东北大学学报(自然科学版) ›› 2024, Vol. 45 ›› Issue (5): 675-682.DOI: 10.12068/j.issn.1005-3026.2024.05.009

• 机械工程 • 上一篇

黄贤振1,2, 于瑞1, 姜智元1, 荣治明3

收稿日期:2023-05-15

出版日期:2024-05-15

发布日期:2024-07-31

作者简介:黄贤振(1982-),男,山东定陶人,东北大学教授,博士生导师.

基金资助:Xian-zhen HUANG1,2, Rui YU1, Zhi-yuan JIANG1, Zhi-ming RONG3

Received:2023-05-15

Online:2024-05-15

Published:2024-07-31

摘要:

以数控机床电主轴为研究对象,旨在分析其轴向热伸长量对电主轴可靠性的影响.采用Svenska Kullager?Fabriken(SKF)摩擦力矩模型对轴承生热量进行分析,设定对流换热系数为边界散热条件,建立了热分析有限元耦合模型,求解电主轴的温度以及轴向热伸长分布.将有限元模型与实验结果进行对比,验证了建立的有限元模型的准确性.考虑随机因素的影响,建立电主轴热变形可靠性分析模型,并采用Kriging模型进行可靠性求解.对电主轴热误差可靠性全局灵敏度进行分析,结果表明,转速和冷却水流量对可靠度影响较大,轴向力和径向力对可靠度影响较小.

中图分类号:

黄贤振, 于瑞, 姜智元, 荣治明. 考虑热误差的电主轴建模与可靠性全局灵敏度分析[J]. 东北大学学报(自然科学版), 2024, 45(5): 675-682.

Xian-zhen HUANG, Rui YU, Zhi-yuan JIANG, Zhi-ming RONG. Modeling and Reliability Global Sensitivity Analysis of Motorized Spindles Considering Thermal Errors[J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 675-682.

| 介质名称 | 密度/(kg·m-3) | 运动黏度×10-6/(m2·s-1) | 普朗特数 | 导热系数/(W·(m·K)-1) |

|---|---|---|---|---|

| 20°冷却水 | 998.5 | 1.006 | 7.020 | 0.599 |

| 22°干空气 | 1.205 | 16.06 | 0.703 | 0.026 |

| ISO VG32 | — | 21 | — | — |

表1 冷却介质参数

Table 1 Cooling medium parameters

| 介质名称 | 密度/(kg·m-3) | 运动黏度×10-6/(m2·s-1) | 普朗特数 | 导热系数/(W·(m·K)-1) |

|---|---|---|---|---|

| 20°冷却水 | 998.5 | 1.006 | 7.020 | 0.599 |

| 22°干空气 | 1.205 | 16.06 | 0.703 | 0.026 |

| ISO VG32 | — | 21 | — | — |

| 部件 | 材料名称 | 密度×103 | 导热系数 | 弹性模量×105 | 泊松比 | 线膨胀系数×10-5 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg·m-3 | W·(m·K)-1 | MPa | ℃-1 | |||||||||||

| 外壳 | HT300 | 7.35 | 50 | 2.1 | 0.32 | 1.22 | ||||||||

| 轴承内、外圈 | GCr15 | 7.83 | 42 | 2.09 | 0.32 | 1.28 | ||||||||

| 滚珠 | Si3N4 | 3.25 | 29.5 | 3.2 | 0.27 | 0.322 | ||||||||

| 定子、转子 | 硅钢 | 7.70 | 12.9 | 2.0 | 0.26 | 1.28 | ||||||||

| 转轴 | 20CrMo | 7.84 | 50 | 2.1 | 0.28 | 1.35 | ||||||||

| 轴环、挡圈 | 1045 | 7.81 | 48.15 | 2.1 | 0.30 | 1.18 | ||||||||

表2 电主轴材料参数

Table 2 Material parameters of the motorized spindle

| 部件 | 材料名称 | 密度×103 | 导热系数 | 弹性模量×105 | 泊松比 | 线膨胀系数×10-5 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg·m-3 | W·(m·K)-1 | MPa | ℃-1 | |||||||||||

| 外壳 | HT300 | 7.35 | 50 | 2.1 | 0.32 | 1.22 | ||||||||

| 轴承内、外圈 | GCr15 | 7.83 | 42 | 2.09 | 0.32 | 1.28 | ||||||||

| 滚珠 | Si3N4 | 3.25 | 29.5 | 3.2 | 0.27 | 0.322 | ||||||||

| 定子、转子 | 硅钢 | 7.70 | 12.9 | 2.0 | 0.26 | 1.28 | ||||||||

| 转轴 | 20CrMo | 7.84 | 50 | 2.1 | 0.28 | 1.35 | ||||||||

| 轴环、挡圈 | 1045 | 7.81 | 48.15 | 2.1 | 0.30 | 1.18 | ||||||||

| 随机变量 | 转速 | 冷却水流量 | 轴向力 | 径向力 |

|---|---|---|---|---|

| r·min-1 | kg·s-1 | N | N | |

| 均值 | 60 000 | 0.167 | 350 | 300 |

| 变异系数 | 0.002 | 0.02 | 0.05 | 0.05 |

表3 随机参数分布

Table 3 Random parameter distribution

| 随机变量 | 转速 | 冷却水流量 | 轴向力 | 径向力 |

|---|---|---|---|---|

| r·min-1 | kg·s-1 | N | N | |

| 均值 | 60 000 | 0.167 | 350 | 300 |

| 变异系数 | 0.002 | 0.02 | 0.05 | 0.05 |

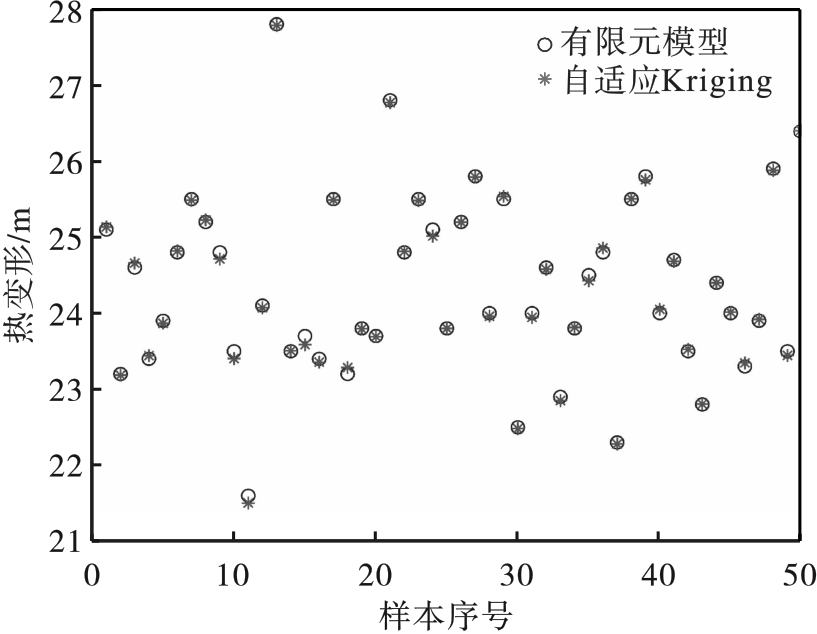

图8 热变形有限元模型计算值与Kriging计算值对比

Fig.8 Comparison between the calculated values of the hot deformation finite element model and the Kriging calculation values

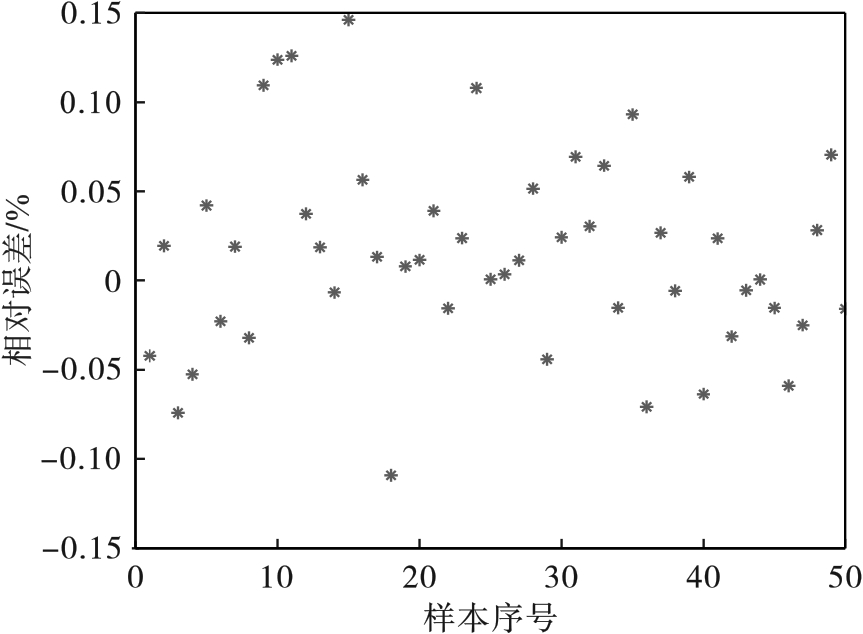

图9 热变形有限元模型计算值与Kriging计算值相对误差

Fig.9 Relative error between the calculated values of the hot deformation finite element model and the Kriging calculation values

| 1 | Aalilija A, Gandin CA, Hachem E.A simple and efficient numerical model for thermal contact resistance based on diffuse interface immersed boundary method[J].International Journal of Thermal Sciences,2021,166:106817. |

| 2 | Mayr J, Jedrzejewski J, Uhlmann E,et al.Thermal issues in machine tools[J].CIRP Annals-Manufacturing Technology,2012,61(2):771-791. |

| 3 | Cao H R, Zhang X W, Chen X F.The concept and progress of intelligent spindles:a review[J].International Journal of Machine Tools and Manufacture,2017,112:21-52. |

| 4 | Zhang L L, Xuan J P, Shi T L,et al.Robust,fractal theory,and FEM‑based temperature field analysis for machine tool spindle[J].The International Journal of Advanced Manufacturing Technology,2020,111(5/6):1571-1586. |

| 5 | Fang B, Cheng M N, Gu T Q,et al.An improved thermal performance modeling for high‑speed spindle of machine tool based on thermal contact resistance analysis[J].The International Journal of Advanced Manufacturing Technology,2022,120(7):5259-5268. |

| 6 | Ma C, Yang J, Zhao L,et al.Simulation and experimental study on the thermally induced deformations of high‑speed spindle system[J].Applied Thermal Engineering,2015,86:251-268. |

| 7 | Yao X P, Hu T, Yin G F,et al.Thermal error modeling and prediction analysis based on OM algorithm for machine tool’s spindle[J]. The International Journal of Advanced Manufacturing Technology,2020,106(7):3345–3356. |

| 8 | Liu K, Li T, Li T J,et al.Thermal behavior analysis of horizontal CNC lathe spindle and compensation for radial thermal drift error[J].The International Journal of Advanced Manufacturing Technology,2018,95(1):1293-1301. |

| 9 | Zhang L X, Gong W J, Zhang K,et al.Thermal deformation prediction of high‑speed motorized spindle based on biogeography optimization algorithm[J].The International Journal of Advanced Manufacturing Technology,2018,97(5):3141-3151. |

| 10 | Lee J, Kim D H, Lee C M.A study on the thermal characteristics and experiments of high‑speed spindle for machine tools[J].International Journal of Precision Engineering and Manufacturing,2015,16(2):293-299. |

| 11 | Harris T A, Kotzalas M N.Essential Concepts of Bearing Technology[M],5th ed.New York:CRC Press,2007. |

| 12 | Liu J L, Ma C, Wang S L,et al.Thermal‑structure interaction characteristics of a high‑speed spindle‑bearing system[J].International Journal of Machine Tools and Manufacture,2019,137:42-57. |

| 13 | Kullager‑Fabriken Svenska.Rolling bearings catalogue[EB/OL].(2018-10-12)[2022-03-24].. |

| 14 | 张雪亮.新型高速电主轴轴承-轴芯热场分布规律与实验研究[D].哈尔滨:哈尔滨理工大学,2019. |

| Zhang Xue‑liang.Distribution law and experimental study of heat field new high‑speed motorized spindle bearing‑spindle core [D].Harbin:Harbin University of Science and Technology,2019. | |

| 15 | Jiang Z Y, Huang X Z, Chang M X,et al.Thermal error prediction and reliability sensitivity analysis of motorized spindle based on Kriging model[J].Engineering Failure Analysis,2021,127:105558. |

| 16 | Yan B, Yan K, Luo T,et al.Thermal coefficients modification of high speed ball bearing by multi‑object optimization method[J].International Journal of Thermal Sciences,2019,137:313-324. |

| 17 | 崔向昆.高速电主轴温度分布及其热位移研究[D].沈阳:沈阳建筑大学,2018. |

| Cui Xiang‑kun.Research on temperature distribution and thermal displacement of high speed spindle[D].Shenyang:Shenyang Jianzhu University,2018. | |

| 18 | Chien C H, Jang J Y.3‑D numerical and experimental analysis of a built‑in motorized high‑speed spindle with helical water cooling channel[J].Applied Thermal Engineering,2008,28(17/18):2327-2336. |

| 19 | 黄贤振,曹辉,张义民.基于蒙特卡罗方法的直角切削切削力概率特性分析[J].东北大学学报(自然科学版),2015,36(2):254-258. |

| Huang Xian‑zhen, Cao Hui, Zhang Yi‑min.Probabilistic analysis of cutting force in orthogonal cutting based on using Monte‑Carlo method[J].Journal of Northeastern University (Natural Science),2015,36(2):254-258. | |

| 20 | Ding P F, Huang X Z, Li Y X,et al.Reliability optimization of cutting parameters considering the diameter error of slender shaft[J].Journal of Mechanical Science and Technology,2021,35(10):4673-4683. |

| 21 | Liu H Z, Huang X Z, Yan M,et al.Dynamic response and time-variant reliability analysis of an eight‑rod shock isolator[J].Proceedings of the Institution of Mechanical Engineers,Part C:Journal of Mechanical Engineering Science,2022,236(13):7041-7054. |

| 22 | 吕震宙,宋述芳,李璐祎,等.结构/机构可靠性设计基础[M],西安:西北工业大学出版社,2019. |

| Zhen‑zhou Lyu, Song Shu‑fang, Li Lu‑yi,et al.Reliability sensitivity analysis of angular contact ball bearing skidding[M],Xi 'an:Northwestern Polytechnical University Press,2019. | |

| 23 | Cui L J, Lu Z Z, Zhao X P.Moment‑independent importance measure of basic random variable and its probability density evolution solution[J].Science China Technological Sciences,2010,53(4):1138-1145. |

| 24 | 黄贤振,朱会彬,姜智元 等.角接触球轴承打滑可靠性灵敏度分析[J].东北大学学报(自然科学版),2021,42(12):1731-1738. |

| Huang Xian‑zhen, Zhu Hui‑bin, Jiang Zhi‑yuan,et al.Fundamental of structure and mechanism reliability design[J].Journal of Northeastern University(Natural Science),2021,42(12):1731-1738. |

| [1] | 高海洋, 王连广, 陈百玲. 轴压下FRP管-混凝土-钢管组合柱可靠性分析[J]. 东北大学学报(自然科学版), 2024, 45(3): 430-438. |

| [2] | 黄贤振, 孙超, 赵成英, 刘洋. 基于改进阿林斯法的数控机床子系统可靠性分配[J]. 东北大学学报(自然科学版), 2024, 45(2): 226-233. |

| [3] | 胡兵, 黄贤振, 杜姗珊. 风电轴承疲劳寿命的可靠性灵敏度分析[J]. 东北大学学报(自然科学版), 2023, 44(8): 1128-1135. |

| [4] | 张东祥, 张弛, 范威, 郭立新. 人工锥体的尺寸对颈椎力学特性的影响[J]. 东北大学学报(自然科学版), 2023, 44(8): 1136-1143. |

| [5] | 黄贤振, 栾晓刚, 朱丽莎, 刘慧珍. 基于双向流固耦合的锥阀阀芯位移可靠性分析[J]. 东北大学学报(自然科学版), 2023, 44(5): 667-673. |

| [6] | 黄贤振, 张安星, 孙楷铂. 打磨机器人的打磨头螺栓组系统可靠性分析[J]. 东北大学学报(自然科学版), 2023, 44(12): 1712-1719. |

| [7] | 查从燚, 孙志礼, 潘陈蓉, 王健. 面向结构可靠性分析的并行自适应加点策略[J]. 东北大学学报(自然科学版), 2023, 44(1): 76-82. |

| [8] | 安国青, 王蕊, 赵晖, 李铁英. 双钢板混凝土组合板在撞击荷载下的动力响应[J]. 东北大学学报(自然科学版), 2022, 43(8): 1192-1200. |

| [9] | 黄贤振, 孙良仕, 丁鹏飞, 朱会彬. 基于可靠性的GH4169车削参数优化[J]. 东北大学学报(自然科学版), 2022, 43(5): 696-702. |

| [10] | 王连广, 蒙玉琪, 王梓晴. 预制压型钢板混凝土组合板和钢梁连接及其有限元分析[J]. 东北大学学报(自然科学版), 2022, 43(4): 575-581. |

| [11] | 陈小辉, 张珩, 刘明月, 侯东晓. 开孔碳纤维复合材料层合板的拉伸失效有限元分析[J]. 东北大学学报(自然科学版), 2022, 43(3): 397-403. |

| [12] | 杨周, 朴银成 , 权哲优. 盘式制动器热-机耦合渐变可靠性灵敏度分析[J]. 东北大学学报(自然科学版), 2022, 43(1): 48-56. |

| [13] | 金海哲, 朱琳, 李怡, 傅全威. 基于改进FMEA的医疗器械人因可靠性评估与应用[J]. 东北大学学报(自然科学版), 2021, 42(9): 1360-1368. |

| [14] | 曹汝男, 孙志礼, 郭凡逸, 王健. 基于Kriging和Monte Carlo的动态可靠性算法[J]. 东北大学学报(自然科学版), 2021, 42(5): 658-664. |

| [15] | 丁鹏飞, 王昌利, 黄贤振, 李禹雄. 细长轴车削加工误差可靠性灵敏度分析[J]. 东北大学学报(自然科学版), 2021, 42(5): 693-699. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||