东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (4): 87-96.DOI: 10.12068/j.issn.1005-3026.2025.20230270

王营1,2,3, 顾晓薇1,2,3, 胥孝川1,2,3, 王青1,2,3

收稿日期:2023-09-18

出版日期:2025-04-15

发布日期:2025-07-01

作者简介:王 营(1995—),男,辽宁北票人,东北大学博士研究生基金资助:Ying WANG1,2,3, Xiao-wei GU1,2,3, Xiao-chuan XU1,2,3, Qing WANG1,2,3

Received:2023-09-18

Online:2025-04-15

Published:2025-07-01

摘要:

为解决碱激发矿渣-粉煤灰胶凝体系中使用氢氧化钠等强碱激发剂导致的凝结时间快、安全性差等问题,将石灰与硫酸钠以物质的量之比1∶1组成复合激发剂对矿渣-粉煤灰胶凝体系进行激发,分析激发剂掺量、粉煤灰掺量对该体系性能的影响,并采用XRD等检测手段探究胶凝体系的水化产物以及水化过程.研究结果表明:石灰-硫酸钠组成的复合激发剂可替代氢氧化钠对矿渣-粉煤灰胶凝体系进行激发,该体系的流动性能和凝结时间可控,胶凝体系中复合激发剂最佳掺量为10%,当粉煤灰掺量在50%以内时,胶凝体系28 d抗压强度均在36 MPa以上;石灰-硫酸钠复合激发剂能有效破坏粉煤灰外壳,促使粉煤灰参与水化反应,提高胶凝体系的后期抗压强度;C-(A)-S-H凝胶、钙矾石胶结不同反应程度和粒径的矿渣、粉煤灰形成致密的基体结构,为胶凝体系提供主要抗压强度.本研究可为新型低碳胶凝材料的制备提供参考.

中图分类号:

王营, 顾晓薇, 胥孝川, 王青. 石灰-硫酸钠复合激发矿渣-粉煤灰胶凝体系水化特征[J]. 东北大学学报(自然科学版), 2025, 46(4): 87-96.

Ying WANG, Xiao-wei GU, Xiao-chuan XU, Qing WANG. Hydration Characteristics of Slag-Fly Ash Cementitious System Activated by Lime-Sodium Sulfate Composite[J]. Journal of Northeastern University(Natural Science), 2025, 46(4): 87-96.

| 原材料 | SiO2 | Al2O3 | Fe2O3 | MgO | CaO |

|---|---|---|---|---|---|

| 粉煤灰 | 54.94 | 34.86 | 5.52 | 0.81 | 0.63 |

| 矿渣 | 34.50 | 17.70 | 0.03 | 7.01 | 34.00 |

表1 原材料化学组成成分(质量分数) ((mass fraction) %)

Table 1 Chemical composition of raw materials

| 原材料 | SiO2 | Al2O3 | Fe2O3 | MgO | CaO |

|---|---|---|---|---|---|

| 粉煤灰 | 54.94 | 34.86 | 5.52 | 0.81 | 0.63 |

| 矿渣 | 34.50 | 17.70 | 0.03 | 7.01 | 34.00 |

| 序号 | 石灰 | 硫酸钠 | 粉煤灰 | 矿渣 | 水 |

|---|---|---|---|---|---|

| T0 | 12.4 | 23.6 | 36 | 324 | 144 |

| T1 | 12.4 | 23.6 | 72 | 288 | 144 |

| T2 | 12.4 | 23.6 | 108 | 252 | 144 |

| T3 | 12.4 | 23.6 | 144 | 216 | 144 |

| T4 | 12.4 | 23.6 | 180 | 180 | 144 |

| T5 | 6.2 | 11.8 | 108 | 252 | 144 |

| T6 | 18.5 | 35.5 | 108 | 252 | 144 |

| T7 | 24.7 | 47.3 | 108 | 252 | 144 |

表 2 石灰-硫酸钠复合激发矿渣-粉煤灰胶凝体系试验配比 (g)

Table 2 Test proportions of slag-fly ash cementitious system activated by lime-sodium sulfate composite

| 序号 | 石灰 | 硫酸钠 | 粉煤灰 | 矿渣 | 水 |

|---|---|---|---|---|---|

| T0 | 12.4 | 23.6 | 36 | 324 | 144 |

| T1 | 12.4 | 23.6 | 72 | 288 | 144 |

| T2 | 12.4 | 23.6 | 108 | 252 | 144 |

| T3 | 12.4 | 23.6 | 144 | 216 | 144 |

| T4 | 12.4 | 23.6 | 180 | 180 | 144 |

| T5 | 6.2 | 11.8 | 108 | 252 | 144 |

| T6 | 18.5 | 35.5 | 108 | 252 | 144 |

| T7 | 24.7 | 47.3 | 108 | 252 | 144 |

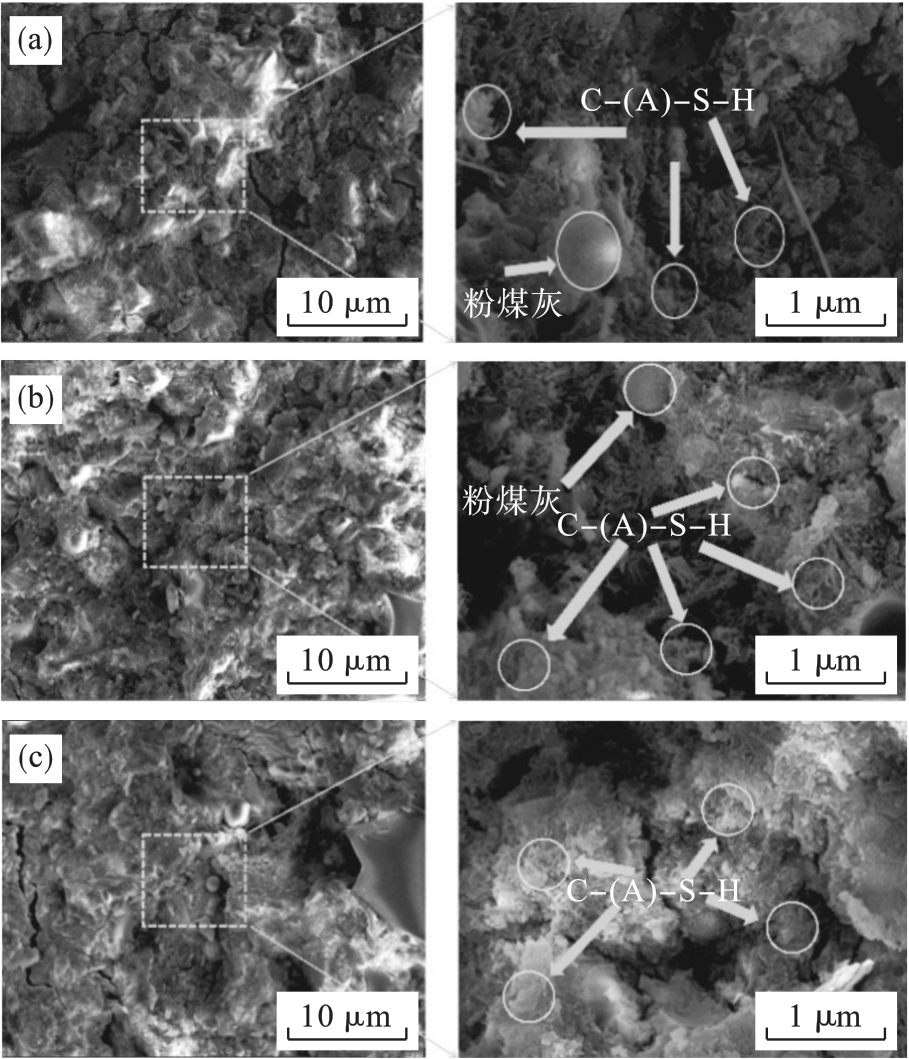

图10 不同粉煤灰掺量下矿渣-粉煤灰胶凝体系微观形貌(a)—粉煤灰掺量10%; (b)—粉煤灰掺量30%;(c)—粉煤灰掺量50%.

Fig.10 Micro-morphology of slag-fly ash cementitious system under different fly ash contents

| 1 | Yang K H, Song J K, Song K I. Assessment of CO2 reduction of alkali-actived concrete[J]. Journal of Cleaner Production, 2013, 39: 265-27. |

| 2 | Gao X, Yu Q L, Brouwers H J H. Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag-fly ash blends[J]. Construction and Building Materials, 2015, 80: 105-115. |

| 3 | Wang J, Wang J X, Huang Y, et al. Preparation of alkali-activated slag-fly ash-metakaolin hydroceramics for immobilizing simulated sodium-bearing waste[J]. Journal of the American Ceramic Society, 2015, 98(5): 1393-1399. |

| 4 | 郑蕻陈, 刘琳. 碱激发体系凝结时间和早期抗压强度变化规律[J].建筑材料学报, 2023, 26(11): 1214-1219. |

| Zheng Hong-chen, Liu Lin. Variation of setting time and early compressive strength of alkali-activated system [J]. Journal of Building Materials, 2023, 26(11): 1214-1219. | |

| 5 | 杨达, 庞来学, 宋迪, 等. 粉煤灰对碱激发矿渣/粉煤灰体系的作用机理研究[J]. 硅酸盐通报, 2021, 40(9): 3005-3011. |

| Yang Da, Pang Lai-xue, Song Di, et al. Reaction mechanism of fly ash in alkali-activated slag/fly ash system[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(9): 3005-3011. | |

| 6 | Tran V A, Nguyen H A. Evaluation on comprehensive properties and bonding performance of practical slag-fly ash blending based alkali-activated material[J]. Journal of Building Engineering, 2022, 62: 105350. |

| 7 | 詹疆淮, 李宏波, 傅博, 等. 不同碱当量、粉煤灰和矿渣掺量对碱激发粉煤灰-矿渣地聚物力学性能及微观结构的影响[J]. 科学技术与工程, 2021, 21(28): 12218-12224. |

| Zhan Jiang-huai, Li Hong-bo, Fu Bo, et al. Effect of different alkali equivalent, fly ash and slag content on the mechanical properties and microstructure of alkali-activated fly ash-slag geopolymer[J]. Science Technology and Engineering, 2021, 21(28): 12218-12224. | |

| 8 | Zhu Y C, Longhi M A, Wang A G, et al. Alkali leaching features of 3-year-old alkali activated fly ash-slag-silica fume: for a better understanding of stability[J]. Composites Part B: Engineering, 2022, 230: 109469. |

| 9 | Abdalqader A F, Jin F, Al-Tabbaa A. Development of greener alkali-activated cement: utilisation of sodium carbonate for activating slag and fly ash mixtures[J]. Journal of Cleaner Production, 2016, 113: 66-75. |

| 10 | Mugahed Amran Y H, Alyousef R, Alabduljabbar H, et al. Clean production and properties of geopolymer concrete: a review[J]. Journal of Cleaner Production, 2020, 251: 119679. |

| 11 | Ma C, Zhao B, Guo S L, et al. Properties and characterization of green one-part geopolymer activated by composite activators[J]. Journal of Cleaner Production, 2019, 220: 188-199. |

| 12 | 李肽脂, 吴锋, 李辉, 等. 复合激发煤气化渣基胶凝材料的制备[J]. 环境工程学报, 2022, 16(7): 2356-2364. |

| Li Tai-zhi, Wu Feng, Li Hui, et al. Preparation of composite activated coal gasification slag-based cementitious materials[J]. Chinese Journal of Environmental Engineering, 2022, 16(7): 2356-2364. | |

| 13 | Yang T, Gao X, Zhang J J, et al. Sulphate resistance of one-part geopolymer synthesized by calcium carbide residue-sodium carbonate-activation of slag[J]. Composites Part B: Engineering, 2022, 242: 110024. |

| 14 | Gao X, Yao X, Yang T, et al. Calcium carbide residue as auxiliary activator for one-part sodium carbonate-activated slag cements: compressive strength, phase assemblage and environmental benefits[J]. Construction and Building Materials, 2021, 308: 125015. |

| 15 | Wu M, Zhang Y S, Jia Y T, et al. The influence of chemical admixtures on the strength and hydration behavior of lime-based composite cementitious materials[J]. Cement and Concrete Composites, 2019, 103: 353-364. |

| 16 | Zhang W, Liu X M, Zhang Z Q, et al. Synergic effects of circulating fluidized bed fly ash-red mud-blast furnace slag in green cementitious materials: hydration products and environmental performance[J]. Journal of Building Engineering, 2022, 58: 105007. |

| 17 | Zhang W, Hao X S, Wei C, et al. Synergistic enhancement of converter steelmaking slag, blast furnace slag, Bayer red mud in cementitious materials: strength, phase composition, and microstructure[J]. Journal of Building Engineering, 2022, 60: 105177. |

| 18 | Guo W C, Zhao Q X, Sun Y J, et al. Effects of various curing methods on the compressive strength and microstructure of blast furnace slag-fly ash-based cementitious material activated by alkaline solid wastes[J]. Construction and Building Materials, 2022, 357: 129397. |

| 19 | Wu M, Zhang Y S, Jia Y T, et al. Influence of sodium hydroxide on the performance and hydration of lime-based low carbon cementitious materials[J]. Construction and Building Materials, 2019, 200: 604-615. |

| 20 | 刘文欢, 胡静, 赵忠忠, 等. 铅冶炼渣基生态胶凝材料的研发及其重金属固化[J]. 材料导报, 2024, 38(6): 22120057. |

| Liu Wen-huan, Hu Jing, Zhao Zhong-zhong, et al. Research and development of lead smelting slag-based ecological cementing material and its heavy metal solidification [J]. Materials Guide, 2024, 38(6): 22120057. | |

| 21 | 徐阳晨, 邢国华, 赵嘉华. 碱矿渣水泥基材料的干燥收缩及减缩技术研究进展[J]. 材料导报, 2023, 37(7): 21060180. |

| Xu Yang-chen, Xing Guo-hua, Zhao Jia-hua. Research progress of drying shrinkage and shrinkage reduction technology of alkali slag cement-based materials [J], Materials Guide, 2023, 37(7): 21060180. | |

| 22 | Luo L, Yao W, Liang G W, et al. Workability, autogenous shrinkage and microstructure of alkali-activated slag/fly ash slurries: effect of precursor composition and sodium silicate modulus[J]. Journal of Building Engineering, 2023, 73: 10671. |

| 23 | Ye H L, Radlińska A. Fly ash-slag interaction during alkaline activation: influence of activators on phase assemblage and microstructure formation[J]. Construction and Building Materials, 2016, 122: 594-606. |

| 24 | Zhao Y H, Yao J, Zhang S Q,et al. Properties and hydration mechanism of eco-friendly binder from circulating fuidized bed bottom ash, carbide slag, and desulfurization gypsum[J]. Constion and Building Materials, 2024, 457: 139411. |

| 25 | Zhou Z L, Li H, Liu N,et al. Development and property optimization of a sustainable phosphogypsum-based cementitious system with groud-granulated blast furnace slag and carbide slag[J].Construction and Building Materials, 2024, 449: 138498. |

| [1] | 章伟琪, 王辉明. 混凝土抗压强度的可解释深度学习预测模型[J]. 东北大学学报(自然科学版), 2024, 45(5): 738-744. |

| [2] | 陈猛, 曹宇新, 王瑜婷. 工程水泥基复合材料高温损伤超声特性[J]. 东北大学学报(自然科学版), 2022, 43(11): 1638-1643. |

| [3] | 程云虹, 杨四辉, 张靖瑜, 童柏强. 陶瓷细骨料替代方式对混凝土抗压强度的影响[J]. 东北大学学报:自然科学版, 2020, 41(11): 1661-1666. |

| [4] | 贾蓬, 杜功成, 任云阳, 吴振东. 振动拌和对混凝土强度及其抗冻性能的影响[J]. 东北大学学报:自然科学版, 2019, 40(12): 1784-1789. |

| [5] | 王宏涛, 储满生, 赵伟, 柳政根. 工艺参数对热压铁焦抗压强度的影响[J]. 东北大学学报:自然科学版, 2016, 37(6): 810-814. |

| [6] | 李艺, 张爽. 干湿循环作用下混杂纤维混凝土抗硫酸盐侵蚀性能[J]. 东北大学学报:自然科学版, 2016, 37(6): 895-899. |

| [7] | 柳政根, 储满生, 王峥, 王宏涛. 高铁铝土矿热压块抗压强度影响因素响应曲面优化[J]. 东北大学学报:自然科学版, 2015, 36(9): 1278-1282. |

| [8] | 赵伟, 储满生, 汤雅婷, 唐珏. 基于田口法的钒钛磁铁矿热压块抗压强度的优化[J]. 东北大学学报:自然科学版, 2015, 36(10): 1441-1444. |

| [9] | 王泽红,王怀,李国峰,于福家. Z-164D溶液对铝土矿强度的影响及其作用机理[J]. 东北大学学报:自然科学版, 2014, 35(1): 112-116. |

| [10] | 冯艳峰,杨天鸿,于庆磊,张哲. 节理岩体宏观力学参数尺寸效应的数值试验[J]. 东北大学学报(自然科学版), 2013, 34(7): 1027-1030. |

| [11] | 唐珏,张勇,储满生,薛向欣. 高铬型钒钛磁铁矿配量增加对氧化球团质量的影响[J]. 东北大学学报(自然科学版), 2013, 34(7): 956-960. |

| [12] | 唐珏,张勇,储满生,薛向欣. 以高铬型钒钛磁铁矿制备氧化球团[J]. 东北大学学报(自然科学版), 2013, 34(4): 545-549. |

| [13] | 程云虹,黄菲,李光禄,秦志生. 陶泥的活性评价及其对混凝土抗压强度的影响[J]. 东北大学学报(自然科学版), 2013, 34(10): 1499-1503. |

| [14] | 高强健,魏国,何奕波,沈峰满. MgO对球团矿抗压强度的影响[J]. 东北大学学报:自然科学版, 2013, 34(1): 103-106. |

| [15] | 罗洪杰;刘宜汉;姚广春;孙挺;. 铝土矿浮选尾矿制取铝硅铁合金时团块性能研究[J]. 东北大学学报(自然科学版), 2012, 33(5): 694-697. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||