东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (5): 643-651.DOI: 10.12068/j.issn.1005-3026.2024.05.005

• 材料与冶金 • 上一篇

张九鑫, 任潇健, 金东正, 田勇

收稿日期:2022-12-12

出版日期:2024-05-15

发布日期:2024-07-31

作者简介:张九鑫(1997-),男,辽宁葫芦岛人,东北大学硕士研究生基金资助:Jiu-xin ZHANG, Xiao-jian REN, Dong-zheng JIN, Yong TIAN

Received:2022-12-12

Online:2024-05-15

Published:2024-07-31

摘要:

常规工艺下特厚船舶用钢奥氏体晶粒细化的程度受限,导致极小尺寸奥氏体晶粒对钢板组织性能的影响尚不明确.利用二次奥氏体化法和热机械控制工艺,研究了细化奥氏体晶粒对特厚EH47止裂钢的显微组织演化及力学性能的影响.结果表明:试轧钢的加热温度从890 ℃升高至1 050 ℃时,原奥氏体晶粒尺寸从14 μm增加至28 μm;铁素体含量的降低导致大角度晶界数量比例由57.4%降低至40.5%;马氏体/奥氏体(martenite/austenite,M/A)岛体积分数从2.0%增加至6.5%;钢板的屈服强度从440 MPa提高到488 MPa.890 ℃轧制钢板的单位体积有效晶界面积为269.0 mm-1,是其显微组织细化、均匀化,并在-100 ℃时具有241 J的冲击功的重要原因.

中图分类号:

张九鑫, 任潇健, 金东正, 田勇. 奥氏体晶粒细化对特厚EH47止裂钢组织性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(5): 643-651.

Jiu-xin ZHANG, Xiao-jian REN, Dong-zheng JIN, Yong TIAN. Effect of Austenite Grain Refinement on Microstructure and Properties of Ultra‑Heavy EH47 Crack Arrest Steel[J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 643-651.

| C | Si | Mn | P | S | Nb+Ti | Ni+Cr+Cu |

|---|---|---|---|---|---|---|

| 0.05 | 0.15 | 1.95 | 0.008 | 0.002 | 0.052 | 1.03 |

表1 EH47连铸坯的化学成分(质量分数) (casting slab (mass fraction) %)

Table 1 Chemical composition of the EH47 continuous

| C | Si | Mn | P | S | Nb+Ti | Ni+Cr+Cu |

|---|---|---|---|---|---|---|

| 0.05 | 0.15 | 1.95 | 0.008 | 0.002 | 0.052 | 1.03 |

| 编号 | 平均弦长/μm | 最大尺寸/μm | 体积分数/% |

|---|---|---|---|

| T890 | 1.4 | 5.5 | 2.0 |

| T970 | 2.5 | 6.3 | 5.5 |

| T1050 | 3.5 | 9.9 | 6.5 |

表2 试轧钢的M/A岛的参数

Table 2 Parameters of the M/A island of test rolled steels

| 编号 | 平均弦长/μm | 最大尺寸/μm | 体积分数/% |

|---|---|---|---|

| T890 | 1.4 | 5.5 | 2.0 |

| T970 | 2.5 | 6.3 | 5.5 |

| T1050 | 3.5 | 9.9 | 6.5 |

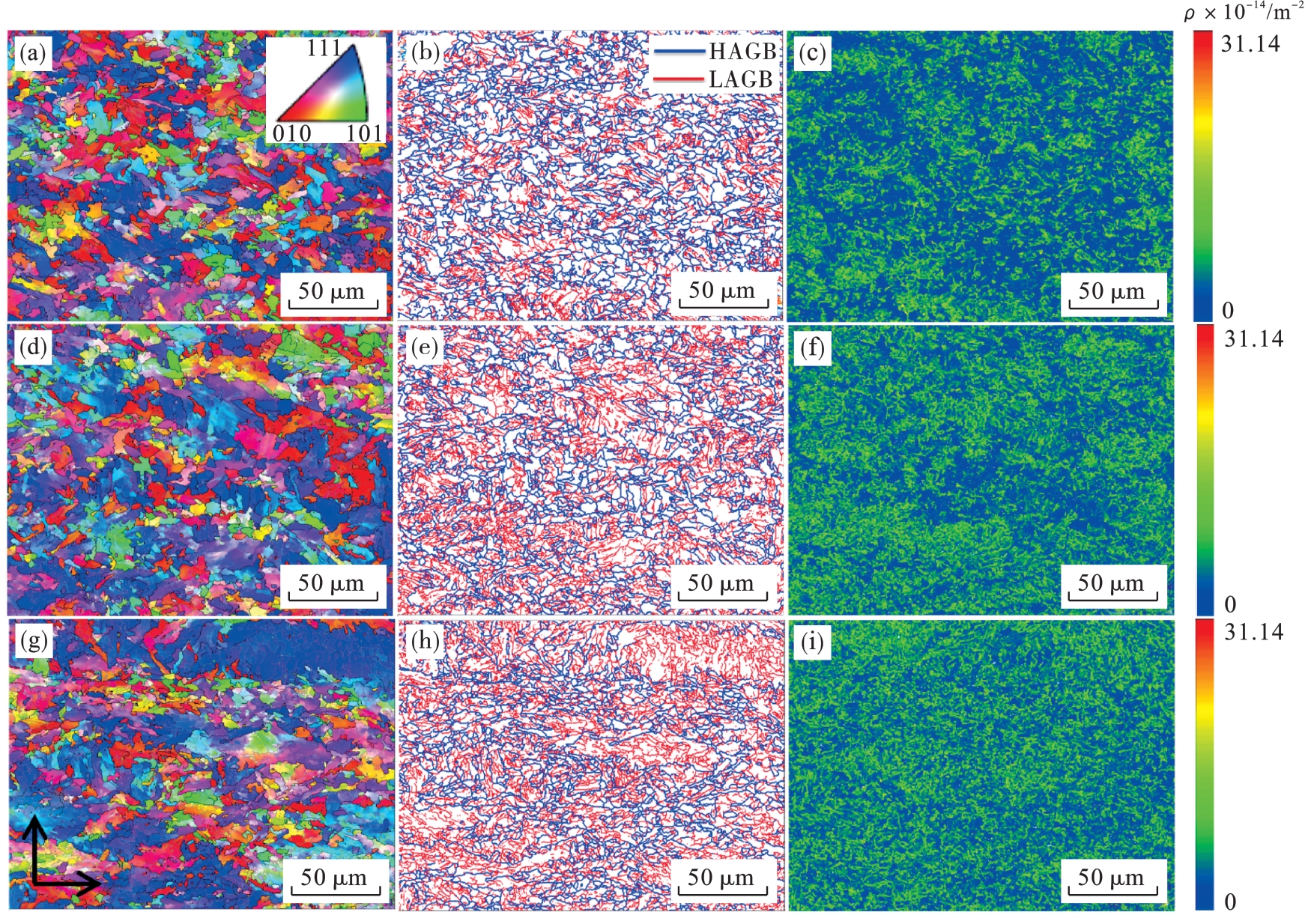

图2 试轧钢1/2厚度的反极图、晶界分布图和位错分布图(a)—T890反极图; (b)—T890晶界分布图; (c)—T890位错分布图; (d)—T970反极图; (e)—T970晶界分布图;(f)—T970位错分布图; (g)—T1050反极图; (h)—T1050晶界分布图; (i)—T970位错分布图.

Fig.2 Inverse pole figure, grain boundary figures and dislocation distribution figures at 1/2 thickness of test rolled steels

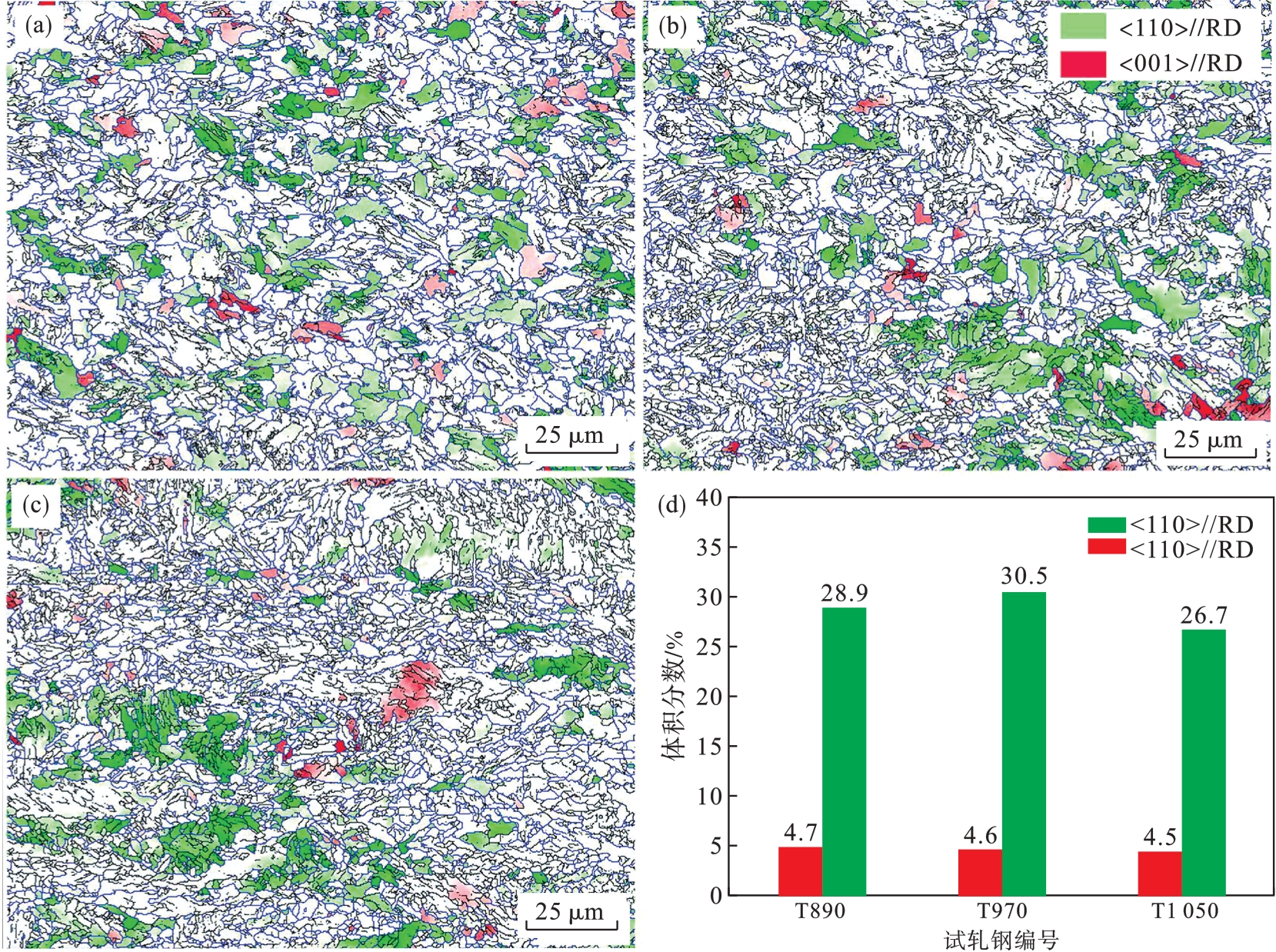

图4 试轧钢1/2厚度的<110>//RD和<001>//RD取向分布和体积分数(a)—T890取向分布; (b)—T970取向分布; (c)—T1050取向分布; (d)—<110>//RD和<001>//RD取向的体积分数.

Fig.4 Orientation distribution and volume fraction of <110>//RD and <001>//RD at 1/2 thickness of test rolled steels

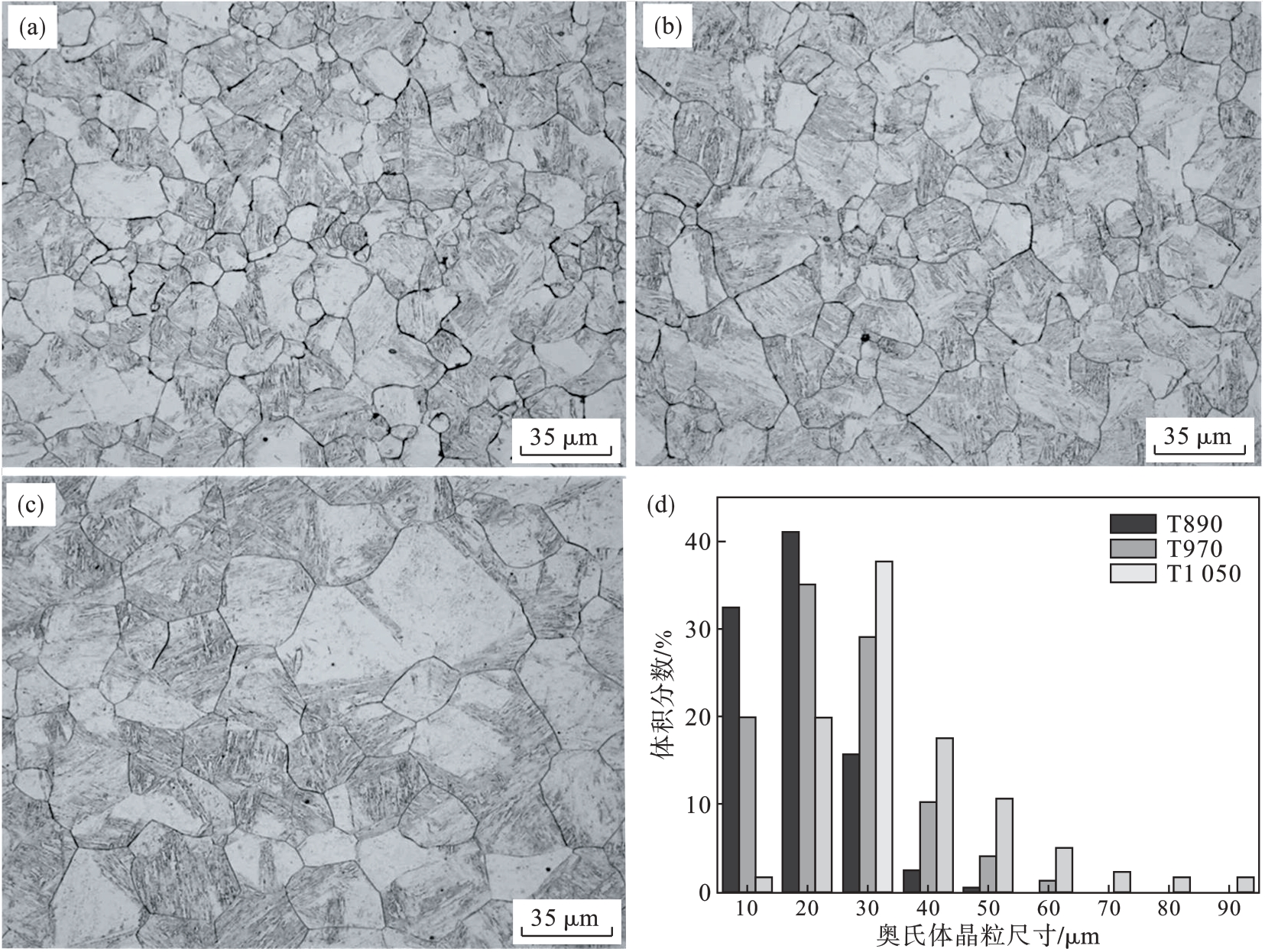

图5 试轧钢的原奥氏体晶粒形貌和不同尺寸晶粒的体积分数(a)—T890原奥氏体晶粒形貌; (b)—T970原奥氏体晶粒形貌;(c)—T1050原奥氏体晶粒形貌; (d)—不同尺寸晶粒的体积分数.

Fig.5 Prior‐austenite grain morphology and the volume fraction of different grain sizes for test rolled steels

| 编号 | 屈服强度 | 抗拉强度 | 延伸率/% | 屈强比 |

|---|---|---|---|---|

| MPa | MPa | |||

| T890 | 440 | 587 | 26.1 | 0.75 |

| T970 | 467 | 610 | 26 | 0.76 |

| T1050 | 488 | 636 | 23.3 | 0.77 |

表3 试轧钢的拉伸测试结果

Table 2 Tensile test results of test rolled steels

| 编号 | 屈服强度 | 抗拉强度 | 延伸率/% | 屈强比 |

|---|---|---|---|---|

| MPa | MPa | |||

| T890 | 440 | 587 | 26.1 | 0.75 |

| T970 | 467 | 610 | 26 | 0.76 |

| T1050 | 488 | 636 | 23.3 | 0.77 |

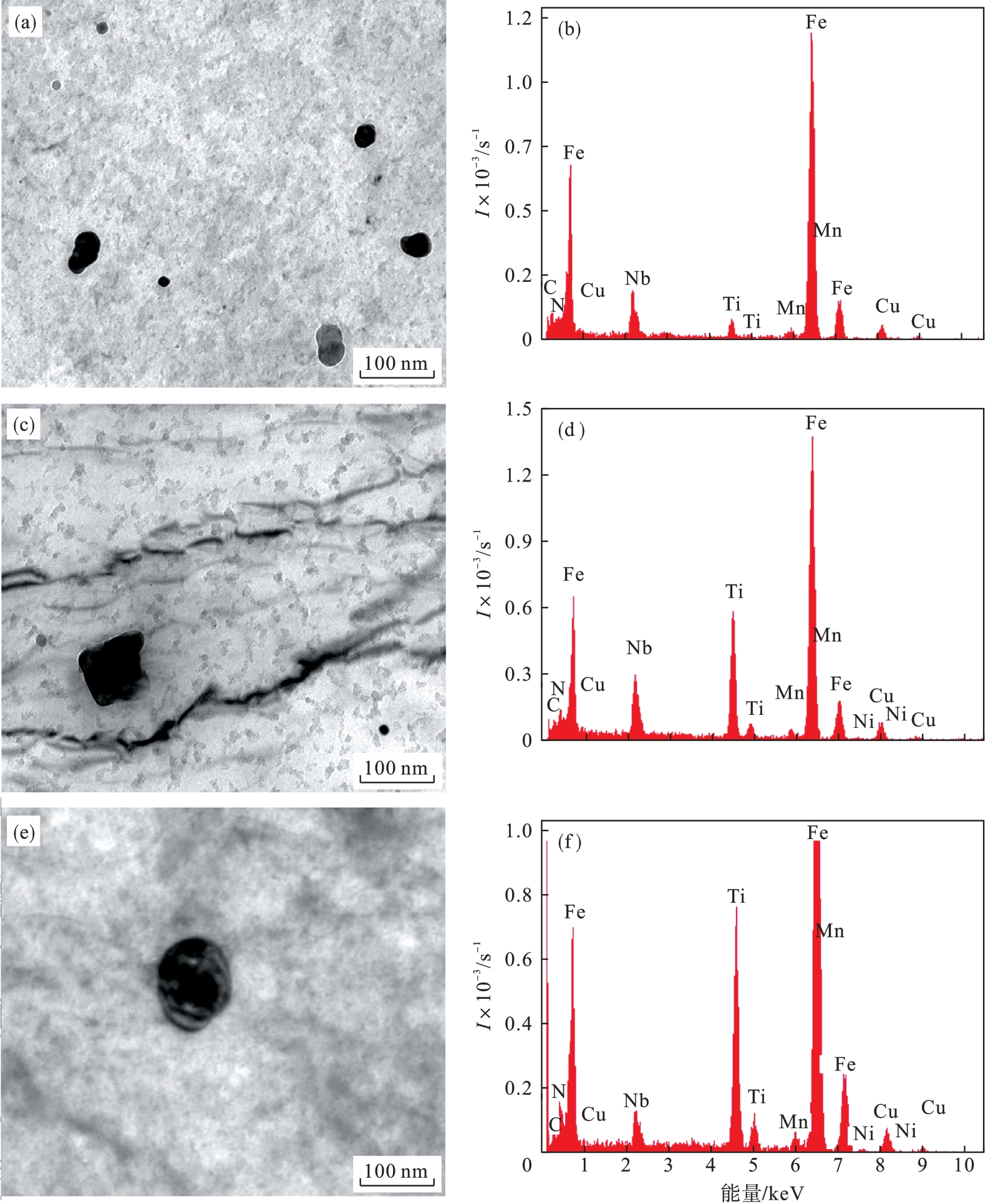

图9 不同奥氏体化温度下析出相的形貌和EDS能谱(a)—T890析出相形貌; (b)—T890 EDS能谱; (c)—T970析出相形貌;(d)—T970 EDS能谱; (e)—T1050析出相形貌; (f)—T1050 EDS能谱.

Fig.9 Morphology and EDS energy spectra of precipitated phases at different austenitization temperatures

| 1 | Wang K, Wu L, Li Y Z,et al.Experimental study on low temperature fatigue performance of polar icebreaking ship steel[J].Ocean Engineering,2020,216:107789. |

| 2 | 国家标准化管理委员会. 船舶及海洋工程用结构钢: [S].北京:中国标准出版社,2022:10. |

| administration Standardization. Structural steel for ship and ocean engineering: [S].Beijing:Standards Press of China,2022:10. | |

| 3 | Wu J Y, Wang B, Wang B X,et al.Toughness and ductility improvement of heavy EH47 plate with grain refinement through inter‑pass cooling[J].Materials Science and Engineering:A,2018,733:117-127. |

| 4 | 温永红,唐荻,武会宾,等.F40 级船板低温韧性机理[J].北京科技大学学报,2008,30(7):724-729. |

| Wen Yong‐hong, Tang Di, Wu Hui‐bin,et al.Low‐temperature toughness characteristics of F40 hull structure steel[J].Journal of University of Science and Technology Beijing,2008,30(7):724-729. | |

| 5 | Xu X N, Tian Y, Ye Q B,et al.Effect of prior austenite grain size on crystallographic characteristics and low‐temperature toughness of a quenched low‐carbon low‐alloy steel[J].Steel Research International,2021,92(11):2100274. |

| 6 | Mandal S, Tewary N K, Ghosh S K,et al.Thermo‐mechanically controlled processed ultrahigh strength steel:microstructure,texture and mechanical properties[J].Materials Science and Engineering:A,2016,663:126-140. |

| 7 | Tian Y, Wang H T, Ye Q B,et al.Effect of rolling reduction below γ non‐recrystallization temperature on pancaked γ,microstructure,texture and low‐temperature toughness for hot rolled steel[J].Materials Science and Engineering:A,2020,794:139640. |

| 8 | Cuddy L J, Bauwin J J, Raley J C.Recrystallization of austenite[J].Metallurgical Transactions A,1980,11(3):381-386. |

| 9 | Lan L Y, Qiu C L, Zhao D W,et al.Effect of austenite grain size on isothermal bainite transformation in low carbon microalloyed steel[J].Materials Science and Technology,2011,27(11):1657-1663. |

| 10 | 国家标准化管理委员会. 金属材料拉伸试验:第1部分 室温试验方法: [S].北京:中国标准出版社,2021:12. |

| administration Standardization. Metallic materials—tensile testing—Part 1:method of test at room temperature: [S].Beijing:Standards Press of China,2021:12. | |

| 11 | Shen X J, Tang S, Chen J,et al.The effect of warm deforming and reversal austenization on the microstructure and mechanical properties of a microalloyed steel[J].Materials Science and Engineering:A,2016,671:182-189. |

| 12 | 杨涛.低碳贝氏体型钢变形奥氏体连续冷却研究[D].上海:上海交通大学,2007. |

| Yang Tao.Study of continuous cooling after austenite deformation of low carbon bainitic steels[D].Shanghai:Shanghai Jiao Tong University,2007. | |

| 13 | Umemoto M, Ohtsuka H, Tamura I.Transformation to pearlite from work‐hardened austenite[J].Transactions of the Iron and Steel Institute of Japan,1983,23(9):775-784. |

| 14 | Ouchi C, Sampei T, Kozasu I.The effect of hot rolling condition and chemical composition on the onset temperature of γ‐α transformation after hot rolling[J].Transactions of the Iron and Steel Institute of Japan,1982,22(3):214-222. |

| 15 | Zheng L, Xu T D.Nonequilibrium grain‐boundary cosegregation of nitrogen and chromium in NiCrMoV steel[J].Metallurgical and Materials Transactions A,2005,36(12):3311-3315. |

| 16 | Zhao M C, Yang K, Xiao F R,et al.Continuous cooling transformation of undeformed and deformed low carbon pipeline steels[J].Materials Science and Engineering:A,2003,355(1/2):126-136. |

| 17 | 齐亮,彭凯,周军,等.TMCP工艺对X100管线钢M/A岛的影响[J].材料导报,2016,30(2):95-98. |

| Qi Liang, Peng Kai, Zhou Jun,et al.Effect of TMCP(thermo‐mechanical control precess) on M/A islands of X100 pipeline steel[J].Materials Reports,2016,30(2):95-98. | |

| 18 | Zhong Y, Xiao F R, Zhang J W,et al.In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra‐fine acicular ferrite pipeline steel[J].Acta Materialia,2006,54(2):435-443. |

| 19 | Wang H T, Tian Y, Ye Q B,et al.Determining role of microstructure on crack arrest and propagation phenomenon in low‐carbon microalloyed steel[J].Materials Science and Engineering:A,2019,761:138009. |

| 20 | Wang C F, Wang M Q, Shi J,et al.Effect of microstructural refinement on the toughness of low carbon martensitic steel[J].Scripta Materialia,2008,58(6):492-495. |

| 21 | Yang X L, Xu Y B, Tan X D,et al.Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel[J].Materials Science and Engineering:A,2014,607:53-62. |

| 22 | Huda N, Midawi A R H, Gianetto J,et al.Influence of martensite‐austenite (MA) on impact toughness of X80 line pipe steels[J].Materials Science and Engineering:A,2016,662:481-491. |

| 23 | Dan W J, Li S H, Zhang W G,et al.The effect of strain‐induced martensitic transformation on mechanical properties of TRIP steel[J].Materials & Design,2008,29(3):604-612. |

| 24 | Jung Y S, Lee Y K, Matlock D K,et al.Effect of grain size on strain‐induced martensitic transformation start temperature in an ultrafine grained metastable austenitic steel[J].Metals and Materials International,2011,17(3):553-556. |

| 25 | 狄国标.高强度海洋平台用钢的强韧化机理研究及产品开发[D].沈阳:东北大学,2010. |

| Di Guo‑biao.Study on strengthening and toughening mechanism and development of high strength offshore platform steel.[D].Shenyang:Northeastern University,2010. | |

| 26 | Hong S G, Kang K B, Park C G.Strain‐induced precipitation of NbC in Nb and Nb‐Ti microalloyed HSLA steels[J].Scripta Materialia,2002,46(2):163-168. |

| [1] | 孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642. |

| [2] | 张雅静, 王金朋, 陈鑫, 吴航宇. 医用可降解Zn-3Cu-xMn合金的制备及性能研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1104-1110. |

| [3] | 王海涛, 李家栋, 邓想涛, 王昭东. 固溶温度对Fe-20Mn-9Al-1.2C低密度钢组织性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(5): 609-616. |

| [4] | 董艳伍, 彭飞, 田家龙, 姜周华. 时效对10Ni10Mn2CuAl钢组织及性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(5): 646-651. |

| [5] | 宋红宇, 刘海涛, 王国栋. 薄带连铸取向硅钢的热轧孪生行为[J]. 东北大学学报(自然科学版), 2022, 43(2): 182-187. |

| [6] | 高彩茹, 屈兵兵, 田余东, 杜林秀. 回火温度对在线淬火Q690q桥梁钢显微组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(7): 927-933. |

| [7] | 毕梦园, 谢仁义, 张艺凡, 衣海龙. CoCrFeNi高熵合金组织演变规律及再结晶动力学[J]. 东北大学学报(自然科学版), 2021, 42(7): 933-938. |

| [8] | 朱成林, 高秀华, 王明明, 宋丽英. 淬火温度对12Cr14Ni2不锈结构钢组织及力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(6): 781-788. |

| [9] | 鲍君峰, 于月光, 贾成厂. ZrO2添加量对等离子放电烧结制备WC-6Co组织和性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(1): 43-48. |

| [10] | 王明明, 高秀华, 杜林秀, 张大征. V-N微合金化X80抗大变形管线钢的组织与力学性能[J]. 东北大学学报:自然科学版, 2020, 41(6): 801-806. |

| [11] | 李彦龙, 吴琼, 秦晓峰, 刘常升. Cr5支承辊接触疲劳损伤及其次表层组织变化[J]. 东北大学学报:自然科学版, 2020, 41(6): 818-823. |

| [12] | 张志强, 何长树, 赵夙, 赵骧. 7075-T6合金超声辅助搅拌摩擦焊接头搅拌区组织与力学性能[J]. 东北大学学报:自然科学版, 2020, 41(12): 1708-1714. |

| [13] | 陈洁, 李长生, 李坤, 涂兴洋. Fe-Mn-1.6Ni-C水电用钢板轧后直接淬火和回火工艺[J]. 东北大学学报:自然科学版, 2019, 40(7): 956-961. |

| [14] | 王晓晖, 康健, 袁国, 王国栋. 等温处理过程热轧TRIP钢残余奥氏体的分解行为[J]. 东北大学学报:自然科学版, 2019, 40(1): 32-37. |

| [15] | 刘静, 刘逸婷. 激光快速成型TC4合金显微组织及力学性能[J]. 东北大学学报:自然科学版, 2018, 39(8): 1132-1136. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||