东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (10): 1459-1468.DOI: 10.12068/j.issn.1005-3026.2024.10.012

• 资源与土木工程 • 上一篇

王营1,2,3, 顾晓薇1,2,3( ), 王青1,2,3, 胥孝川1,2,3

), 王青1,2,3, 胥孝川1,2,3

收稿日期:2023-05-23

出版日期:2024-10-31

发布日期:2024-12-31

通讯作者:

顾晓薇

作者简介:王 营(1995-),男,辽宁北票人,东北大学博士研究生基金资助:

Ying WANG1,2,3, Xiao-wei GU1,2,3( ), Qing WANG1,2,3, Xiao-chuan XU1,2,3

), Qing WANG1,2,3, Xiao-chuan XU1,2,3

Received:2023-05-23

Online:2024-10-31

Published:2024-12-31

Contact:

Xiao-wei GU

About author:GU Xiao-wei,E-mail:guxiaowei@mail.neu.edu.cn摘要:

为分析石灰基矿渣-钢渣复合胶凝材料的性能及水化机理,对不同质量分数的钢渣、石灰复合胶凝材料的力学性能和工作性能进行讨论,并通过XRD等检测手段探究复合胶凝材料的水化产物、化学结构以及微观形貌.研究结果表明:石灰基矿渣-钢渣复合胶凝材料中钢渣最佳质量分数为30%,养护28 d抗压强度达到32.3 MPa;复合胶凝材料水化产物主要为C-(A)-S-H凝胶、水化碳铝酸钙、Ca(OH)2、方解石,其中C-(A)-S-H凝胶相互交错搭接为复合胶凝材料提供主要抗压强度;石灰基矿渣-钢渣复合胶凝材料中钢渣质量分数在20%~30%时不会对胶凝材料中C-(A)-S-H凝胶生成量产生较大影响且可以促进矿渣水化;适量钢渣具有充填效应使复合胶凝材料中微裂缝减少,基体更加致密,提高复合胶凝材料的力学性能.

中图分类号:

王营, 顾晓薇, 王青, 胥孝川. 石灰基矿渣-钢渣复合胶凝材料性能及水化机理[J]. 东北大学学报(自然科学版), 2024, 45(10): 1459-1468.

Ying WANG, Xiao-wei GU, Qing WANG, Xiao-chuan XU. Properties and Hydration Mechanism of Lime-Based Slag‑Steel Slag Composite Cementitious Materials[J]. Journal of Northeastern University(Natural Science), 2024, 45(10): 1459-1468.

| 材料 | SiO2 | Al2O3 | Fe2O3 | MgO | CaO |

|---|---|---|---|---|---|

| 钢渣 | 13.24 | 4.35 | 25.12 | 3.6 | 37.35 |

| 矿渣 | 34.50 | 17.70 | 1.03 | 6.01 | 34.00 |

表1 材料化学组成成分(质量分数) (%)

Table 1 Chemical composition of the material (mass fraction)

| 材料 | SiO2 | Al2O3 | Fe2O3 | MgO | CaO |

|---|---|---|---|---|---|

| 钢渣 | 13.24 | 4.35 | 25.12 | 3.6 | 37.35 |

| 矿渣 | 34.50 | 17.70 | 1.03 | 6.01 | 34.00 |

| 组号 | 石灰 | 钢渣 | 矿渣 | 水 |

|---|---|---|---|---|

| T0 | 43.2 | 0 | 316.8 | 144 |

| T1 | 43.2 | 36 | 280.8 | 144 |

| T2 | 43.2 | 72 | 244.8 | 144 |

| T3 | 43.2 | 108 | 208.8 | 144 |

| T4 | 43.2 | 144 | 172.8 | 144 |

| T5 | 54.0 | 108 | 198.0 | 144 |

| T6 | 64.8 | 108 | 187.2 | 144 |

表2 复合胶凝材料抗压强度实验各种材料配合比 (g)

Table2 Mix ratio of various materials in strength test of composite cementitious materials compressive

| 组号 | 石灰 | 钢渣 | 矿渣 | 水 |

|---|---|---|---|---|

| T0 | 43.2 | 0 | 316.8 | 144 |

| T1 | 43.2 | 36 | 280.8 | 144 |

| T2 | 43.2 | 72 | 244.8 | 144 |

| T3 | 43.2 | 108 | 208.8 | 144 |

| T4 | 43.2 | 144 | 172.8 | 144 |

| T5 | 54.0 | 108 | 198.0 | 144 |

| T6 | 64.8 | 108 | 187.2 | 144 |

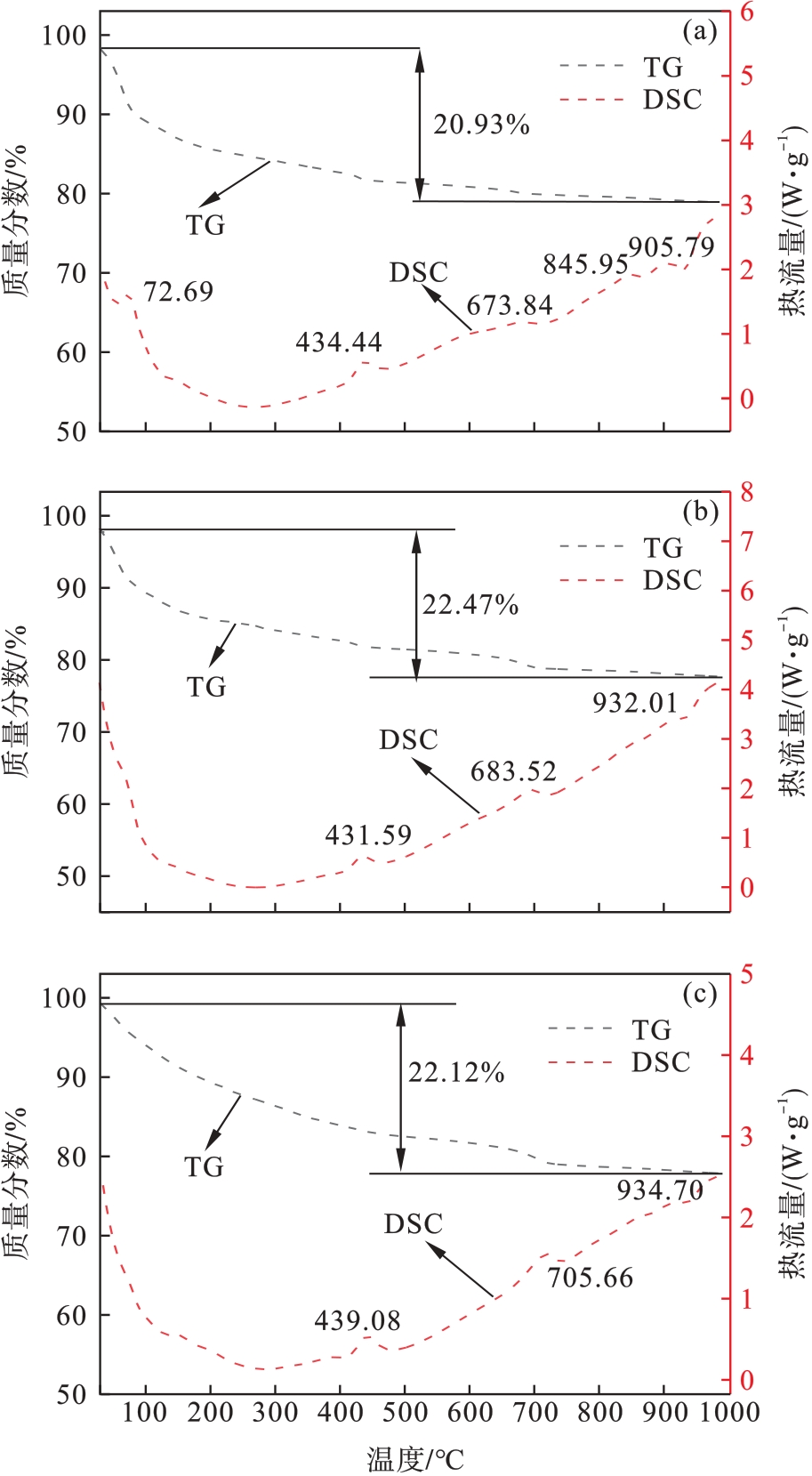

图12 不同钢渣质量分数的复合胶凝材料的热分析(a)—无钢渣; (b)—20%钢渣; (c)—40%钢渣.

Fig.12 Thermal analysis of composite cementitiousmaterials with different steel slag mass fraction

图13 不同钢渣质量分数复合胶凝材料的SEM图(a),(b)—无钢渣; (c),(d)—20%钢渣;(e),(f)—40%钢渣.

Fig.13 SEM images of composite cementitious materials with different steel slag mass fraction

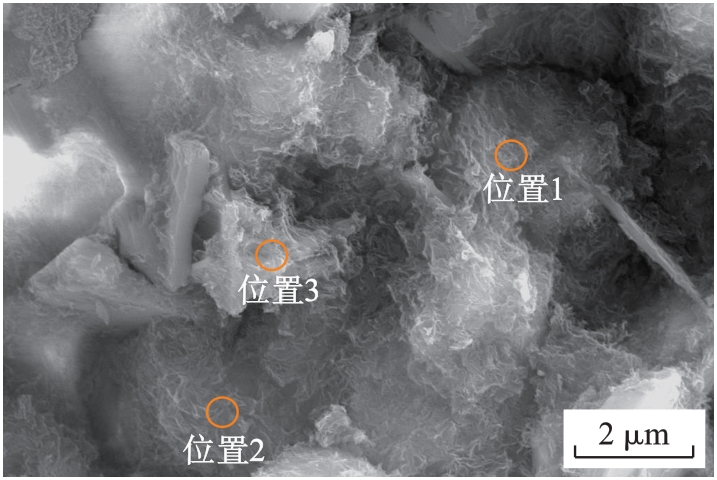

图15 石灰基矿渣-钢渣复合胶凝材料中C-(A)-S-H凝胶EDS点扫描位置

Fig.15 EDS spot scanning position of C-(A)-S-H gel in lime?based slag?steel slag composite cementitious materials

| 位置 | Ca | Si | Al | Mg | S |

|---|---|---|---|---|---|

| 1 | 48.92 | 7.08 | 2.14 | 0.65 | 0.55 |

| 2 | 39.36 | 8.68 | 2.99 | 1.16 | 0.67 |

| 3 | 32.81 | 4.83 | 6.77 | 0.91 | 2.32 |

表3 复合胶凝材料中C-(A)-S-H凝胶主要元素的质量分数 (gel in composite cementitious materials %)

Table3 Mass fraction of main elements of C-(A)-S-H

| 位置 | Ca | Si | Al | Mg | S |

|---|---|---|---|---|---|

| 1 | 48.92 | 7.08 | 2.14 | 0.65 | 0.55 |

| 2 | 39.36 | 8.68 | 2.99 | 1.16 | 0.67 |

| 3 | 32.81 | 4.83 | 6.77 | 0.91 | 2.32 |

| 1 | Yang K H, Song J K, Song K I.Assessment of CO2 reduction of alkali‑activated concrete[J].Journal of Cleaner Production,2013,39:265-272. |

| 2 | Wang J, Wang J X, Huang Y,et al.Preparation of alkali‑activated slag‑fly ash‑metakaolin hydroceramics for immobilizing simulated sodium‑bearing waste[J].Journal of the American Ceramic Society,2015,98(5):1393-1399. |

| 3 | Davidovits J.Geopolymers and geopolymeric materials[J].Journal of Thermal Analysis,1989,35(2):429-441. |

| 4 | O’Connor J, Nguyen T B T, Honeyands T,et al.Production,characterisation,utilisation,and beneficial soil application of steel slag:a review[J].Journal of Hazardous Materials,2021,419:126478. |

| 5 | Shi C H, Wang X C, Zhou S,et al.Mechanism,application,influencing factors and environmental benefit assessment of steel slag in removing pollutants from water:a review[J].Journal of Water Process Engineering,2022,47:102666. |

| 6 | Han F H, Zhang Z Q.Properties of 5‑year‑old concrete containing steel slag powder[J].Powder Technology,2018,334:27-35. |

| 7 | Muhmood L, Vitta S, Venkateswaran D.Cementitious and pozzolanic behavior of electric arc furnace steel slags[J].Cement and Concrete Research,2009,39(2):102-109. |

| 8 | 崔孝炜,倪文,任超.钢渣矿渣基全固废胶凝材料的水化反应机理[J],材料研究学报,2017,31(9):687-694. |

| Cui Xiao‑wei, Ni Wen, Ren Chao.Hydration reactionmechanism of slag‑based solid waste cementitious materials[J].Journal of Materials Research,2017,31(9):687-694. | |

| 9 | 李颖,吴保华,倪文,等.矿渣-钢渣-石膏体系早期水化反应中的协同作用[J].东北大学学报(自然科学版),2020,41(4):581-586. |

| Li Ying, Wu Bao‑hua, Ni Wen,et al.Synergies in early hydration reaction of slag‑steel slag‑gypsum system[J].Journal of Northeastern University (Natural Science),2020,41(4):581-586. | |

| 10 | Duan S Y, Liao H Q, Cheng F Q,et al.Investigation into the synergistic effects in hydrated gelling systems containing fly ash,desulfurization gypsum and steel slag[J].Construction and Building Materials,2018,187:1113-1120. |

| 11 | Duan S Y, Liao H Q, Song H P,et al.Performance improvement to ash‑cement blocks by adding ultrafine steel slag collected from a supersonic steam‑jet smasher[J].Construction and Building Materials,2019,212:140-148. |

| 12 | Zhao J H, Li Z H, Wang D M,et al.Hydration superposition effect and mechanism of steel slag powder and granulated blast furnace slag powder[J].Construction and Building Materials,2023,366:130101. |

| 13 | Chen P, Ma B G, Tan H B,et al.Improving the mechanical property and water resistance of β‑hemihydrate phosphogypsum by incorporating ground blast‑furnace slag and steel slag[J].Construction and Building Materials,2022,344:128265. |

| 14 | Wu M, Zhang Y S, Jia Y T,et al.Influence of sodium hydroxide on the performance and hydration of lime‑based low carbon cementitious materials[J].Construction and Building Materials,2019,200:604-615. |

| 15 | Zhang W, Hao X S, Wei C,et al.Synergistic enhancement of converter steelmaking slag,blast furnace slag,bayer red mud in cementitious materials:strength,phase composition,and microstructure[J].Journal of Building Engineering,2022,60:105177. |

| 16 | Zhang W, Liu X M, Zhang Z Q,et al.Synergic effects of circulating fluidized bed fly ash‑red mud‑blastfurnace slag in green cementitious materials:hydration products and environmental performance[J].Journal of Building Engineering,2022,58:105007. |

| 17 | Matschei T, Lothenbach B, Glasser F P.The AFm phase in Portland cement[J].Cement and Concrete Research,2007,37(2):118-130. |

| 18 | 曹伟达,杨全兵.碳化养护对钢渣-熟石灰固碳砖耐久性的影响[J].建筑材料学报,2023,26(3):324-331.. |

| Cao Wei‑da, Yang Quan‑bing.Effect on carbonization curing on durability of carbon fixing steel slag‑hydrated lime brick[J].Journal of Building Materials,2023,26(3):324-331. | |

| 19 | An Q, Pan H M, Zhao Q X,et al.Strength development and microstructure of sustainable geopolymers made from alkali‑activated ground granulated blast‑furnace slag,calcium carbide residue,and red mud[J].Construetion and Building Materials,2022,356:712-721. |

| 20 | 徐东,倪文,汪群慧,等.碱渣复合胶凝材料制备无熟料混凝土[J],哈尔滨工业大学学报,2020,52(8):151-160. |

| Xu Dong, Ni Wen, Wang Qun‑hui,et al.Preparation of non‑clinker concrete using alkaline residue composite cementitious materials[J].Journal of Harbin Institute of Technology,2020,52(8):151-160. | |

| 21 | Guo W C, Zhao Q X, Sun Y J,et al.Effects of various curing methods on the compressive strength and microstructure of blast furnace slag‑fly ash‑based cementitious material activated by alkaline solid wastes[J].Construction and Building Materials,2022,357:129397. |

| 22 | Lodeiro I G, Macphee D E, Palomo A,et al.Effect of alkalis on fresh C-S-H gels.FT-IR analysis[J].Cement and Concrete Research,2009,39(3):147-153. |

| 23 | Wu M, Zhang Y S, Jia Y T,et al.Effects of sodium sulfate on the hydration and properties of lime‑based low carbon cementitious materials[J].Journal of Cleaner Production,2019,220:677-687. |

| 24 | Zhao W Y, Guo Q Q, Do X Q, et al.Impact response of steel‑concrete composite panels:experiments and FE analyses[J].Steel and Composite Structures,2018,26(3):255-263. |

| 25 | 苏运辉,徐家兴,张立刚,等.偏高岭土对大掺量石灰石粉水泥抗氯离子渗透性能的影响[J].铁道科学与工程学报,2023,20(10):3779-3788. |

| Su Yun‑hui, Xu Jia‑xing, Zhang Li‑gang,et al.Effect of metakaolin on the resistance to chloride ion permeability of cement with high‑volume of limestone powder[J].Journal of Railway Science and Engineering,2023,20(10):3779-3788. | |

| 26 | 倪文,李颖,许成文,等.矿渣-电炉还原渣全固废胶凝材料的水化机理[J].中南大学学报(自然科学版),2019,50(10):2342-2351. |

| Ni Wen, Li Ying, Xu Cheng‑wen,et al.Hydration mechanism of blast furnace slag‑reduction slag based solid waste cementing materials[J].Journal of Central South University (Science and Technology),2019,50(10):2342-2351. | |

| 27 | Vincent M, Sandrine‑Garid B, Isabelle D B.The influence of an ion‑exchange resin on the kinetics of hydration of tricalcium silicate[J].Cement and Concrete Research,2010,40:1459-1464. |

| 28 | Taylor H F W, Turner A B.Reactions of tricalcium silicate paste with organic liquids[J].Cement and Concrete Research,1987,17(4):613-623. |

| [1] | 柳静献, 代峰, 毛宁. 酸碱交互腐蚀对芳纶滤料性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(7): 1034-1040. |

| [2] | 王海涛, 李家栋, 邓想涛, 王昭东. 固溶温度对Fe-20Mn-9Al-1.2C低密度钢组织性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(5): 609-616. |

| [3] | 任朝晖, 李竺鸿, 王云贺, 张梓婷. 超声滚压微锻造增材件表面力学性能[J]. 东北大学学报(自然科学版), 2023, 44(5): 634-641. |

| [4] | 毛宁, 牛荟蓉, 柳静献. 聚芳恶二唑纤维耐酸特性的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(5): 719-725. |

| [5] | 邸洪双, 柯浩鹏, 张天宇. 多步热处理对含Cu中碳低合金钢组织与性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(3): 340-348. |

| [6] | 左玉波, 凌放, 韩友, 朱庆丰. 固溶后冷轧变形量对2195铝锂合金组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(2): 199-205. |

| [7] | 田妮 , 张耀中, 周轶然, 秦广华. Zr对Al-10Zn-2.5Mg-1.6Cu合金板材组织与性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(7): 951-958. |

| [8] | 赵宇辉, 高孟秋, 赵吉宾, 贺晨. 增减材复合制造WC颗粒增强316L不锈钢材料组织性能[J]. 东北大学学报(自然科学版), 2022, 43(2): 197-205. |

| [9] | 王胤, 李勇, 钱晓明, 张博四. 真空离心铸造冷却速率对7055铝合金组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(12): 1769-1776. |

| [10] | 张广泰, 吴锐, 李雪藩, 阿迪力·赛买提. 老化-荷载作用下叠层轮胎隔震垫时变力学性能[J]. 东北大学学报(自然科学版), 2021, 42(8): 1180-1186. |

| [11] | 高彩茹, 屈兵兵, 田余东, 杜林秀. 回火温度对在线淬火Q690q桥梁钢显微组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(7): 927-933. |

| [12] | 朱成林, 高秀华, 王明明, 宋丽英. 淬火温度对12Cr14Ni2不锈结构钢组织及力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(6): 781-788. |

| [13] | 董硕, 沙松, 蒙世仟, 荣冠. 液氮冷却作用下三类高温岩石力学性能试验研究[J]. 东北大学学报(自然科学版), 2021, 42(11): 1591-1599. |

| [14] | 蔡志辉 , 文光奇, 韩阿康, 张开华. 调质工艺对V微合金油井管用钢力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(10): 1414-1420. |

| [15] | 鲍君峰, 于月光, 贾成厂. ZrO2添加量对等离子放电烧结制备WC-6Co组织和性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(1): 43-48. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||