Journal of Northeastern University(Natural Science) ›› 2025, Vol. 46 ›› Issue (3): 28-45.DOI: 10.12068/j.issn.1005-3026.2025.20240182

• Materials & Metallurgy • Previous Articles Next Articles

Yang ZHAO, Yu-hang WANG, Tao ZHANG( ), Fu-hui WANG

), Fu-hui WANG

Received:2024-10-16

Online:2025-03-15

Published:2025-05-29

Contact:

Tao ZHANG

About author:ZHANG Tao E-mail:zhangtao@mail.neu.edu.cn

CLC Number:

Yang ZHAO, Yu-hang WANG, Tao ZHANG, Fu-hui WANG. Research Progress on the Corrosion Failure Behavior of Coatings on Aluminum Alloy for Semiconductor Fabrication Equipment[J]. Journal of Northeastern University(Natural Science), 2025, 46(3): 28-45.

| 湿法擦拭流程 | 湿法清洗流程 |

|---|---|

1. 启动腔室清洁 2. 冷却腔室 3. 泄压开腔 4. 湿洁净布擦拭面板 5. 使用N2干燥面板 6. 关闭腔室 7. 加热腔室 8. 腔室检漏 9. 刻蚀/沉积工艺验证 10. 恢复运行 | 1. 启动腔室清洁 2. 冷却腔室 3. 泄压开腔 4. 拆卸腔室部件 5. 在清洗溶液中浸泡腔室部件 6. 烘干腔室部件 7. 更换腔室部件 8. 关闭腔室 9. 加热腔室 10. 腔室检漏 11. 刻蚀/沉积工艺验证 12. 恢复运行 |

Table 1 Wet wiping/cleaning procedures[14-16]

| 湿法擦拭流程 | 湿法清洗流程 |

|---|---|

1. 启动腔室清洁 2. 冷却腔室 3. 泄压开腔 4. 湿洁净布擦拭面板 5. 使用N2干燥面板 6. 关闭腔室 7. 加热腔室 8. 腔室检漏 9. 刻蚀/沉积工艺验证 10. 恢复运行 | 1. 启动腔室清洁 2. 冷却腔室 3. 泄压开腔 4. 拆卸腔室部件 5. 在清洗溶液中浸泡腔室部件 6. 烘干腔室部件 7. 更换腔室部件 8. 关闭腔室 9. 加热腔室 10. 腔室检漏 11. 刻蚀/沉积工艺验证 12. 恢复运行 |

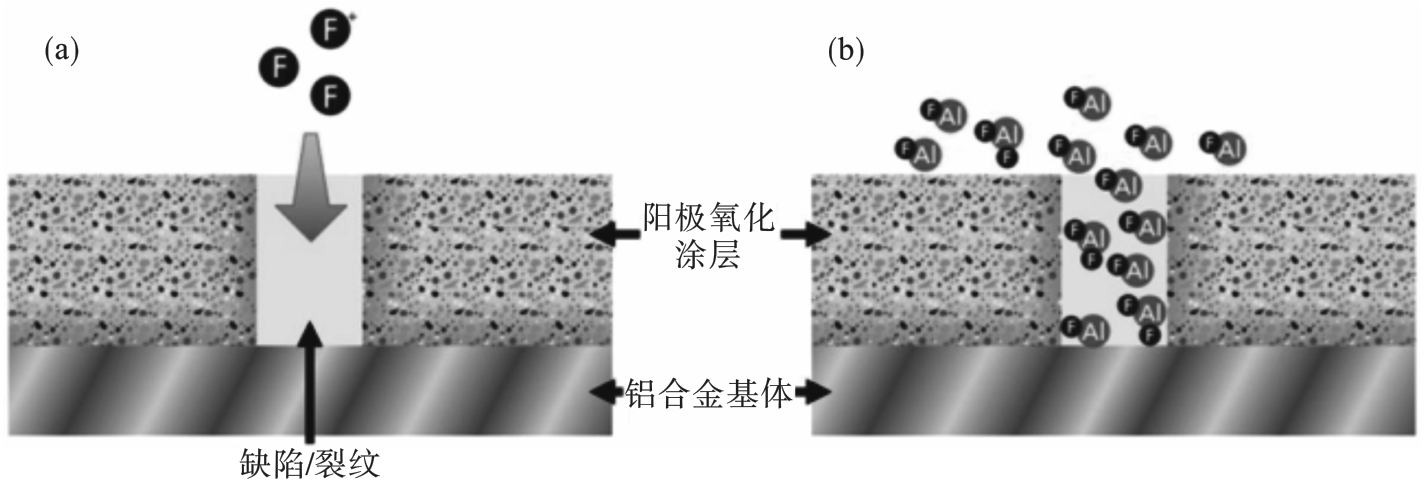

Fig. 9 Cross-sectional schematic illustrating fluorine radicals penetrating the defects/cracks in the anodized aluminum and reacting with the aluminum substrate[17]

| 1 | SIA State of industry report 2023[R/OL].Washington, D C (2023). . |

| 2 | Winter R, Korzec D, Engemann J. Remote and direct cleaning by use of microwave plasma source SLAN II: comparative study[J]. Surface and Coatings Technology, 1997, 91(1/2): 101-106. |

| 3 | Manos D M, Flamm D L. Plasma etching: an introduction[M]. Boston: Academic Press, 1989. |

| 4 | Rasgon S A. Origin, evolution, and control of sidewall line edge roughness transfer during plasma etching[D]. Cambridge: Massachusetts Institute of Technology, 2005. |

| 5 | Donnelly V M, Kornblit A. Plasma etching: yesterday, today, and tomorrow[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2013, 31(5): 050825-050873. |

| 6 | Hamedani Y, Macha P, Bunning T J, et al. Plasma-enhanced chemical vapor deposition: where we are and the outlook for the future[M]//Chemical Vapor Deposition-Recent Advances and Applications in Optical, Solar Cells and Solid State Devices. London: InTech,2016. |

| 7 | Armacost M, Hoh P D, Wise R, et al. Plasma-etching processes for ULSI semiconductor circuits[J]. IBM Journal of Research and Development, 1999, 43: 39-72. |

| 8 | Wang Y H, Zhao Y, Wang S G, et al. Thermodynamics-based sealing method for anodized aluminum used in semiconductor processing apparatuses[J]. Journal of Materials Science & Technology, 2025, 216: 241-259. |

| 9 | Ullal S J, Godfrey A R, Edelberg E, et al. Effect of chamber wall conditions on Cl and Cl2 concentrations in an inductively coupled plasma reactor[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2002, 20(1): 43-52. |

| 10 | Kota G P. Experimental beam studies of plasma-surface interactions[D]. Berkeley: University of California, Berkeley, 1998. |

| 11 | Vempaire D, Cunge G. Probing radical kinetics in the afterglow of pulsed discharges by absorption spectroscopy with light emitting diodes: application to BCl radical[J]. Applied Physics Letters, 2009, 94(2): 021504. |

| 12 | Hong S, Lin X, John M K, et al. Dense oxide coated component of a plasma processing chamber and method of manufacture thereof: US9123651B2[P/OL]. 2015[2024-07-10]. . |

| 13 | Daugherty J, Shih H, Xu L, et al. Corrosion resistant aluminum coating on plasma chamber components: US9337002B2[P/OL]. 2016[2024-07-10]. . |

| 14 | Smith B C, Young A. Optimizing chamber cleans for better film deposition performance optimizing chamber cleans for better film deposition performance[J]. Journal of the Electrochemical Society, 2001, 148(11): C721-C727. |

| 15 | Hong S. Corrosion resistance[M]. London: IntechOpen, 2012. |

| 16 | Bourget L, Brucker G, Feaver M, et al. MKS instrument handbook: semiconductor devices and process technology. 2nd ed.[M]. Andover: MKS Instruments, 2023. |

| 17 | Cunge G, Pelissier B, Joubert O, et al. New chamber walls conditioning and cleaning strategies to improve the stability of plasma processes[J]. Plasma Sources Science and Technology, 2005, 14(3): 599-609. |

| 18 | Huang Y L, Shih H, Daugherty J, et al. Evaluation of the properties of anodized aluminum 6061 subjected to thermal cycling treatment using electrochemical impedance spectroscopy (EIS)[J]. Corrosion Science, 2009, 51(10): 2493-2501. |

| 19 | Advanced Energy Industries I. Remote plasma source chamber anodization[R/OL].2018[2024-07-10].. |

| 20 | Raoux S, Cheung D, Fodor M, et al. Growth, trapping and abatement of dielectric particles in PECVD systems[J]. Plasma Sources Science Technology, 1997, 6(3): 405-414. |

| 21 | Tanaka J, Shiraishi K. Evaluation of growth and cleaning rates of chamber-wall deposition during silicon gate etching[J]. E-Journal of Surface Science and Nanotechnology, 2013, 11: 1-7. |

| 22 | Kim M S, Lee J W. Effect of seasoning-layer stress on fluorine diffusion[J]. AIP Advances, 2020, 10(8): 1-8. |

| 23 | Vos M F J. Development and understanding of advanced atomic layer deposition process: AlF3, Co and Ru[D]. Eindhoven: Eindhoven University of Technology, 2019. |

| 24 | Nojiri K. Dry etching technology for semiconductors. 1st ed.[M]. Tokyo: Springer Cham, 2015: 8-12. |

| 25 | Younesy S, Petit-Etienne C, Barnola S, et al. Cleaning chamber walls after ITO plasma etching process[C]// Advanced Etch Technology for Nanopatterning IX. San Jose, 2020: 85-91. |

| 26 | Miwa K, Takada N, Sasaki K. Fluorination mechanisms of Al2O3 and Y2O3 surfaces irradiated by high-density CF4∕O2 and SF6∕O2 plasmas[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2009, 27(4): 831-835. |

| 27 | Padron-Wells G, Vanoverloop M, Yeo J, et al. Fluorine saturated yttrium (YF) based coatings for advanced semiconductor ULSI manufacturing[C]//2019 30th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC). Saratoga Springs, 2019: 1-6. |

| 28 | Lee S S, Kim M J, Chung C W, et al. Degradation test for an anodic aluminum oxide film in plasma etching[J]. Journal of the Korean Physical Society, 2019, 74(11): 1046-1051. |

| 29 | Kim D M, Oh Y S, Kim S, et al. The erosion behaviors of Y2O3 and YF3 coatings under fluorocarbon plasma[J]. Thin Solid Films, 2011, 519(20): 6698-6702. |

| 30 | Lutze J W, Perera A H, Krusius J P. Anisotropic reactive ion etching of aluminum using Cl2, BCl3, and CH4 gases[J]. Journal of the Electrochemical Society, 1990, 137(1): 249-252. |

| 31 | Frank W E. Approaches for patterning of aluminum[J]. Microelectronic Engineering, 1997, 33(1/2/3/4): 85-100. |

| 32 | Tokunaga K, Redeker F C, Danner D A, et al. Comparison of aluminum etch rates in carbon tetrachloride and boron trichloride plasmas[J]. Journal of The Electrochemical Society, 1981, 128(4): 851-855. |

| 33 | Keaton A L, Hess D W. Aluminum etching in boron tribromide plasmas[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 1985, 3(3): 962-966. |

| 34 | Jeong C H, Kim D W, Lee H Y, et al. Sapphire etching with BCl3/HBr/Ar plasma[J]. Surface and Coatings Technology, 2003, 171(1/2/3): 280-284. |

| 35 | Jeong C H, Kim D W, Bae J W, et al. Dry etching of sapphire substrate for device separation in chlorine-based inductively coupled plasmas[J]. Materials Science and Engineering B: Solid-State Materials for Advanced Technology, 2002, 93(1/2/3): 60-63. |

| 36 | Fukumoto H, Fujikake I, Takao Y, et al. Plasma chemical behaviour of reactants and reaction products during inductively coupled CF4 plasma etching of SiO2 [J]. Plasma Sources Science and Technology, 2009, 18(4): 045027-045044. |

| 37 | Singh V K, Shaqfeh E S G, McVittie J P. Study of silicon etching in CF4/O2 plasmas to establish surface re-emission as the dominant transport mechanism[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 1994, 12(5): 2952-2962. |

| 38 | Cunge G, Vempaire D, Ramos R, et al. Radical surface interactions in industrial silicon plasma etch reactors[J]. Plasma Sources Science and Technology, 2010, 19(3): 034017-034028. |

| 39 | Hsueh H P, McGrath R T, Ji B, et al. Ion energy distributions and optical emission spectra in NF3-based process chamber cleaning plasmas[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 2001, 19(4): 1346. |

| 40 | Juvonen P. Effects of non-metallic inclusions on fatigue properties of calcium treated steels[D]. Helsinki: Helsinki University of Technology, 2004. |

| 41 | Outka D, Kim Y, Chen A, et al. Method of reducing aluminum fluoride deposits in plasma etch reactor: US6770214B2[P/OL]. 2004[2024-07-15].. |

| 42 | Ramos R, Cunge G, Pelissier B, et al. Cleaning aluminum fluoride coatings from plasma reactor walls in SiCl4/Cl2 plasmas[J]. Plasma Sources Science and Technology, 2007, 16(4): 711-715. |

| 43 | Smith D L, Bruce R H. Si and Al etching and product detection in a plasma beam under ultrahigh vacuum[J]. Journal of The Electrochemical Society, 1982, 129: 2045-2051. |

| 44 | Cunge G, Kogelschatz M, Sadeghi N. Production and loss mechanisms of SiCl x etch products during silicon etching in a high density HBr/Cl2/O2 plasma[J]. Journal of Applied Physics, 2004, 96(8): 4578-4587. |

| 45 | Raoux S, Tanaka T, Bhan M, et al. Remote microwave plasma source for cleaning chemical vapor deposition chambers: technology for reducing global warming gas emissions[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 1999, 17(2): 477-485. |

| 46 | Bai B. An experimental study and modeling of transformer coupled toroidal plasma processing of materials[D]. Cambridge: Massachusetts Institute of Technology, 2006. |

| 47 | Kim S B, Seo H, Kim Y, et al. Remote RF oxygen plasma cleaning of the photoresist residue and RIE-related fluorocarbon films[J]. Journal of the Korean Physical Society, 2002, 41(2): 247-250. |

| 48 | Ningel K P, Theirich D, Engemann J. Characterizing the remote plasma polymerization of octafluorocyclobutane induced by RF-driven hollow-cathode discharge[J]. Surface & Coatings Technology, 1998, 98(1/2/3): 1142-1147. |

| 49 | Theirich D, Ningel K P, Engemann J. A novel remote technique for high rate plasma polymerization with radio frequency plasmas[J]. Surface and Coatings Technology, 1996, 87: 628-633. |

| 50 | Wei G. Kinetics modeling and 3-dimensional simulation of surface roughness during plasma etching[D]. Boston: Massachusetts Institute of Technology, 2009. |

| 51 | Li X, Hua X F, Ling L, et al. Surface chemical changes of aluminum during NF3-based plasma processing used for in situ chamber cleaning[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2004, 22(1): 158-164. |

| 52 | So J, Choi E, Kim J T, et al. Improvement of plasma resistance of anodic aluminum-oxide film in sulfuric acid containing cerium(IV) ion[J]. Coatings, 2020, 10(2): 1-10. |

| 53 | Shin J S, Kim M, Song J B, et al. Fluorine plasma corrosion resistance of anodic oxide film depending on electrolyte temperature[J]. Applied Science and Convergence Technology, 2018, 27(1): 9-13. |

| 54 | Vallejo G R, Dayton D D. Ultra high purity electroplated sluminum coatings for critical components in dry etch and process chamber environments[R/OL]. 2015[2024-07-15]. . |

| 55 | Wang Y J, Ma X X, Guo G W. Electrodeposition of aluminum on 316L stainless steel from molten salts based on chlorides[J]. Key Engineering Materials, 2008, 373/374: 273-276. |

| 56 | Maniam K K, Paul S. A review on the electrodeposition of aluminum and aluminum alloys in ionic liquids[J]. Coatings, 2021, 11(1): 1-36. |

| 57 | Zhang M M, Kamavarum V, Reddy R G. New electrolytes for aluminum production: ionic liquids[J]. JOM, 2003, 55(11): 54-57. |

| 58 | Liu Q X, Zein El Abedin S, Endres F. Electrodeposition of nanocrystalline aluminum: breakdown of imidazolium cations modifies the crystal size[J]. Journal of the Electrochemical Society, 2008, 155(5): D357. |

| 59 | Bakkar A, Neubert V. Electrodeposition and corrosion characterisation of micro-and nano-crystalline aluminium from AlCl3/1-ethyl-3-methylimidazolium chloride ionic liquid[J]. Electrochimica Acta, 2013, 103: 211-218. |

| 60 | O’Donnell R J, Daugherty J E. Productivity enhancing thermal sprayed yttria-containing coating for plasma reactor: US20050150866A1[P/OL]. 2005[2024-07-15].. |

| 61 | Lin T K, Wang W K, Huang S Y, et al. Comparison of erosion behavior and particle contamination in mass-production CF4/O2 plasma chambers using Y2O3 and YF3 protective coatings[J]. Nanomaterials, 2017, 7(7): 183-192. |

| 62 | Miwa K, Sawai T, Aoyama M, et al. Particle reduction using Y2O3 material in an etching tool[C]//IEEE International Symposium on Semiconductor Manufacturing Conference Proceedings. Piscataway: IEEE, 2007: 479-482. |

| 63 | Song J B, Kim J T, Oh S G, et al. Contamination particles and plasma etching behavior of atmospheric plasma sprayed Y2O3 and YF3 coatings under NF3 plasma[J]. Coatings, 2019, 9(2): 102-110. |

| 64 | Ashizawa H, Yoshida K. Plasma-resistance evaluation of yttrium oxyfluoride coating prepared by aerosol deposition method[J]. International Journal of Applied Ceramic Technology, 2022, 19: 375-382. |

| 65 | Tai C N, Koh E S, Akari K. Macroparticles on TiN films prepared by the arc ion plating process[J]. Surface and Coatings Technology, 1990, 43: 324-335. |

| 66 | Jun A. Aerosol deposition of ceramic thick films at room temperature: densification mechanism of ceramic layers[J]. Journal of the American Ceramic Society, 2006, 89(6): 1834-1839. |

| 67 | Jun A. Room temperature impact consolidation (RTIC) of fine ceramic powder by aerosol deposition method and applications to microdevices[J]. Journal of Thermal Spray Technology, 2008, 17(2): 181-198. |

| 68 | Ashizawa H, Yoshida K. Investigation of fluoride layer of yttria coatings prepared by aerosol deposition method[J]. Journal of the Ceramic Society of Japan, 2021, 129(1): 46-53. |

| 69 | Le Gouil A, Pargon E, Cunge G, et al. Chemical analysis of deposits formed on the reactor walls during silicon and metal gate etching processes[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 2006, 24(5): 2191-2197. |

| 70 | Cunge G, Mori M, Kogelschatz M, et al. Time-resolved measurements of Cl2 density in high-density plasmas and application[J]. Applied Physics Letters, 2006, 88: 051501-051503. |

| 71 | Kim T W, Aydil E S, Soc J E, et al. Effects of chamber wall conditions on Cl concentration and Si etch rate uniformity in plasma etching reactors[J]. Journal of the Electrochemical Society, 2003, 150(7): G418-G427. |

| 72 | Kota G P, Coburn J W, Graves D B. The recombination of chlorine atoms at surfaces[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 1998, 16(1): 270-277. |

| 73 | Kota G P, Coburn J W, Graves D B. Heterogeneous recombination of atomic bromine and fluorine[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 1999, 17(1): 282-290. |

| 74 | Cunge G, Sadeghi N, Ramos R. Influence of the reactor wall composition on radicals’ densities and total pressure in Cl2 inductively coupled plasmas: II. during silicon etching[J]. Journal of Applied Physics, 2007, 102(9): 1-12. |

| 75 | Cunge G, Sadeghi N, Ramos R. Influence of the reactor wall composition on radicals’ densities and total pressure in Cl2 inductively coupled plasmas: I. without silicon etching[J]. Journal of Applied Physics, 2007, 102(9): 093304-093312. |

| 76 | Xu S, Sun Z, Qian X, et al. Characteristics and mechanism of etch process sensitivity to chamber surface condition[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 2001, 19(1): 166-171. |

| [1] | GENG Jian, WANG Xiao-dong, GUO Mei-ru, REN Zheng-yi. Effects of the Length of the Anode Cylinder in the Miniature Sputter Ion Pump on the Pumping Characteristics [J]. Journal of Northeastern University(Natural Science), 2023, 44(11): 1596-1603. |

| [2] | LIU Wan-suo, YUE Xiang-ji, LIN Zeng. Study on Characteristics of NS/DSMC Two-Way Coupling Method Applied to Transition Flow Simulation in PECVD [J]. Journal of Northeastern University(Natural Science), 2023, 44(11): 1591-1596. |

| [3] | BAO Jun-feng, YU Yue-guang, JIA Cheng-chang. Effects of ZrO2 Addition Amount on Microstructure and Mechanical Property of WC-6Co Prepared by Spark Plasma Sintering [J]. Journal of Northeastern University(Natural Science), 2021, 42(1): 43-48. |

| [4] | SHEN Ling-ling, ZHAO Bo, XU Jun-li, SHI Zhong-ning. Preparation of Nano Cuprous Oxide by Plasma Induced Cathode Discharge Electrolysis [J]. Journal of Northeastern University Natural Science, 2019, 40(5): 668-672. |

| [5] | XU Zhi-feng, ZHOU Xiang-kui, WANG Kai, WANG Qiang. Fabrication of Ultrafine-Grained Gradient Cemented Carbide by SPS Pre-sintered Method [J]. Journal of Northeastern University Natural Science, 2018, 39(11): 1593-1597. |

| [6] | LI Lin-min, LI Bao-kuan, LIU Li-chao, CAO Xia. Dynamic Mesh Simulation of Fluid Flow, Heat Transfer and Interface Tracking in TIG Welding Process [J]. Journal of Northeastern University Natural Science, 2017, 38(10): 1411-1416. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||