东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (10): 96-103.DOI: 10.12068/j.issn.1005-3026.2025.20249012

高宇波1,2, 包燕平1, 王敏1, 王郢2

收稿日期:2024-03-18

出版日期:2025-10-15

发布日期:2026-01-13

作者简介:高宇波(1984—),男,江苏常州人,北京科技大学博士研究生Yu-bo GAO1,2, Yan-ping BAO1, Min WANG1, Ying WANG2

Received:2024-03-18

Online:2025-10-15

Published:2026-01-13

摘要:

通过建立与高碳钢小方坯连铸机械压下过程相匹配的三维热力耦合数值模型,从外观变形、两相区变形以及应变等方面对该过程中铸坯的变形行为进行了分析研究.研究结果表明,高碳钢小方坯机械压下过程的变形行为与压下量及实施压下的位置密切相关.压下量增大,铸坯外观变形和由压下导致的两相区减少面积增加,内部产生的应变也呈增大趋势,而压下效率则随着压下量的增加而降低;随着压下位置的提前,铸坯两侧向宽度方向扩展的变形趋势增强,压下效率增加,且随着压下位置对应中心固相率的降低,铸坯中心区域受沿宽展左右两侧拉应变的强度和区域均呈现增大趋势.

中图分类号:

高宇波, 包燕平, 王敏, 王郢. 高碳钢小方坯机械压下过程变形行为数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(10): 96-103.

Yu-bo GAO, Yan-ping BAO, Min WANG, Ying WANG. Numerical Simulation on Deformation Behavior of High-Carbon Steel Billet During Mechanical Reduction Process[J]. Journal of Northeastern University(Natural Science), 2025, 46(10): 96-103.

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.86 | 0.20 | 0.52 | ≤0.010 | ≤0.010 | ≤0.05 | ≤0.03 |

表1 研究钢种化学成分(质量分数) ((mass fraction) %)

Table 1 Chemical composition of studied steel grade

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.86 | 0.20 | 0.52 | ≤0.010 | ≤0.010 | ≤0.05 | ≤0.03 |

| 断面尺寸 | 弧形半径/m | 结晶器有效长度 | 二冷区长度/m | 压辊直径/mm | 压下覆盖区间/m |

|---|---|---|---|---|---|

| mm×mm | mm | ||||

| 160×160 | 10 | 800 | 7.7 | 450 | 13.6~18.0 |

表2 小方坯连铸机基本参数

Table 2 Basic parameters of billet caster

| 断面尺寸 | 弧形半径/m | 结晶器有效长度 | 二冷区长度/m | 压辊直径/mm | 压下覆盖区间/m |

|---|---|---|---|---|---|

| mm×mm | mm | ||||

| 160×160 | 10 | 800 | 7.7 | 450 | 13.6~18.0 |

| 拉速/(m·min-1) | 二冷强度/(L·kg-1) | 过热度/℃ | 单辊压下量区间/mm | 压下位置区间 |

|---|---|---|---|---|

| 2.3 | 0.35 | 20~35 | 1~5 | 0.1~0.9 |

表3 浇注及压下参数

Table 3 Parameters for casting and reduction

| 拉速/(m·min-1) | 二冷强度/(L·kg-1) | 过热度/℃ | 单辊压下量区间/mm | 压下位置区间 |

|---|---|---|---|---|

| 2.3 | 0.35 | 20~35 | 1~5 | 0.1~0.9 |

| 参数 | 2# | 3# | 4# | 5# | 6# |

|---|---|---|---|---|---|

| 压下作用力计算值/kN | 32.6 | 109.1 | 203.8 | 306.8 | 254.4 |

| 压下作用力实测值/kN | 31 | 106 | 196 | 295 | 264 |

| 偏差/% | 4.91 | 2.84 | 3.83 | 3.85 | -3.77 |

表4 压下作用力计算值与实测值对比

Table 4 Comparison of calculated values and measured values of reduction reaction forces

| 参数 | 2# | 3# | 4# | 5# | 6# |

|---|---|---|---|---|---|

| 压下作用力计算值/kN | 32.6 | 109.1 | 203.8 | 306.8 | 254.4 |

| 压下作用力实测值/kN | 31 | 106 | 196 | 295 | 264 |

| 偏差/% | 4.91 | 2.84 | 3.83 | 3.85 | -3.77 |

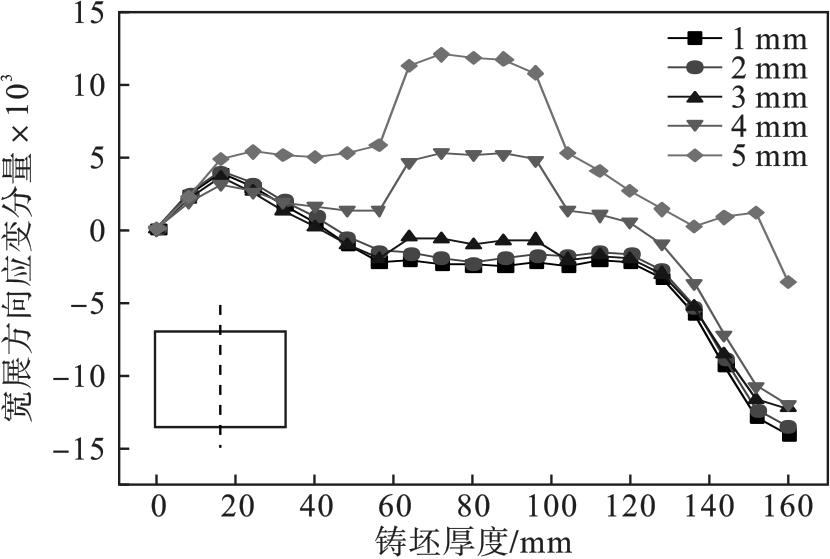

图15 压下量对宽展方向应变分量沿铸坯表面中心垂直方向分布的影响(a)—1 mm; (b)—2 mm; (c)—3 mm;(d)—4 mm; (e)—5 mm.

Fig.15 Effect of reduction amount on distribution of strain component in spread direction along vertical central line of billet surface strain component in spread direction

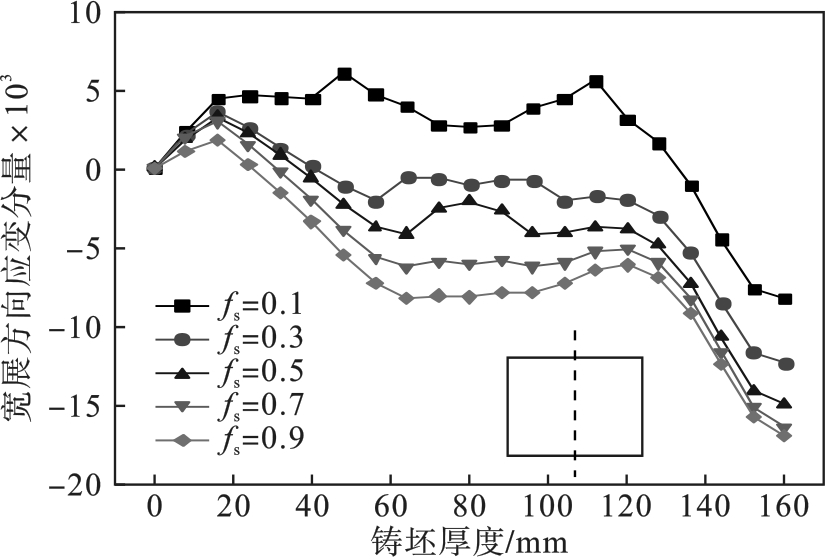

图17 压下位置对宽展方向应变分量沿铸坯表面中心垂直方向分布的影响(a)—fs=0.1; (b)—fs=0.3; (c)—fs=0.5;(d)—fs=0.7; (e)—fs=0.9.

Fig.17 Effect of reduction position on distribution of strain component in spread direction along vertical central line of billet surface strain component in spread direction

| [1] | Chen C Y, Wang L, Sun M, et al. Recent advances in inclusions and central segregation control technology in tyre cord steel and saw wire steel[J]. Ironmaking & Steelmaking, 2023, 50(2): 179-214. |

| [2] | Sivesson P, Ortlund T, Widell B. Improvement of inner quality in continuously cast billets through thermal soft reduction and use of multivariate analysis of saved process variables[J]. Ironmaking & Steelmaking, 1996, 23(6): 504-511. |

| [3] | Zhang Z, Wu M H, Zhang H J, et al. Modeling of the as-cast structure and macrosegregation in the continuous casting of a steel billet: effect of M-EMS[J]. Journal of Materials Processing Technology, 2022, 301: 117434. |

| [4] | Han Y S, Yan W, Zhang J S, et al. Comparison and integration of final electromagnetic stirring and thermal soft reduction on continuous casting billet[J]. Journal of Iron and Steel Research International, 2021, 28(2): 160-167. |

| [5] | Zhang M Y, Bao Y P, Zhao L H, et al. Improvement of carbon segregation in cast bloom and heredity in hot-rolled bar[J]. Metallurgical Research & Technology, 2021, 118(6): 610. |

| [6] | Zong N F, Jing T, Liu Y. Comparative studies on a chamfer technology and a convex roll technology during the soft reduction process[J]. Archives of Metallurgy and Materials, 2021, 66(3): 819-829. |

| [7] | Zhang J Y, Wu C H, Ji C, et al. Evolution of microporosities in wide-thick continuous casting slab during heavy reduction process[J]. Steel Research International, 2022, 93(7): 2000601. |

| [8] | Yang B, Wang M L, Zhang H, et al. Optimization of heavy reduction process on continuous-casting bloom[J]. Metals, 2022, 12(11): 1873. |

| [9] | Chen X H, Deng W, Niu S. Industrial application of mechanical reduction on continuous casting of bearing steel bloom[J]. Processes, 2021, 9(12): 2280. |

| [10] | Okimori M, Nishihara R, Fukunaga S, et al. Development of soft reduction techniques for preventing center porosity occurrence in large size bloom[J]. Tetsu-to-Hagane, 1994, 80(8): 120-123. |

| [11] | Byrne C, Tercelli C. Mechanical soft reduction in billet casting[J]. Steel Times International, 2002, 26(10): 33-35. |

| [12] | Ludlow V, Normanton A, Anderson A, et al. Strategy to minimise central segregation in high carbon steel grades during billet casting[J]. Ironmaking & Steelmaking, 2005, 32(1): 68-74. |

| [13] | Zeng J, Chen W Q, Wang Q X, et al. Improving Inner quality in continuous casting rectangular billets: comparison between mechanical soft reduction and final electromagnetic stirring[J]. Transactions of the Indian Institute of Metals, 2016, 69(8): 1623-1632. |

| [14] | Nabeshima S, Nakato H, Fujii T, et al. Control of centerline segregation in continuously cast blooms by continuous forging process[J]. ISIJ International, 1995, 35(6): 673-679. |

| [15] | Gao Y B, Bao Y.P, Wang Y, et al. Development of a novel strand reduction technology for the continuous casting of homogeneous high-carbon steel billet[J]. Steel Research International, 2023, 94(5): 2200740. |

| [16] | Zhang M Y, Bao Y P, Zhao L H, et al. Formation and control of central cracks in alloy steel ZKG223[J]. Steel Research International, 2022, 93(11): 2200289. |

| [17] | Wu C H, Ji C, Zhu M Y. Numerical simulation of bulging deformation for wide-thick slab under uneven cooling conditions[J]. Metallurgical and Materials Transactions B, 2018, 49(3): 1346-1359. |

| [18] | Zong N F, Huang J, Liu Y, et al. Controlling centre segregation and shrinkage cavities without internal crack in as-cast bloom of steel GCr15 induced by soft reduction technologies[J]. Ironmaking & Steelmaking, 2021, 48(8): 944-952. |

| [1] | 郝云龙, 谢清华, 倪培远, 厉英. 钢液稀土合金化过程多相流动及混匀行为研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 73-80. |

| [2] | 陈百玲, 牛金辉, 王连广, 许刚. 装配式钢管-拉森钢板桩围堰结构数值模拟分析[J]. 东北大学学报(自然科学版), 2025, 46(6): 102-112. |

| [3] | 林秀丽, 樊敏, 杨津硕, 柳静献. 90°弯头上下游风速及颗粒物质量浓度分布特征与测量[J]. 东北大学学报(自然科学版), 2025, 46(5): 113-125. |

| [4] | 王海艳, 冯岩, 王庆超, 于万春. 碳纤维增强复合材料螺栓连接力学特性分析[J]. 东北大学学报(自然科学版), 2025, 46(5): 71-79. |

| [5] | 韩宇超, 谢清华, 倪培远, 厉英. 旋流喷吹角度对RH精炼多相流及混匀行为的影响[J]. 东北大学学报(自然科学版), 2025, 46(4): 16-23. |

| [6] | 王述红, 任明珠, 李世宇, 董福瑞. 近距离穿越既有车站不等强度注浆变形的控制[J]. 东北大学学报(自然科学版), 2025, 46(2): 126-135. |

| [7] | 于珂凡, 赵亮, 董辉, 何永清. 柔性柱初始倾角对微通道传热增强的影响[J]. 东北大学学报(自然科学版), 2025, 46(2): 42-49. |

| [8] | 李中正, 吴朝霞, 王金杨, 康增鑫. 铁矿石烧结过程传质传热数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(1): 35-43. |

| [9] | 袁熙, 马明旭, 陈杰, 王哲英. 无油涡旋真空泵主轴冷却装置数值模拟研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 92-98. |

| [10] | 郑智群, 黄贤振, 姜智元, 苗兴琳. 基于Kriging模型的螺旋波纹管流动换热特性及结构优化[J]. 东北大学学报(自然科学版), 2024, 45(7): 992-1001. |

| [11] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [12] | 孟祥宁, 王明江, 刘向阳, 生月伟. 连铸结晶器缓振行为分析[J]. 东北大学学报(自然科学版), 2024, 45(5): 668-674. |

| [13] | 张晋瑞, 姚锡文, 许开立, 孙修. 矿井智能巡检车CO传感器搭载位置优化[J]. 东北大学学报(自然科学版), 2024, 45(5): 721-728. |

| [14] | 姚毓超, 刘中秋, 荣文杰, 李宝宽. 喂钢带碳浓度对连铸大圆坯宏观偏析的影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 499-506. |

| [15] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||