东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (7): 94-107.DOI: 10.12068/j.issn.1005-3026.2025.20240200

收稿日期:2024-10-30

出版日期:2025-07-15

发布日期:2025-09-24

通讯作者:

韩清凯

基金资助:

Qing-kai HAN1( ), Yu-lai ZHAO2, Shu-jun MA2, Chang-xin YU3

), Yu-lai ZHAO2, Shu-jun MA2, Chang-xin YU3

Received:2024-10-30

Online:2025-07-15

Published:2025-09-24

Contact:

Qing-kai HAN

摘要:

高性能滚动轴承作为重大装备的核心基础部件,其智能化需求在风电、工程机械和轨道交通等领域日益迫切.首先,分析了智能轴承的技术特点,总结了国内外相关研究进展与发展动态.然后,重点讨论了感知微系统内嵌式智能轴承的系统组成、工作原理与关键技术,包括功能结构一体化设计、感知机理与数字化传感技术、精密制造与装配工艺,以及性能检测与试验考核.最后,对智能轴承技术的未来发展趋势和推广应用前景进行了评述与展望,为相关领域技术创新与产业化提供了理论支撑和实践指导.

中图分类号:

韩清凯, 赵宇来, 马树军, 于长鑫. 感知微系统内嵌式智能轴承关键技术与应用展望[J]. 东北大学学报(自然科学版), 2025, 46(7): 94-107.

Qing-kai HAN, Yu-lai ZHAO, Shu-jun MA, Chang-xin YU. Key Technologies and Future Applications of Smart Bearing Embedded Perception Microsystems[J]. Journal of Northeastern University(Natural Science), 2025, 46(7): 94-107.

| 序号 | 机构名称 | 典型技术 | 典型产品 | 应用领域 |

|---|---|---|---|---|

| 1 | 瑞典斯凯孚公司(SKF) | 复合传感器集成、自主数据分析和诊断、远程监控云端 | “Insight Metro”智能轴承[ | 风电、轨道交通、汽车、机床等 |

| 2 | 德国舍弗勒公司(FAG) | 多功能传感器集成、自感知状态监测、远程监控云端 | “FAG-Variosense”系列智能轴承[ | 轨道交通、汽车、机床、风电等 |

| 3 | 美国铁姆肯公司(TIMKEN) | 联合负荷分析、超高速应用分析等 | “TRBS”智能轴承监测系统 | 风电、航空航天、医疗等 |

| 4 | 日本恩梯恩公司(NTN) | 三轴负荷传感器、旋转传感器、挤压切削花键 | “Smart Sensor Bearing”智能轴承[ | 轨道交通、汽车、机床等 |

| 5 | 日本精工株式会社(NSK) | 传感器集成、剩余寿命预测技术及实时报警 | “Ensk”智能轴承[ | 汽车、机床、泵和压缩机等 |

表1 代表性智能轴承研究机构及其典型技术与产品

Table 1 Representative smart bearing research institutions and their typical technologies and products

| 序号 | 机构名称 | 典型技术 | 典型产品 | 应用领域 |

|---|---|---|---|---|

| 1 | 瑞典斯凯孚公司(SKF) | 复合传感器集成、自主数据分析和诊断、远程监控云端 | “Insight Metro”智能轴承[ | 风电、轨道交通、汽车、机床等 |

| 2 | 德国舍弗勒公司(FAG) | 多功能传感器集成、自感知状态监测、远程监控云端 | “FAG-Variosense”系列智能轴承[ | 轨道交通、汽车、机床、风电等 |

| 3 | 美国铁姆肯公司(TIMKEN) | 联合负荷分析、超高速应用分析等 | “TRBS”智能轴承监测系统 | 风电、航空航天、医疗等 |

| 4 | 日本恩梯恩公司(NTN) | 三轴负荷传感器、旋转传感器、挤压切削花键 | “Smart Sensor Bearing”智能轴承[ | 轨道交通、汽车、机床等 |

| 5 | 日本精工株式会社(NSK) | 传感器集成、剩余寿命预测技术及实时报警 | “Ensk”智能轴承[ | 汽车、机床、泵和压缩机等 |

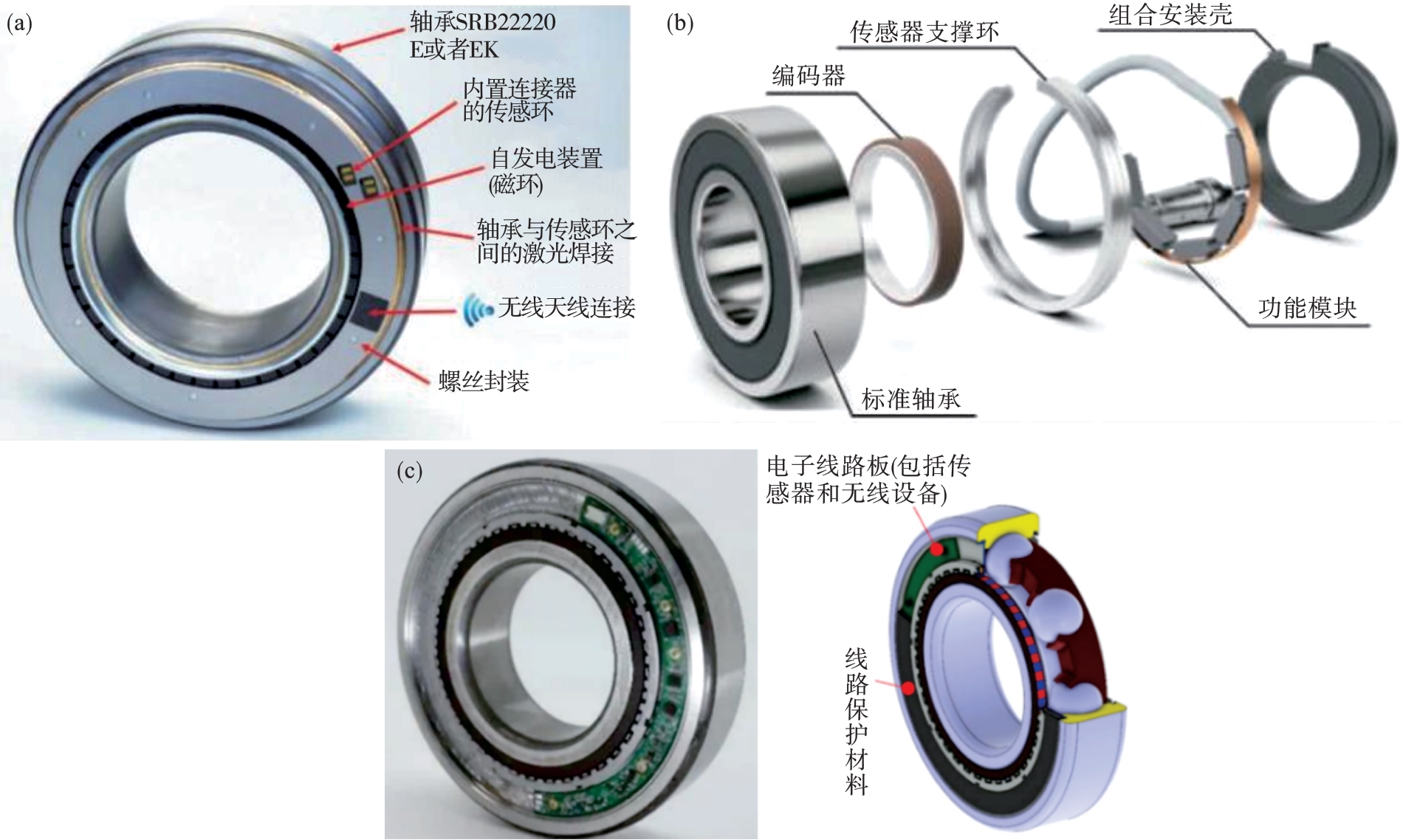

图2 国外代表性智能轴承结构(a)—SKF公司的“Insight Metro”智能轴承[20]; (b)—FAG公司的“FAG-Variosense”智能轴承[21];(c)—NTN公司的“Smart Sensor Bearing”智能轴承[22].

Fig.2 Representative smart bearing structures abroad

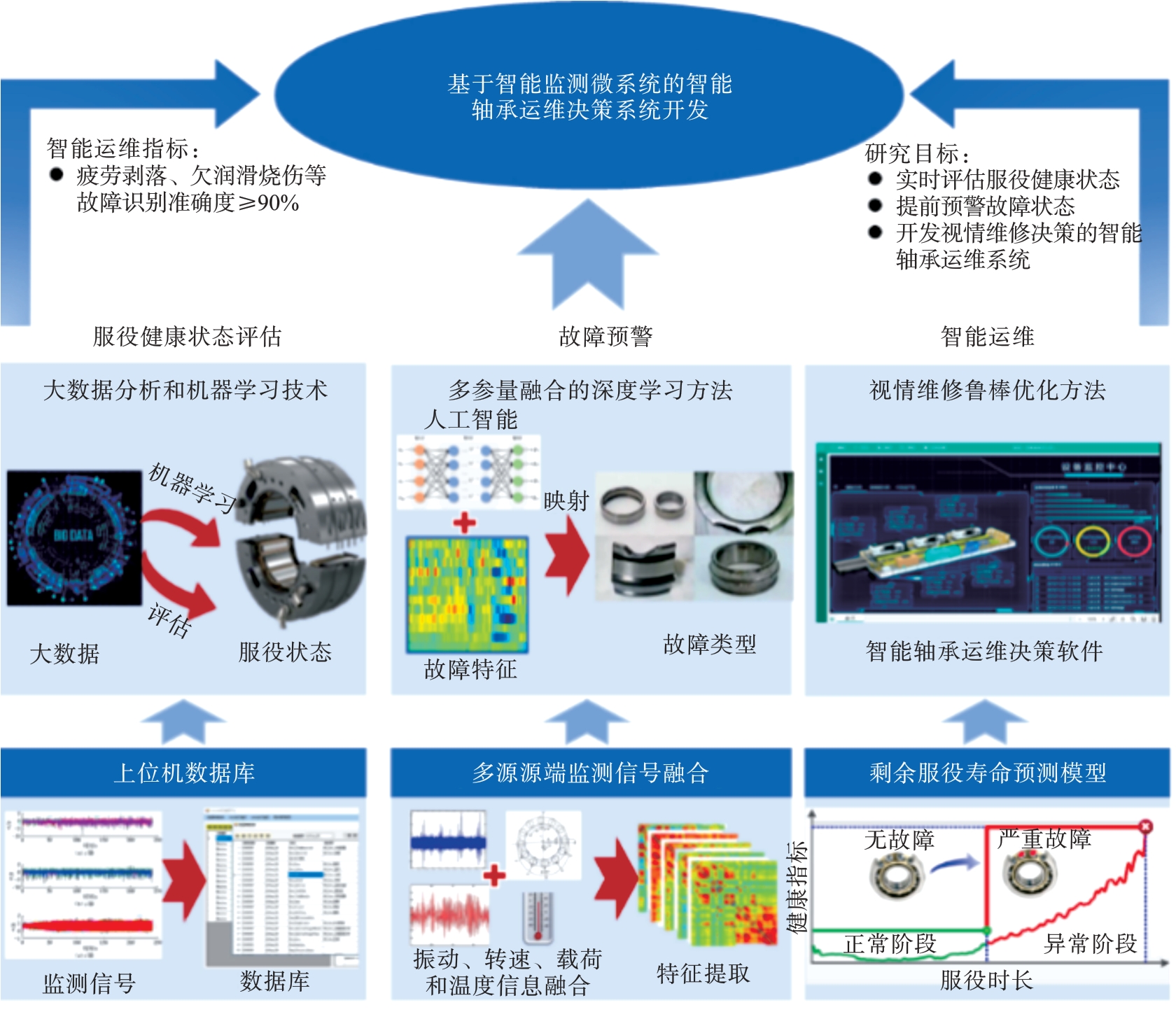

图7 感知微系统内嵌式智能轴承的状态监测与智能运维原理

Fig.7 Principle of condition monitoring and intelligent operation and maintenance of smart bearing embedded perception microsystem

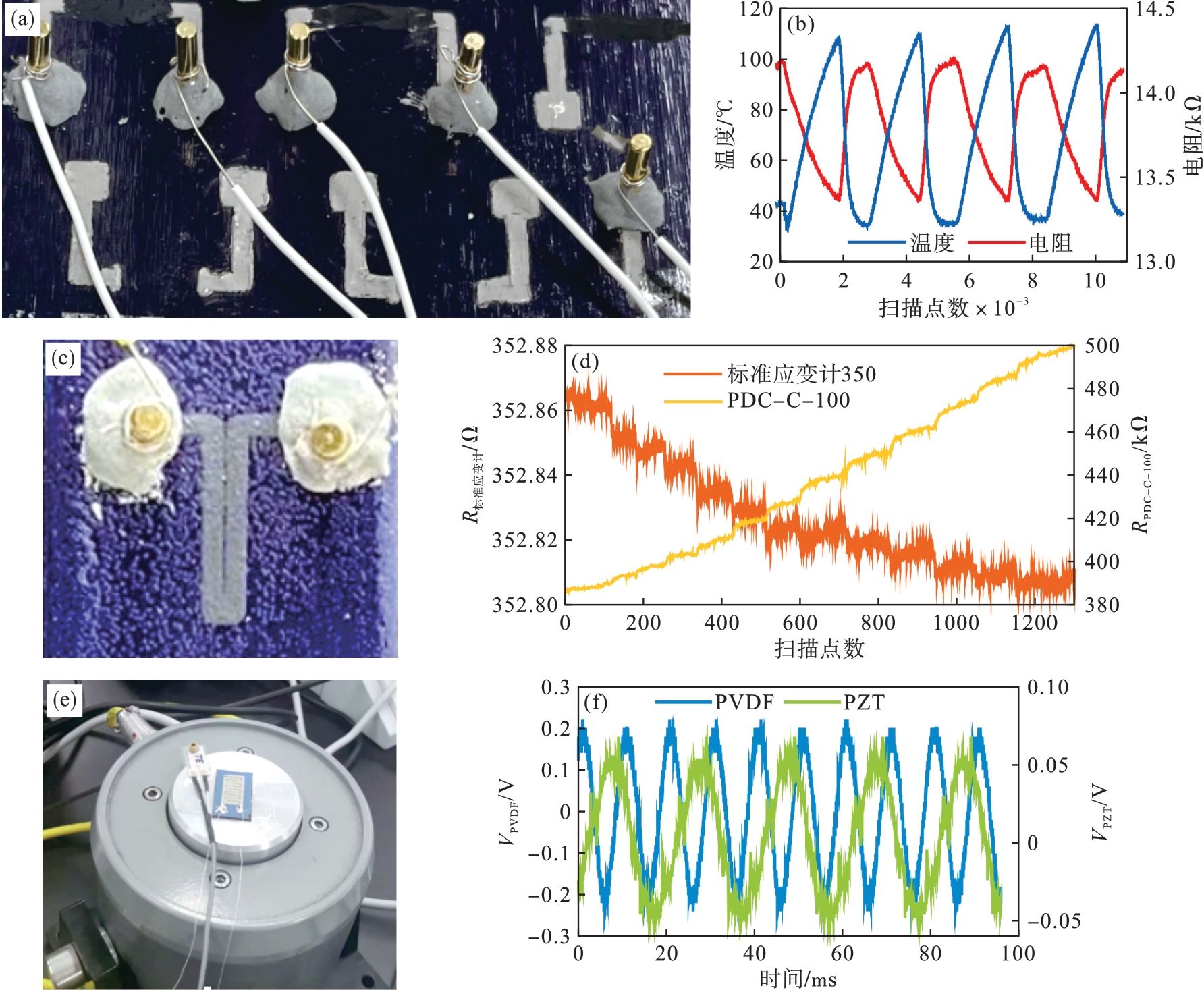

图11 基于先驱体陶瓷制备的薄膜传感器注:PVDF为聚偏氟乙烯;PZT为锆太酸铅.(a)—金属基薄膜温度传感器样片; (b)—温度传感测试曲线; (c)—金属基薄膜应变传感器样片;(d)—应变传感电阻测试曲线; (e)—金属基压电薄膜加速度传感器样片; (f)—加速度传感测试曲线.

Fig.11 Thin-film sensors based on precursor ceramic fabrication

| [1] | 王政.制造强国 步履铿锵[N/OL].人民日报,2022-08-15[2024-08-01]. . |

| Wang Zheng. Make a powerful country, with a sonorous step[N/OL]. People's Daily, 2022-08-15[2024-08-01]. | |

| [2] | 跟着总书记看中国|制造强国[EB/OL].(2024-07-29) [2024-08-01]. . |

| (Follow the general Secretary to see China | manufacturing powerhouse[EB/OL]. (2024-07-29) [2024-08-01]. ) | |

| [3] | 周济. 推进制造业数字化转型、智能化升级[J]. 现代制造, 2024(2): 54. |

| Zhou Ji. Promote digital transformation and intelligent upgrading of manufacturing industry[J]. Maschinen Markt, 2024(2): 54. | |

| [4] | 何加群. 论我国重大技术装备轴承的自主安全可控[J]. 轴承, 2022(1): 1-17. |

| He Jia-qun. Discussion on independence, safety and controllability of bearings for major technical equipment in China[J]. Bearing, 2022(1): 1-17. | |

| [5] | 马芳, 刘璐. 航空轴承技术现状与发展[J]. 航空发动机, 2018, 44(1): 85-90. |

| Ma Fang, Liu Lu. Present situation and development of aviation bearing technology[J]. Aeroengine, 2018, 44(1): 85-90. | |

| [6] | 陈金海, 李伟, 张文远, 等. 智能滚动轴承监测方法与技术研究现状综述[J]. 机械强度, 2021, 43(3): 509-516. |

| Chen Jin-hai, Li Wei, Zhang Wen-yuan, et al. Research status of smart rolling bearing monitoring methods[J]. Journal of Mechanical Strength, 2021, 43(3): 509-516. | |

| [7] | Brusa E. Design of a kinematic vibration energy harvester for a smart bearing with piezoelectric/magnetic coupling[J]. Mechanics of Advanced Materials and Structures, 2020, 27(15): 1322-1330. |

| [8] | 朱永生, 张盼, 袁倩倩, 等. 智能轴承关键技术及发展趋势[J]. 振动.测试与诊断, 2019, 39(3): 455-462, 665. |

| Zhu Yong-sheng, Zhang Pan, Yuan Qian-qian, et al. Key technologies and development trend of smart bearing[J]. Journal of Vibration, Measurement & Diagnosis, 2019, 39(3): 455-462, 665. | |

| [9] | 高航, 吕青, Gao Robert X. 基于微传感器的智能轴承技术[J]. 中国机械工程, 2003, 14(21): 1883-1885. |

| Gao Hang, Qing Lyu, Gao R X. Technology of smart bearing based on microsensors[J]. China Mechanical Engineering, 2003, 14(21): 1883-1885. | |

| [10] | Fukushima Y, Goto T, Toyoguchi Y, et al. Development of sensor integrated bearing “Talking Bearings TM”[J]. NTN Technical Review, 2022(89): 35-40. |

| [11] | Zaghari B, Weddell A S, Esmaeili K, et al. High-temperature self-powered sensing system for a smart bearing in an aircraft jet engine[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(9): 6165-6174. |

| [12] | Choi D, Sung T, Kwon J Y. A self-powered smart roller-bearing based on a triboelectric nanogenerator for measurement of rotation movement[J]. Advanced Materials Technologies, 2018, 3(12): 1800219. |

| [13] | Zhang Y, Wang W, Wu X, et al. A comprehensive review on self-powered smart bearings[J]. Renewable and Sustainable Energy Reviews, 2023, 183: 113446. |

| [14] | Guimarães O A, Almeida S A, de Jose A C, et al. Design and experimental analysis of a smart bearing using shape memory alloy springs[J]. Journal of Intelligent Material Systems and Structures, 2020, 31(11): 1390-1402. |

| [15] | 张志鑫, 牛青波, 杨明奇, 等. 基于多物理量集成的智能轴承监测系统[J]. 轴承, 2024(4): 55-63. |

| Zhang Zhi-xin, Niu Qing-bo, Yang Ming-qi, et al. Intelligent bearing monitoring system based on multi physical quantity integration[J]. Bearing, 2024(4): 55-63. | |

| [16] | 林昙涛, 牛青波, 马天旭, 等. 基于Transformer的智能轴承声-振融合故障诊断[J]. 轴承, 2023(2): 67-73. |

| Lin Tan-tao, Niu Qing-bo, Ma Tian-xu, et al. Acoustic-vibration fusion fault diagnosis for intelligent bearing based on transformer[J]. Bearing, 2023(2): 67-73. | |

| [17] | Han Q K, Ding Z, Qin Z Y, et al. A triboelectric rolling ball bearing with self-powering and self-sensing capabilities[J]. Nano Energy, 2020, 67: 104277. |

| [18] | 邵毅敏, 涂文兵, 叶军. 新型智能轴承的结构与监测能力分析[J]. 轴承, 2012(5): 27-31. |

| Shao Yi-min, Tu Wen-bing, Ye Jun. Analysis on structure and monitoring capability of new type smart bearings[J]. Bearing, 2012(5): 27-31. | |

| [19] | 陈小龙, 仲志丹, 李云峰, 等. 基于智能滚子的轴承接触载荷测量方法[J]. 轴承, 2024(10): 18-25. |

| Chen Xiao-long, Zhong Zhi-dan, Li Yun-feng, et al. Measurement method for contact load of bearings based on intelligent rollers[J]. Bearing, 2024(10): 18-25. | |

| [20] | 培恩.斯凯孚(SKF)发布突破性的轴承状态监测技术: 斯凯孚洞悉[J]. 润滑与密封, 2013, 38(5): 18. |

| Paine.SKF released a breakthrough bearing condition monitoring technology:SKF insight[J]. Lubrication Engineering, 2013, 38(5): 18. | |

| [21] | Andreas S. Bearing with airborne sensors[EB/OL]. (2017-08-23)[2024-09-10].. |

| [22] | 恩梯恩开发出内置传感器的万向节轮毂单元[J]. 润滑与密封, 2013, 38(3): 60. |

| (Entien developed a universal joint hub unit with built-in sensors[J]. Lubrication Engineering, 2013, 38(3): 60.) | |

| [23] | NSK. NSK高性能轴承成功应用于北海道新干线列车[EB/OL]. (2015-12-14)[2024-08-01]. . |

| NSK. NSK high-performance bearings have been successfully applied to the Hokkaido Shinkansen trains [EB/OL]. (2015-12-14)[2024-08-01]. | |

| [24] | 邵毅敏, 涂文兵, 周晓君, 等. 基于嵌入式多参量传感器的智能轴承[J]. 中国机械工程, 2010, 21(21): 2527-2531. |

| Shao Yi-min, Tu Wen-bing, Zhou Xiao-jun, et al. Smart bearing based on embedded multi-parameter sensors[J]. China Mechanical Engineering, 2010, 21(21): 2527-2531. | |

| [25] | 斯凯孚公司.传感化的滚子:201811607467.7[P]. 2022-02-08. |

| SKF.Sensorized roller:201811607467.7[P]. 2022-02-08. | |

| [26] | 肖嘉伟, 张艺超, 陈市, 等. 嵌入式智能轴承信息感知测点优化方法[J]. 轴承, 2023(2): 12-18. |

| Xiao Jia-wei, Zhang Yi-chao, Chen Shi, et al. Optimization method for information sensing measuring points of embedded smart bearing[J]. Bearing, 2023(2): 12-18. | |

| [27] | 陈金海, 张文远, 罗梦婷, 等. 智能滚动轴承内圈温度监测系统研究[J]. 仪表技术与传感器, 2021(10): 103-108. |

| Chen Jin-hai, Zhang Wen-yuan, Luo Meng-ting, et al. Research on temperature monitoring system of inner ring of intelligent rolling bearing[J]. Instrument Technique and Sensor, 2021(10): 103-108. | |

| [28] | 张文远, 陈金海, 花国然, 等. 嵌入式智能轴承结构分析与振动监测系统设计[J]. 机械强度, 2022, 44(6): 1293-1299. |

| Zhang Wen-yuan, Chen Jin-hai, Hua Guo-ran, et al. Research on embedded smart bearing structure analysis and vibration monitoring system design[J]. Journal of Mechanical Strength, 2022, 44(6): 1293-1299. | |

| [29] | Chen J H, Zhang W Y, Wang H. Intelligent bearing structure and temperature field analysis based on finite element simulation for sustainable and green manufacturing[J]. Journal of Intelligent Manufacturing, 2021, 32(3): 745-756. |

| [30] | 刘浩, 杨拥民, 陈仲生. 基于嵌入式传感器的智能轴承结构分析[J]. 兵工自动化, 2006, 25(6): 43-45. |

| Liu Hao, Yang Yong-min, Chen Zhong-sheng. Structural analysis of smart bearing based on embedded sensor[J]. Ordnance Industry Automation, 2006, 25(6): 43-45. | |

| [31] | 张以忱, 刘希东, 巴德纯, 等. 智能轴承用薄膜传感器[J]. 真空, 2003, 40(6): 6-10. |

| Zhang Yi-chen, Liu Xi-dong, Ba De-chun, et al. Thin film sensor application in smart bearing[J]. Vacuum, 2003, 40(6): 6-10. | |

| [32] | Bashir I, Zaghari B, Harvey T J, et al. Design and testing of a sensing system for aero-engine smart bearings[C]// Proceedings of EUROSENSORS 2018. Graz,2018: 1005-1009. |

| [33] | 朱晓枭, 周瑜, 刘云飞, 等. 微系统技术发展现状及趋势[J]. 电声技术, 2021, 45(7): 21-29. |

| Zhu Xiao-xiao, Zhou Yu, Liu Yun-fei, et al. Development status and trends of microelectronic information system[J]. Audio Engineering, 2021, 45(7): 21-29. | |

| [34] | Chen M F, Chen F C, Chiou W C, et al. System on integrated chips (SoIC(TM) for 3D heterogeneous integration[C]//2019 IEEE 69th Electronic Components and Technology Conference (ECTC). Las Vegas,2019: 594-599. |

| [35] | Ki W, Lee W, Mok I, et al. Chip stackable, ultra-thin, high-flexibility 3D FOWLP (3D SWIFT® technology) for hetero-integrated advanced 3D WL-SiP[C]// IEEE 68th Electronic Components and Technology Conference (ECTC). San Diego, 2018: 580-586. |

| [36] | Ganusov I K, Iyer M A, Cheng N, et al. Agilex™ generation of Intel® FPGAs[C]//2020 IEEE Hot Chips 32 Symposium (HCS). Palo Alto, 2020: 1-26. |

| [37] | Bhutani A, Gottel B, Lipp A, et al. Packaging solution based on low-temperature cofired ceramic technology for frequencies beyond 100 GHz[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology, 2019,9(5):945-954. |

| [38] | 闫柯, 高闯, 朱永生, 等. 基于碲化镉量子点的滚动轴承内圈测温原理与实现技术[J]. 机械工程学报, 2017, 53(4): 134-140. |

| Yan Ke, Gao Chuang, Zhu Yong-sheng, et al. Research on the temperature measurement principle and realization technology of rolling bearing inner ring based on CdTe quantum dots[J]. Journal of Mechanical Engineering, 2017, 53(4): 134-140. | |

| [39] | 葛亮. 基于嵌入式传感器的铁路车辆智能轴承关键技术研究[D]. 重庆:重庆大学,2009:24-26. |

| Ge Liang. Research on key technologies of intelligent bearings for railway vehicles based on embedded sensors[D]. Chongqing: Chongqing University, 2009: 24-26. |

| [1] | 罗亨发, 于天壮, 周世华. 基于GRM-IConvNeXt模型的滚动轴承故障诊断方法[J]. 东北大学学报(自然科学版), 2025, 46(5): 62-70. |

| [2] | 于滨, 孙红春, 叶大勇. 齿轮故障机理嵌入的变负载智能故障诊断[J]. 东北大学学报(自然科学版), 2025, 46(4): 61-70. |

| [3] | 王娜, 崔月磊, 罗亮, 王子从. 基于WP-TRP的滚动轴承故障诊断方法[J]. 东北大学学报(自然科学版), 2025, 46(3): 20-27. |

| [4] | 王宏伟, 李磊, 刘晨宇, 汪洵. 基于变参数模型的智能车辆转向执行器故障诊断[J]. 东北大学学报(自然科学版), 2024, 45(7): 913-920. |

| [5] | 张执锦, 李鹤, 黄宇实, 王文学. 深度残差收缩网络在滚动轴承故障诊断中的应用[J]. 东北大学学报(自然科学版), 2024, 45(11): 1587-1594. |

| [6] | 王宏伟, 张昊天, 韩杰, 刘晨宇. 不确定车辆电子稳定控制系统传感器故障估计[J]. 东北大学学报(自然科学版), 2023, 44(1): 1-8. |

| [7] | 王娜, 李杨, 彭锟. 基于多角度特征提取的舵机故障诊断方法[J]. 东北大学学报(自然科学版), 2022, 43(9): 1240-1249. |

| [8] | 侯东晓, 穆金涛, 方成, 时培明. 基于GADF与引入迁移学习的ResNet34对变速轴承的故障诊断[J]. 东北大学学报(自然科学版), 2022, 43(3): 383-389. |

| [9] | 任朝晖, 于天壮, 丁东, 周世华. 基于VMD-DBN的滚动轴承故障诊断方法[J]. 东北大学学报(自然科学版), 2021, 42(8): 1105-1110. |

| [10] | 罗忠, 徐迪, 李雷, 马辉. 基于改进二阶循环平稳解卷积的轴承故障检测方法[J]. 东北大学学报(自然科学版), 2021, 42(5): 673-678. |

| [11] | 王新刚, 王超, 韩凯忠. 基于优化VMD和MCKD的滚动轴承早期故障诊断方法[J]. 东北大学学报(自然科学版), 2021, 42(3): 373-381. |

| [12] | 张永超, 李琦, 任朝晖, 周世华. 基于域适应与分类器差异的滚动轴承跨域故障诊断[J]. 东北大学学报(自然科学版), 2021, 42(3): 367-372. |

| [13] | 李国军, 李依擎, 邱勇. 园区供热管网泄漏工况建模及分析[J]. 东北大学学报:自然科学版, 2020, 41(10): 1402-1409. |

| [14] | 徐林, 郑晓彤, 付博, 田歌. 基于改进GAN算法的电机轴承故障诊断方法[J]. 东北大学学报:自然科学版, 2019, 40(12): 1679-1684. |

| [15] | 侯延彬, 陈炳均, 高宪文. 基于GM-ELM的有杆泵抽油井故障诊断[J]. 东北大学学报:自然科学版, 2019, 40(12): 1673-1678. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||