东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 105-112.DOI: 10.12068/j.issn.1005-3026.2025.20250013

• 研究论文 • 上一篇

张涛, 刘闯, 张一, 王福会

收稿日期:2025-02-26

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

张涛

作者简介:张 涛(1977—),男,辽宁阜新人,东北大学教授,博士生导师基金资助:Tao ZHANG, Chuang LIU, Yi ZHANG, Fu-hui WANG

Received:2025-02-26

Online:2025-08-15

Published:2025-11-24

Contact:

Tao ZHANG

摘要:

采用电沉积、真空浸渍和常规浸渍3种工艺对Mg-0.45Zn-0.45Ca合金上的微弧氧化涂层进行硅烷偶联剂(KH550)硅烷化处理.通过扫描电镜、维氏硬度计和电化学测试等,研究了硅烷化处理工艺对医用镁合金表面微弧氧化涂层的缺陷封闭效果和在模拟体液(SBF)中长期降解性能的影响.结果表明,3种工艺均可在微弧氧化涂层表面获得硅烷薄膜.其中,利用电沉积可制备出厚度为1.5~7 μm的硅烷膜层,对微弧氧化涂层有很好的封闭效果,且可有效提高涂层的硬度和附着力.此外,电沉积工艺处理的涂层在模拟体液中浸泡3个月后仍可有效保护镁合金基体,满足可降解生物医用镁合金的需求.因此,利用微弧氧化和KH550硅烷电沉积处理的Mg-0.45Zn-0.45Ca合金具有成为可降解镁合金植入物的潜力.

中图分类号:

张涛, 刘闯, 张一, 王福会. 硅烷化处理对镁合金表面微弧氧化涂层降解性能的影响[J]. 东北大学学报(自然科学版), 2025, 46(8): 105-112.

Tao ZHANG, Chuang LIU, Yi ZHANG, Fu-hui WANG. Effect of Silanization on Degradation Performance of Micro-arc Oxidation Coatings on Magnesium Alloys Surfaces[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 105-112.

| Mn | Cu | Zn | Si | Ca | Al | Fe | Mg |

|---|---|---|---|---|---|---|---|

| 0.036 | 0.000 4 | 0.60 | 0.037 | 0.31 | 0.026 | 0.003 | 余量 |

表1 Mg-0.45Ca-0.45Zn合金的成分(质量分数) ((mass fraction) %)

Table 1 Compositions of Mg-0.45Ca-0.45Zn alloys

| Mn | Cu | Zn | Si | Ca | Al | Fe | Mg |

|---|---|---|---|---|---|---|---|

| 0.036 | 0.000 4 | 0.60 | 0.037 | 0.31 | 0.026 | 0.003 | 余量 |

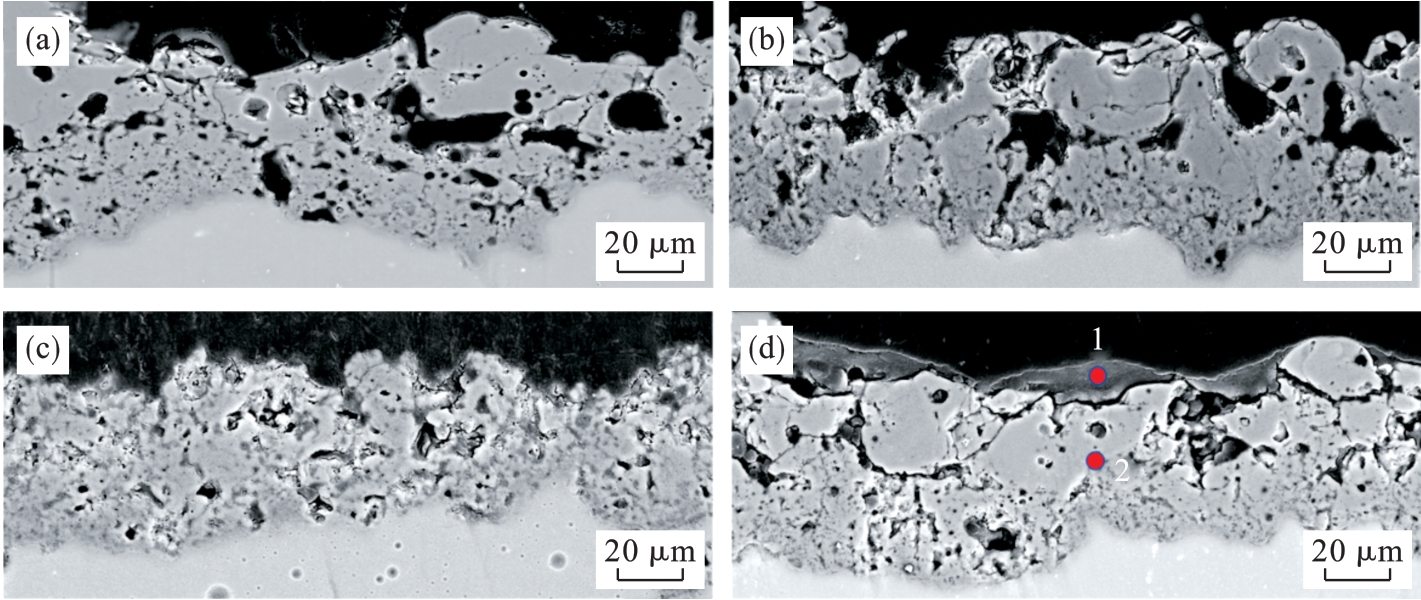

图1 PEO涂层及不同工艺制备的PEO/KH550复合涂层的SEM图像(a)—PEO涂层; (b)—常规浸渍制备的PEO/KH550复合涂层;(c)—真空浸渍制备的PEO/KH550复合涂层; (d)—电沉积制备的PEO/KH550复合涂层.

Fig.1 SEM images of PEO coating and PEO/KH550 composite coatings prepared by different processes

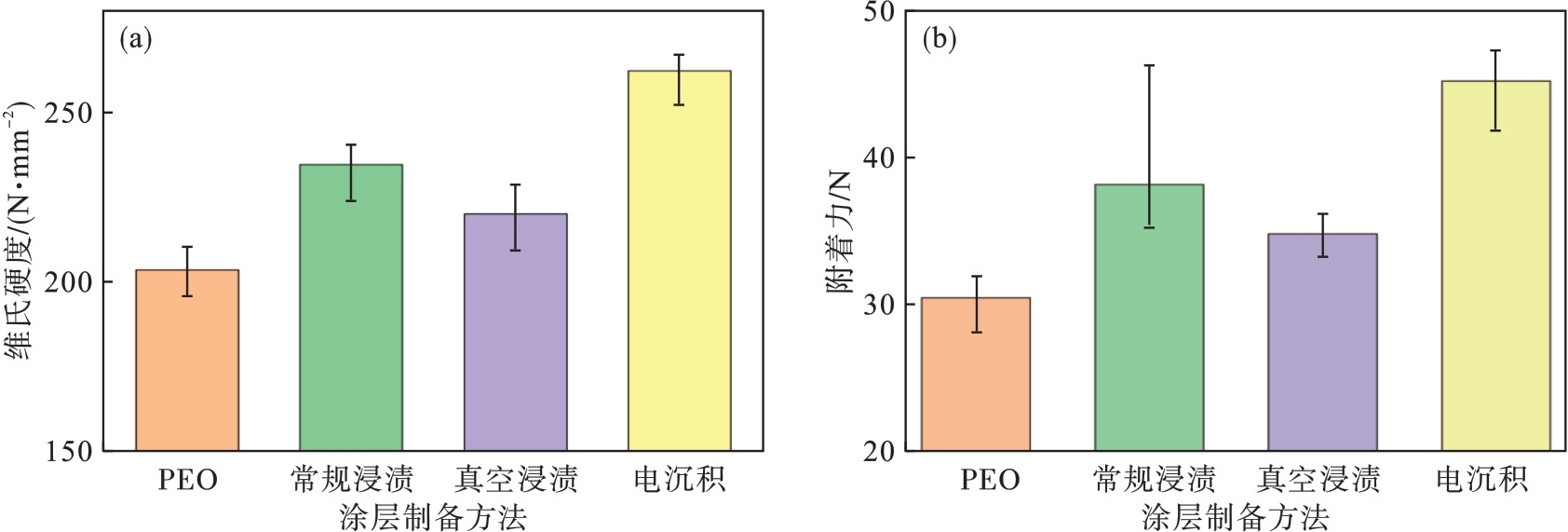

图3 PEO涂层及不同工艺制备的PEO/KH550复合涂层的维氏硬度和附着力(a)—维氏硬度; (b)—附着力.

Fig.3 Vickers hardness and adhesion of PEO coating and PEO/KH550 composite coatings prepared by different processes

| 样品 | icorr/(µA·cm-2) | Ecorr/V | Eb/V |

|---|---|---|---|

| PEO | 0.029 | -1.91 | -1.62 |

PEO/KH550 常规浸渍 | 0.028 | -1.74 | -1.32 |

| PEO/KH550电沉积 | 0.002 | -1.78 | -1.21 |

PEO/KH550 真空浸渍 | 0.062 | -1.79 | -1.34 |

表3 动电位极化曲线拟合结果 (polarization curves)

Table 3 Fitting results of potentiodynamic

| 样品 | icorr/(µA·cm-2) | Ecorr/V | Eb/V |

|---|---|---|---|

| PEO | 0.029 | -1.91 | -1.62 |

PEO/KH550 常规浸渍 | 0.028 | -1.74 | -1.32 |

| PEO/KH550电沉积 | 0.002 | -1.78 | -1.21 |

PEO/KH550 真空浸渍 | 0.062 | -1.79 | -1.34 |

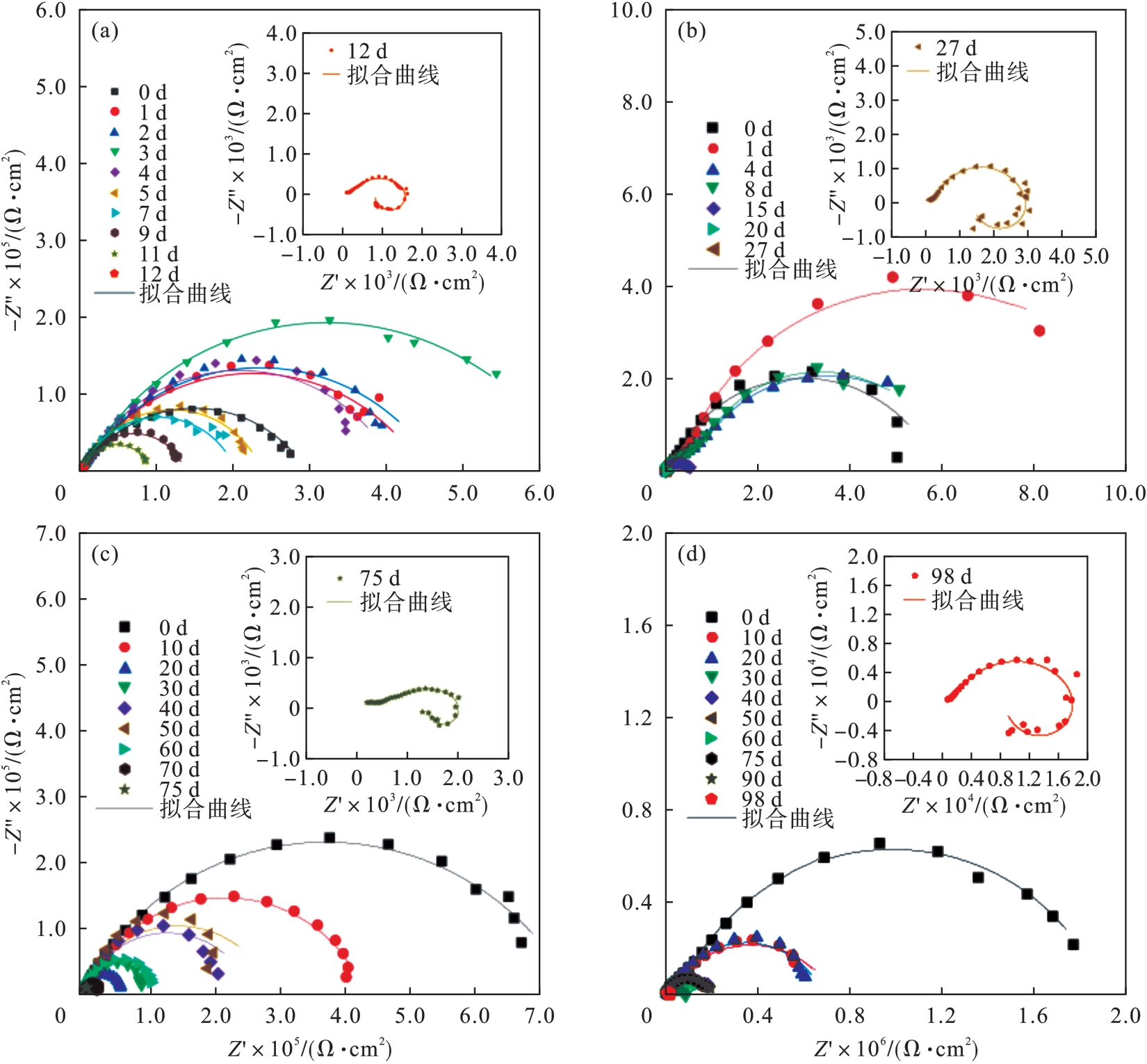

图5 PEO涂层及不同工艺制备的PEO/KH550复合涂层在SBF中浸泡不同天数的阻抗谱(a)—PEO涂层; (b)—常规浸渍制备的PEO/KH550复合涂层;(c)—真空浸渍制备的PEO/KH550复合涂层; (d)—电沉积制备的PEO/KH550复合涂层.

Fig.5 Impedance spectrum of PEO coating and PEO/KH550 composite coatings prepared by different processes after immersion in SBF for different days

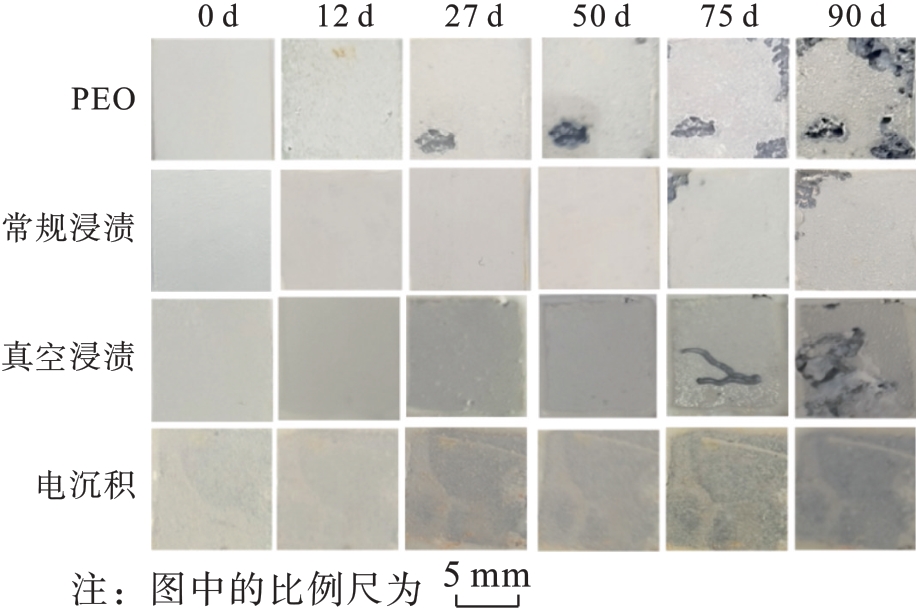

图8 PEO涂层及不同工艺制备的PEO/KH550复合涂层在SBF中浸泡不同天数后的形貌

Fig.8 Morphology of PEO coating and PEO/KH550 composite coatings prepared by different processes after immersion in SBF for different days

| [1] | Agarwal-Harding K J, Meara J G, Greenberg S L M, et al.Estimating the global incidence of femoral fracture from road traffic collisions a literature review [J].Journal of Bone and Joint Surgery-American Volume, 2015, 97A(6): e31. |

| [2] | Johnell O, Kanis J A.An estimate of the worldwide prevalence and disability associated with osteoporotic fractures [J].Osteoporosis International, 2006, 17(12): 1726-1733. |

| [3] | Odén A, Mccloskey E V, Kanis J A, et al.Burden of high fracture probability worldwide: secular increases 2010-2040 [J].Osteoporosis International, 2015, 26(9): 2243-2248. |

| [4] | Gao X Z, Dai C Y, Jia Q, et al.In vivo corrosion behavior of biodegradable magnesium alloy by MAF treatment [J].Scanning, 2021, 2021: 5530788. |

| [5] | Wang J L, Xu J K, Hopkins C, et al.Biodegradable magnesium-based implants in orthopedics:a general review and perspectives [J].Advanced Science, 2020, 7(8):1902443. |

| [6] | Witte F.The history of biodegradable magnesium implants: a review [J].Acta Biomaterialia, 2010, 6(5): 1680-1692. |

| [7] | Sankara Narayanan T S N, Park I S, Lee M H.Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: prospects and challenges [J].Progress in Materials Science, 2014, 60: 1-71. |

| [8] | Ali W, Li M Z, Tillmann L, et al.Bioabsorbable WE43 Mg alloy wires modified by continuous plasma-electrolytic oxidation for implant applications.part I: processing, microstructure and mechanical properties [J].Biomaterials Advances, 2023, 146: 213314. |

| [9] | Moga S, Malinovschi V, Marin A, et al.Mechanical and corrosion-resistant coatings prepared on AZ63 Mg alloy by plasma electrolytic oxidation [J].Surface & Coatings Technology, 2023, 462: 129464. |

| [10] | Zhu L J, Li H Z, Ma Q M, et al.The mechanism for tuning the corrosion resistance and pore density of plasma electrolytic oxidation (PEO) coatings on Mg alloy with fluoride addition [J].Journal of Magnesium and Alloys, 2023, 11(8): 2823-2832. |

| [11] | Moreno L, Mohedano M, Arrabal R, et al.Development and screening of (Ca-P-Si-F)-PEO coatings for biodegradability control of Mg-Zn-Ca alloys [J].Journal of Magnesium and Alloys, 2022, 10(8): 2220-2237. |

| [12] | Shi B Y, Xu J Q, Zou J W, et al.Advances in amelioration of plasma electrolytic oxidation coatings on biodegradable magnesium and alloys [J].Heliyon, 2024, 10(4): e24348. |

| [13] | Jang Y, Tan Z Q, Jurey C, et al.Understanding corrosion behavior of Mg-Zn-Ca alloys from subcutaneous mouse model: effect of Zn element concentration and plasma electrolytic oxidation [J].Materials Science & Engineering C:Materials for Biological Applications, 2015, 48: 28-40. |

| [14] | Tsakiris V, Tardei C, Clicinschi F M.Biodegradable Mg alloys for orthopedic implants :a review [J].Journal of Magnesium and Alloys, 2021, 9(6): 1884-1905. |

| [15] | Gaur S, Singh Raman R K, Khanna A S.In vitro investigation of biodegradable polymeric coating for corrosion resistance of Mg-6Zn-Ca alloy in simulated body fluid [J].Materials Science and Engineering: C, 2014, 42: 91-101. |

| [16] | Zomorodian A, Brusciotti F, Fernandes A, et al.Anti-corrosion performance of a new silane coating for corrosion protection of AZ31 magnesium alloy in Hank's solution [J].Surface & Coatings Technology, 2012, 206(21): 4368-4375. |

| [17] | 吴茂江.硅与人体健康 [J].微量元素与健康研究, 2012, 29(2): 65-67. |

| Wu Mao-jiang.The relationship between silicon and human health[J].Studies of Trace Elements and Health, 2012, 29(2): 65-67. | |

| [18] | Telmenbayar L, Ramu A G, Erdenebat T O, et al.Anticorrosive lanthanum embedded PEO/GPTMS coating on magnesium alloy by plasma electrolytic oxidation with silanization [J].Materials Today Communications, 2022, 33: 104662. |

| [19] | Córdoba L C, Hélary C, Montemor F, et al.Bi-layered silane-TiO2/collagen coating to control biodegradation and biointegration of Mg alloys [J].Materials Science and Engineering: C, 2019, 94: 126-138. |

| [20] | Mandelli A, Bestetti M, Da Forno A, et al.A composite coating for corrosion protection of AM60B magnesium alloy [J].Surface and Coatings Technology, 2011, 205(19): 4459-65. |

| [21] | Hamrahi B, Yarmand B, Massoudi A.Improved in-vitro corrosion performance of titanium using a duplex system of plasma electrolytic oxidation and graphene oxide incorporated silane coatings [J].Surface and Coatings Technology, 2021, 422: 127558. |

| [22] | Wattoo A G, Song Z L, Iqbal M Z, et al.Effect of zinc concentration on physical properties of copper oxide (Cu1- x Zn x O) [J].Journal of Materials Science:Materials in Electronics, 2015, 26(12): 9795-9800. |

| [23] | Chen S G, Cai Y C, Zhuang C, et al.Electrochemical behavior and corrosion protection performance of bis-[triethoxysilylpropyl] tetrasulfide silane films modified with TiO2 sol on 304 stainless steel [J].Applied Surface Science, 2015, 331: 315-326. |

| [24] | Sun W, Wang L D, Wu T T, et al.Inhibiting the corrosion-promotion activity of graphene [J].Chemistry of Materials, 2015, 27(7): 2367-2373. |

| [25] | Shacham R, Avnir D, Mandler D.Electrodeposition of methylated sol-gel films on conducting surfaces [J].Advanced Materials, 1999, 11(5): 384-388. |

| [26] | Li C M, Guo C C, Fitzpatrick V, et al.Design of biodegradable, implantable devices towards clinical translation [J].Nature Reviews Materials, 2020, 5(1): 61-81. |

| [27] | Chandra G, Pandey A.Preparation strategies for Mg-alloys for biodegradable orthopaedic implants and other biomedical applications: a review [J].IRBM, 2022, 43(3): 229-249. |

| [28] | 吴海江, 杨飞英, 彭成章, 等.AZ91D压铸镁合金表面硅烷膜固化工艺的优化 [J].材料保护, 2015, 48(8), 41-43, 48. |

| Wu Hai-jiang, Yang Fei-ying, Peng Cheng-zhang, et al.Curing process optimization of silane coating on AZ91D magnesium alloy[J].Materials Protection, 2015, 48(8): 41-43, 48. | |

| [29] | 刘国杰, 黑恩成.附加压力与分散系统的稳定性 [J].大学化学, 2016, 31(1): 54-58. |

| Liu Guo-jie, En-cheng Hei.The additional pressure and the stability of disperse system[J].University Chemistry, 2016, 31(1): 54-58. |

| [1] | 张瑞, 周金勾, 马广超, 狄跃忠. 盐湖水氯镁石电沉积法制备镁铝水滑石[J]. 东北大学学报(自然科学版), 2025, 46(6): 50-55. |

| [2] | 赵阳, 王宇航, 张涛, 王福会. 半导体制程设备铝合金涂层腐蚀失效行为研究进展[J]. 东北大学学报(自然科学版), 2025, 46(3): 28-45. |

| [3] | 杨尚武, 瞿海霞, 黎恒君, 刘常升. 激光熔覆(Ti,W)C增强镍基涂层的性能[J]. 东北大学学报(自然科学版), 2024, 45(7): 953-959. |

| [4] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [5] | 余犇, 王冬晓, 刘禹, 李建平. AZ31镁合金薄板热油恒温成形数值模拟与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 179-186. |

| [6] | 温雪龙, 韩凤兵, 巩亚东, 黄雄俊. 沉积时间对真空离子镀TiC涂层微磨具表面性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(6): 857-863. |

| [7] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [8] | 温雪龙, 李佳育, 李欣妍. TiC涂层微磨具磨削表面质量影响因素[J]. 东北大学学报(自然科学版), 2022, 43(4): 534-540. |

| [9] | 狄跃忠, 马广超, 沈自强, 崔智春. SO2-4对电沉积法制备氢氧化镁的影响[J]. 东北大学学报:自然科学版, 2020, 41(10): 1415-1420. |

| [10] | 程春龙, 乐启炽. Al含量对AZ系镁合金燃点的影响[J]. 东北大学学报:自然科学版, 2019, 40(9): 1263-1267. |

| [11] | 高峰, 孙伟, 高俊男. 基于有限元法的硬涂层-整体叶盘振动特性[J]. 东北大学学报:自然科学版, 2019, 40(5): 688-693. |

| [12] | 许妮君, 刘常升, 冯欣俣, 孙挺. 激光工艺对45钢表面梯度熔覆层组织性能的影响[J]. 东北大学学报:自然科学版, 2019, 40(4): 495-499. |

| [13] | 马小英, 孙志礼, 张毅博, 臧旭. 基于Kriging-PSO智能算法优化焊接工艺参数[J]. 东北大学学报:自然科学版, 2019, 40(3): 370-375. |

| [14] | 高峰, 孙伟, 倪陈兵. 大小叶盘-硬涂层阻尼结构的解析建模和振动分析[J]. 东北大学学报:自然科学版, 2019, 40(2): 244-250. |

| [15] | 张雅静, 郭廷廷, 李帅平, 彭武贤. 医用可降解Mg-3Zn-0.5Sr合金耐蚀性及细胞毒性[J]. 东北大学学报:自然科学版, 2018, 39(7): 976-980. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||