东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (11): 1579-1586.DOI: 10.12068/j.issn.1005-3026.2024.11.008

收稿日期:2023-05-31

出版日期:2024-11-15

发布日期:2025-02-24

通讯作者:

温雪龙

作者简介:温雪龙(1985-),男,辽宁沈阳人,东北大学副教授基金资助:

Xue-long WEN( ), Wen-bo ZHANG, Ya-dong GONG, Jun-peng LI

), Wen-bo ZHANG, Ya-dong GONG, Jun-peng LI

Received:2023-05-31

Online:2024-11-15

Published:2025-02-24

Contact:

Xue-long WEN

About author:WEN Xue-long, E-mail:wenxl@me.neu.edu.cn摘要:

通过对高熵合金进行三维槽铣和侧铣的铣削力仿真分析,研究了不同加工参数对铣削力的影响规律.针对FeCoNiCrAl0.1,FeCoNiCrAl0.5,FeCoNiCrMo0.1三种铸态高熵合金设计正交与单因素铣削实验,通过测量实验中的铣削力,探讨了不同加工方式、铣削参数、刀具和不同元素成分及含量对铣削力的影响规律.仿真及实验结果表明:随着铣削速度的增加,铣削深度和进给速度的减小,槽铣和侧铣的铣削力都减小,相同加工参数下槽铣的铣削切向力和法向力分别比侧铣高404.30%和761.06%. Al元素含量高的高熵合金铣削力大.HMX涂层刀具的铣削力小于SGS涂层刀具,铣削力平均降低10.6%.实验结果为高熵合金的高效加工提供了理论参考.

中图分类号:

温雪龙, 张文波, 巩亚东, 李俊鹏. FeCoNiCr系高熵合金铣削力仿真与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(11): 1579-1586.

Xue-long WEN, Wen-bo ZHANG, Ya-dong GONG, Jun-peng LI. Simulation and Experimental Study on Milling Force of FeCoNiCr High Entropy Alloy[J]. Journal of Northeastern University(Natural Science), 2024, 45(11): 1579-1586.

| 实验 | vw/(mm·min-1) | vc/(m·min-1) | ap/mm | ||

|---|---|---|---|---|---|

铣削深 度单因 素实验 | 100 | 75.4 | 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 | ||

铣削速 度单因 素实验 | 100 | 37.7 47.1 56.5 66.0 75.4 84.8 94.2 103.7 113.1 | 0.3 | ||

表1 单因素仿真实验参数 (parameters)

Table 1 Simulated single factor experiment

| 实验 | vw/(mm·min-1) | vc/(m·min-1) | ap/mm | ||

|---|---|---|---|---|---|

铣削深 度单因 素实验 | 100 | 75.4 | 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 | ||

铣削速 度单因 素实验 | 100 | 37.7 47.1 56.5 66.0 75.4 84.8 94.2 103.7 113.1 | 0.3 | ||

| 元素 | FeCoNiCrAl0.1 | FeCoNiCrAl0.5 | FeCoNiAlMo0.1 |

|---|---|---|---|

| Fe | 24.47 | 23.36 | 23.75 |

| Co | 25.85 | 24.64 | 25.05 |

| Ni | 25.72 | 24.56 | 24.96 |

| Cr | 22.79 | 21.75 | 22.11 |

| Al | 1.18 | 5.65 | — |

| Mo | — | — | 4.08 |

表2 原子质量比 (%)

Table 2 Atomic mass ratio

| 元素 | FeCoNiCrAl0.1 | FeCoNiCrAl0.5 | FeCoNiAlMo0.1 |

|---|---|---|---|

| Fe | 24.47 | 23.36 | 23.75 |

| Co | 25.85 | 24.64 | 25.05 |

| Ni | 25.72 | 24.56 | 24.96 |

| Cr | 22.79 | 21.75 | 22.11 |

| Al | 1.18 | 5.65 | — |

| Mo | — | — | 4.08 |

| 型号 | 涂层 | 刃长H | 刃径D | 总长L |

|---|---|---|---|---|

| HMX | 超晶纳米涂层 | 20 | 6 | 50 |

| SGS | Ti-NAMITE-X | 25 | 6 | 58 |

表3 铣刀参数 (mm)

Table 3 Cutter parameters

| 型号 | 涂层 | 刃长H | 刃径D | 总长L |

|---|---|---|---|---|

| HMX | 超晶纳米涂层 | 20 | 6 | 50 |

| SGS | Ti-NAMITE-X | 25 | 6 | 58 |

| 参数 | 水平 |

|---|---|

| vc/(m·min-1) | 37.7 56.5 75.4 94.2 113.1 |

| vw/(mm·min-1) | 30 60 90 120 150 |

| ap/mm | 0.1 0.2 0.4 0.6 0.8 |

表4 槽铣正交参数

Table 4 Slot milling orthogonal parametes

| 参数 | 水平 |

|---|---|

| vc/(m·min-1) | 37.7 56.5 75.4 94.2 113.1 |

| vw/(mm·min-1) | 30 60 90 120 150 |

| ap/mm | 0.1 0.2 0.4 0.6 0.8 |

| 参数 | 水平 |

|---|---|

| vc/(m·min-1) | 37.7 56.5 75.4 94.2 113.1 |

| vw/(mm·min-1) | 30 60 90 120 150 |

| ap/mm | 0.1 0.2 0.4 0.6 0.8 |

表5 侧铣正交参数

Table 5 Side milling orthogonal parameters

| 参数 | 水平 |

|---|---|

| vc/(m·min-1) | 37.7 56.5 75.4 94.2 113.1 |

| vw/(mm·min-1) | 30 60 90 120 150 |

| ap/mm | 0.1 0.2 0.4 0.6 0.8 |

| vc/(m·min-1) | vw/(mm·min-1) | ap/mm |

|---|---|---|

37.7 45.2 52.8 60.3 67.9 75.4 82.9 90.5 98.0 105.6 | 90 | 0.25 |

| 67.9 | 30 45 60 75 90 105 120 135 150 165 | 0.25 |

| 67.9 | 90 | 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 |

表6 侧铣单因素参数(ae=3 mm)

Table 6 Side milling single factor parameters (ae=3 mm)

| vc/(m·min-1) | vw/(mm·min-1) | ap/mm |

|---|---|---|

37.7 45.2 52.8 60.3 67.9 75.4 82.9 90.5 98.0 105.6 | 90 | 0.25 |

| 67.9 | 30 45 60 75 90 105 120 135 150 165 | 0.25 |

| 67.9 | 90 | 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 |

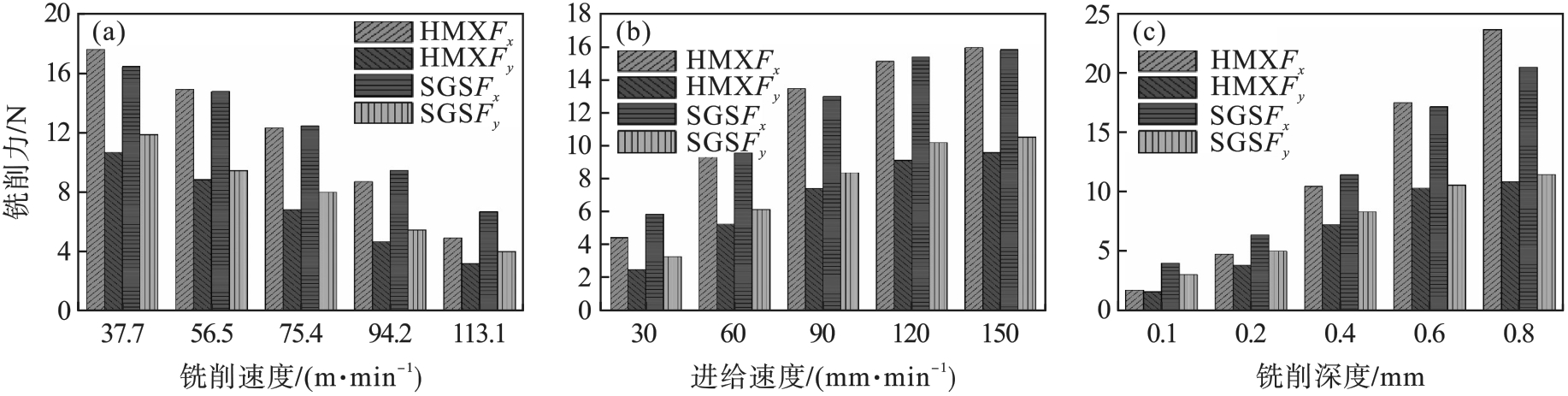

图10 不同涂层刀具的铣削力对比(a)—不同涂层刀具下铣削速度对铣削力的影响; (b)—不同涂层刀具下进给速度对铣削力的影响;(c)—不同涂层刀具下铣削深度对铣削力的影响.

Fig.10 Comparison of the milling forces of different coating tools

| 参数 | 数据点 | b0 | b1 | b2 | b3 | R2/% | F |

|---|---|---|---|---|---|---|---|

Al系Fx 优化前 Al系Fx 优化后 | 25 | 8.695 9 | 1.178 5 | 0.616 8 | -0.985 2 | 98.92 | 641.42 |

| 22 | 7.872 2 | 1.228 5 | 0.697 6 | -0.925 9 | 99.13 | 758.09 | |

Al系Fy 优化前 Al系Fy 优化后 | 25 | 7.228 6 | 0.870 4 | 0.706 9 | -0.945 8 | 99.07 | 742.11 |

| 23 | 7.313 0 | 0.868 2 | 0.696 8 | -0.952 8 | 99.36 | 980.36 |

表7 显著性检验

Table 7 Significance test

| 参数 | 数据点 | b0 | b1 | b2 | b3 | R2/% | F |

|---|---|---|---|---|---|---|---|

Al系Fx 优化前 Al系Fx 优化后 | 25 | 8.695 9 | 1.178 5 | 0.616 8 | -0.985 2 | 98.92 | 641.42 |

| 22 | 7.872 2 | 1.228 5 | 0.697 6 | -0.925 9 | 99.13 | 758.09 | |

Al系Fy 优化前 Al系Fy 优化后 | 25 | 7.228 6 | 0.870 4 | 0.706 9 | -0.945 8 | 99.07 | 742.11 |

| 23 | 7.313 0 | 0.868 2 | 0.696 8 | -0.952 8 | 99.36 | 980.36 |

| 1 | Sun J, Zhao W X, Yan P,et al.High temperature tensile properties of as‑cast and forged CrMnFeCoNi high entropy alloy[J].Materials Science and Engineering:A,2022,850:143570. |

| 2 | Xiang T, Zhao M, Du P,et al.Heat treatment effects on microstructure and mechanical properties of TiZrNbTa high‑entropy alloy[J].Journal of Alloys and Compounds,2023,930:167408. |

| 3 | Kaushik L, Kim M S, Singh J,et al.Deformation mechanisms and texture evolution in high entropy alloy during cold rolling[J].International Journal of Plasticity,2021,141:102989. |

| 4 | Lee C F, Shun T T.Age heat treatment of Al0.5CoCrFe1.5NiTi0.5 high‑entropy alloy[J].Metals,2021,11(1):1416-1427. |

| 5 | Malatji N, Lengopeng T, Pityana S,et al.Effect of heat treatment on the microstructure,microhardness,and wear characteristics of AlCrFeCuNi high‑entropy alloy[J].The International Journal of Advanced Manufacturing Technology,2020,111(7):2021-2029. |

| 6 | Gökhan S, Motorcu A R, Nohutçu S.Single and multi‑objective optimization for cutting force and surface roughness in peripheral milling of Ti6Al4V using fixed and variable helix angle tools[J].Journal of Manufacturing Processes,2022,80:529-545. |

| 7 | Gaikhe V, Sahu J, Pawade R.Optimization of cutting parameters for cutting force minimization in helical ball end milling of inconel 718 by using genetic algorithm[J].Procedia CIRP,2018,77:477-480. |

| 8 | 王振宇,张荣闯,于天彪.圆柱直齿轮铣削加工无干涉刀具路径规划[J].东北大学学报(自然科学版),2022,43(7):988-995. |

| Wang Zhen‑yu, Zhang Rong‑chuang, Yu Tian‑biao.Interference‑free tool path generation for milling of spur gears[J].Journal of Northeastern University (Natural Science),2022,43(7):988-995. | |

| 9 | 贾东洲,李长河,张彦彬,等.钛合金生物润滑剂电牵引磨削性能及表面形貌评价[J].机械工程学报,2022,58(5):198-211. |

| Jia Dong‑zhou, Li Chang‑he, Zhang Yan‑bin,et al.Grinding performance and surface morphology evaluation of titanium alloy using electric traction bio micro lubricant[J].Journal of Mechanical Engineering,2022,58(5):198-211. | |

| 10 | 许文昊,李长河,张彦彬,等.静电雾化微量润滑研究进展与应用[J].机械工程学报,2023,59(7):110-138. |

| Xu Wen‑hao, Li Chang‑he, Zhang Yan‑bin,et al.Research progress and application of electrostatic atomization minimum quantity lubrication[J].Journal of Mechanical Engineering,2023,59(7):110-138. | |

| 11 | Zhou R H.Analytical model of milling forces prediction in five‑axis milling process[J].The International Journal of Advanced Manufacturing Technology,2020,111(9):3045-3054. |

| 12 | 邓云飞,张永,吴华鹏,等.6061-T651铝合金动态力学性能及J-C本构模型的修正[J].机械工程学报,2020,56(20):74-81. |

| Deng Yun‑fei, Zhang Yong, Wu Hua‑peng,et al.Dynamic mechanical properties and modification of J-C constitutive model of 6061-T651 aluminum alloy[J].Journal of Mechanical Engineering,2020,56(20):74-81. |

| [1] | 王海芳, 乔鼎杰, 吴天浩, 黄鹏. 基于改进VINS-Mono算法的状态估计方法[J]. 东北大学学报(自然科学版), 2024, 45(9): 1287-1293. |

| [2] | 赵英博, 修世超, 洪远, 步新宇. 户外型AGV越障仿真方法与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1107-1114. |

| [3] | 傅大学, 狄跃忠, 王耀武. 基于床层传热的皮江法炼镁过程优化[J]. 东北大学学报(自然科学版), 2024, 45(4): 523-529. |

| [4] | 周云光, 王书海, 陈晗, 李明. 精密车削镍基单晶高温合金去除机理仿真与实验[J]. 东北大学学报(自然科学版), 2024, 45(10): 1452-1458. |

| [5] | 侯鹏帅, 周大鹏, 杨大鹏, 陈杰. 基于多传感器融合的无人舰载机舰面定位研究[J]. 东北大学学报(自然科学版), 2024, 45(1): 1-9. |

| [6] | 杨欣, 樊振刚, 张根保, 冉琰. 数控转台蜗轮转动元动作的热变形有限元分析[J]. 东北大学学报(自然科学版), 2024, 45(1): 76-84. |

| [7] | 张家豪, 邹平, 魏事宇, 梁付强. 单激励三维超声车削加工技术的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1152-1159. |

| [8] | 于长永,赵楚,马海涛刘晓寒, 邹平, 曲圆辉, 方立廷. 提升304不锈钢加工表面的单激励三维振动切削装置设计[J]. 东北大学学报(自然科学版), 2023, 44(6): 816-823. |

| [9] | 饶红艳, 王少杰, 侯亮, 苏德赢. 基于改进粒子群优化算法的混凝土泵车全局功率匹配[J]. 东北大学学报(自然科学版), 2023, 44(6): 840-848. |

| [10] | 黄贤振, 栾晓刚, 朱丽莎, 刘慧珍. 基于双向流固耦合的锥阀阀芯位移可靠性分析[J]. 东北大学学报(自然科学版), 2023, 44(5): 667-673. |

| [11] | 温雪龙, 王承宝, 刘文博, 任海洋. 选区激光熔化FeCoNiCr系高熵合金微观组织的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(4): 536-543. |

| [12] | 罗忠, 吴东泽, 李雷, 葛长闯. 转子系统动力学仿真平台设计与实验验证[J]. 东北大学学报(自然科学版), 2023, 44(3): 375-381. |

| [13] | 卢晓红, 顾瀚, 丛晨, 阮飞翔. Inconel 718介观尺度薄壁件微铣削力预测[J]. 东北大学学报(自然科学版), 2023, 44(2): 242-250. |

| [14] | 耿健, 王晓冬, 郭美如, 黄海龙. 流量计法测量微型溅射离子泵抽速的方法[J]. 东北大学学报(自然科学版), 2022, 43(9): 1298-1305. |

| [15] | 王海芳, 崔阳阳, 李鸣飞, 李广宇. 基于改进RRT*FN的移动机器人路径规划算法[J]. 东北大学学报(自然科学版), 2022, 43(9): 1217-1225. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||