东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (5): 636-642.DOI: 10.12068/j.issn.1005-3026.2024.05.004

• 材料与冶金 • 上一篇

孙行1, 陈伟2, 罗昌2, 刘常升1

收稿日期:2022-12-12

出版日期:2024-05-15

发布日期:2024-07-31

作者简介:孙 行(1997-),男,辽宁鞍山人,东北大学硕士研究生Hang SUN1, Wei CHEN2, Chang LUO2, Chang-sheng LIU1

Received:2022-12-12

Online:2024-05-15

Published:2024-07-31

摘要:

为了满足对轧辊表面快速修复的需求,采用激光熔覆技术,将自主设计并制备的高钒半高速钢合金粉末熔覆到轧辊合金钢表面,考虑到锻钢轧辊和激光熔覆层组织之间的差异性,为了稳定组织,对熔覆层进行回火处理,回火温度为500 ℃并保温2 h.结果表明,熔覆层的相组成主要是马氏体;其表面主要是细小等轴晶,晶内马氏体呈针状平行分布,回火后分解为铁素体和碳化物;其横截面的平均硬度为663.4 HV,是基体硬度的1.8倍;熔覆层平均摩擦系数为0.708,磨损率为6.142×10-6 mm3·N-1·m-1,磨损性能较基体提高25倍,磨损形貌较好,与磨损量结果保持一致.

中图分类号:

孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642.

Hang SUN, Wei CHEN, Chang LUO, Chang-sheng LIU. Microstructure and Properties of Tempered High Vanadium Semi High Speed Steel Alloy Cladding Layer[J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 636-642.

| 材料 | C | Si | Mn | Cr | Ni | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| 基体 | 0.74 | 0.70~0.90 | 0.25~0.45 | 5.00~5.50 | 0.25 | 0.96 | 0.40 | 余量 |

| 半高速钢合金粉末 | 0.74 | — | — | — | — | — | 1.60 | 余量 |

表1 轧辊合金钢及高钒半高速钢合金粉末化学成分(质量分数) ((mass fraction) %)

Table 1 The composition of roller alloy steel and high vanadium semi high speed steel alloy powder

| 材料 | C | Si | Mn | Cr | Ni | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|

| 基体 | 0.74 | 0.70~0.90 | 0.25~0.45 | 5.00~5.50 | 0.25 | 0.96 | 0.40 | 余量 |

| 半高速钢合金粉末 | 0.74 | — | — | — | — | — | 1.60 | 余量 |

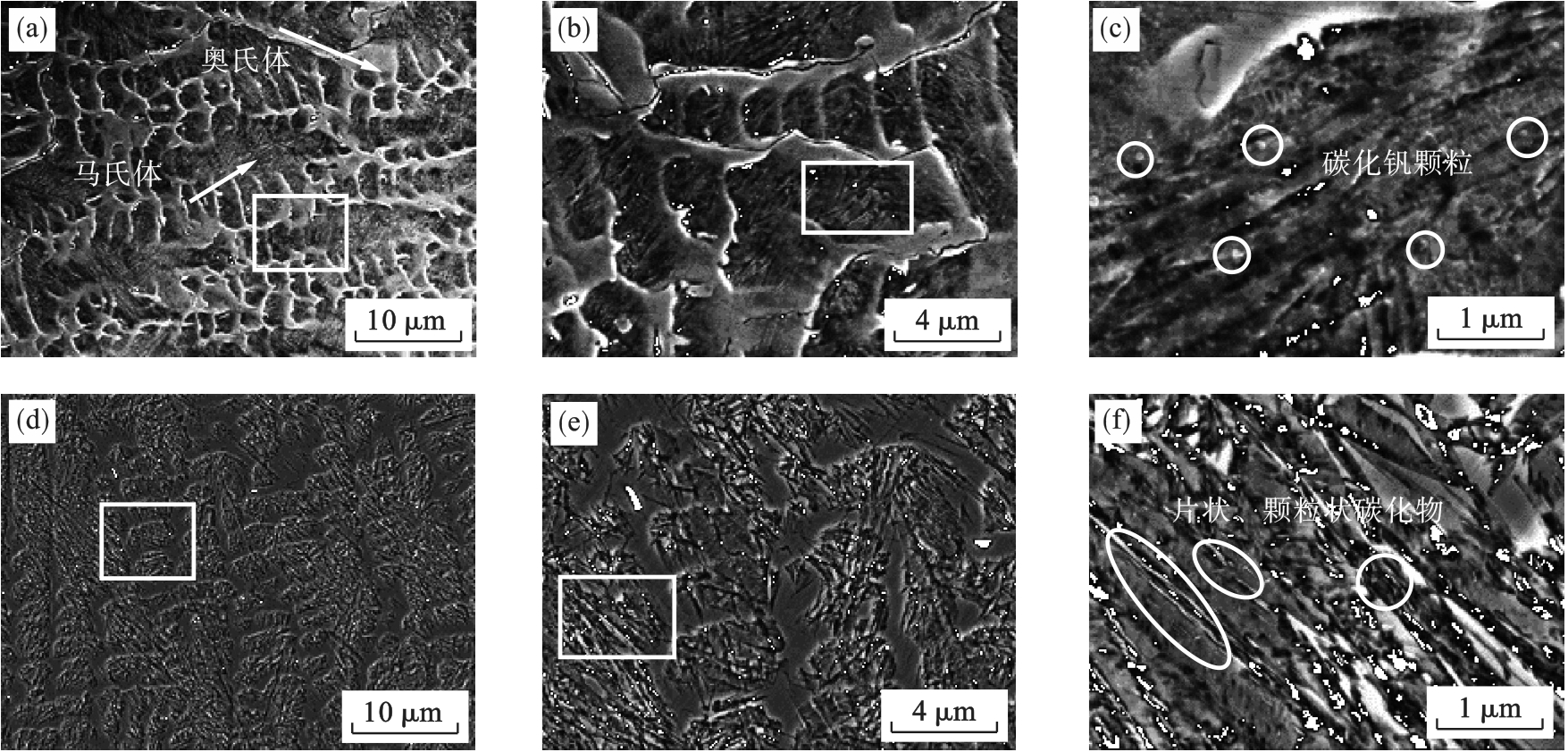

图3 回火前后熔覆层的显微组织(a)—熔覆层回火前; (b)—图a局部放大; (c)—图b局部放大; (d)—熔覆层回火后; (e)—图d局部放大; (f)—图e局部放大.

Fig.3 Microstructure of cladding layer before and after tempering

| 点 | C | Fe | V | Cr | Mo | Si |

|---|---|---|---|---|---|---|

| 1 | 21.60 | 48.54 | 6.73 | 8.95 | 13.72 | 0.47 |

| 2 | 24.80 | 33.20 | 4.34 | 15.88 | 21.37 | 0.41 |

| 3 | 2.59 | 85.66 | 0.55 | 4.54 | 3.34 | 0.33 |

表2 图5c中碳化物分析结果(质量分数) (%)

Table 2 Analysis results of carbides in figure 5c (mass fraction)

| 点 | C | Fe | V | Cr | Mo | Si |

|---|---|---|---|---|---|---|

| 1 | 21.60 | 48.54 | 6.73 | 8.95 | 13.72 | 0.47 |

| 2 | 24.80 | 33.20 | 4.34 | 15.88 | 21.37 | 0.41 |

| 3 | 2.59 | 85.66 | 0.55 | 4.54 | 3.34 | 0.33 |

| 样品 | 磨痕宽度/mm | 磨损体积/mm3 | 磨损率/(mm3·N-1·m-1) | 最大摩擦系数 |

|---|---|---|---|---|

| 基体 | 1.865 | 1.112 89 | 154.567×10-6 | 0.783 |

| 熔覆层 | 0.656 | 0.044 42 | 6.142×10-6 | 0.708 |

表3 激光熔覆层摩擦磨损实验结果

Table 3 Friction and wear test results of laser cladding layer

| 样品 | 磨痕宽度/mm | 磨损体积/mm3 | 磨损率/(mm3·N-1·m-1) | 最大摩擦系数 |

|---|---|---|---|---|

| 基体 | 1.865 | 1.112 89 | 154.567×10-6 | 0.783 |

| 熔覆层 | 0.656 | 0.044 42 | 6.142×10-6 | 0.708 |

| 1 | Meng L, Zhu B B, Xian C,et al.Comparison on the wear properties and rolling contact fatigue damage behaviors of rails by laser cladding and laser‐induction hybrid cladding[J].Wear,2020,458/459:203421. |

| 2 | Zhang S H, Zhang G L, Liu J S,et al.A fast rigid‐plastic finite element method for online application in strip rolling[J].Finite Elements in Analysis and Design,2010,46(12):1146-1154. |

| 3 | Kanematsu W.A review of rolling contact fatigue behavior of silicon nitride focusing on testing practices and crack propagation analysis[J].Wear,2018,400/401:10-20. |

| 4 | 白万真,魏世忠,龙锐,等.冷轧辊典型失效形式分析综述[J].铸造技术,2006,27(9):1010-1014. |

| Bai Wan‐zhen, Wei Shi‐zhong, Long Rui,et al.Analysis and review on typical failure forms of cold roll[J].Foundry Technology,2006,27(9):1010-1014. | |

| 5 | Qu H W, Liao B, Liu L G,et al.Precipitation rule of carbides in a new high speed steel for rollers[J].Calphad,2012,36:144-150. |

| 6 | Zhu H T, Zhu Q, Tieu A K,et al.A Simulation of wear behaviour of high‐speed steel hot rolls by means of high temperature pin‐on‐disc tests[J].Wear,2013,302(1/2):1310-1318. |

| 7 | 宫开令,高春利,张自立.半高速钢轧辊材料性能的研究[J].轧钢,2003(6):22-24. |

| Gong Kai‑ling, Gao Chun‑li, Zhang Zi‑li.Research of performance of easy‐cut high speed of roll[J].Steel Rolling,2003(6):22-24. | |

| 8 | 吴琼,孙大乐.半高速钢冷轧辊材料的锻后淬火工艺[J].钢铁,2011,46 (8):68-72,77. |

| Wu Qiong, Sun Da‐le.Ausform hardening process of semi‐HSS cold forged roll materials[J].Iron & Steel,2011,46 (8):68-72,77. | |

| 9 | 鲁莎,郭秋娟,田明艳.半高速钢轧辊显微组织和碳化物类型研究[J].大型铸锻件,2017(2):4-6,49. |

| Lu Sha, Guo Qiu‑juan, Tian Ming‑yan.Study on the microstructure and carbide types of semi‑high speed steel roll[J].Heavy Casting and Forging,2017(2):4-6,49. | |

| 10 | Zhu L D, Xue P S, Qing L,et al.Recent research and development status of laser cladding:A review[J].Optics & Laser Technology,2021,138:106915. |

| 11 | Selvaraj K S, Prasad S K, Yasin S Y,et al.Additive manufacturing of dental material parts via laser melting deposition:a review,technical issues,and future research directions[J].Journal of Manufacturing Processes,2022,76:67-78. |

| 12 | Liu Y, Yang J J, Yang H,et al.Cu‐bearing 316L stainless steel coatings produced by laser melting deposition:microstructure and corrosion behavior in simulated body fluids[J].Surface and Coatings Technology,2021,428:127868. |

| 13 | 王彦芳,赵晓宇,陆文俊,等.抽油杆接箍表面高速激光熔覆不锈钢涂层的组织与性能[J].中国激光,2021,48(6):175-184. |

| Wang Yan‐fang, Zhao Xiao‐yu, Lu Wen‐jun,et al.Microstructure and properties of high speed laser cladding stainless steel coating on sucker rod coupling[J].Chinese Journal of Lasers,2021,48(6):175-184. | |

| 14 | Rahman N U, Rooij M B D, Matthews D T A,et al.Wear characterization of multilayer laser cladded high speed steels[J].Tribology International,2019,130:52-62. |

| 15 | Hashemi N, Mertens A, Montrieux H M,et al.Oxidative wear behaviour of laser clad high speed steel thick deposits:influence of sliding speed,carbide type and morphology[J].Surface & Coatings Technology,2017,315:519-529. |

| 16 | Wang M J, Wang Y, Sun F F.Tempering behavior of a semi‐high speed steel containing nitrogen[J].Materials Science and Engineering A,2006,438/439/440:1139-1142. |

| 17 | 葛永胜,朱国芳,王成辉,等.半高速钢轧辊的锻造工艺研究[J].大型铸锻件,2006(2):1-3. |

| Ge Yong‐sheng, Zhu Guo‐fang, Wang Cheng‐hui,et al.The forging process of semi‐high speed steel roll[J].Heavy Casting and Forging,2006(2):1-3. | |

| 18 | 尹钟大,刘德富,徐德祥,等.冷轧工作辊用半高速钢的二次硬化效应[J].钢铁,2006,41(2):72-75. |

| Yi Zhong‐da, Liu De‐fu, Xu De‐xiang,et al.Secondary hardening of semi high speed steel for cold work rolls[J].Iron & Steel,2006,41(2):72-75. | |

| 19 | Wei S Z, Zhu J H, Xu L J.Effects of vanadium and carbon on microstructures and abrasive wear resistance of high speed steel[J].Tribology International,2006,39(7):641-648. |

| 20 | Zhao Z Z, Cao Y L, Wan X L,et al.Effect of cooling rate on carbide characteristics of the high vanadium high‐speed steel[J].ISIJ International,2022,62(3):524-531. |

| 21 | Cao Y L, Zhao Z R, Wan X L.Carbide characteristics of high vanadium high‐speed steel manufactured by electroslag remelting[J].ISIJ International,2022,62(7):1430-1438. |

| 22 | Rahman N U, Capuano L, Cabeza S,et al.Directed energy deposition and characterization of high‑carbon high speed steels[J].Additive Manufacturing,2019,30:100838. |

| [1] | 姚文博, 刘忱, 商硕, 刘常升. 扫描速度对激光熔覆Fe-Al合金熔覆层组织及性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(2): 170-178. |

| [2] | 张雅静, 王金朋, 陈鑫, 吴航宇. 医用可降解Zn-3Cu-xMn合金的制备及性能研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1104-1110. |

| [3] | 王海涛, 李家栋, 邓想涛, 王昭东. 固溶温度对Fe-20Mn-9Al-1.2C低密度钢组织性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(5): 609-616. |

| [4] | 董艳伍, 彭飞, 田家龙, 姜周华. 时效对10Ni10Mn2CuAl钢组织及性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(5): 646-651. |

| [5] | 宋红宇, 刘海涛, 王国栋. 薄带连铸取向硅钢的热轧孪生行为[J]. 东北大学学报(自然科学版), 2022, 43(2): 182-187. |

| [6] | 刘庚, 李慧杰, 王庆海, 叶其斌. 690MPa级海洋平台用特厚齿条钢的回火稳定性[J]. 东北大学学报(自然科学版), 2022, 43(2): 188-196. |

| [7] | 王青华, 程杨洋, 王慧鑫. 锆基非晶合金激光微织构处理及摩擦磨损性能[J]. 东北大学学报(自然科学版), 2022, 43(11): 1575-1582. |

| [8] | 高彩茹, 屈兵兵, 田余东, 杜林秀. 回火温度对在线淬火Q690q桥梁钢显微组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(7): 927-933. |

| [9] | 毕梦园, 谢仁义, 张艺凡, 衣海龙. CoCrFeNi高熵合金组织演变规律及再结晶动力学[J]. 东北大学学报(自然科学版), 2021, 42(7): 933-938. |

| [10] | 朱成林, 高秀华, 王明明, 宋丽英. 淬火温度对12Cr14Ni2不锈结构钢组织及力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(6): 781-788. |

| [11] | 郗文超, 宋博学, 梁赢东, 于天彪. 原位生成NbC增强YCF102熔覆层热力学与耐磨性研究[J]. 东北大学学报(自然科学版), 2021, 42(4): 538-543. |

| [12] | 鲍君峰, 于月光, 贾成厂. ZrO2添加量对等离子放电烧结制备WC-6Co组织和性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(1): 43-48. |

| [13] | 辛博, 程光, 姚俊, 巩亚东. 自适应FGM激光熔覆成形的粉体快速混合机理[J]. 东北大学学报:自然科学版, 2020, 41(8): 1123-1128. |

| [14] | 王明明, 高秀华, 杜林秀, 张大征. V-N微合金化X80抗大变形管线钢的组织与力学性能[J]. 东北大学学报:自然科学版, 2020, 41(6): 801-806. |

| [15] | 李彦龙, 吴琼, 秦晓峰, 刘常升. Cr5支承辊接触疲劳损伤及其次表层组织变化[J]. 东北大学学报:自然科学版, 2020, 41(6): 818-823. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||