东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (4): 490-498.DOI: 10.12068/j.issn.1005-3026.2024.04.005

• 材料与冶金 • 上一篇

蒋金哲, 刘越, 刘春明

收稿日期:2022-11-27

出版日期:2024-04-15

发布日期:2024-06-26

作者简介:蒋金哲(1990-),男,河南洛阳人,东北大学博士研究生基金资助:Jin-zhe JIANG, Yue LIU, Chun-ming LIU

Received:2022-11-27

Online:2024-04-15

Published:2024-06-26

摘要:

二次碳化物的尺寸、含量对高碳高合金马氏体钢的力学性能及耐磨性有着重要影响.本文采用扫描电子显微镜、透射电子显微镜和磨粒磨损实验等手段,研究了高碳高合金马氏体钢锻造及球化退火过程中二次碳化物的演变行为及其对高碳高合金马氏体钢力学性能及耐磨性的影响.结果表明:球化退火显著增加了锻造空冷态实验钢中二次碳化物的含量及尺寸;在奥氏体化过程中,二次碳化物通过钉扎晶界显著细化了奥氏体晶粒,同时二次碳化物的存在降低了马氏体中合金元素固溶量,进而有效提升了实验钢的冲击韧性.高硬度的微米级二次碳化物配合高韧性马氏体基体可有效阻碍磨粒切削并减轻磨损表面的微观断裂,进而提升实验钢的耐磨性.

中图分类号:

蒋金哲, 刘越, 刘春明. 二次碳化物特征调控及其对高碳高合金马氏体钢耐磨性的影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 490-498.

Jin-zhe JIANG, Yue LIU, Chun-ming LIU. Regulation of Secondary Carbide Characteristics and Its Effect on Wear Resistance of High Carbon High Alloy Martensitic Steel[J]. Journal of Northeastern University(Natural Science), 2024, 45(4): 490-498.

| C | Si | Mn | Cr | Mo | V | Ni | W | Nb | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.85 | 0.90 | 0.43 | 6.76 | 1.82 | 0.30 | 0.85 | 0.35 | 0.25 | 0.005 | 0.02 |

表1 实验钢化学成分(质量分数) (%)

Table 1 Chemical composition of experimental steel(mass fraction)

| C | Si | Mn | Cr | Mo | V | Ni | W | Nb | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.85 | 0.90 | 0.43 | 6.76 | 1.82 | 0.30 | 0.85 | 0.35 | 0.25 | 0.005 | 0.02 |

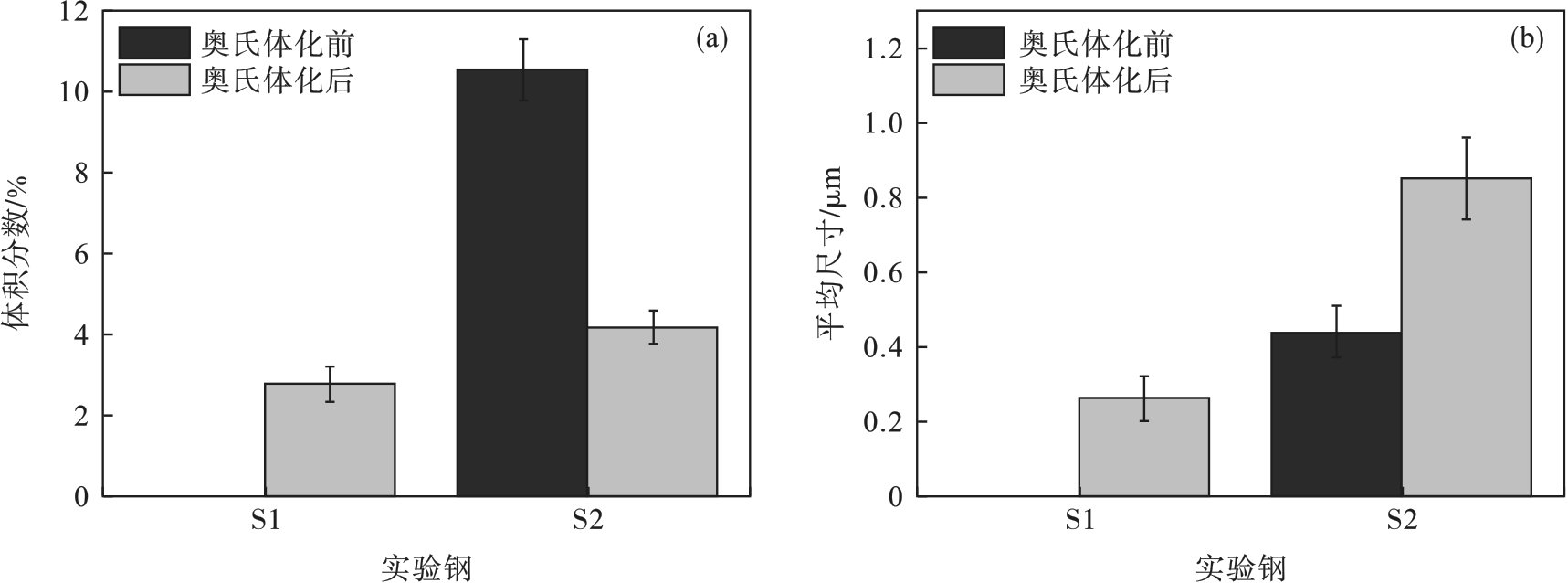

图8 奥氏体化前后实验钢中二次碳化物体积分数及平均尺寸(a)—二次碳化物体积分数; (b)—二次碳化物平均尺寸.

Fig.8 Volume fraction and average size of secondary carbide in experimental steels before and after austenitizing

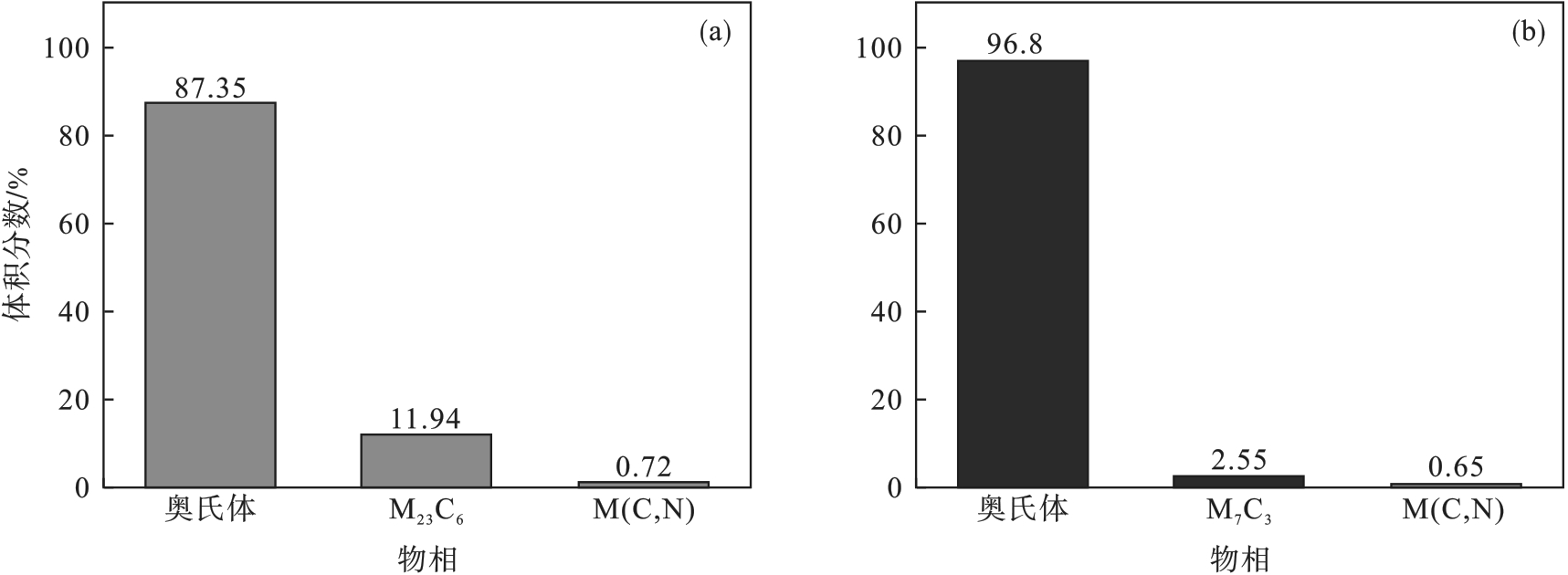

图9 通过JmatPro软件模拟计算出的850 °C保温4 h、1 025 °C保温1.5 h后实验钢中各物相体积分数(a)—850 °C保温4 h; (b)—1 025 °C保温1.5 h.

Fig.9 Phase volume fractions in experimental steels held at 850 °C for 4 h and 1 025 °C for 1.5 h respectively calculated with JmatPro software

| 1 | Wang F, Qian D S, Hua L,et al.Tempering response and improved mechanical properties in secondary hardened steel by introducing an optimized austempering process[J].Materials Science and Engineering:A,2021,807:140895. |

| 2 | Zhang X H, Xia Y M, Zhang Y C,et al.Experimental study on wear behaviors of TBM disc cutter ring under drying,water and seawater conditions[J].Wear,2017,392/393:109-117. |

| 3 | Qi Y F, Li J, Shi C B,et al.Effect of directional solidification of electroslag remelting on the microstructure and primary carbides in an austenitic hot‐work die steel[J].Journal of Materials Processing Technology,2017,249:32-38. |

| 4 | Wen D C.Erosion and wear behavior of nitrocarburized DC53 tool steel[J]. Wear,2010,268(3/4):629-636. |

| 5 | Liu W F, Cao Y F, Guo Y F,et al.Characteristics and transformation of primary carbides during austenitization in Cr4Mo4V bearing steel[J].Materials Characterization,2020,169:110636 |

| 6 | Zhang J, Li J, Shi C B,et al.Growth and agglomeration behaviors of eutectic M7C3 carbide in electroslag remelted martensitic stainless steel[J].Journal of Materials Research and Technology,2021,11:1490-1505. |

| 7 | Vahdat S E, Pournaghi A, Mohamadinia A,et al.Effect of interface strength of M23C6 in steel matrix on tensile toughness and strength[J].Procedia Materials Science,2014,6:208-215. |

| 8 | Zhu Q T, Li J, Shi C B,et al. Effect of electroslag remelting on carbides in 8Cr13MoV martensitic stainless steel[J].International Journal of Minerals,Metallurgy,and Materials,2015,22(11):1149-1156. |

| 9 | 张杰.高品质刀剪用钢碳化物的形成与弥散化控制研究 [D].北京:北京科技大学,2021. |

| Zhang Jie.Formation and dispersion control of carbides in the steel used for high‐quality knives and shears [D].Beijing:University of Science and Technology Beijing,2021. | |

| 10 | 孙秀华,康爱军,曹莹,等.热加工工艺对Cr12MoV钢的共晶碳化物影响[J].金属加工(热加工),2018(11):78-80. |

| Sun Xiu‐hua, Kang Ai‐jun, Cao Ying,et al.Effect of thermal processing on co‐crystal carbide of Cr12MoV steel[J].MW Metal Forming,2018(11):78-80. | |

| 11 | Zhou B, Shen Y, Chen J,et al.Breakdown behavior of eutectic carbide in high speed steel during hot compression[J]. Journal of Iron and Steel Research,International,2011,18(1):41-48. |

| 12 | Jiang J Z, Liu Y, Liu C M.Effect of tempering temperature on the microstructure,mechanical properties and abrasive wear behavior of a new C‐Cr‐Mo‐V alloy steel used in TBM cutter ring[J].Journal of Materials Research and Technology,2022,20:195-209. |

| 13 | Jiang J Z, Liu Y, Liu C M.Effect of forging ratio on the microstructure,mechanical properties and abrasive wear behavior of a new C‐Cr‐Mo‐V martensitic steel[J]. Journal of Materials Research and Technology,2022,19:4076-4091. |

| 14 | Amirabdollahian S, Deirmina F, Pellizzari M,et al.Tempering behavior of a direct laser deposited hot work tool steel:influence of quenching on secondary hardening and microstructure[J].Materials Science and Engineering:A,2021,814:141126. |

| 15 | Zhang S L, Sun X J, Dong H.Effect of deformation on the evolution of spheroidization for the ultra high carbon steel[J].Materials Science and Engineering:A,2006,432(1/2):324-332. |

| 16 | 冷焕辉,刘振宝,梁剑雄,等.多向锻造对超高强度不锈钢组织及力学性能的影响[J].中国冶金,2021,31(6):26-33. |

| Leng Huan‐hui, Liu Zhen‐bao, Liang Jian‐xiong,et al.Effect of multiple‐direction forging on microstructure and mechanical properties of ultra‐high strength stainless steel[J]. China Metallurgy,2021,31(6):26-33. | |

| 17 | Ren F C, Chen F, Chen J,et al.Hot deformation behavior and processing maps of AISI 420 martensitic stainless steel[J]. Journal of Manufacturing Processes,2018,31:640-649. |

| 18 | 林鹏,孙立国,马党参,等.压铸模具钢4Cr5Mo2V的组织和碳化物的高温行为[J].钢铁研究学报,2019,31(8):762-769. |

| Lin Peng, Sun Li‐guo, Ma Dang‐shen,et al.Research on high temperature behavior of microstructure and carbide in die casting 4Cr5Mo2V steel[J].Journal of Iron and Steel Research,2019,31(8):762-769. | |

| 19 | Tian J L, Wang W, Li H B,et al.Effect of deformation on precipitation hardening behavior of a maraging steel in the aging process[J].Materials Characterization,2019,155:109827. |

| 20 | 杨洪波,王快社,王庆娟,等.GCr15轴承钢渗碳体球化的长大机制[J].材料热处理学报,2012,33(8):79-83. |

| Yang Hong‐bo, Wang Kuai‐she, Wang Qing‐juan,et al.Spheroidizing growth mechanism of cementite in GCr15 bearing steel[J].Transactions of Materials and Heat Treatment,2012,33(8):79-83. | |

| 21 | 马超,罗海文.GCr15轴承钢热处理过程中碳化物的析出与演变行为[J].材料工程,2017,45(6):97-103. |

| Ma Chao, Luo Hai‑wen.Precipitation and evolution behavior of carbide during heat treatments of GCr15 bearing steel[J].Journal of Materials Engineering,2017,45(6):97-103. | |

| 22 | Hwang K C, Lee S, Lee H C.Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls.part II:fracture behavior [J].Materials Science and Engineering:A,1998,254(1/2):296-304. |

| 23 | 陈强,王涌,晁国强,等.渗碳齿轮淬火内应力分布及其对变形的影响[J].机车车辆工艺,2017(4):1-5. |

| Chen Qiang, Wang Yong, Chao Guo‐qiang,et al.The internal stress distribution of carburized gear after quenching operation and its influence on deformation[J].Locomotive & Rolling Stock Technology,2017(4):1-5. | |

| 24 | Yan X C, Hu J, Wang L Y,et al.The coupled effect of thermal and mechanical stabilities of austenite on the wear resistance in a 0.2C‐5Mn‐1.6Si steel down to cryogenic temperatures [J].Wear,2021,486/487:204116. |

| 25 | Wei F X, Cheng B S, Chew L T,et al.Grain distribution characteristics and effect of diverse size distribution on the Hall‐Petch relationship for additively manufactured metal alloys[J].Journal of Materials Research and Technology,2022,20:4130-4136. |

| 26 | Zhang X H, Lin L K, Xia Y M,et al.Experimental study on wear of TBM disc cutter rings with different kinds of hardness[J].Tunnelling and Underground Space Technology,2018,82:346-357. |

| 27 | Huang L, Deng X T, Jia Y,et al.Effects of using (Ti,Mo)C particles to reduce the three‐body abrasive wear of a low alloy steel [J].Wear,2018,410/411:119-126. |

| 28 | Deng X T, Wang Z D, Han Y,et al.Microstructure and abrasive wear behavior of medium carbon low alloy martensitic abrasion resistant steel[J].Journal of Iron and Steel Research,International,2014,21(1):98-103. |

| 29 | 刘罗锦.高钛高耐磨钢中TiC析出行为及对性能的影响 [D].北京:钢铁研究总院,2019. |

| Liu Luo‑jin.TiC precipitation behavior and its effect on properties in high titanium and high wear‑resistant steels [D].Beijing: Central Iron & Steel Research Institute,2019. |

| [1] | 刘俊汝, 张国华, 周国治. w(Fe)/w(Ni)对Mo2FeB2基金属陶瓷的影响[J]. 东北大学学报(自然科学版), 2023, 44(9): 1269-1278. |

| [2] | 郗文超, 宋博学, 梁赢东, 于天彪. 原位生成NbC增强YCF102熔覆层热力学与耐磨性研究[J]. 东北大学学报(自然科学版), 2021, 42(4): 538-543. |

| [3] | 张颖, 赵长盛, 苑文博, 郝丽娜. 仿人机械手设计与硬度感知研究[J]. 东北大学学报:自然科学版, 2020, 41(3): 349-355. |

| [4] | 辛博, 周显新, 巩亚东. 变厚度熔覆层沉积成形工艺与性能研究[J]. 东北大学学报:自然科学版, 2020, 41(3): 374-379. |

| [5] | 韩东序, 杜林秀, 吴红艳, 齐敏. 轧后冷却速率对GCr15轴承钢球化组织的影响[J]. 东北大学学报:自然科学版, 2019, 40(10): 1392-1397. |

| [6] | 刘永刚, 侯立良, 秦大同, 胡明辉. 基于BP神经网络的煤层硬度多等级识别方法[J]. 东北大学学报:自然科学版, 2018, 39(8): 1163-1168. |

| [7] | 张德胜, 张勤, 于云鹤, 杨洪英. 钇对银基合金靶材坯料微观组织及性能的影响[J]. 东北大学学报:自然科学版, 2018, 39(6): 813-817. |

| [8] | 陈庆强, 刘宇洋, 赵志浩, 朱庆丰. 热处理工艺对AZ61镁合金干摩擦磨损性能的影响[J]. 东北大学学报:自然科学版, 2017, 38(11): 1554-1558. |

| [9] | 孙茜, 邸洪双, 李峻臣. 780MPa级微合金钢的激光相变硬化工艺及组织性能[J]. 东北大学学报:自然科学版, 2016, 37(6): 785-789. |

| [10] | 马廉洁, 巩亚东, 于爱兵, 曹小兵. 基于BP和GA的微晶玻璃点磨削表面硬度数值拟合[J]. 东北大学学报:自然科学版, 2016, 37(2): 213-217. |

| [11] | 孙有政, 刘帅, 李进宝, 刘常升. 镍含量对激光熔覆层微结构及硬度的影响[J]. 东北大学学报:自然科学版, 2016, 37(11): 1551-1554. |

| [12] | 彭良贵, 刘伟杰, 刘相华, 支颖. 基于动态碳配分机制的高强塑积热成形钢研究[J]. 东北大学学报:自然科学版, 2015, 36(8): 1110-1115. |

| [13] | 于驰, 高秀华, 王平, 牛西茜. 货油舱用耐蚀钢连续冷却的转变规律[J]. 东北大学学报:自然科学版, 2015, 36(4): 479-483. |

| [14] | 任桂华, 张滨. 5083铝合金表面化学镀Ni-P镀层的力学性能[J]. 东北大学学报:自然科学版, 2015, 36(3): 383-387. |

| [15] | 陈庆安, 刘相华. 40Cr厚向性能差异化钢板的组织与性能[J]. 东北大学学报:自然科学版, 2015, 36(2): 204-207. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||