东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 93-104.DOI: 10.12068/j.issn.1005-3026.2025.20240196

朱琦, 丁超凡, 闫俊丽, 张涛

收稿日期:2024-10-29

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

朱琦

作者简介:朱 琦(1983—),男,江苏镇江人,东北大学教授,博士生导师.

基金资助:Qi ZHU, Chao-fan DING, Jun-li YAN, Tao ZHANG

Received:2024-10-29

Online:2025-08-15

Published:2025-11-24

Contact:

Qi ZHU

摘要:

传统的金属腐蚀探测手段存在操作复杂、不能实时探测、价格昂贵等缺点,而荧光探针具有灵敏度高、结构简单、无损探测、原位探测、实时探测等优点,是一种有前景的金属早期腐蚀探测方法,可在金属早期腐蚀阶段自主指示涂层损伤和金属腐蚀.根据金属的腐蚀过程综述了荧光探针探测腐蚀的原理,将其分为对pH敏感、对金属离子敏感、对涂层损伤敏感3类,这些探针能根据pH变化、金属离子存在和涂层损伤显示荧光反应,作为腐蚀开始的早期预警.总结了不同种类荧光探针的应用场景和优缺点,最后对荧光探针探测技术的发展前景进行了展望.

中图分类号:

朱琦, 丁超凡, 闫俊丽, 张涛. 用于金属腐蚀探测的荧光探针研究进展[J]. 东北大学学报(自然科学版), 2025, 46(8): 93-104.

Qi ZHU, Chao-fan DING, Jun-li YAN, Tao ZHANG. Research Progress of Fluorescent Probes for Metal Corrosion Detection[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 93-104.

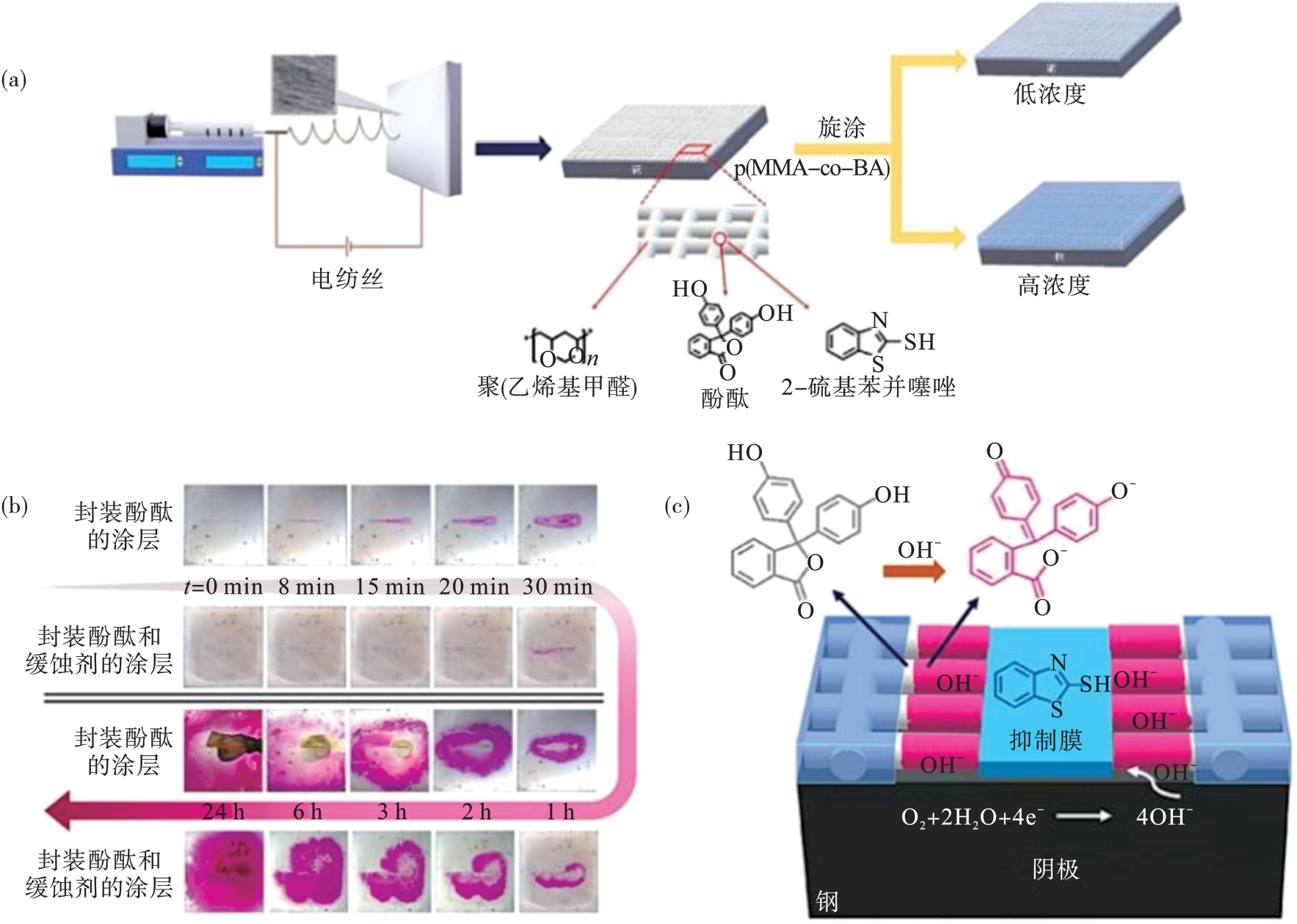

图2 负载酚酞和缓蚀剂的涂层的腐蚀抑制与预警机制[8]注:p(MMA-co-BA)为聚甲基丙烯酸甲酯-丙烯酸丁酯(a)—涂料设计方案; (b)—腐蚀传感涂层表面随浸泡时间t的变化情况; (c)—双功能涂层工作机理.

Fig.2 Corrosion inhibition and early warning mechanism of coatings loaded with phenolphthalein and corrosion inhibitors [8]

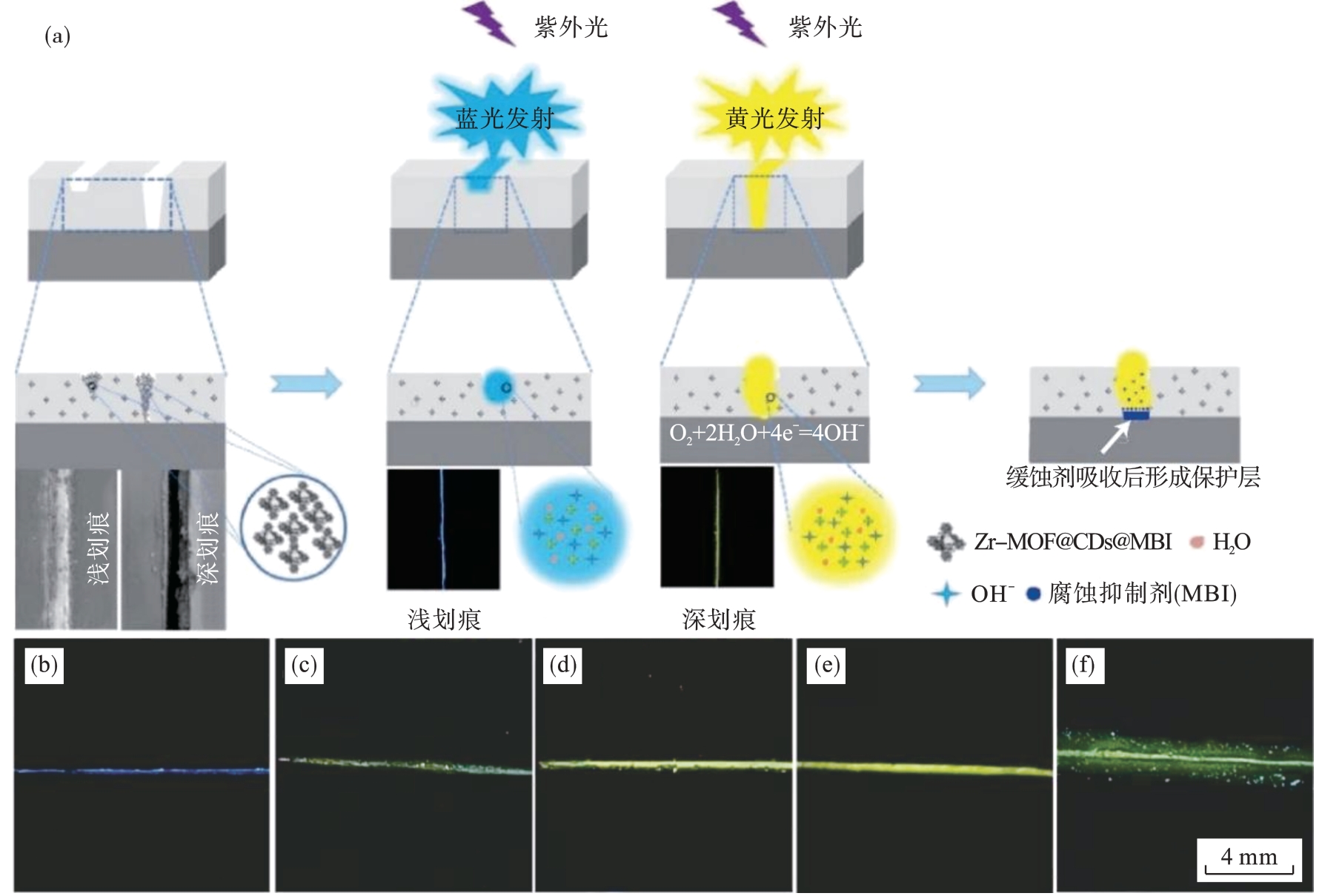

图3 负载Zr-MOF@CD@MBI纳米填料的智能涂层在金属腐蚀中的损伤预警与修复机制[17](a)—涂层损伤预警(浅划痕)和及时报告/修复金属腐蚀(深划痕)的智能涂层示意图;(b)—浸泡1 h; (c)—浸泡6 h; (d)—浸泡12 h; (e)—浸泡24 h; (f)—浸泡48 h.

Fig.3 Damage warning and repair mechanism of intelligent coating loaded with Zr-MOF@CD@MBI nanofillers in metal corrosion [17]

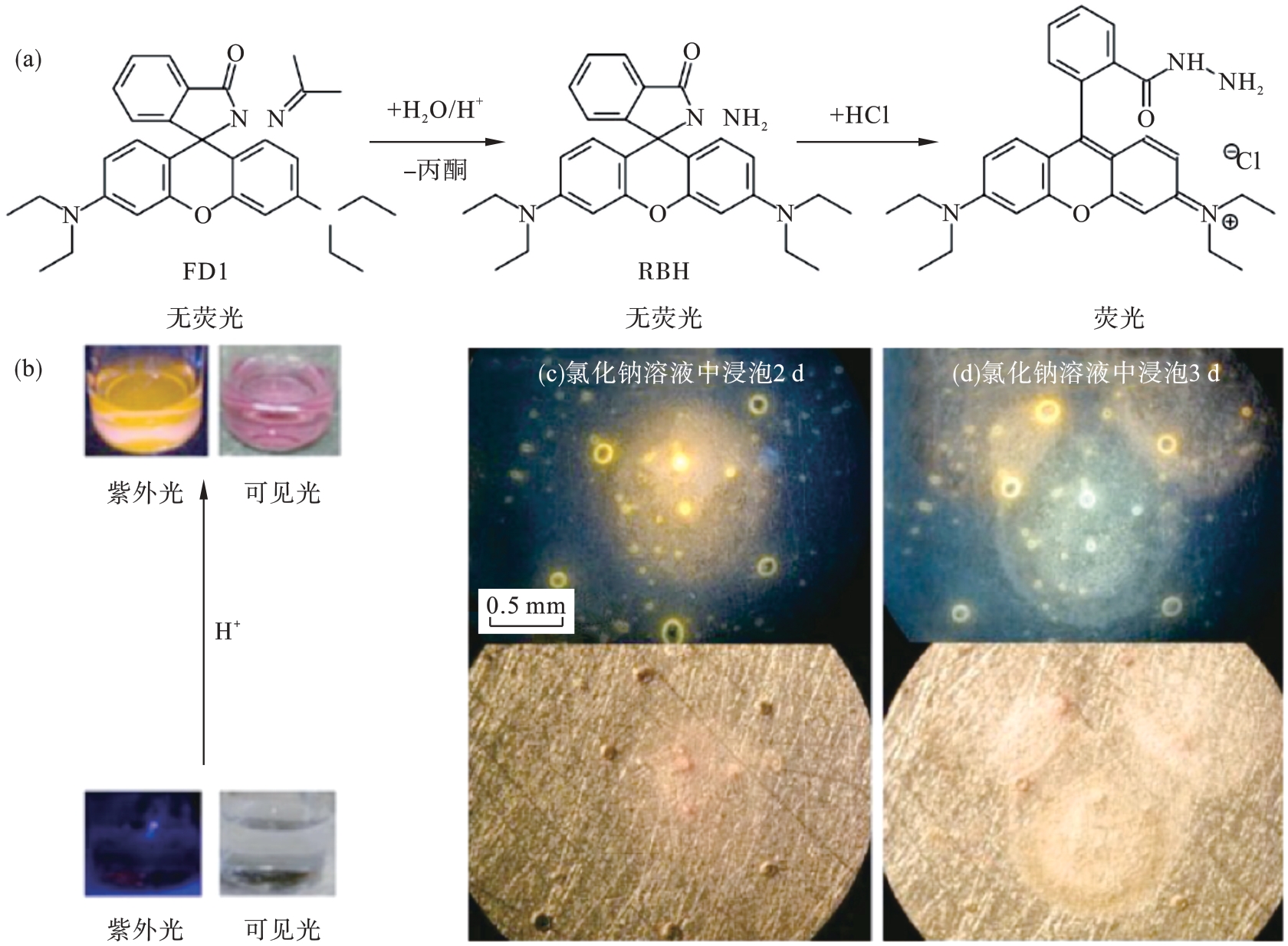

图4 FD1在酸性环境下的荧光机制、荧光发射和含FD1的透明环氧涂层的Al 1052在3.5%NaCl溶液中浸泡不同天数后的图像[20](a)—在低pH下FD1的荧光机制; (b)—酸性环境下的FD1在510 nm波长光激发下的荧光发射; (c)—浸泡2 d; (d)—浸泡3 d.

Fig.4 Fluorescence mechanism and fluorescence emission of FD1 in acidic environments and images of FD1-contain-ing transparent epoxy-coated Al 1052 after immersion in 3.5% NaCl solution for different days [20]

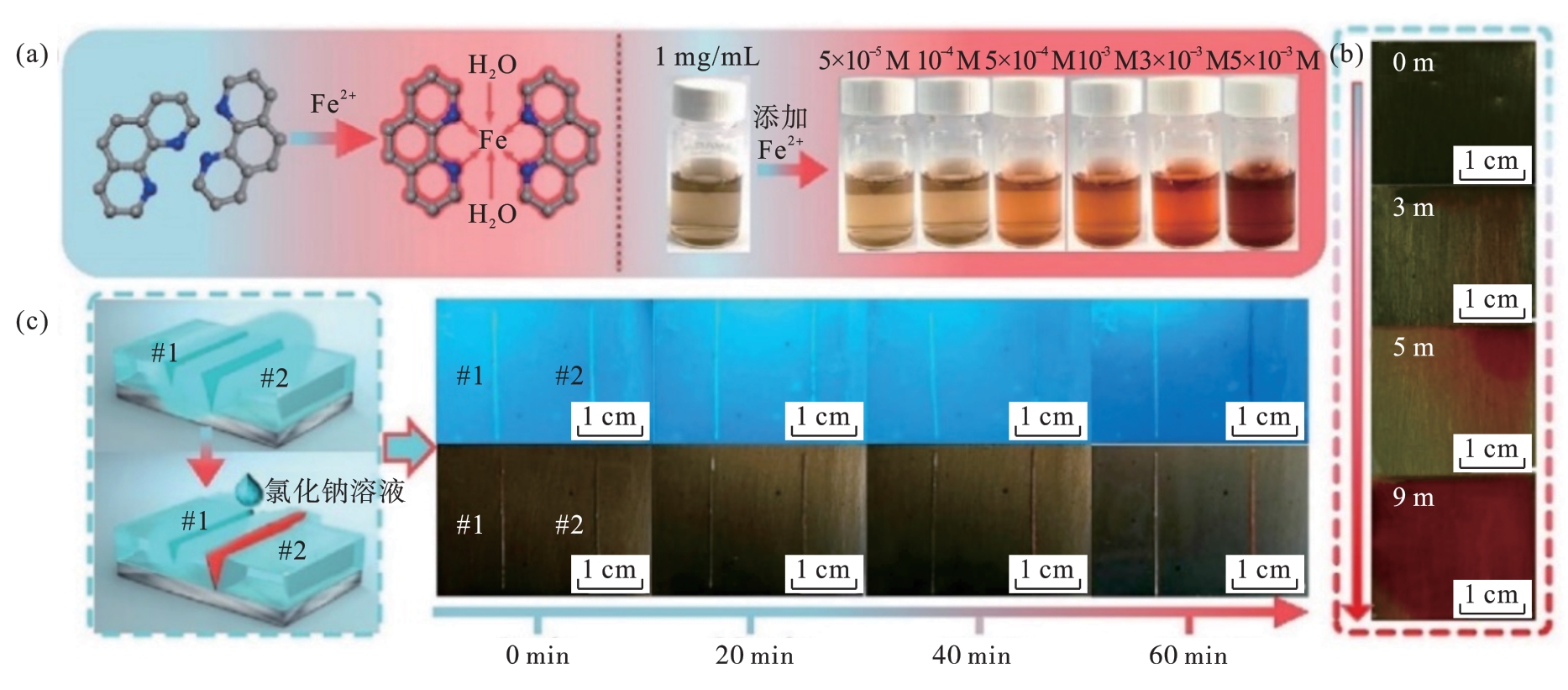

图5 Phen与Fe2+反应机理及其对涂层样品性能的影响[23](a)—Phen与Fe²⁺反应机理及不同浓度下颜色变化; (b)—涂层样品环境放置9个月后的照片;(c)—紫外光和可见光下的性能示意图及划痕照片.

Fig.5 Reaction mechanism of Phen with Fe2+ and its effect on properties of coated samples[23]

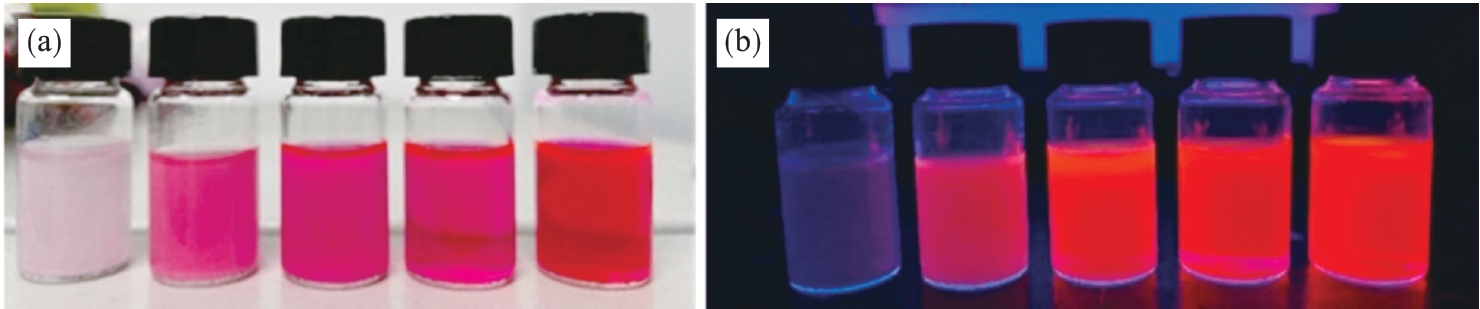

图6 在不同光源下激发不同含量Fe3+的S-Rxbxja乙醇溶液[32](a)—自然光; (b)—紫外光.

Fig.6 Excitation of ethanol solutions of S-Rxbxja different contents of Fe3+ under different light sources[32]

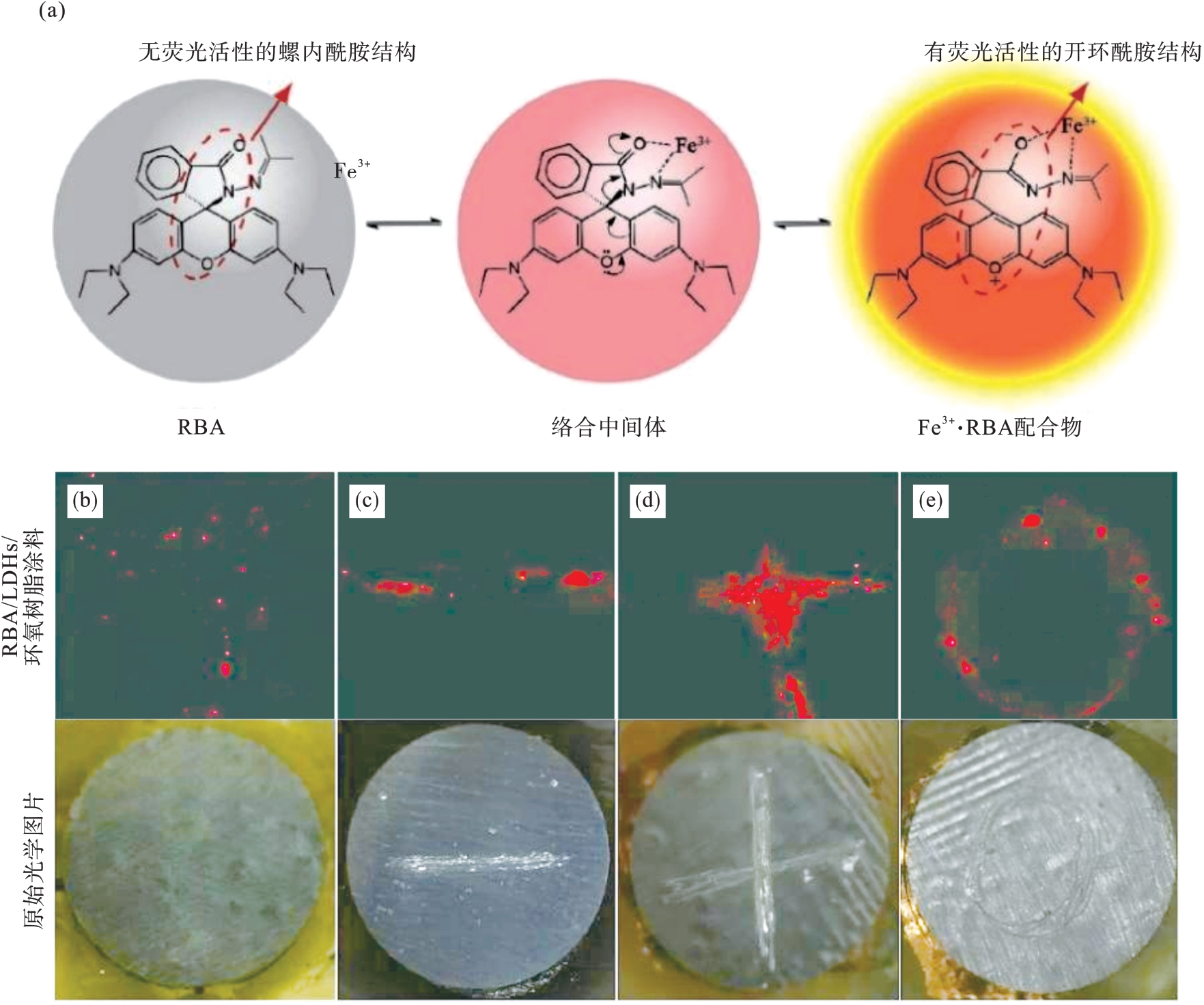

图7 RBA荧光开关机制及涂层腐蚀检测性能[30](a)—荧光开关机制; (b)—无划痕; (c)—“—”形划痕; (d)—“X”形划痕; (e)—“O”形划痕.

Fig.7 RBA fluorescence switching mechanism and coating corrosion detection performance[30]

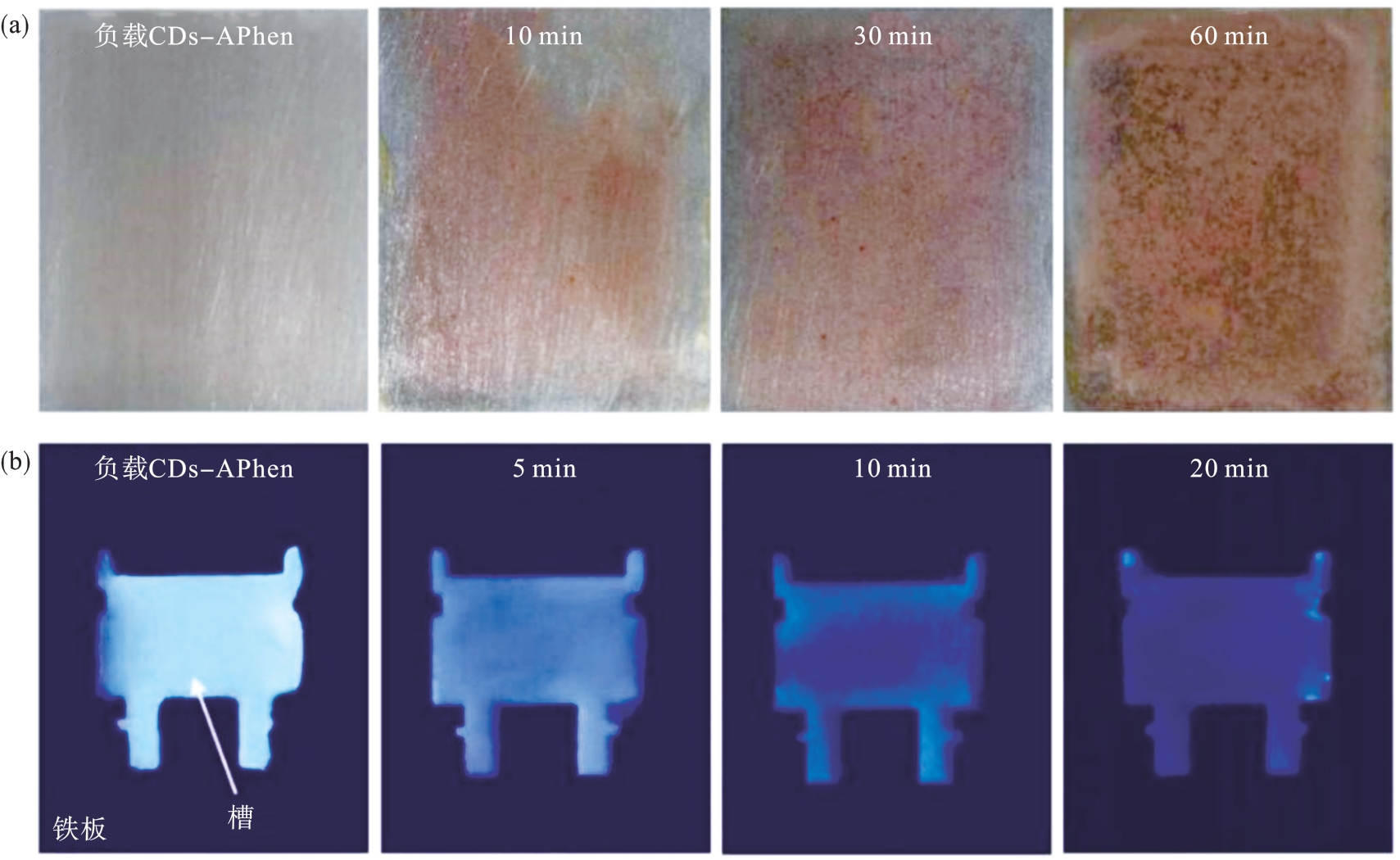

图8 负载CDs-APhen的Q235钢在HCl溶液中浸泡后的光学与紫外线图像[37](a)—光学图像; (b)—紫外图像.

Fig.8 Optical and UV images of Q235 steel loaded with CDs-APhen after immersion in HCl solution [37]

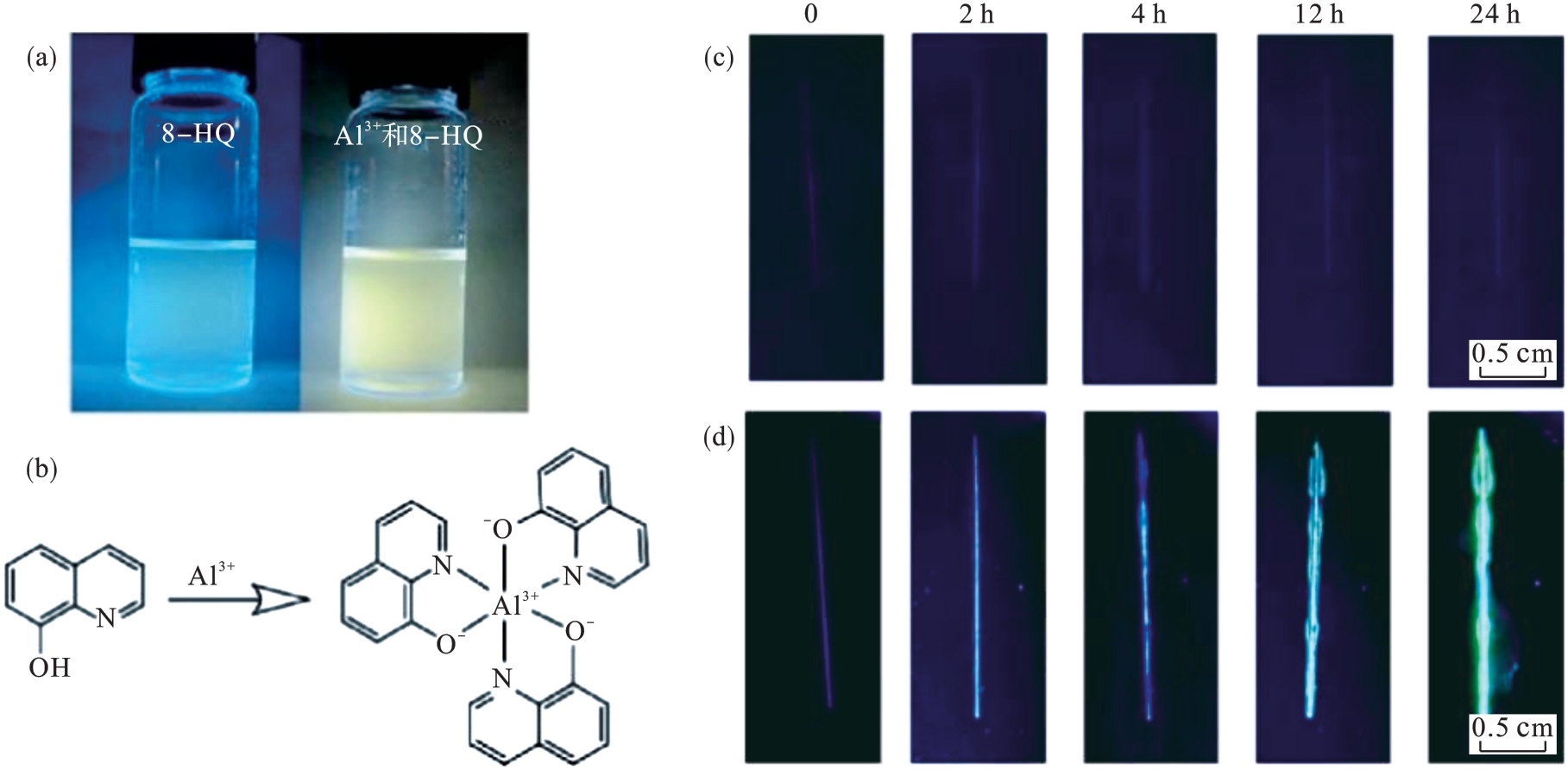

图9 8-HQ与铝离子的络合及含有不同浓度探针的涂层荧光预警性能[42](a)—荧光图像; (b)—络合机理; (c)—探针质量分数为0; (b)—探针质量分数为7.5%.

Fig.9 Complexation of 8-HQ with aluminum ions and fluorescence early-warning properties of coatings containing probes of different concentrations [42]

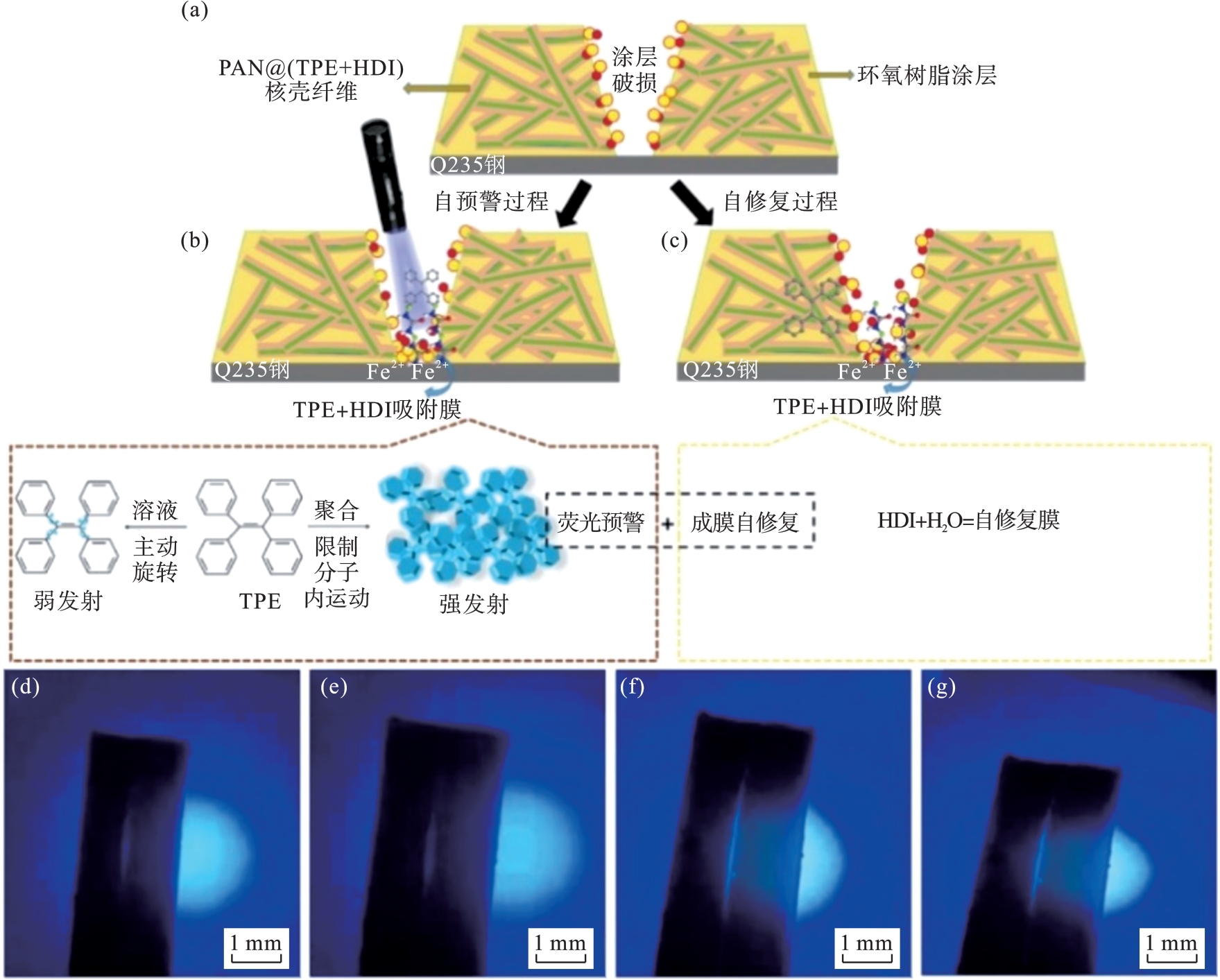

图10 环氧树脂/PAN@(HDI+TPE)纤维涂层的自预警与自修复机制及涂层在质量分数为3.5%的NaCl溶液中浸泡不同时间后的图像[46](a)—纤维涂层示意图; (b)—自预警机制; (c)—自修复机制; (d)—1 h; (e)—5 h; (f)—30 h; (g)—120 h.

Fig.10 Mechanism of self-warning and self-repair of epoxy/PAN@(HDI+TPE) fiber coatings and images of coatings after immersion in 3.5 wt% NaCl solution for different duration[46]

| [1] | Li X G, Zhang D W, Liu Z Y, et al. Materials science: share corrosion data [J]. Nature, 2015, 527(7579): 441-442. |

| [2] | Hou B R, Li X G, Ma X M, et al. The cost of corrosion in China [J]. NPJ Materials Degradation, 2017, 1(1): 4. |

| [3] | Gao T F, Sun H, Hong Y Q, et al. Hidden corrosion detection using laser ultrasonic guided waves with multi-frequency local wavenumber estimation [J]. Ultrasonics, 2020, 108: 106182. |

| [4] | Marinetti S, Vavilov V. IR thermographic detection and characterization of hidden corrosion in metals: general analysis [J]. Corrosion Science, 2010, 52(3): 865-872. |

| [5] | Jamshidi V, Davarnejad R. Simulation of corrosion detection inside wellbore by X-ray backscatter radiography [J]. Applied Radiation and Isotopes, 2019, 145: 116-119. |

| [6] | Van Ede M C, Fichtner A, Angst U. Nondestructive detection and quantification of localized corrosion rates by electrochemical tomography [J]. NDT & E International, 2024, 142: 103005. |

| [7] | Xiao H W, Wang Y J, Gu L, et al. Smart sensing coatings for early warning of degradations: a review [J]. Progress in Organic Coatings, 2023, 177: 107418. |

| [8] | Salaluk S, Auepattana‐Aumrung K, Thongchaivetcharat K, et al. Nanonetwork composite coating for sensing and corrosion inhibition [J]. Advanced Materials Interfaces, 2020, 7(20): 2001073. |

| [9] | Maia F, Tedim J, Bastos A C, et al. Nanocontainer-based corrosion sensing coating [J]. Nanotechnology, 2013, 24(41): 415502. |

| [10] | Calle L M, Li W. Handbook of smart coatings for materials protection [M]. Cambridge: Elsevier, 2014: 370-422. |

| [11] | Galvão T L P, Sousa I, Wilhelm M, et al. Improving the functionality and performance of AA2024 corrosion sensing coatings with nanocontainers [J]. Chemical Engineering Journal, 2018, 341: 526-538. |

| [12] | Zhang J, Frankel G S. Corrosion-sensing behavior of an acrylic-based coating system [J]. Corrosion, 1999, 55(10): 957-967. |

| [13] | Maia F, Tedim J, Bastos A C, et al. Active sensing coating for early detection of corrosion processes [J]. RSC Advances, 2014, 4(34): 17780-17786. |

| [14] | Lee T H, Song Y K, Park S H, et al. Dual stimuli responsive self-reporting material for chemical reservoir coating [J]. Applied Surface Science, 2018, 434: 1327-1335. |

| [15] | Liu G, Wheat H G. Use of a fluorescent indicator in monitoring underlying corrosion on coated aluminum 2024-T4 [J]. Journal of The Electrochemical Society, 2009, 156(4): C160-C166. |

| [16] | Wang J P, Wang J K, Zhou Q, et al. Adaptive polymeric coatings with self‐reporting and self‐healing dual functions from porous core-shell nanostructures [J]. Macromolecular Materials and Engineering, 2018, 303(4): 1700616. |

| [17] | Fan D H, Li L J, Qi K, et al. pH-responsive fluorescent metal‐organic framework as a functional nanofiller for smart coatings [J]. Inorganic Chemistry, 2023, 62(30): 11887-11896. |

| [18] | Pidaparti R M, Neblett E B, Miller S A, et al. Monitoring the corrosion process of Al alloys through pH induced fluorescence [J]. Smart Materials and Structures, 2008, 17(1): 015001. |

| [19] | Zhang M, Gao Y H, Li M Y, et al. A selective turn-on fluorescent sensor for FeIII and application to bioimaging [J]. Tetrahedron Letters, 2007, 48(21): 3709-3712. |

| [20] | Augustyniak A, Ming W H. Early detection of aluminum corrosion via “turn-on” fluorescence in smart coatings [J]. Progress in Organic Coatings, 2011, 71(4): 406-412. |

| [21] | Su F F, Du X C, Shen T, et al. Aggregation-induced emission luminogens sensors: sensitive fluorescence ‘Turn-On’ response for pH and visually chemosensoring on early detection of metal corrosion [J]. Progress in Organic Coatings, 2021, 153: 106122. |

| [22] | Xiao M D, Zhang Y M, Xiao X Z, et al. Autonomous damage detection of epoxy coatings enabled by clusteroluminescence of commercial polyamide 650 curing agent without external AIEgens [J]. Chemical Engineering Journal, 2024, 498: 155670. |

| [23] | Cheng L, Liu C B, Zhao H C, et al. Hierarchically self‐reporting and self‐healing photothermal responsive coatings towards smart corrosion protection [J]. Chemical Engineering Journal, 2023, 467: 143463. |

| [24] | Wang J K, Ma L W, Chen Z B, et al. Multi-channel preparation and high‐throughput screening of coating fillers with optimized corrosion sensing and inhibition properties for smart protective coatings [J]. Corrosion Science, 2023, 222: 111390. |

| [25] | Liu C B, Jin Z Y, Cheng L, et al. Synthesis of nanosensors for autonomous warning of damage and self-repairing in polymeric coatings [J]. Nanoscale, 2020, 12(5): 3194-3204. |

| [26] | Cao L, Wang Q, Wang W, et al. Synthesis of smart nanofiber coatings with autonomous self‐warning and self‐healing functions [J]. ACS Applied Materials & Interfaces, 2022, 14(23): 27168-27176. |

| [27] | Liu T, Zhang D W, Ma L W, et al. Smart protective coatings with self‐sensing and active corrosion protection dual functionality from pH-sensitive calcium carbonate microcontainers [J]. Corrosion Science, 2022, 200: 110254. |

| [28] | Liu C B, Wu H, Qiang Y J, et al. Design of smart protective coatings with autonomous self-healing and early corrosion reporting properties [J]. Corrosion Science, 2021, 184: 109355. |

| [29] | Song L Y, Zhu Y B, Wang J F, et al. Inorganic phosphate regulated high luminescence NaYF4:Yb3+, Er3+ as an iron ion fluorescent nanoprobe [J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 2023, 300: 122903. |

| [30] | Lyu J, Yue Q X, Ding R, et al. Intelligent anti‐corrosion and corrosion detection coatings based on layered supramolecules intercalated by fluorescent off‐on probes [J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 118: 309-324. |

| [31] | Roshan S, Sarabi Dariani A A, Mokhtari J. Monitoring underlying epoxy-coated St-37 corrosion via 8-hydroxyquinoline as a fluorescent indicator [J]. Applied Surface Science, 2018, 440: 880-888. |

| [32] | Wang Q, Song Y H, Liu Y, et al. Composite fluorescence probe towards a smart coating for early corrosion detection of carbon steel [J]. Journal of Electroanalytical Chemistry, 2024, 972: 118641. |

| [33] | Guo H L, Zhu C J, Yuan Z H, et al. Facile hydrogels of AIEgens applied as reusable sensors for in situ and early warning of metallic corrosion [J]. ACS Applied Materials & Interfaces, 2023, 15(6): 8530-8536. |

| [34] | Dhole G S, Gunasekaran G, Naik R, et al. Fluorescence based corrosion detecting epoxy coating [J]. Progress in Organic Coatings, 2020, 138: 105425. |

| [35] | Liu Z, Jia R N, Jian Y, et al. N-doped carbon dots as a multifunctional platform for real-time corrosion monitoring and inhibition [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 650: 129499. |

| [36] | Wu S H, Wang J K, Liu T, et al. Sulfosalicylic acid modified carbon dots as effective corrosion inhibitor and fluorescent corrosion indicator for carbon steel in HCl solution [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 661: 130951. |

| [37] | Ma L W, Xu D, Wu S H, et al. Polyurethane coatings with corrosion inhibition and color-fluorescence damage reporting properties based on APhen‐grafted carbon dots [J]. Corrosion Science, 2024, 232: 112038. |

| [38] | Jiao D Z, Liu C B, Qiang Y J, et al. Ni-Zn bimetal‐organic framework nanoprobes reinforced polymeric coating to achieve dual-responsive warning of coating damage and interfacial corrosion [J/OL]. Nano Materials Science, 2024:[2024-07-10]. |

| [39] | Guo L L, Yan L R, He Y Y, et al. Hyperbranched polyborate: a non-conjugated fluorescent polymer with unanticipated high quantum yield and multicolor emission[J]. Angewandte Chemie International Edition, 2022, 61(29): e202204383. |

| [40] | 吴松林, 于美, 李松梅, 等. 基于8-羟基喹啉荧光敏感化合物的铝合金腐蚀监测技术[J]. 北京科技大学学报, 2009, 31(8): 1013-1018. |

| Wu Song‐lin, Yu Mei, Li Song‐mei, et al. Fluorescent technology for corrosion prediction of aluminum alloys based on 8-hydroxy-quinoline [J]. Journal of University of Science and Technology Beijing, 2009, 31(8): 1013-1018. | |

| [41] | Hu Y F, Cao X K, Ma X Z, et al. A bifunctional epoxy coating doped by cerium (III)-8-hydroxyquinoline: early self-reporting and stimuli‐responsive inhibition on corrosion of Al substrate [J]. Progress in Organic Coatings, 2023, 182: 107616. |

| [42] | Li W, Tao J J, Chen Y X, et al. Porous microspheres with corrosion sensing and active protecting abilities towards intelligent self-reporting and anti‐corrosion coating [J]. Progress in Organic Coatings, 2023, 178: 107468. |

| [43] | Fan D H, Liu X B, Qi K, et al. A smart‐sensing coating based on dual-emission fluorescent Zr-MOF composite for autonomous warning of coating damage and aluminum corrosion [J]. Progress in Organic Coatings, 2022, 172: 107150. |

| [44] | Meng Z Y, Yin J, Li M X, et al. A novel schiff base‐modified dialdehyde cellulose‐based fluorescent probe for Al3+ and its application in environmental analysis[J]. Macromolecular Rapid Communications, 2022, 43(2): 2100608. |

| [45] | Ji X H, Duan J Z, Zhao X, et al. Application of AIE luminogen‐loaded core‐shell fibers in self‐warning and self‐healing polymer coatings with enhanced corrosion resistance [J]. Composites Part A: Applied Science and Manufacturing, 2024, 182: 108213. |

| [46] | Cheng L, Jiao D Z, Cao L, et al. Fluorescein-loaded nanoflowers driven smart anticorrosion coating for hierarchically visually monitoring of early failure process [J]. Progress in Organic Coatings, 2024, 194: 108579. |

| [47] | Guo Z H, Li T, Chen T L, et al. Salt-gated releasing effect to open visual self‐reporting/self‐repairing function of coatings toward corrosion protection [J]. ACS Sustainable Chemistry & Engineering, 2023, 11(12): 4738-4748. |

| [48] | Lin Z, Ouyang Q F, Guo C R, et al. Fluorescent probe‐based fiber optic sensor for real‐time monitoring of chloride ions in coastal concrete structures [J]. Sensors, 2024, 24(12): 3700. |

| [1] | 张涛, 刘闯, 张一, 王福会. 硅烷化处理对镁合金表面微弧氧化涂层降解性能的影响[J]. 东北大学学报(自然科学版), 2025, 46(8): 105-112. |

| [2] | 孟凡帝, 万心语, 蔡亚慧, 刘莉. 热场辅助机械力化学法制备界面化学键合防腐涂层[J]. 东北大学学报(自然科学版), 2025, 46(8): 113-123. |

| [3] | 赵阳, 王宇航, 张涛, 王福会. 半导体制程设备铝合金涂层腐蚀失效行为研究进展[J]. 东北大学学报(自然科学版), 2025, 46(3): 28-45. |

| [4] | 任朝晖, 贾昌烨, 武志伦, 王云贺. 超声旋转微锻造增材件数值模拟[J]. 东北大学学报(自然科学版), 2025, 46(2): 57-63. |

| [5] | 杨尚武, 瞿海霞, 黎恒君, 刘常升. 激光熔覆(Ti,W)C增强镍基涂层的性能[J]. 东北大学学报(自然科学版), 2024, 45(7): 953-959. |

| [6] | 刘纪红, 张律恒, 杨海旭. 一种细胞荧光显微图像饱和伪影修复算法[J]. 东北大学学报(自然科学版), 2024, 45(7): 921-927. |

| [7] | 刘俊汝, 张国华, 周国治. w(Fe)/w(Ni)对Mo2FeB2基金属陶瓷的影响[J]. 东北大学学报(自然科学版), 2023, 44(9): 1269-1278. |

| [8] | 陈洋洋, 孟凡一, 蔡景治, 苑春苗. 金属氧化物对镁粉尘层火蔓延的增强机制[J]. 东北大学学报(自然科学版), 2023, 44(12): 1778-1784. |

| [9] | 姬亚锋, 牛晶, 王晓军, 孙杰. 2205双相不锈钢变厚度轧制过程仿真分析[J]. 东北大学学报(自然科学版), 2022, 43(8): 1097-1105. |

| [10] | 温雪龙, 韩凤兵, 巩亚东, 黄雄俊. 沉积时间对真空离子镀TiC涂层微磨具表面性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(6): 857-863. |

| [11] | 刘建坡, 武峰, 王人, 张俊杰. 基于模糊综合评价的深部巷道破坏定量风险评估[J]. 东北大学学报(自然科学版), 2022, 43(5): 733-739. |

| [12] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [13] | 温雪龙, 李佳育, 李欣妍. TiC涂层微磨具磨削表面质量影响因素[J]. 东北大学学报(自然科学版), 2022, 43(4): 534-540. |

| [14] | 李英华, 吴纪国, 钱杰, 孙嘉茹. 单一及复合环境友好型淋洗剂修复铅污染土壤[J]. 东北大学学报(自然科学版), 2022, 43(1): 103-110. |

| [15] | 吴雅菊, 许开立, 王若菌, 徐晓虎. 高温熔融金属作业安全完整性评价[J]. 东北大学学报(自然科学版), 2021, 42(4): 576-581. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||