东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (6): 102-112.DOI: 10.12068/j.issn.1005-3026.2025.20230335

陈百玲, 牛金辉, 王连广, 许刚

收稿日期:2023-12-15

出版日期:2025-06-15

发布日期:2025-09-01

作者简介:陈百玲(1972—),女,山东龙口人,东北大学副教授基金资助:Bai-ling CHEN, Jin-hui NIU, Lian-guang WANG, Gang XU

Received:2023-12-15

Online:2025-06-15

Published:2025-09-01

摘要:

为解决常规钢板桩围堰遇坚硬土层插打难度大及锁口钢管桩围堰止水效果差的问题,提出一种装配式钢管-钢板桩围堰,充分利用了钢管桩刚度大、钢板桩止水效果好的优点.通过ABAQUS对该结构进行数值分析表明,角部的钢管桩极大改善了钢板桩围堰角部剥脱以及对支撑依赖度高的不足,增加钢管桩数量可以改善结构受力情况.3道支撑尤其是封底混凝土对抑制钢板桩变形的发展最有效.同时,该结构可以有效抑制河床土体的变形.土体最大水平和竖向变形集中在抽水初始阶段和清淤阶段,分别占最大变形的89.9%和65.2%,结构的3道支撑与封底混凝土可以很好地抑制抽水与清淤阶段变形.

中图分类号:

陈百玲, 牛金辉, 王连广, 许刚. 装配式钢管-拉森钢板桩围堰结构数值模拟分析[J]. 东北大学学报(自然科学版), 2025, 46(6): 102-112.

Bai-ling CHEN, Jin-hui NIU, Lian-guang WANG, Gang XU. Numerical Simulation Analysis of Prefabricated Steel-Tubular and Larsen Steel-Sheet Pile Cofferdam Structure[J]. Journal of Northeastern University(Natural Science), 2025, 46(6): 102-112.

| 施工工况 | 深度/m | 施工概况 |

|---|---|---|

| 工况1 | — | 地应力平衡 |

| 工况2 | 2.0 | 降水至2.0 m深处 |

| 工况3 | 1.5 | 在1.5 m深处安装第1道支撑 |

| 工况4 | 5.0 | 降水至5.0 m深处 |

| 工况5 | 4.5 | 在4.5 m深处安装第2道支撑 |

| 工况6 | 8.0 | 降水至8.0 m深处 |

| 工况7 | 7.5 | 在7.5 m深处安装第3道支撑 |

| 工况8 | 10.0 | 降水至10.0 m深处 |

| 工况9 | 12.0 | 清淤至12.0 m深处 |

| 工况10 | 12.0 | 浇筑2.0 m厚封底混凝土 |

表1 围堰施工工况

Table 1 Working conditions of cofferdam

| 施工工况 | 深度/m | 施工概况 |

|---|---|---|

| 工况1 | — | 地应力平衡 |

| 工况2 | 2.0 | 降水至2.0 m深处 |

| 工况3 | 1.5 | 在1.5 m深处安装第1道支撑 |

| 工况4 | 5.0 | 降水至5.0 m深处 |

| 工况5 | 4.5 | 在4.5 m深处安装第2道支撑 |

| 工况6 | 8.0 | 降水至8.0 m深处 |

| 工况7 | 7.5 | 在7.5 m深处安装第3道支撑 |

| 工况8 | 10.0 | 降水至10.0 m深处 |

| 工况9 | 12.0 | 清淤至12.0 m深处 |

| 工况10 | 12.0 | 浇筑2.0 m厚封底混凝土 |

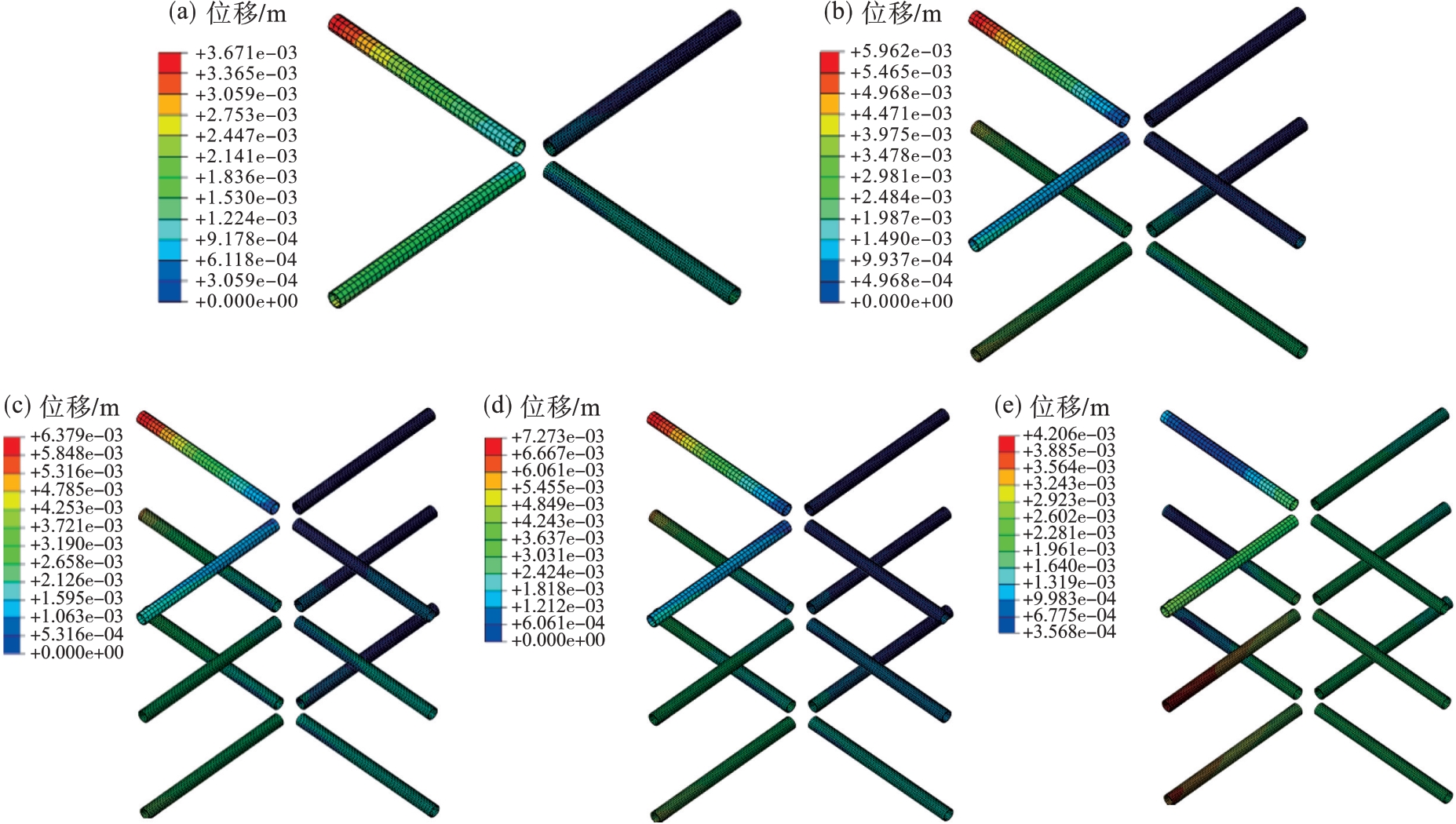

图15 不同施工工况下钢管支撑变形云图(a)—工况3,4; (b)—工况5,6; (c)—工况7,8; (d)—工况9; (e)—工况10.

Fig.15 Deformation nephogram of steel-tubular support under different working conditions

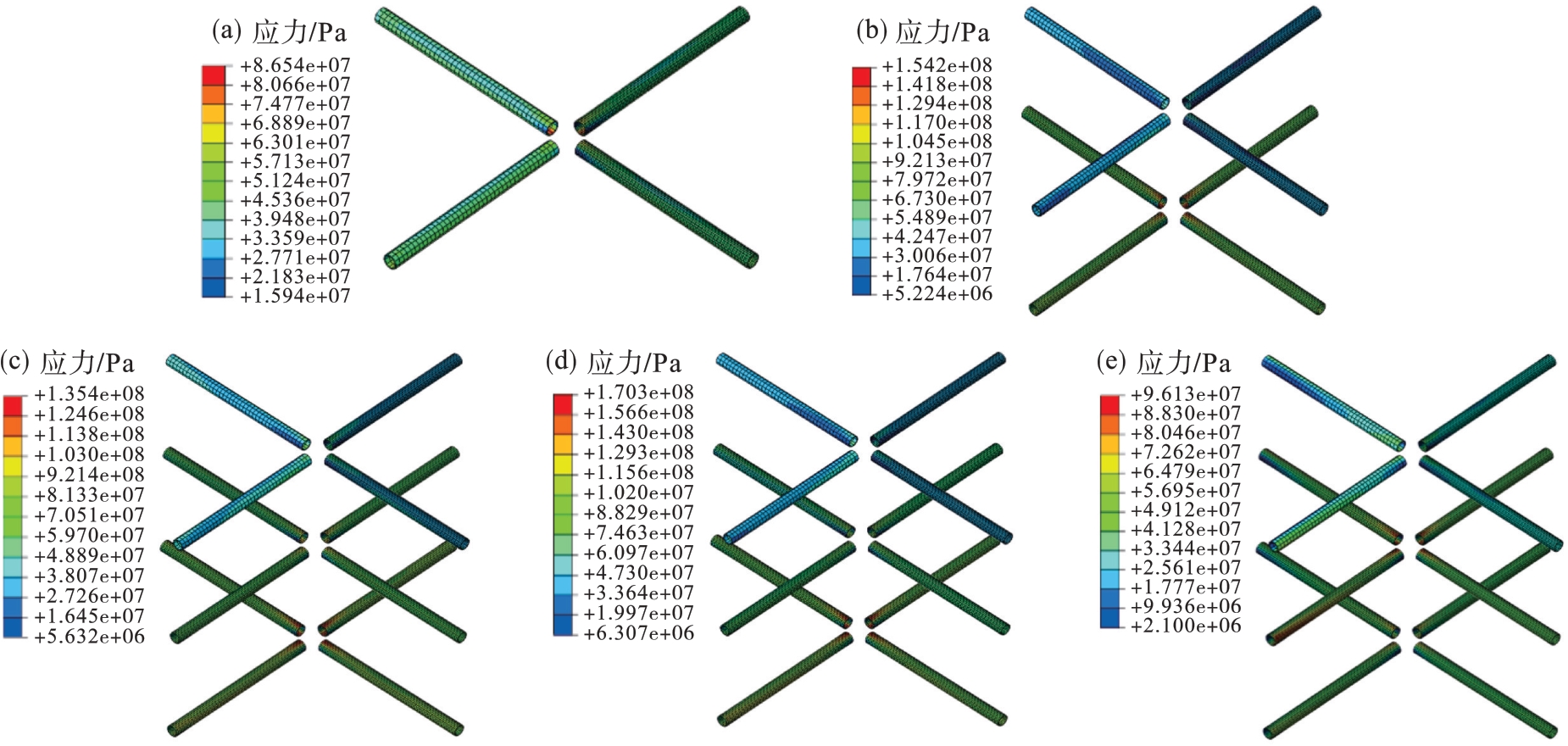

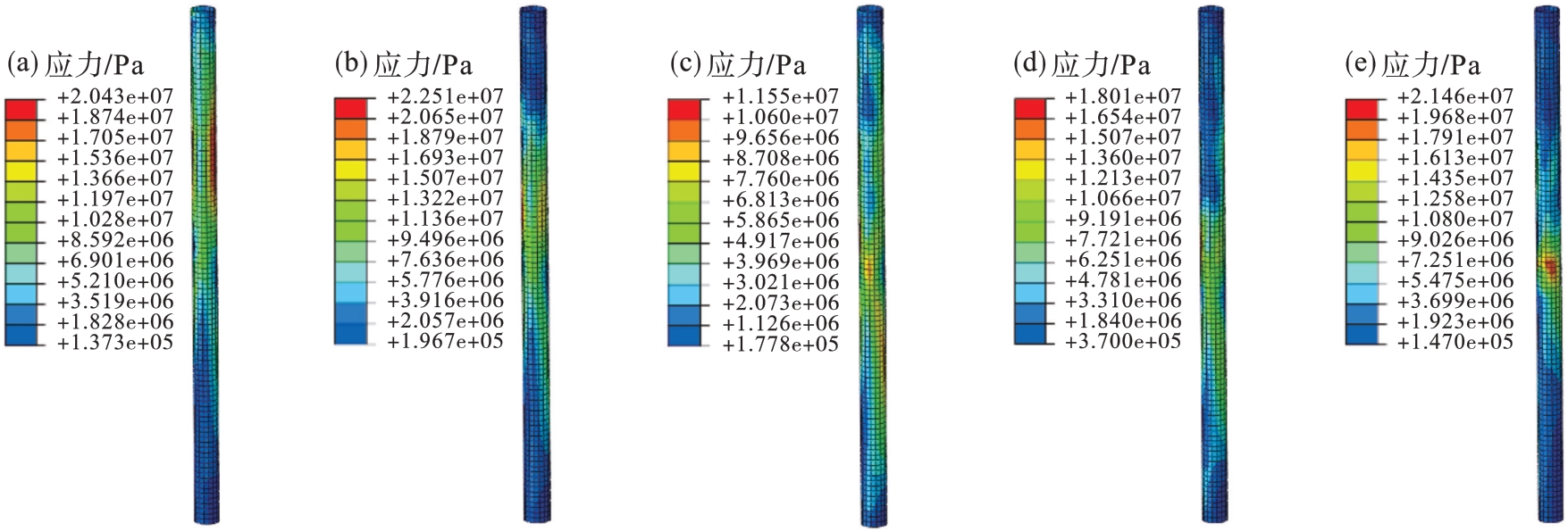

图16 不同施工工况下钢管支撑应力云图(a)—工况3,4; (b)—工况5,6; (c)—工况7,8; (d)—工况9; (e)—工况10.

Fig.16 Stress nephogram of steel-tubular support under different working conditions

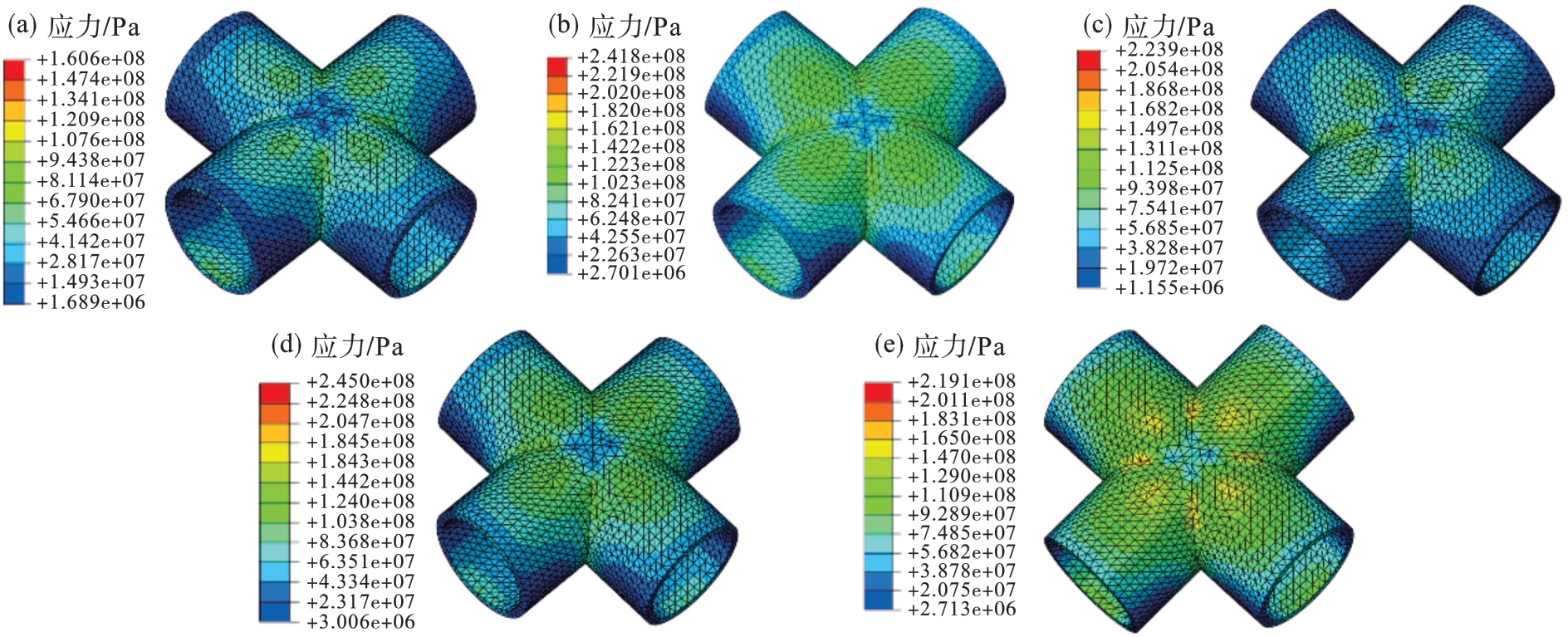

图17 不同施工工况下支撑连接件应力云图(a)—工况3,4; (b)—工况5,6; (c)—工况7,8; (d)—工况9; (e)—工况10.

Fig.17 Stress nephogram of supporting connectors under different working conditions

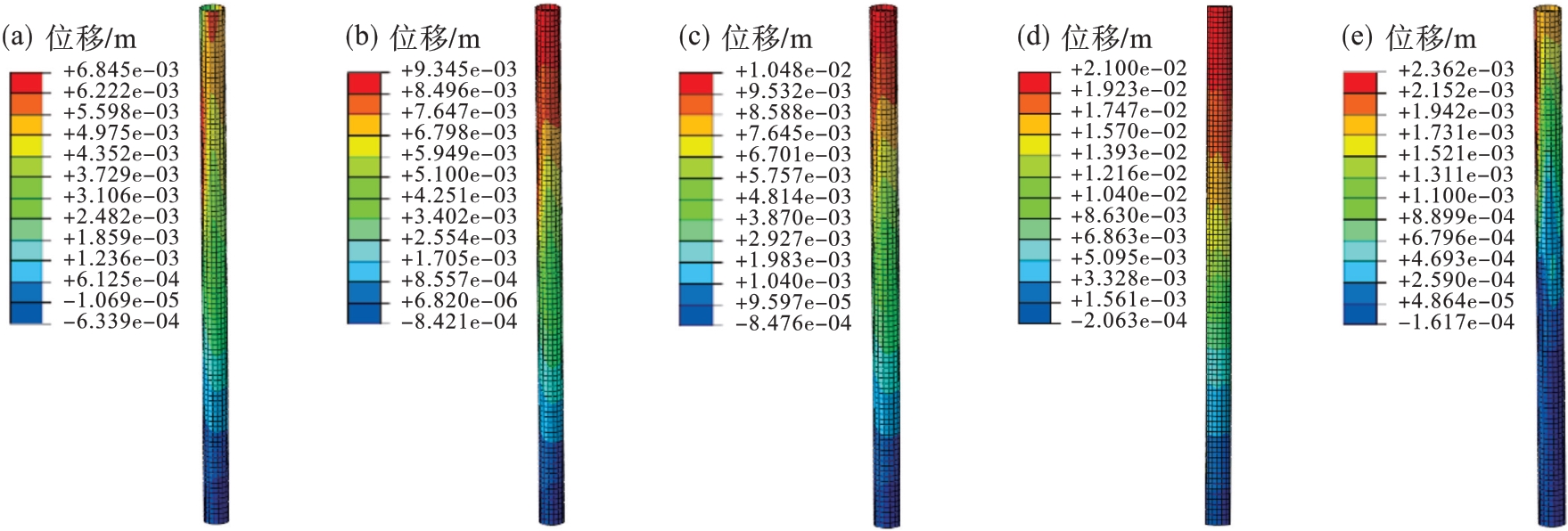

图18 不同施工工况下钢管桩变形云图(a)—工况3,4; (b)—工况5,6; (c)—工况7,8; (d)—工况9; (e)—工况10.

Fig.18 Deformation nephogram of steel-tubular pile under different working conditions

图19 不同施工工况下钢管桩应力云图(a)—工况3,4; (b)—工况5,6; (c)—工况7,8; (d)—工况9; (e)—工况10.

Fig.19 Stress nephogram of steel-tubular pile under different working conditions

| [1] | Sadeghi K, Sofy S, Baiz Z. Application of sheet piles in onshore and marine structure[J]. Asian Journal of Natural & Applied Sciences, 2018, 7(1): 10-18. |

| [2] | Li P, Sun X F, Chen J J, et al. Effects of new construction technology on performance of ultralong steel sheet pile cofferdams under tidal action[J]. Geomechanics and Engineering, 2021, 27(6): 561-571. |

| [3] | Xu F, Li S C, Zhang Q Q, et al. Analysis and design implications on stability of cofferdam subjected to water wave action[J]. Marine Georesources & Geotechnology, 2016, 34(2): 181-187. |

| [4] | Wang J F, Xiang H W, Yan J G. Numerical simulation of steel sheet pile support structures in foundation pit excavation[J]. International Journal of Geomechanics, 2019, 19(4): 05019002. |

| [5] | Jiang Y, Guo F, Wang W L, et al. Stability study of a double-row steel sheet pile cofferdam structure on soft ground[J]. Water, 2023, 15(14): 2643. |

| [6] | Qian J C, Zhang J. Monitoring and analysis of horizontal displacement of a single-rowed steel sheet pile cofferdam[J]. Soil Engineering and Foundation, 2020, 34(2): 261-264. |

| [7] | 张玉成, 杨光华, 姜燕, 等. 软土地区双排钢板桩围堰支护结构的应用及探讨[J]. 岩土工程学报, 2012, 34(sup1): 659-665. |

| Zhang Yu-cheng, Yang Guang-hua, Jiang Yan, et al. Application and discussion of double-row steel sheet pile cofferdam supporting structure in soft soil area[J]. Chinese Journal of Geotechnical Engineering, 2012, 34 (sup1): 659-665. | |

| [8] | 贺文波. 高深水区钢板桩围堰逆作法施工技术研究[J]. 武汉理工大学学报, 2018, 40(3): 59-64. |

| He Wen-bo. Reverse construction technology for steel-sheet-pile cofferdam in high-water area[J]. Journal of Wuhan University of Technology, 2018, 40 (3): 59-64. | |

| [9] | Fang M S, Yu L Z, Tan Y. Methods used to construct underwater pile caps on the Hong Kong—Zhuhai—Macao Bridge[J]. Proceedings of the Institution of Civil Engineers:Bridge Engineering. 2021, 174(1): 3-12. |

| [10] | He M, Xu Q B, Chen S X. Design and practice of underwater steel pipe pile cofferdam[J]. Science Discovery, 2022, 10 (2): 41-47. |

| [11] | Wu J, Zhou Z F, Xia W J, et al. A novel excavation and construction method for an extra-long underwater tunnel in soft soils[J]. Advances in Civil Engineering, 2021, 2021(1): 6184411. |

| [12] | Zhu Y, Li X J, Shi Z M, et al. Dynamic behavior of double steel sheet pile cofferdam under different wave actions[J]. IOP Conference Series: Earth and Environmental Science,2021, 861(7): 072019. |

| [13] | Ye J B, He X L. Response of dual-row retaining pile walls under surcharge load [J]. Mechanics of Advanced Materials and Structures, 2022, 29(11): 1614-1625. |

| [14] | Ti Z L, Qin S Q, Li Y L, et al. Extreme wave monitoring and in situ wave pressure measurement for the cofferdam construction of the pingtan strait bridge[C]// Structures Congress. Denver, 2017: 629-642. |

| [15] | Park M C, Lee J S, Kim D, et al. Small-scaled laboratory experiments for dynamic stability monitoring of large circular steel pipe cofferdam of marine bridge foundation[J]. Journal of the Korean Geotechnical Society, 2019, 35(12): 123-134. |

| [16] | 魏鹏飞, 刘杰. 软土地基深基础组合结构支护技术研究[J]. 公路, 2019, 64(1): 136-140. |

| Wei Peng-fei, Liu Jie. Study on supporting technology of deep foundation composite structure in soft soil foundation[J]. Highway, 2019, 64 (1): 136-140. |

| [1] | 林秀丽, 樊敏, 杨津硕, 柳静献. 90°弯头上下游风速及颗粒物质量浓度分布特征与测量[J]. 东北大学学报(自然科学版), 2025, 46(5): 113-125. |

| [2] | 王海艳, 冯岩, 王庆超, 于万春. 碳纤维增强复合材料螺栓连接力学特性分析[J]. 东北大学学报(自然科学版), 2025, 46(5): 71-79. |

| [3] | 韩宇超, 谢清华, 倪培远, 厉英. 旋流喷吹角度对RH精炼多相流及混匀行为的影响[J]. 东北大学学报(自然科学版), 2025, 46(4): 16-23. |

| [4] | 王述红, 任明珠, 李世宇, 董福瑞. 近距离穿越既有车站不等强度注浆变形的控制[J]. 东北大学学报(自然科学版), 2025, 46(2): 126-135. |

| [5] | 于珂凡, 赵亮, 董辉, 何永清. 柔性柱初始倾角对微通道传热增强的影响[J]. 东北大学学报(自然科学版), 2025, 46(2): 42-49. |

| [6] | 李中正, 吴朝霞, 王金杨, 康增鑫. 铁矿石烧结过程传质传热数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(1): 35-43. |

| [7] | 袁熙, 马明旭, 陈杰, 王哲英. 无油涡旋真空泵主轴冷却装置数值模拟研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 92-98. |

| [8] | 郑智群, 黄贤振, 姜智元, 苗兴琳. 基于Kriging模型的螺旋波纹管流动换热特性及结构优化[J]. 东北大学学报(自然科学版), 2024, 45(7): 992-1001. |

| [9] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [10] | 张晋瑞, 姚锡文, 许开立, 孙修. 矿井智能巡检车CO传感器搭载位置优化[J]. 东北大学学报(自然科学版), 2024, 45(5): 721-728. |

| [11] | 韦忍, 苏志坚, 杜以达, 王燕斌. 复合磁场作用下板坯结晶器内钢液流动、传热与凝固的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(4): 514-522. |

| [12] | 王雨萌, 关凯, 朱万成, 刘洪磊. 基于现场监测与数值模拟结合的采动诱发围岩失稳与地表沉降研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 234-243. |

| [13] | 李刚, 周雷, 张晓宇, 张凯. 连通设备粉尘爆炸泄压面积确定方法[J]. 东北大学学报(自然科学版), 2024, 45(2): 276-281. |

| [14] | 陈百玲, 殷悦, 高海洋, 王连广. 预制钢板夹心混凝土组合板与柱连接及其有限元分析[J]. 东北大学学报(自然科学版), 2024, 45(10): 1476-1484. |

| [15] | 侯俊旭, 杨天鸿, 马凯, 赵永. “亿级”自由度数值模拟技术及其工程应用[J]. 东北大学学报(自然科学版), 2023, 44(9): 1298-1308. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||