东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (1): 99-109.DOI: 10.12068/j.issn.1005-3026.2025.20230192

陈晓明1,2, 余建业3, 刘顺1,2, 曾翀1

收稿日期:2023-07-05

出版日期:2025-01-15

发布日期:2025-03-25

作者简介:陈晓明(1990—),男,河南郑州人,东北大学秦皇岛分校讲师,博士.

基金资助:Xiao-ming CHEN1,2, Jian-ye YU3, Shun LIU1,2, Chong ZENG1

Received:2023-07-05

Online:2025-01-15

Published:2025-03-25

摘要:

基于有限元分析和性能测试对铝合金汽车轮毂进行轻量化设计.首先,利用ANSYS Workbench对轮毂模型进行结构静力学分析,得到车辆静止满载状态下轮毂的应力和变形分布规律.其次,通过对轮毂前6阶模态的分析,得到轮毂各阶固有频率和变形量,并探明轮毂在发动机和路面激励下的共振规律.然后,在轮毂弯曲疲劳、径向疲劳和冲击仿真的基础上,对轮毂轮辐进行拓扑优化以获得轻量化轮毂模型.最后,对轻量化轮毂进行性能试验,并将轻量化轮毂与原始轮毂的试验结果进行对比,分析优化前后的轮毂各项性能的变化,确保轻量化后的轮毂模型符合强度要求.

中图分类号:

陈晓明, 余建业, 刘顺, 曾翀. 基于有限元模拟的SUV汽车铝合金轮毂轻量化设计[J]. 东北大学学报(自然科学版), 2025, 46(1): 99-109.

Xiao-ming CHEN, Jian-ye YU, Shun LIU, Chong ZENG. Lightweight Design of SUV Automobile Aluminum Alloy Wheel Hub Based on Finite Element Simulation[J]. Journal of Northeastern University(Natural Science), 2025, 46(1): 99-109.

| 整车质量/kg | 最大功率/kW | 最大扭矩/(N·m) | 变速器传动效率/% | 一档传动比 | 主减速比 |

|---|---|---|---|---|---|

| 1 865 | 138 | 252 | 95 | 3.5 | 4.356 |

表1 车辆参数

Table 1 Vehicle parameters

| 整车质量/kg | 最大功率/kW | 最大扭矩/(N·m) | 变速器传动效率/% | 一档传动比 | 主减速比 |

|---|---|---|---|---|---|

| 1 865 | 138 | 252 | 95 | 3.5 | 4.356 |

| 密度 | 弹性模量 | 泊松比 | 屈服强度 |

|---|---|---|---|

| 2 700 | 72.4 | 0.33 | 239 |

表2 A356铝合金材料属性

Table 2 Material properties of A356 aluminum alloy

| 密度 | 弹性模量 | 泊松比 | 屈服强度 |

|---|---|---|---|

| 2 700 | 72.4 | 0.33 | 239 |

| 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa |

|---|---|---|---|---|---|---|---|

| 5 | 102.64 | 50 | 103.79 | 95 | 109.12 | 140 | 106.18 |

| 10 | 105.99 | 55 | 103.47 | 100 | 112.19 | 145 | 104.56 |

| 15 | 108.56 | 60 | 102.74 | 105 | 114.42 | 150 | 102.73 |

| 20 | 110.34 | 65 | 102.62 | 110 | 115.81 | 155 | 102.11 |

| 25 | 111.29 | 70 | 104.55 | 115 | 116.34 | 160 | 102.80 |

| 30 | 111.42 | 75 | 105.70 | 120 | 116.00 | 165 | 102.92 |

| 35 | 110.73 | 80 | 106.06 | 125 | 114.80 | 170 | 102.28 |

| 40 | 109.22 | 85 | 105.64 | 130 | 112.75 | 175 | 100.87 |

| 45 | 106.90 | 90 | 105.24 | 135 | 109.87 | 180 | 101.02 |

表3 各角度对应的等效应力值

Table 3 Corresponding quivalent stress values at different angular

| 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa | 角度/(°) | 等效应力/MPa |

|---|---|---|---|---|---|---|---|

| 5 | 102.64 | 50 | 103.79 | 95 | 109.12 | 140 | 106.18 |

| 10 | 105.99 | 55 | 103.47 | 100 | 112.19 | 145 | 104.56 |

| 15 | 108.56 | 60 | 102.74 | 105 | 114.42 | 150 | 102.73 |

| 20 | 110.34 | 65 | 102.62 | 110 | 115.81 | 155 | 102.11 |

| 25 | 111.29 | 70 | 104.55 | 115 | 116.34 | 160 | 102.80 |

| 30 | 111.42 | 75 | 105.70 | 120 | 116.00 | 165 | 102.92 |

| 35 | 110.73 | 80 | 106.06 | 125 | 114.80 | 170 | 102.28 |

| 40 | 109.22 | 85 | 105.64 | 130 | 112.75 | 175 | 100.87 |

| 45 | 106.90 | 90 | 105.24 | 135 | 109.87 | 180 | 101.02 |

| t/s | Y轴方向速度/(mm·s-1) |

|---|---|

| 0.029 6 | -248.62 |

| 0.029 8 | -121.72 |

| 0.030 0 | 18.052 |

| 0.030 2 | 162.79 |

表4 冲锤的速度变化

Table 4 Velocity changes of the hammer

| t/s | Y轴方向速度/(mm·s-1) |

|---|---|

| 0.029 6 | -248.62 |

| 0.029 8 | -121.72 |

| 0.030 0 | 18.052 |

| 0.030 2 | 162.79 |

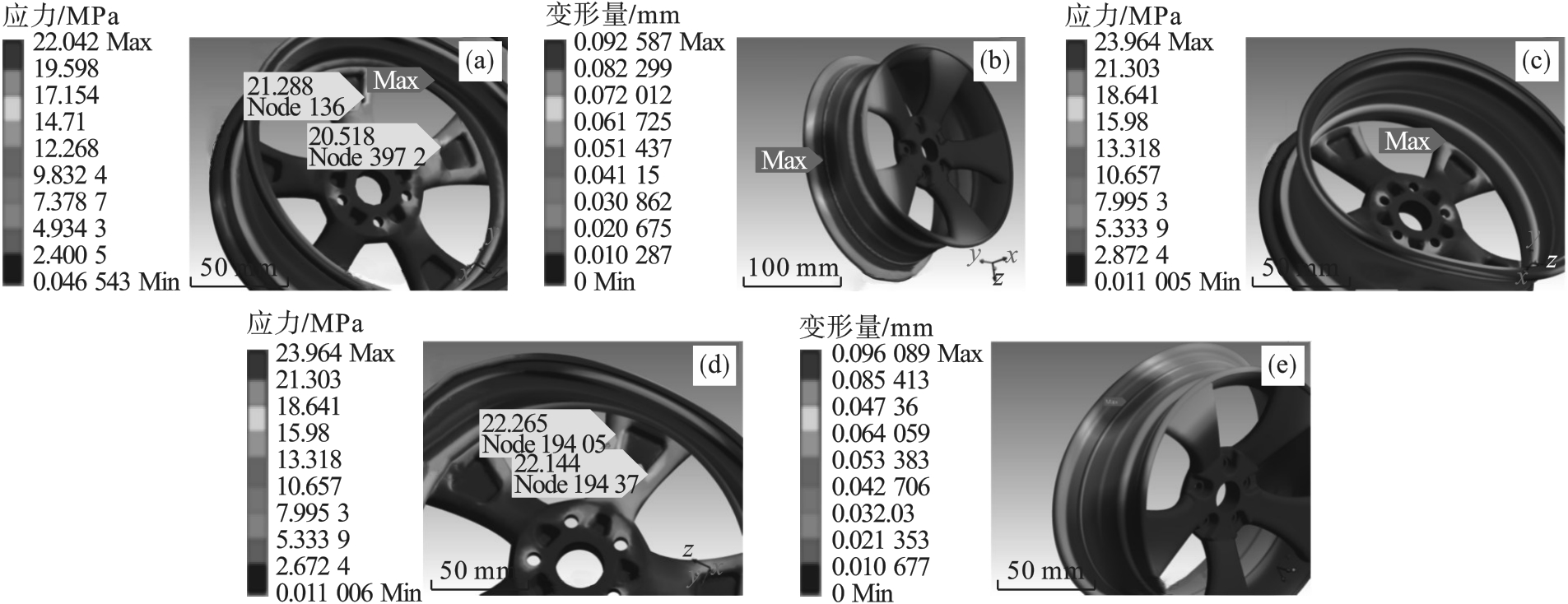

图15 轻量化设计后径向疲劳试验的应力和变形云图(a)—窗口处载荷应力云图; (b)—窗口处载荷变形云图; (c)—辐条处载荷应力云图;(d)—辐条处载荷节点云图; (e)—辐条处载荷变形云图.

Fig.15 Stress and deformation cloud map of radial fatigue testing after lightweight design

| 参数 | 质量/kg | 一阶固有频率/Hz | 静态结构 最大应力 | 弯曲疲劳试验 最大应力 | 径向疲劳试验 最大应力 | 冲击试验 最大应力 |

|---|---|---|---|---|---|---|

| MPa | MPa | MPa | MPa | |||

| 轻量化前 | 14.512 | 344.27 | 26.282 | 116.34 | 99.79 | 115.36 |

| 轻量化后 | 13.467 | 310.41 | 42.229 | 149.02 | 23.964 | 115.29 |

表5 轻量化设计前后数据对比

Table 5 Comparison of data before and after lightweight design

| 参数 | 质量/kg | 一阶固有频率/Hz | 静态结构 最大应力 | 弯曲疲劳试验 最大应力 | 径向疲劳试验 最大应力 | 冲击试验 最大应力 |

|---|---|---|---|---|---|---|

| MPa | MPa | MPa | MPa | |||

| 轻量化前 | 14.512 | 344.27 | 26.282 | 116.34 | 99.79 | 115.36 |

| 轻量化后 | 13.467 | 310.41 | 42.229 | 149.02 | 23.964 | 115.29 |

| 1 | Ridha R A.Finite element analysis of automatic wheels[J].SAE Automotive Engineering Congress and Exposition,1976,85(1):760085. |

| 2 | Shah V, Patel P, Keshav M.Modeling and analysis of integrated wheel hub[J].Journal of Physics:Conference Series,2022,2256:012035. |

| 3 | Käumle F, Schnell R.Entwicklungszeit von Leichtmetallrädern verkürzen[J].Materials Testing,1998,40(10):394-398. |

| 4 | Topaç M M, Ercan S, Kuralay N S.Fatigue life prediction of a heavy vehicle steel wheel under radial loads by using finite element analysis[J].Engineering Failure Analysis,2012,20:67-79. |

| 5 | Muthuraj R, Badrinarayanan R, Sundararajan T.Improvement in the wheel design using realistic loading conditions—FEA and experimental stress comparison[C]//16th Asia Pacific Automotive Engineering Conference.Pune:the Automotive Research Association of India,2011:280106. |

| 6 | Karandikar H M, Fuchs W.Fatigue life prediction for wheels by simulation of the rotating bending test[J].SAE Transactions,1990,99:180-190. |

| 7 | Ferran G, Barros C R M, di Pasquale E,et al.Simplified numerical simulation of forming a car wheel disk using the SIMEX explicit FEM code,and comparisons with press‑shop results[J].Journal of Materials Processing Technology,1996,60(1/2/3/4):523-528. |

| 8 | Abe Y, Mori K, Ebihara O.Optimisation of the distribution of wall thickness in the multistage sheet metal forming of wheel disks[J].Journal of Materials Processing Technology,2002,125:792-797. |

| 9 | 秦德申.轿车车轮动态应力的测试与分析[J].汽车工程,1989(4):58-65. |

| Qin De‑shen.Test and analysis of the dynamic stress of car wheels[J].Automotive Engineering,1989(4):58-65. | |

| 10 | 孙建鹏.铝合金轮毂设计分析平台的建立及疲劳寿命研究[D].合肥:合肥工业大学,2014. |

| Sun Jian‑peng.Establishment of design and analysis platform and fatigue life research of wheel hub[D].Hefei:Hefei University of Technology,2014. | |

| 11 | 宋渊.铝合金轮毂轻量化设计(CAE)[D].合肥:合肥工业大学,2014. |

| Song Yuan.Lightweight design of aluminum alloy wheel hubs(CAE)[D].Hefei:Hefei University of Technology,2014. | |

| 12 | 王科,王国林,朱志武.基于有限元法的汽车轮毂强度分析[J].机械工程师,2013(1):32-33. |

| Wang Ke, Wang Guo‑lin, Zhu Zhi‑wu.Strength analysis of automobile wheels based on the finite element method[J].Mechanical Engineer,2013(1):32-33. | |

| 13 | 王倩倩,王静,韩欣欣.基于ANSYS Workbench的越野汽车轮毂有限元分析及优化[J].汽车实用技术,2022(4):72-75. |

| Wang Qian‑qian, Wang Jing, Han Xin‑xin.Finite element analysis and optimization of off‑road vehicle wheels based on ANSYS Workbench[J].Automobile Applied Technology,2022(4):72-75. | |

| 14 | Sinokrot T, Nakhaeinejad M, Shabana A A.A velocity transformation method for the nonlinear dynamic simulation of railroad vehicle systems[J].Nonlinear Dynamics,2008,51(1):289-307. |

| 15 | Stearns J, Srivatsan T S, Gao X,et al.Analysis of stress and strain distribution in a vehicle wheel:finite element analysis versus the experimental method[J].The Journal of Strain Analysis for Engineering Design,2005,40(6):513-523. |

| 16 | Hawkins G, Kumar V.Structural analysis of alloy wheels[J].Journal of Physics:Conference Series,2020,1478:012007. |

| 17 | Marron G, Teracher P.The application of high‑strength,hot‑rolled steels in auto wheels[J].JOM,1996,48(7):16-20. |

| 18 | Raju P R, Satyanarayana B, Ramji K,et al.Evaluation of fatigue life of aluminum alloy wheels under radial loads[J].Engineering Failure Analysis,2007,14(5):791-800. |

| 19 | Riesner M, DeVries R I.Finite element analysis and structural optimization of vehicle wheels[C]//International Congress & Exposition.Detroit,1983:830133. |

| 20 | Karthikeyan K, Kishore R, Jeeva K,et al.Topology optimization of an ATV wheel hub[J].Journal of Physics:Conference Series,2021,2027:012022. |

| 21 | 肖占龙,孙跃东.基于ANSYS的汽车轮毂的轻量化研究[J].农业装备与车辆工程,2022,60(2):143-148. |

| Xiao Zhan‑long, Sun Yue‑dong.Research on the lightweight of automobile wheels based on ANSYS[J].Agricultural Equipment & Vehicle Engineering,2022,60(2):143-148. | |

| 22 | Pang W, Wang W P, Zhang W H,et al.Modeling and optimization for lightweight design of aluminum alloy wheel hub[J].Key Engineering Materials,2016,723:322-328. |

| 23 | Chu D M, Bai W J, He Y,et al.Research on lightweight technology of new carbon fiber wheel hub structure[J].IOP Conference Series:Earth and Environmental Science,2021,632(5):052071. |

| [1] | 黄贤振, 于瑞, 姜智元, 荣治明. 考虑热误差的电主轴建模与可靠性全局灵敏度分析[J]. 东北大学学报(自然科学版), 2024, 45(5): 675-682. |

| [2] | 丁发兴, 罗开源, 雷建雄, 吕飞. 高轴压比CFST柱-组合梁单边螺栓节点抗震性能分析[J]. 东北大学学报(自然科学版), 2024, 45(12): 1787-1797. |

| [3] | 丁发兴, 束舒东, 张经科, 何畅. 开口截面钢-混凝土组合梁纯扭力学性能[J]. 东北大学学报(自然科学版), 2024, 45(10): 1485-1493. |

| [4] | 张东祥, 张弛, 范威, 郭立新. 人工锥体的尺寸对颈椎力学特性的影响[J]. 东北大学学报(自然科学版), 2023, 44(8): 1136-1143. |

| [5] | 李杰, 贾长旺, 成林海, 赵旗. 随机路面下轮毂电机偏心对电动汽车平顺性影响[J]. 东北大学学报(自然科学版), 2022, 43(8): 1113-1119. |

| [6] | 安国青, 王蕊, 赵晖, 李铁英. 双钢板混凝土组合板在撞击荷载下的动力响应[J]. 东北大学学报(自然科学版), 2022, 43(8): 1192-1200. |

| [7] | 王连广, 蒙玉琪, 王梓晴. 预制压型钢板混凝土组合板和钢梁连接及其有限元分析[J]. 东北大学学报(自然科学版), 2022, 43(4): 575-581. |

| [8] | 陈小辉, 张珩, 刘明月, 侯东晓. 开孔碳纤维复合材料层合板的拉伸失效有限元分析[J]. 东北大学学报(自然科学版), 2022, 43(3): 397-403. |

| [9] | 张耀满, 李万鹏, 杨铭宇. 球头铣刀加工钛合金零件的铣削力特性[J]. 东北大学学报:自然科学版, 2020, 41(6): 852-857. |

| [10] | 黄智, 吴湘, 王洪艳, 周涛. 整体叶盘磨抛机床叶片型面磨头结构拓扑优化设计[J]. 东北大学学报:自然科学版, 2019, 40(8): 1149-1153. |

| [11] | 李军超, 谢锋, 赵泽, 龚鹏程. 金属板材渐进成形的数值模拟及破裂预测[J]. 东北大学学报:自然科学版, 2019, 40(4): 488-494. |

| [12] | 范例, 谢里阳, 张娜. 重卡驱动桥壳疲劳稳健性与轻量化设计[J]. 东北大学学报:自然科学版, 2019, 40(3): 365-369. |

| [13] | 冯乃诗, 王宏, 胡佛, 李康. 软体机器手纤维增强式三腔体结构设计与分析[J]. 东北大学学报:自然科学版, 2019, 40(10): 1461-1466. |

| [14] | 吴青龙, 周奇才, 熊肖磊, 焦洪宇. 塔式起重机臂架腹杆布局及尺寸优化设计[J]. 东北大学学报:自然科学版, 2018, 39(9): 1309-1314. |

| [15] | 宋波, 王连广, 王春刚. 帽形加劲复杂卷边槽钢柱的稳定性能[J]. 东北大学学报:自然科学版, 2018, 39(1): 143-147. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||