东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (4): 24-32.DOI: 10.12068/j.issn.1005-3026.2025.20230317

石浩强, 李家栋, 赵鹏, 李勇

收稿日期:2023-11-27

出版日期:2025-04-15

发布日期:2025-07-01

作者简介:石浩强(1997—),男,河南洛阳人,东北大学硕士研究生基金资助:Hao-qiang SHI, Jia-dong LI, Peng ZHAO, Yong LI

Received:2023-11-27

Online:2025-04-15

Published:2025-07-01

摘要:

基于东北大学中试气垫炉的几何模型和实验数据,建立了流固耦合模型,研究了气垫炉中带材漂浮形态的影响因素.结果表明:该模型能够准确模拟不同影响因素下铜带材在气垫炉内的漂浮形态.气垫压力、带材张力、带材厚度是带材漂浮形态的主要影响因素,改变带材上、下表面的气垫压力,带材变形量会明显减少或增大;薄带材的张力每增加一倍,带材的上、下喷嘴附近的最大变形减小为原来1/2;带材厚度每增加0.5 mm,在相同的带材表面气垫压力下,带材的最大变形量显著减小.气垫炉内温度是次要因素,炉温不同,但带材的表面上、下气垫压力相同,带材变形量近似相等.该数值模拟为研究气垫炉内带材悬浮过程中的变形机理提供了新的手段和思路.

中图分类号:

石浩强, 李家栋, 赵鹏, 李勇. 铜合金带材气垫式热处理过程漂浮形态的数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(4): 24-32.

Hao-qiang SHI, Jia-dong LI, Peng ZHAO, Yong LI. Numerical Simulation of Floating Morphology of Copper Alloy Strip in Air Cushion Heat Treatment Process[J]. Journal of Northeastern University(Natural Science), 2025, 46(4): 24-32.

| 组别 | 带材规格 | 下、上喷嘴 高度 /mm | 下、上喷嘴 风速/(m·s -1) | 带材下表面 气垫压力/Pa | 带材上表面气垫压力/Pa | 带材压力 差/Pa | 带材自身压力/Pa |

|---|---|---|---|---|---|---|---|

| 1 | 0.5 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 126.43 | 65.17 | 61 |

| 2 | 1.0 mm 铜带材3-3,27 ℃ | 90-110 | 27.37-0.94 | 360.88 | 244.54 | 116.34 | 122 |

| 3 | 1.0 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 5.43 | 139.17 | 122 |

| 4 | 1.5 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 19.66 | 171.93 | 183 |

| 5 | 0.5 mm 铜带材3-3,600 ℃ | 80-120 | 34.20-30.78 | 191.71 | 128.35 | 6.35 | 61 |

表 1 应用于流固耦合的带材压力数据

Table 1 Strip pressure data for fluid-structure interaction

| 组别 | 带材规格 | 下、上喷嘴 高度 /mm | 下、上喷嘴 风速/(m·s -1) | 带材下表面 气垫压力/Pa | 带材上表面气垫压力/Pa | 带材压力 差/Pa | 带材自身压力/Pa |

|---|---|---|---|---|---|---|---|

| 1 | 0.5 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 126.43 | 65.17 | 61 |

| 2 | 1.0 mm 铜带材3-3,27 ℃ | 90-110 | 27.37-0.94 | 360.88 | 244.54 | 116.34 | 122 |

| 3 | 1.0 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 5.43 | 139.17 | 122 |

| 4 | 1.5 mm 铜带材3-3,27 ℃ | 90-110 | 20.52-17.10 | 191.59 | 19.66 | 171.93 | 183 |

| 5 | 0.5 mm 铜带材3-3,600 ℃ | 80-120 | 34.20-30.78 | 191.71 | 128.35 | 6.35 | 61 |

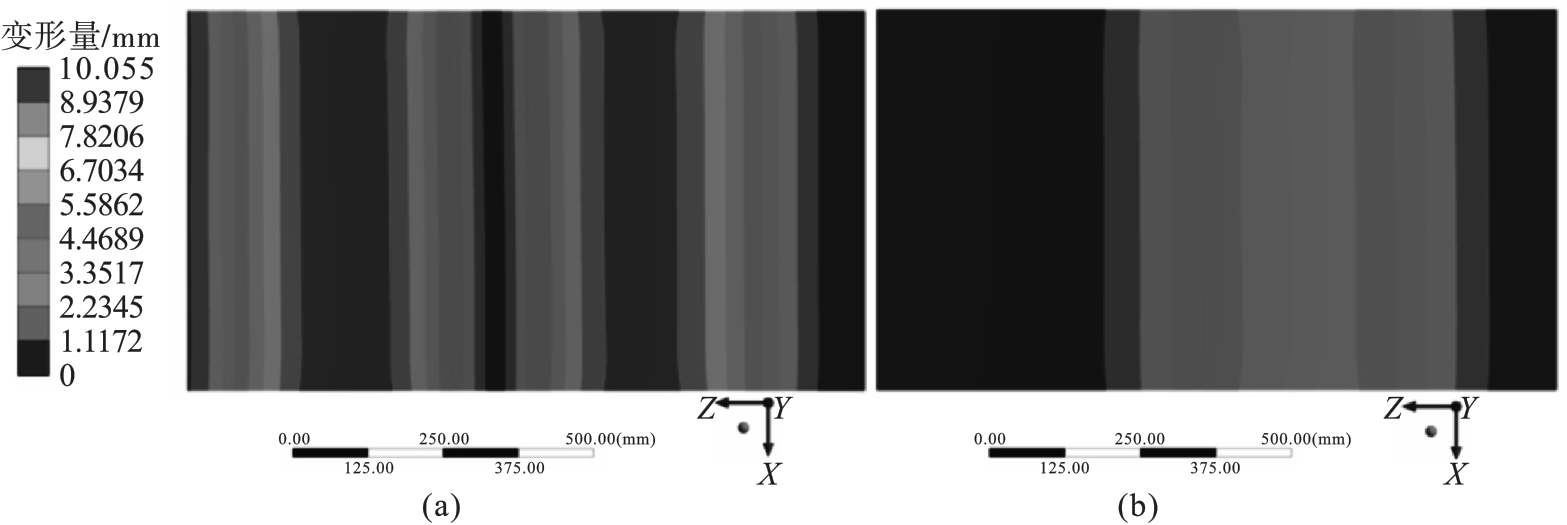

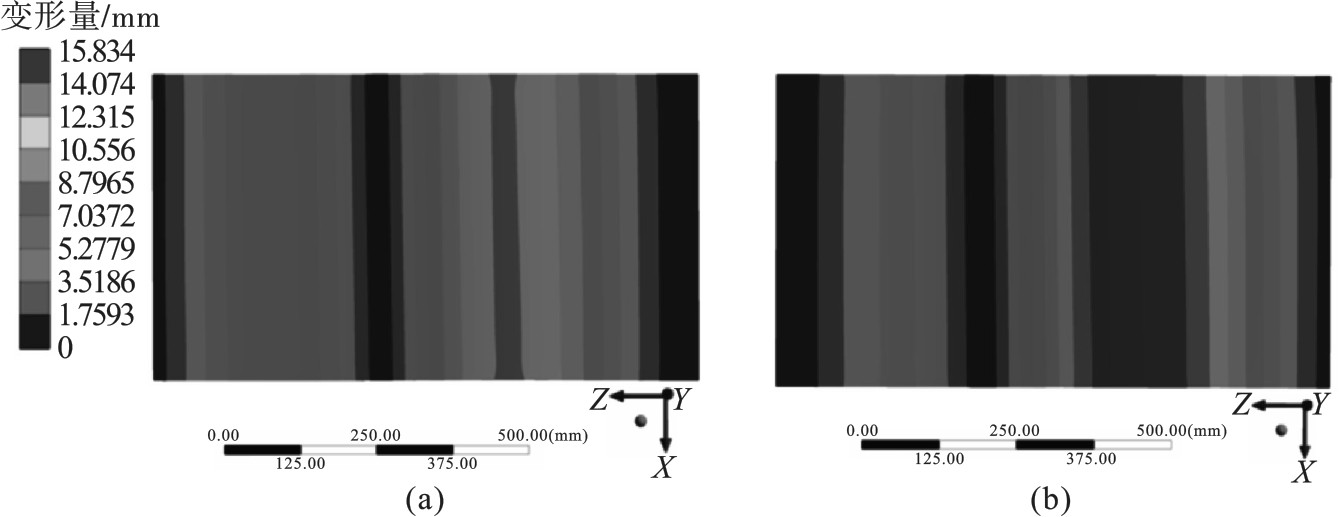

图 7 第 2,3 组压力分布对带材变形影响模拟结果(a)—第2组; (b)—第3组.

Fig.7 Second and third groups of pressure distribution affect the deformation of strip to simulate the results

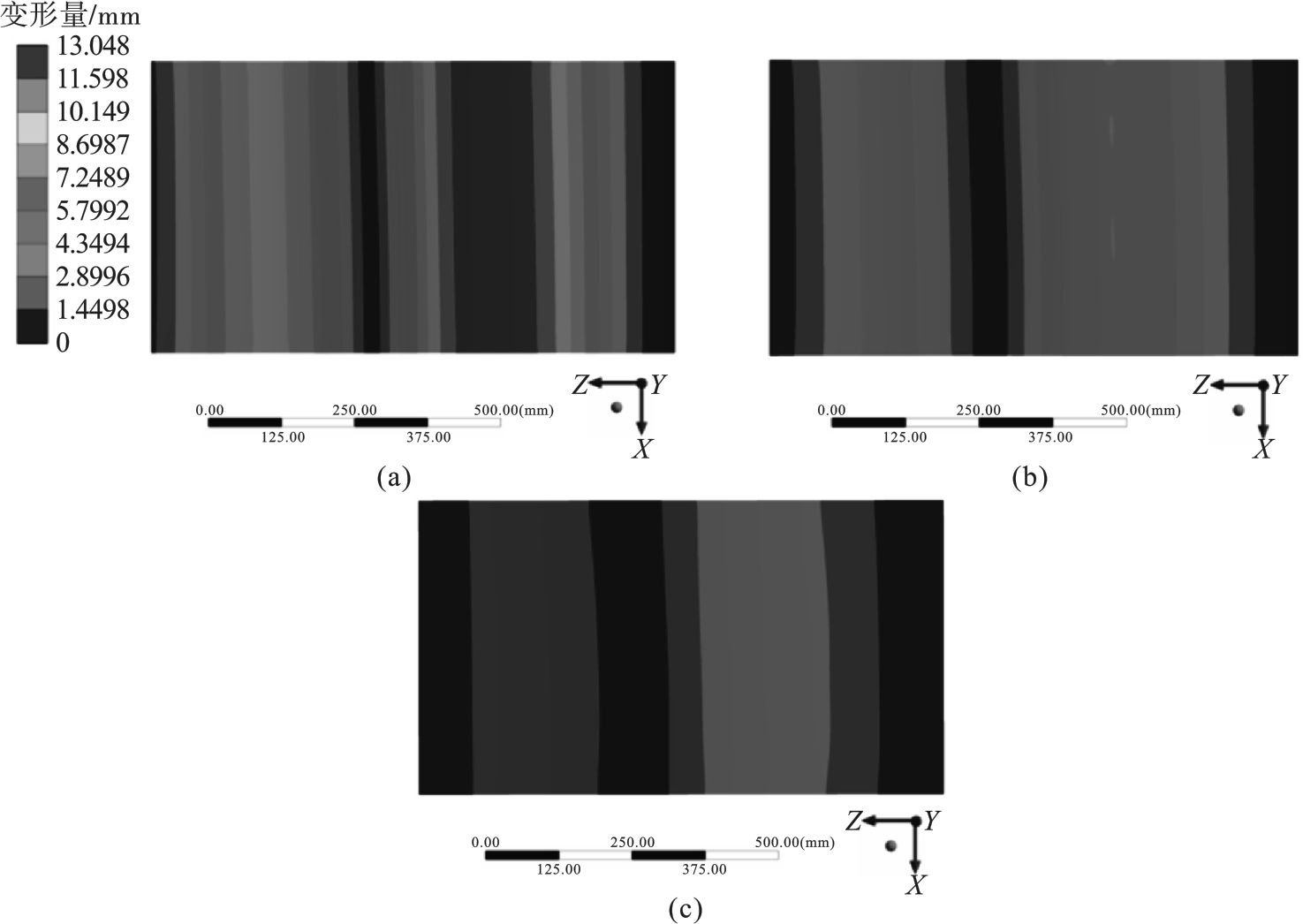

图 8 第 1 组带材张力对带材变形影响的模拟结果(a)—F=1 N·mm-2; (b)—F=2 N·mm-2; (c)—F=4 N·mm-2.

Fig. 8 First group of strip tension affects the simulation results of strip deformation

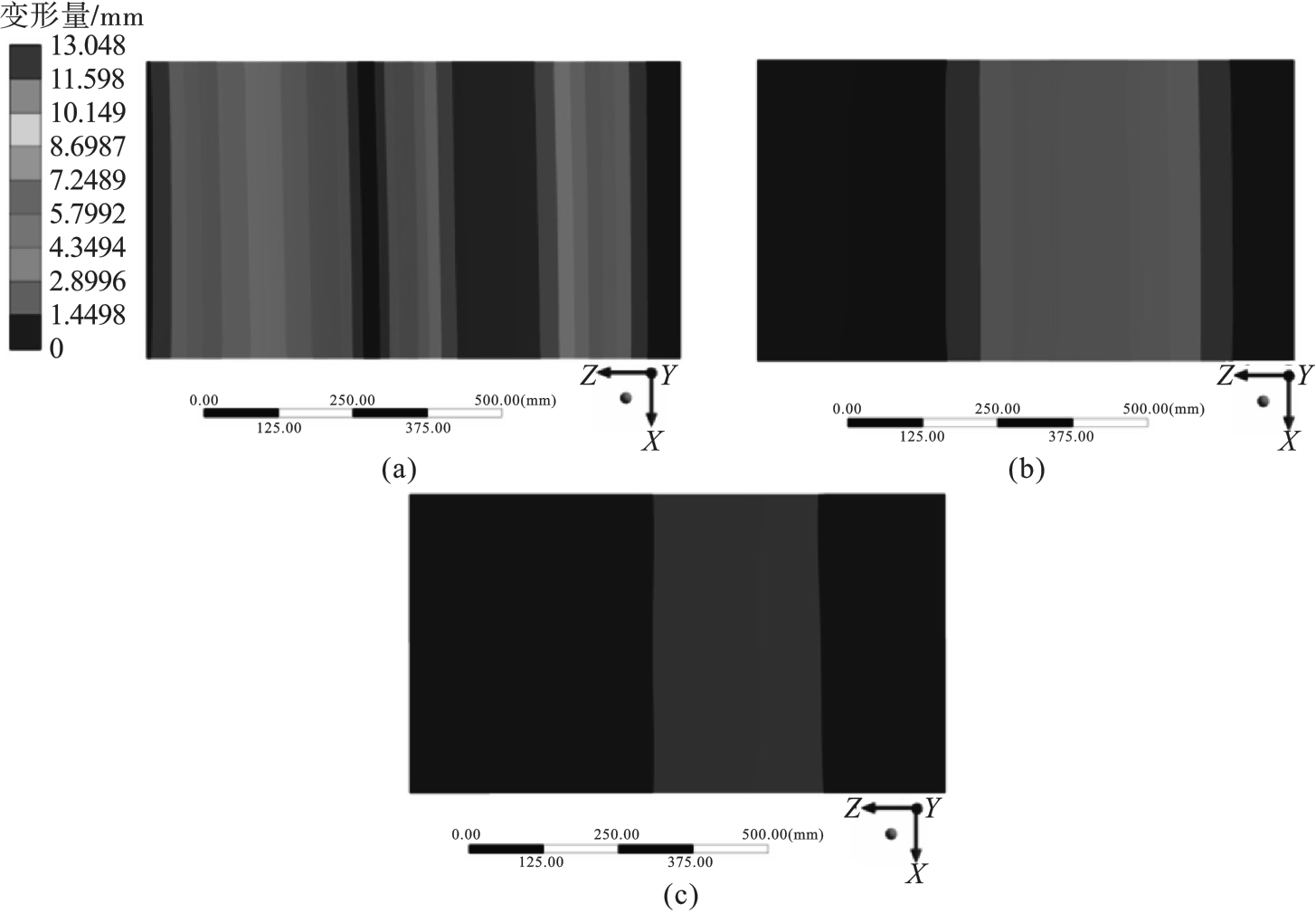

图 9 第 1 组、第 3 组和第 4 组带材厚度对带材变形影响模拟结果(a)—0.5 mm; (b)—1.0 mm; (c)—1.5 mm.

Fig. 9 Simulation results of the influence of strip thickness on strip deformation in groups 1, 3 and 4

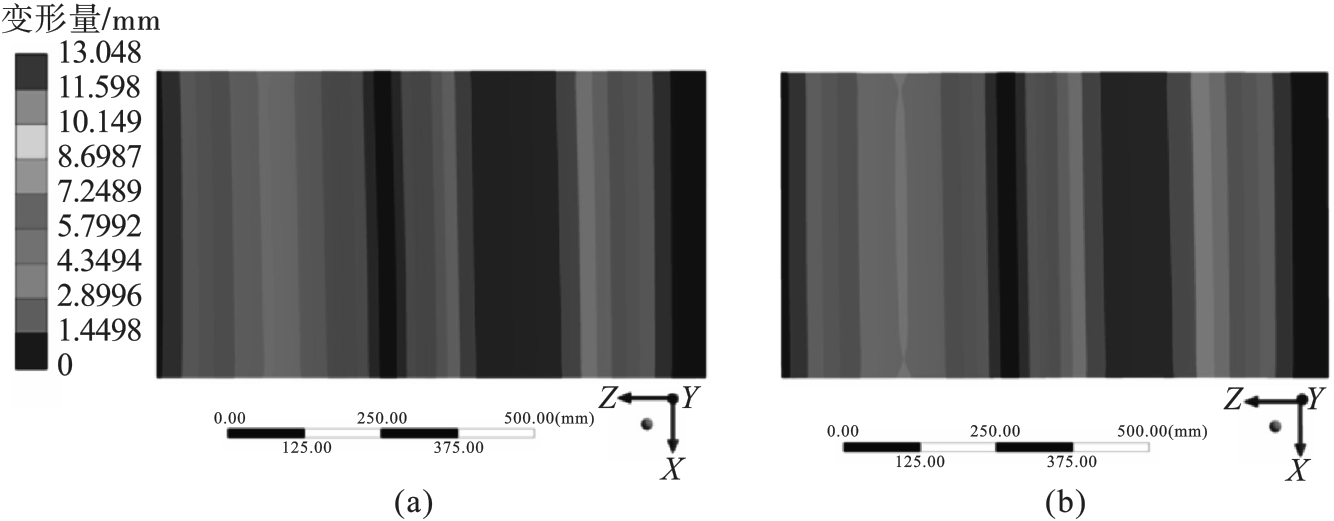

图 10 第 1 组和第 5 组气垫炉温度对带材变形影响模拟结果(a)—27 ℃; (b)—600 ℃.

Fig. 10 Simulation results of the influence of the air cushion furnace temperature on strip deformation in groups 1 and 5

图 11 第 5 组带材约束方式对带材变形影响模拟结果(a)—Z轴负方向固定约束; (b)—Z轴正方向固定约束.

Fig. 11 Simulation results of the strip restraint method affects on the strip deformation in groups 5

| 影响因素 | 作用方式 | 板形控制应用 |

|---|---|---|

| 气垫压力 | 气垫炉喷嘴喷射的高速气流在带材表面形成气垫压力,托举带材悬浮在空气中并使得带材发生近似正弦形变形,是产生变形的关键 | 满足带材漂浮的前提下,通过调整带材的上、下气垫压力来控制带材的变形 |

| 带材张力 | 气垫炉前与炉后的张力辊组施加在带材前进方向两端的微张力 | 增大带材的张力可以降低带材的变形量,有利于薄带材的板形控制 |

带材材料、 厚度 | 带材的材料和厚度由工厂的生产工艺确定,其通过改变带材的密度和刚度等物理参数来影响板形 | 对于较厚带材和刚度较高的带材无法形成合理的变形,可以调整其他影响因素 |

| 漂浮高度 | 控制带材在不同的漂浮高度,以获得不同的带材压力 | 气垫炉可以提供的气垫压力相对固定,通过改变漂浮高度可以更好地适配不同带材的要求,但要保持带材与上、下喷嘴的安全距离 |

| 炉内温度 | 由带材热处理工艺确定 | 炉温通过影响带材压力进而影响板形 |

表 2 影响带材漂浮形态的因素总结

Table 2 Summary of factors affecting the floating morphology of the strip

| 影响因素 | 作用方式 | 板形控制应用 |

|---|---|---|

| 气垫压力 | 气垫炉喷嘴喷射的高速气流在带材表面形成气垫压力,托举带材悬浮在空气中并使得带材发生近似正弦形变形,是产生变形的关键 | 满足带材漂浮的前提下,通过调整带材的上、下气垫压力来控制带材的变形 |

| 带材张力 | 气垫炉前与炉后的张力辊组施加在带材前进方向两端的微张力 | 增大带材的张力可以降低带材的变形量,有利于薄带材的板形控制 |

带材材料、 厚度 | 带材的材料和厚度由工厂的生产工艺确定,其通过改变带材的密度和刚度等物理参数来影响板形 | 对于较厚带材和刚度较高的带材无法形成合理的变形,可以调整其他影响因素 |

| 漂浮高度 | 控制带材在不同的漂浮高度,以获得不同的带材压力 | 气垫炉可以提供的气垫压力相对固定,通过改变漂浮高度可以更好地适配不同带材的要求,但要保持带材与上、下喷嘴的安全距离 |

| 炉内温度 | 由带材热处理工艺确定 | 炉温通过影响带材压力进而影响板形 |

| 1 | 田军涛. 气垫式连续退火炉在高精度铜带生产中的应用[J]. 有色冶金设计与研究, 2009, 30(4): 38-41. |

| Tian Jun-tao. Application of air-cushion continual annealing furnace in production of high precision copper strip[J]. Nonferrous Metals Engineering & Research, 2009, 30(4): 38-41. | |

| 2 | 苏晓莉, 王业科. 铝合金大规格带材气垫炉连续固溶热处理机组[J]. 轻合金加工技术, 2011, 39(7): 29-32. |

| Su Xiao-li, Wang Ye-ke. Domestic largest air cushion furnace in continuous solution heat treatment line for aluminum alloy strip[J]. Light Alloy Fabrication Technology, 2011, 39(7): 29-32. | |

| 3 | 干志成. 气垫炉[J]. 工业加热, 1986(4): 5. |

| Gan Zhi-cheng. Air cushion furnace[J]. Industrial Heating, 1986(4): 5. | |

| 4 | 陈文修, 何英和, 刘非轼, 等. 气垫式金属板带材连续热处理炉内气体动力过程的研究[J]. 中南矿冶学院学报, 1987, 18(2): 145-150, 230. |

| Chen Wen-xiu, He Ying-he, Liu Fei-shi, et al. A study of gas dynamics process in air cushion furnace of continuous heat treatment for metal plate-strip[J]. Journal of Central South University (Science and Technology), 1987, 18(2): 145-150, 230. | |

| 5 | Chang Y B, Moretti P M. Aerodynamic characteristics of pressure-pad air bars[J]. Journal of Applied Mechanics, 2000, 67(1) : 256-277. |

| 6 | Ozmen Y. Confined impinging twin air jets at high Reynolds numbers[J]. Experimental Thermal and Fluid Science, 2011, 35(2): 355-363. |

| 7 | Kathuria V, Ruhl S, Kaushik N, et al. An experimental investigation of the hover and forward speed aerodynamic characteristics of several tracked air cushion vehicle (TACV) models[J]. Industrial Crops and Products, 2012, 46(3): 274-283. |

| 8 | Hall J K, Kristoffersen Y. The R/H Sabvabaa: a research hovercraft for marine geophysical work in the most inaccessible area of the Arctic Ocean[J]. The Leading Edge, 2009, 28(8): 932-935. |

| 9 | 侯帅, 王超, 王坤, 等. 气垫炉缝隙喷嘴传热特性研究[J]. 轻合金加工技术, 2012, 41(3): 45-48. |

| (Hou Shuai, Wang Chao, Wang Kun, et al, Study on heat transfer characteristics of slot nozzle in air cushion furnace[J]. Light Alloy Fabrication Technology, 2012, 41(3): 45-48.) | |

| 10 | Hou S, Li Y, Wang Z D, et al. Study on floating force and heat transfer of circular nozzle in air cushion furnace[J]. Industrial Furnace,2012,35( 1) : 1-4. |

| 11 | 王占军, 张笑宇, 李贤君, 等. 气垫式退火炉内流场的数值模拟[J]. 金属热处理, 2017, 42(1): 171-174. |

| Wang Zhan-jun, Zhang Xiao-yu, Li Xian-jun, et al. Numerical simulation of flow field in air-cushion annealing furnace[J]. Heat Treatment of Metals, 2017, 42(1): 171-174. | |

| 12 | Hao Y J, Bai X J. Large deformation of elastic beam thin plate in transverse flow[J]. Chinese Journal of Applied Mechanics, 2009, 26(2): 304-307. |

| 13 | 宋晓娟, 白象忠. 浅拱形薄壳在流体作用下的变形与应力分析[J]. 机械强度, 2011, 33(5): 690-695. |

| Song Xiao-juan, Bai Xiang-zhong. Analysis on the small deformation of a thin arched shell in fluid[J]. Journal of Mechanical Strength, 2011, 33(5): 690-695. | |

| 14 | 周小利, 白象忠. 弹性圆柱薄壳在流体中的变形与内力分析[J]. 工程力学, 2007, 24(5): 47-52. |

| Zhou Xiao-li, Bai Xiang-zhong. Analysis on the deformation and internal force of an elastic thin cylindrical shell in fluid[J]. Engineering Mechanics, 2007, 24(5): 47-52. | |

| 15 | Cho H K. Flow-induced vibration of a web floating over a pressure-pad air bar[D]. Stillwater: Oklahoma State University, 2005. |

| 16 | Moretti P M. Lateral deflections of webs in air-flotation ovens[J]. Journal of Applied Mechanics, 2004, 71(3): 314-320. |

| [1] | 赵阳, 王宇航, 张涛, 王福会. 半导体制程设备铝合金涂层腐蚀失效行为研究进展[J]. 东北大学学报(自然科学版), 2025, 46(3): 28-45. |

| [2] | 孙涛, 纪良鑫, 杨先理, 胡贤磊. 时空约束的变厚度控制模型及应用[J]. 东北大学学报(自然科学版), 2025, 46(3): 46-51. |

| [3] | 黄贤振, 王旭, 丁鹏飞, 姜智元. 考虑铣削表面形貌的工艺参数可靠性优化[J]. 东北大学学报(自然科学版), 2025, 46(3): 80-87. |

| [4] | 张耀满, 吴双金, 饶兆峰. 电火花线切割Inconel 718温度场分析与加工建模[J]. 东北大学学报(自然科学版), 2025, 46(3): 88-96. |

| [5] | 周晓光, 赵金帆, 姜珊, 曹光明. 多道次变形条件下V-N微合金钢的流变应力模型[J]. 东北大学学报(自然科学版), 2025, 46(2): 35-41. |

| [6] | 任朝晖, 贾昌烨, 武志伦, 王云贺. 超声旋转微锻造增材件数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(2): 57-63. |

| [7] | 孙瑶, 董俊逸, 唐本甲, 李思慧. 电火花加工单晶硅微结构的表面质量及成形精度[J]. 东北大学学报(自然科学版), 2025, 46(2): 96-103. |

| [8] | 胡贤磊, 朱永胜, 支颖. 差厚板U形件工艺孔成形性能仿真[J]. 东北大学学报(自然科学版), 2024, 45(8): 1080-1087. |

| [9] | 杨尚武, 瞿海霞, 黎恒君, 刘常升. 激光熔覆(Ti,W)C增强镍基涂层的性能[J]. 东北大学学报(自然科学版), 2024, 45(7): 953-959. |

| [10] | 赵家豪, 曲扬, 罗洪杰, 杨世杰. 烧结工艺对多孔钛微观结构及力学性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(6): 816-822. |

| [11] | 孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642. |

| [12] | 张九鑫, 任潇健, 金东正, 田勇. 奥氏体晶粒细化对特厚EH47止裂钢组织性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(5): 643-651. |

| [13] | 杨庭松, 黄敦亮, 孙文权, 何安瑞. 电磁调控轧辊的热力胀形行为及高效控制方法[J]. 东北大学学报(自然科学版), 2024, 45(5): 660-667. |

| [14] | 黄贤振, 于瑞, 姜智元, 荣治明. 考虑热误差的电主轴建模与可靠性全局灵敏度分析[J]. 东北大学学报(自然科学版), 2024, 45(5): 675-682. |

| [15] | 周晓光, 马鑫, 姜珊, 刘振宇. ESP工艺下DP600热轧双相钢铁素体相变模型[J]. 东北大学学报(自然科学版), 2024, 45(4): 483-489. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||