0.649 | 0.677 | 0.367 | 243.90 |

| 2 | YOLOv8+WIoU | 0.791 | 0.650 | 0.754 | 0.458 | 204.08 |

| 3 | YOLOv8+WIoU+SimAM | 0.790 | 0.681 | 0.806 | 0.476 | 178.57 |

| 4 | YOLOv8+WIoU+SimAM+DCN | 0.891 | 0.892 | 0.918 | 0.524 | 147.06 |

表4 消融实验结果

Table 4 Results of ablation experiments

| 组别 | 模型 | P | R | mAP_0.5 | mAP_0.5∶0.95 | 帧率/(帧· |

|---|---|---|---|---|---|---|

| 1 | YOLOv8 | 0.743 | 0.649 | 0.677 | 0.367 | 243.90 |

| 2 | YOLOv8+WIoU | 0.791 | 0.650 | 0.754 | 0.458 | 204.08 |

| 3 | YOLOv8+WIoU+SimAM | 0.790 | 0.681 | 0.806 | 0.476 | 178.57 |

| 4 | YOLOv8+WIoU+SimAM+DCN | 0.891 | 0.892 | 0.918 | 0.524 | 147.06 |

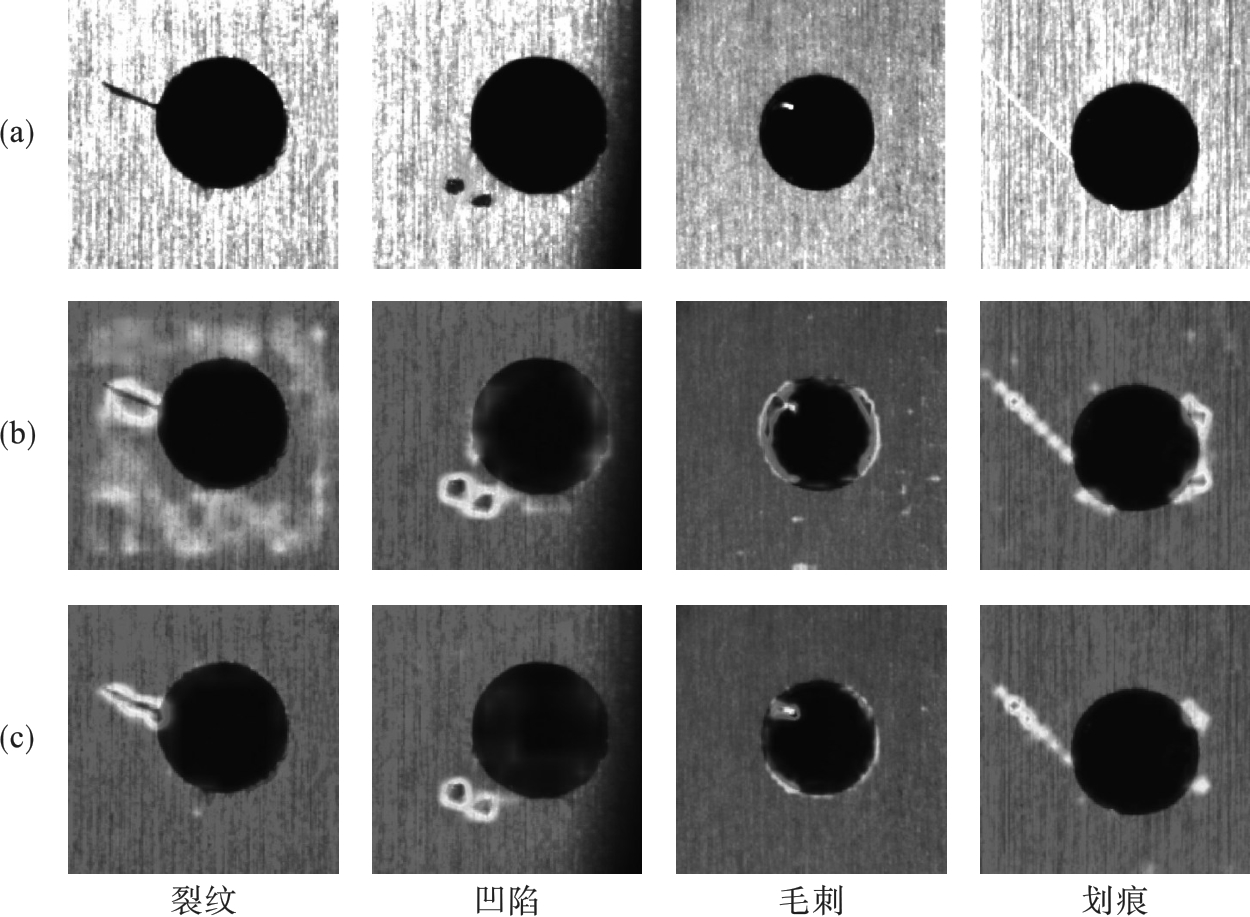

图11 改进后模型与原始模型的热力图对比(a)—缺陷原图; (b)—YOLOv8模型可视化热力图; (c)—改进YOLOv8模型可视化热力图.

Fig.11 Comparison of heat maps between the improved model and the original model

| 1 | Wang J, Zhu C R, Yang Y P,et al.Effect of riveting displacement on the mechanical behavior of CFRP bolted joints with elliptical‑head non‑lug self‑locking rivet nut[J].International Journal of Advanced Manufacturing Technology,2023,125(5/6):2161-2182. |

| 2 | 吕帅帅,杨宇,王彬文,等.基于改进Mask-RCNN的飞行器结构裂纹自动检测方法[J].振动、测试与诊断,2021,41(3):487-494,620. |

| Shuai‑shuai Lyu, Yang Yu, Wang Bin‑wen,et al.An automatic crack detection method for structure test based on improved Mask-RCNN[J].Journal of Vibration,Measurement & Diagnosis,2021,41(3):487-494,620. | |

| 3 | Liu Y X, Wu D B, Liang J W,et al.Aeroengine blade surface defect detection system based on improved faster RCNN[J].International Journal of Intelligent Systems,2023:1992415. |

| 4 | 潘睿志,林涛,李超,等.基于深度学习的多尺寸汽车轮辋焊缝检测与定位系统研究[J].光学精密工程,2023,31(8):1174-1187. |

| Pan Rui‑zhi, Lin Tao, Li Chao,et al.Research on multi size automobile rim weld detection and positioning system based on depth learning[J].Optics and Precision Engineering,2023,31(8):1174-1187. | |

| 5 | Aboah A, Wang B, Bagci U,et al.Real‑time multi‑class helmet violation detection using few‑shot data sampling technique and YOLOv8[C]//2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW).Vancouver,2023:5350-5358. |

| 6 | Feng C J, Zhong Y J, Gao Y,et al.TOOD:task‑aligned one‑stage object detection[C]//2021 IEEE/CVF International Conference on Computer Vision (ICCV).Montreal,2021:3490-3499. |

| 7 | Li X, Wang W H, Wu L J,et al.Generalized focal loss:learning qualified and distributed bounding boxes for dense object detection[J].ArXiv,2022:2006.04388. |

| 8 | Dai J F, Qi H Z, Xiong Y W,et al.Deformable convolutional networks[C]//2017 IEEE International Conference on Computer Vision (ICCV).Venice,2017:764-773. |

| 9 | Zhu X Z, Hu H, Lin S,et al.Deformable ConvNets V2:more deformable,better results[C]//2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR).Long Beach,2019:9300-9308. |

| 10 | Hu J, Shen L, Albanie S,et al.Squeeze‑and‑excitation networks[J].IEEE Transaction on Pattern Analysis and Machine Intelligence,2020,42(8):2011-2023. |

| 11 | Woo S, Park J, Lee J Y,et al.CBAM:convolutional block attention module[C]//European Conference on Computer Vision.Cham:Springer,2018:3-19. |

| 12 | Park J, Woo S, Lee J Y,et al.BAM:bottleneck attention module[J].ArXiv,2022:1807.06514. |

| 13 | Yang L X, Zhang R Y, Li L D,et al.SimAM:a simple,parameter‑free attention module for convolutional neural networks[C]//International Conference on Machine Learning (ICML).San Diego,2021:1-12. |

| 14 | Tong Z J, Chen Y H, Xu Z W,et al.Wise-IoU:bounding box regression loss with dynamic focusing mechanism[J].ArXiv,2023:2301.10051. |

| 15 | Selvaraju R R, Cogswell M, Das A,et al.Grad-CAM:visual explanations from deep networks via gradient‑based localization[J].International Journal of Computer Vision,2020,128(2):336-359. |

| [1] | 刘炎, 卜齐杰, 赵红晨, 郭鑫. 基于多源异构信息的浮选过程运行状态评价[J]. 东北大学学报(自然科学版), 2024, 45(9): 1217-1226. |

| [2] | 刘伟嵬, 邱佳鹤, 胡光大, 刘泽远. 基于改进YOLOv5的退役轴类零件表面损伤检测方法[J]. 东北大学学报(自然科学版), 2024, 45(7): 1002-1010. |

| [3] | 田岸霖, 雷为民, 张鹏, 张伟. 一种基于编解码结构的多尺度边缘检测方法[J]. 东北大学学报(自然科学版), 2024, 45(7): 936-943. |

| [4] | 郭立新, 毕素涛, 赵明扬. 基于改进YOLOv4轻量化网络的机械手状态检测算法[J]. 东北大学学报(自然科学版), 2024, 45(6): 769-775. |

| [5] | 马原, 佘黎煌, 李佳蔚, 鲍喜荣. 基于注意力机制的自适应图卷积三维点云识别算法[J]. 东北大学学报(自然科学版), 2024, 45(6): 786-792. |

| [6] | 冯虎, 宋克臣, 崔文琦, 颜云辉. 基于元学习的带钢表面缺陷小样本语义分割[J]. 东北大学学报(自然科学版), 2024, 45(3): 354-360. |

| [7] | 马淑华, 李立振, 秦汉民, 沙晓鹏. 基于PP-PicoDet-XS的改进铝型材表面缺陷检测算法[J]. 东北大学学报(自然科学版), 2024, 45(11): 1557-1564. |

| [8] | 张执锦, 李鹤, 黄宇实, 王文学. 深度残差收缩网络在滚动轴承故障诊断中的应用[J]. 东北大学学报(自然科学版), 2024, 45(11): 1587-1594. |

| [9] | 刘梦园, 吴朝霞, 王金杨, 閤光磊. 基于TST-LSTM模型的烧结料层透气性预测[J]. 东北大学学报(自然科学版), 2024, 45(10): 1379-1385. |

| [10] | 孙颖, 周雅茹, 张雪英. 融合功能性副语言比例系数的语音情感识别[J]. 东北大学学报(自然科学版), 2024, 45(1): 40-48. |

| [11] | 姜杨, 刘成, 丁其川, 王力. 基于双注意力机制的COVID-19病灶CT图像分割方法[J]. 东北大学学报(自然科学版), 2023, 44(9): 1259-1268. |

| [12] | 周嵩, 高天寒. 基于注意力机制RNN模型的癫痫患者脑电信号识别方法[J]. 东北大学学报(自然科学版), 2023, 44(8): 1098-1103. |

| [13] | 丁其川, 王力, 刘成. 融合长距离信道注意力与病理特征的肺结节分类[J]. 东北大学学报(自然科学版), 2023, 44(4): 476-485. |

| [14] | 陈城, 史培新, 王占生, 贾鹏蛟. 基于融合多注意力机制的深度学习的盾构荷载预测方法[J]. 东北大学学报(自然科学版), 2023, 44(11): 1631-1638. |

| [15] | 林清扬, 陈晓方, 谢永芳. 基于残差卷积自注意力神经网络的铝电解过热度识别方法[J]. 东北大学学报(自然科学版), 2023, 44(1): 8-17. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||