东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (3): 407-414.DOI: 10.12068/j.issn.1005-3026.2024.03.013

收稿日期:2022-07-19

出版日期:2024-03-15

发布日期:2024-05-17

通讯作者:

陈猛

作者简介:陈 猛(1981-),男,辽宁开原人,东北大学副教授.

基金资助:Received:2022-07-19

Online:2024-03-15

Published:2024-05-17

Contact:

Meng CHEN

About author:CHEN Meng, E-mail: cmwhut@163.com摘要:

为研究回收轮胎聚合物(recycled tyre polymer,RTP)和聚乙烯醇(polyvinyl alcohol,PVA)混杂纤维对工程水泥基复合材料(engineered cementitious composites,ECC)干缩性能的影响,对RTP-PVA混杂纤维总体积分数为2.0%的ECC进行流动性、直接拉伸和干缩试验,并分析混杂纤维作用机理和干缩计算模型.结果表明:RTP纤维替代率为12.5%~50%对ECC流动性影响不大,比单掺PVA纤维的ECC流动性降低1.09%~3.69%.ECC的抗拉强度随RTP纤维替代率的增加而降低,不同比例的混杂纤维比单掺PVA纤维的ECC抗拉强度降低了23.6%~56.6%.不同比例混杂纤维ECC干缩率曲线趋势相近,7 d时干缩率为28 d时的80.92%~82.77%.ECC的干缩率随RTP纤维替代率的增加而降低,28 d时不同RTP纤维替代率的混杂纤维比单掺PVA纤维的ECC干缩率降低了0.80%~2.09%.RTP-PVA混杂纤维可在ECC中协同发挥作用抑制基体干缩,结合试验结果得到适合RTP-PVA混杂纤维ECC的指数型干缩预测模型.

中图分类号:

陈猛, 洪宇. RTP-PVA混杂纤维的工程水泥基复合材料干缩性能试验研究[J]. 东北大学学报(自然科学版), 2024, 45(3): 407-414.

Meng CHEN, Yu HONG. Test Study on Drying Shrinkage Properties of Engineered Cementitious Composites with RTP‐PVA Hybrid Fibre[J]. Journal of Northeastern University(Natural Science), 2024, 45(3): 407-414.

| 纤维类型 | 长度/mm | 直径/μm | 密度/(g·cm-3) | 抗拉强度/MPa | 弹性模量/GPa |

|---|---|---|---|---|---|

| RTP | 5.2±2.4 | 21.4±4.4 | 1.476±0.003 | 761±115 | 3.8±0.7 |

| PVA | 12 | 40 | 1.3 | 1 560 | 41 |

表1 纤维的物理及力学性能

Table 1 Physical and mechanical properties of fibres

| 纤维类型 | 长度/mm | 直径/μm | 密度/(g·cm-3) | 抗拉强度/MPa | 弹性模量/GPa |

|---|---|---|---|---|---|

| RTP | 5.2±2.4 | 21.4±4.4 | 1.476±0.003 | 761±115 | 3.8±0.7 |

| PVA | 12 | 40 | 1.3 | 1 560 | 41 |

| 材料类型 | m/ kg | 体积分数/% | RTP纤维替代率/% | |||||

|---|---|---|---|---|---|---|---|---|

| 水泥 | 粉煤灰 | 硅砂 | 水 | 减水剂 | RTP纤维 | PVA纤维 | ||

| P2.0R0 | 42.5 | 676 | 451 | 335 | 4.96 | 0 | 2.0 | 0 |

| P1.75R0.25 | 42.5 | 676 | 451 | 335 | 4.96 | 0.25 | 1.75 | 12.5 |

| P1.5R0.5 | 42.5 | 676 | 451 | 335 | 4.96 | 0.5 | 1.5 | 25 |

| P1.25R0.75 | 42.5 | 676 | 451 | 335 | 4.96 | 0.75 | 1.25 | 37.5 |

| P1.0R1.0 | 42.5 | 676 | 451 | 335 | 4.96 | 1.0 | 1.0 | 50 |

表2 材料ECC配合比

Table 2 Mixture proportions of materials ECC

| 材料类型 | m/ kg | 体积分数/% | RTP纤维替代率/% | |||||

|---|---|---|---|---|---|---|---|---|

| 水泥 | 粉煤灰 | 硅砂 | 水 | 减水剂 | RTP纤维 | PVA纤维 | ||

| P2.0R0 | 42.5 | 676 | 451 | 335 | 4.96 | 0 | 2.0 | 0 |

| P1.75R0.25 | 42.5 | 676 | 451 | 335 | 4.96 | 0.25 | 1.75 | 12.5 |

| P1.5R0.5 | 42.5 | 676 | 451 | 335 | 4.96 | 0.5 | 1.5 | 25 |

| P1.25R0.75 | 42.5 | 676 | 451 | 335 | 4.96 | 0.75 | 1.25 | 37.5 |

| P1.0R1.0 | 42.5 | 676 | 451 | 335 | 4.96 | 1.0 | 1.0 | 50 |

| 材料类型 | 双曲线模型 | 单对数模型 | 指数模型 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | R2 | ?2×104 | c | d | R2 | ?2×104 | f | g | R2 | ?2×104 | |

| P2.0R0 | 19.21 | 4.68 | 0.973 | 10.52 | 0.25 | 5.09 | 0.938 | 23.92 | 1.04 | -0.22 | 0.992 | 3.30 |

| P1.75R0.25 | 18.25 | 4.63 | 0.968 | 11.33 | 0.20 | 4.86 | 0.931 | 24.74 | 1.05 | -0.23 | 0.990 | 3.58 |

| P1.5R0.5 | 18.17 | 4.85 | 0.968 | 11.28 | 0.03 | 4.85 | 0.934 | 23.52 | 1.06 | -0.22 | 0.989 | 3.72 |

| P1.25R0.75 | 17.22 | 5.11 | 0.966 | 10.68 | -0.14 | 4.59 | 0.935 | 20.79 | 1.06 | -0.22 | 0.987 | 3.90 |

| P1.0R1.0 | 17.30 | 5.58 | 0.955 | 14.60 | -0.47 | 4.63 | 0.925 | 24.30 | 1.08 | -0.21 | 0.980 | 6.46 |

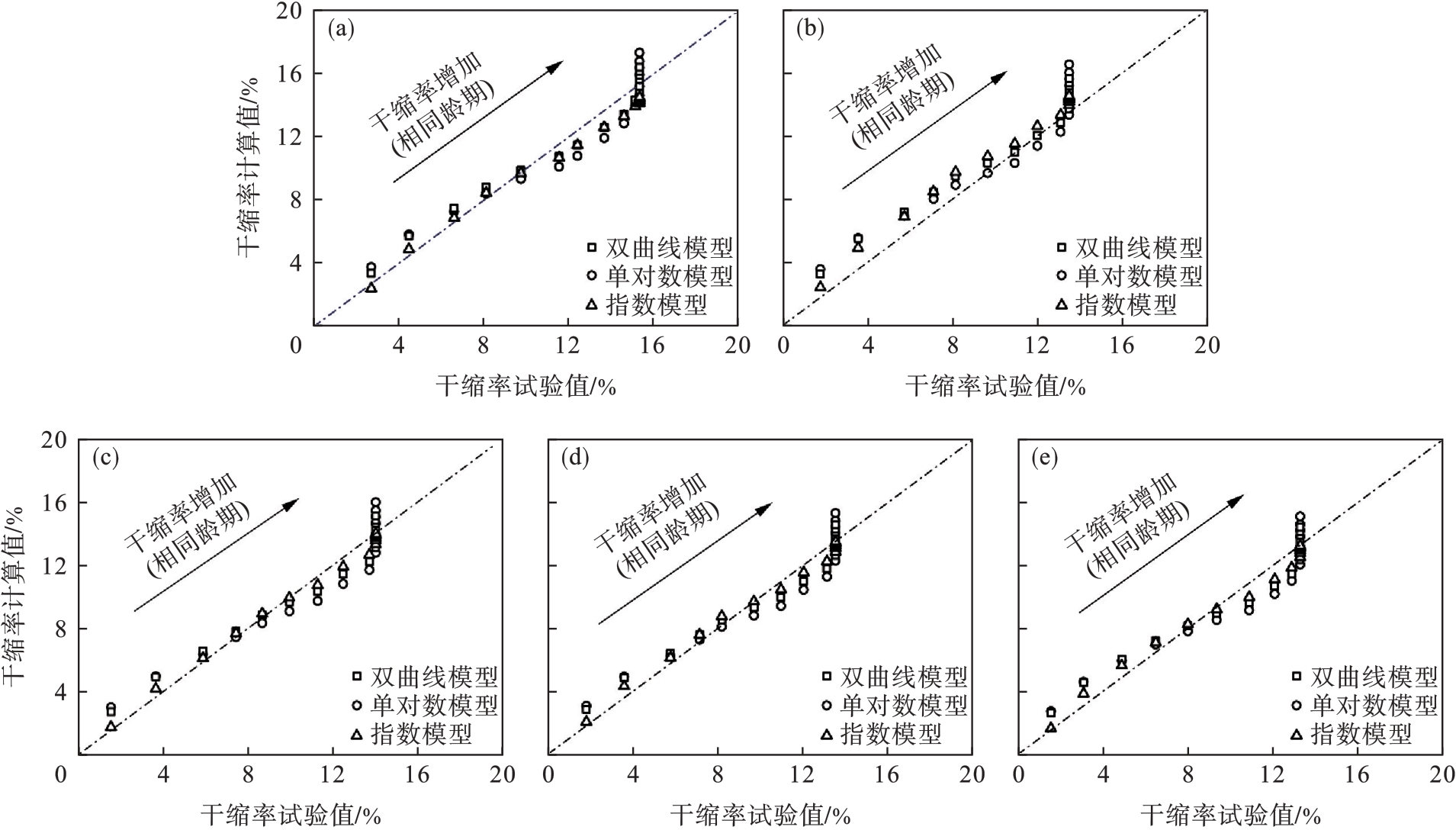

表3 不同预测模型拟合参数及相关系数

Table 3 Fitness parameters and correlation coefficient of different predicting models

| 材料类型 | 双曲线模型 | 单对数模型 | 指数模型 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | R2 | ?2×104 | c | d | R2 | ?2×104 | f | g | R2 | ?2×104 | |

| P2.0R0 | 19.21 | 4.68 | 0.973 | 10.52 | 0.25 | 5.09 | 0.938 | 23.92 | 1.04 | -0.22 | 0.992 | 3.30 |

| P1.75R0.25 | 18.25 | 4.63 | 0.968 | 11.33 | 0.20 | 4.86 | 0.931 | 24.74 | 1.05 | -0.23 | 0.990 | 3.58 |

| P1.5R0.5 | 18.17 | 4.85 | 0.968 | 11.28 | 0.03 | 4.85 | 0.934 | 23.52 | 1.06 | -0.22 | 0.989 | 3.72 |

| P1.25R0.75 | 17.22 | 5.11 | 0.966 | 10.68 | -0.14 | 4.59 | 0.935 | 20.79 | 1.06 | -0.22 | 0.987 | 3.90 |

| P1.0R1.0 | 17.30 | 5.58 | 0.955 | 14.60 | -0.47 | 4.63 | 0.925 | 24.30 | 1.08 | -0.21 | 0.980 | 6.46 |

图11 不同模型干缩率计算值与试验值对比(a)—P2.0R0; (b)—P1.75R0.25; (c)—P1.5R0.5; (d)—P1.25R0.75; (e)—P1.0R1.0.

Fig.11 Comparison between calculated value and experimental value of drying shrinkage rate of different models

| 1 | Gao S L, Wang Z, Wang W C,et al. Effect of shrinkage‐reducing admixture and expansive agent on mechanical properties and drying shrinkage of engineered cementitious composite (ECC)[J].Construction and Building Materials,2018,179:172-185. |

| 2 | Ma H, Zhang Z G, Ding B,et al.Investigation on the adhesive characteristics of engineered cementitious composites (ECC) to steel bridge deck[J].Construction and Building Materials,2018,191:679-691. |

| 3 | Yu J T, Lin J H, Zhang Z G,et al. Mechanical performance of ECC with high‐volume fly ash after sub‐elevated temperatures[J].Construction and Building Materials,2015,99:82-89. |

| 4 | Zheng Y Z, Wang W W, Brigham J C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer:BFRP grid and ECC[J].Construction and Building Materials,2016,115:424-437. |

| 5 | Zhang J, Gao Y, Wang Z B. Evaluation of shrinkage induced cracking performance of low shrinkage engineered cementitious composite by ring tests[J].Composites Part B:Engineering,2013,52:21-29. |

| 6 | Chen M, Chen W, Zhong H,et al.Experimental study on dynamic compressive behaviour of recycled tyre polymer fibre reinforced concrete[J].Cement and Concrete Composites,2019,98:95-112. |

| 7 | Chen M, Zhong H, Zhang M Z. Flexural fatigue behaviour of recycled tyre polymer fibre reinforced concrete[J].Cement and Concrete Composites,2020,105:103441. |

| 8 | Chen M, Zhong H, Wang H,et al. Behaviour of recycled tyre polymer fibre reinforced concrete under dynamic splitting tension[J].Cement and Concrete Composites,2020,114:103764. |

| 9 | Zhong H, Zhang M Z.Dynamic splitting tensile behaviour of engineered geopolymer composites with hybrid polyvinyl alcohol and recycled tyre polymer fibres[J].Journal of Cleaner Production,2022,379:134779. |

| 10 | Serdar M, Baričević A, Rukavina M J,et al.Shrinkage behaviour of fibre reinforced concrete with recycled tyre polymer fibres[J].International Journal of Polymer Science,2015,2015:1-9. |

| 11 | Baricevic A, Pezer M, Rukavina M J,et al. Effect of polymer fibers recycled from waste tires on properties of wet‑sprayed concrete[J].Construction and Building Materials,2018,176:135-144. |

| 12 | Zhong H, Zhang M Z. Effect of recycled tyre polymer fibre on engineering properties of sustainable strain hardening geopolymer composites[J].Cement and Concrete Composites,2021,122:104167. |

| 13 | Feng Z J, Zhou Y W, Sui L L,et al. Optimal design of a low‐cost high‐performance hybrid fiber engineered cementitious composites[J].Construction and Building Materials,2022,345:128372. |

| 14 | Wang Z B, Wang P Y, Zhu F Q.Synergy effect of hybrid steel‐polyvinyl alcohol fibers in engineered cementitious composites:fiber distribution and mechanical performance[J].Journal of Building Engineering,2022,62:105348. |

| 15 | Wang Q S, Yi Y, Ma G W,et al.Hybrid effects of steel fibers,basalt fibers and calcium sulfate on mechanical performance of PVA‑ECC containing high‐volume fly ash[J].Cement and Concrete Composites,2019,97:357-368. |

| 16 | Standard test method for flow of hydraulic cement mortar: [S].West Conshohocken:ASTM International,2015. |

| 17 | Standard practice for use of apparatus for the determination of length change of hardened cement paste,mortar,and concrete:C490/C490M-17 [S].West Conshohocken:ASTM International,2017. |

| 18 | Hsie M, Tu C J, Song P S.Mechanical properties of polypropylene hybrid fiber‑reinforced concrete[J].Materials Science and Engineering:A,2008,494:153-157. |

| 19 | Zhong H, Chen M, Zhang M Z. Engineering properties of sustainable engineered cementitious composites with recycled tyre polymer fibres[J],Construction and Building Materials,2023,370:130672. |

| 20 | Wang Q H, Wang Y Y, Geng Y,et al.Experimental study and prediction model for autogenous shrinkage of recycled aggregate concrete with recycled coarse aggregate[J].Construction and Building Materials,2021,268:121197. |

| 21 | Yousefieh N, Joshaghani A, Hajibandeh E,et al. Influence of fibers on drying shrinkage in restrained concrete[J].Construction and Building Materials,2017,148:833-845. |

| 22 | Tran N P, Gunasekara C, Law D W,et al. A critical review on drying shrinkage mitigation strategies in cement‐based materials[J].Journal of Building Engineering,2021,38:102210. |

| 23 | Tang S W, Huang D H, He Z.A review of autogenous shrinkage models of concrete[J].Journal of Building Engineering,2021,44:103412. |

| 24 | 徐世烺,刘志凤.超高韧性水泥基复合材料干缩性能及其对抗裂能力的影响[J].水利学报,2010,41(12):1491-1496. |

| Xu Shi‑lang, Liu Zhi‑feng.The effect of ultra‑high toughness cementitious composites on drying shrinkage properties crack resistance[J].Journal of Hydraulic Engineering,2010,41 (12):1491-1496. |

| [1] | 閤光磊, 吴朝霞, 刘梦园, 姜玉山. 基于GMM-KNN-LSTM的烧结矿化学指标预测[J]. 东北大学学报(自然科学版), 2024, 45(3): 314-322. |

| [2] | 刘克奇, 杜佃春, 赵文, 丁万涛. 基于机器学习的泥水盾构关键掘进参数预测与优化[J]. 东北大学学报(自然科学版), 2023, 44(11): 1621-1630. |

| [3] | 陈猛, 王瑜婷, 曹宇新. 回收轮胎聚合物纤维混凝土干缩性能研究[J]. 东北大学学报(自然科学版), 2023, 44(1): 123-129. |

| [4] | 矫志杰, 王志强, 罗钧译, 许志鹏. 中厚板角轧过程的形状预测模型研究[J]. 东北大学学报(自然科学版), 2022, 43(6): 815-820. |

| [5] | 陈兵, 韩烬阳, 唐晓垒, 夏搏然. 基于机器学习的拉矫延伸率预测模型及数值分析[J]. 东北大学学报(自然科学版), 2022, 43(2): 236-242. |

| [6] | 陈猛, 曹宇新, 王瑜婷. 工程水泥基复合材料高温损伤超声特性[J]. 东北大学学报(自然科学版), 2022, 43(11): 1638-1643. |

| [7] | 宫琦, 陈秉智, 李永华, 夏清. 地铁电源模块故障分析及预测方法[J]. 东北大学学报(自然科学版), 2022, 43(1): 8-16. |

| [8] | 郭永春, 郑海燕, 胡心光, 沈峰满. CaO-SiO2-MgO-Al2O3四元渣系Al2O3活度预测模型[J]. 东北大学学报(自然科学版), 2021, 42(5): 652-657. |

| [9] | 陈猛, 刘阳波, 陶云霄, 王浩. 回收轮胎聚合物纤维混凝土性能试验研究[J]. 东北大学学报:自然科学版, 2020, 41(6): 870-874. |

| [10] | 李伟, 朱浮声, 王晓初, 赵延明. 纳米混凝土的制备及其干缩性能研究[J]. 东北大学学报:自然科学版, 2017, 38(8): 1173-1177. |

| [11] | 朱子宗, 谢杨洋, 武强, 石国京. 新疆库拜煤改质炼焦及冷态强度预测[J]. 东北大学学报:自然科学版, 2017, 38(12): 1726-1730. |

| [12] | 刘青, 袁玮, 王宝, 彭良振. 基于GA-BP神经网络的金精矿品位的预测[J]. 东北大学学报:自然科学版, 2015, 36(2): 237-240. |

| [13] | 刘江,文光华,唐萍,李云峰. 微合金钢初始凝固中奥氏体开始长大的温度[J]. 东北大学学报:自然科学版, 2014, 35(3): 370-374. |

| [14] | 李刚;于天彪;费学婷;王宛山;. 一种基于CSM模型的TBM刀盘比能预测方法[J]. 东北大学学报(自然科学版), 2012, 33(12): 1766-1769. |

| [15] | 郭宪臻;陈先利;关志民;沈峰满;. 炼铁设备故障预测模型的建立与应用[J]. 东北大学学报(自然科学版), 2011, 32(9): 1265-1268+1298. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||