东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (2): 96-103.DOI: 10.12068/j.issn.1005-3026.2025.20230253

收稿日期:2023-11-21

出版日期:2025-02-15

发布日期:2025-05-20

通讯作者:

孙瑶

作者简介:孙 瑶(1990—),女,辽宁锦州人,东北大学副教授.

基金资助:

Yao SUN( ), Jun-yi DONG, Ben-jia TANG, Si-hui LI

), Jun-yi DONG, Ben-jia TANG, Si-hui LI

Received:2023-11-21

Online:2025-02-15

Published:2025-05-20

Contact:

Yao SUN

摘要:

以电火花加工(EDM)P型单晶硅为实验对象,探究单晶硅加工表面的形貌特征及微观放电凹坑特性,揭示电火花加工单晶硅的材料去除机理,即应力蚀除作用大于熔化和气化蚀除作用.开展单晶硅微槽和微孔的加工工艺实验研究,探究电火花加工单晶硅微结构的成形精度、尺寸偏差、截面轮廓起伏高度和表面质量,揭示主要加工参数对电火花加工单晶硅的材料去除率、表面形貌、表面粗糙度的影响规律.

中图分类号:

孙瑶, 董俊逸, 唐本甲, 李思慧. 电火花加工单晶硅微结构的表面质量及成形精度[J]. 东北大学学报(自然科学版), 2025, 46(2): 96-103.

Yao SUN, Jun-yi DONG, Ben-jia TANG, Si-hui LI. Surface Quality and Forming Accuracy of Monocrystalline Silicon Microstructures by Electrical Discharge Machining[J]. Journal of Northeastern University(Natural Science), 2025, 46(2): 96-103.

| 因素 | 水平 | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Ip/A | 40 | 110 | 230 | 320 |

| Ton/μs | 4 | 6 | 13 | 15 |

| Fw/N | 9 | 12 | 15 | 16 |

表1 单晶硅微槽加工因素和水平

Table 1 Factors and levels for micro-groove of the monocrystalline silicon

| 因素 | 水平 | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Ip/A | 40 | 110 | 230 | 320 |

| Ton/μs | 4 | 6 | 13 | 15 |

| Fw/N | 9 | 12 | 15 | 16 |

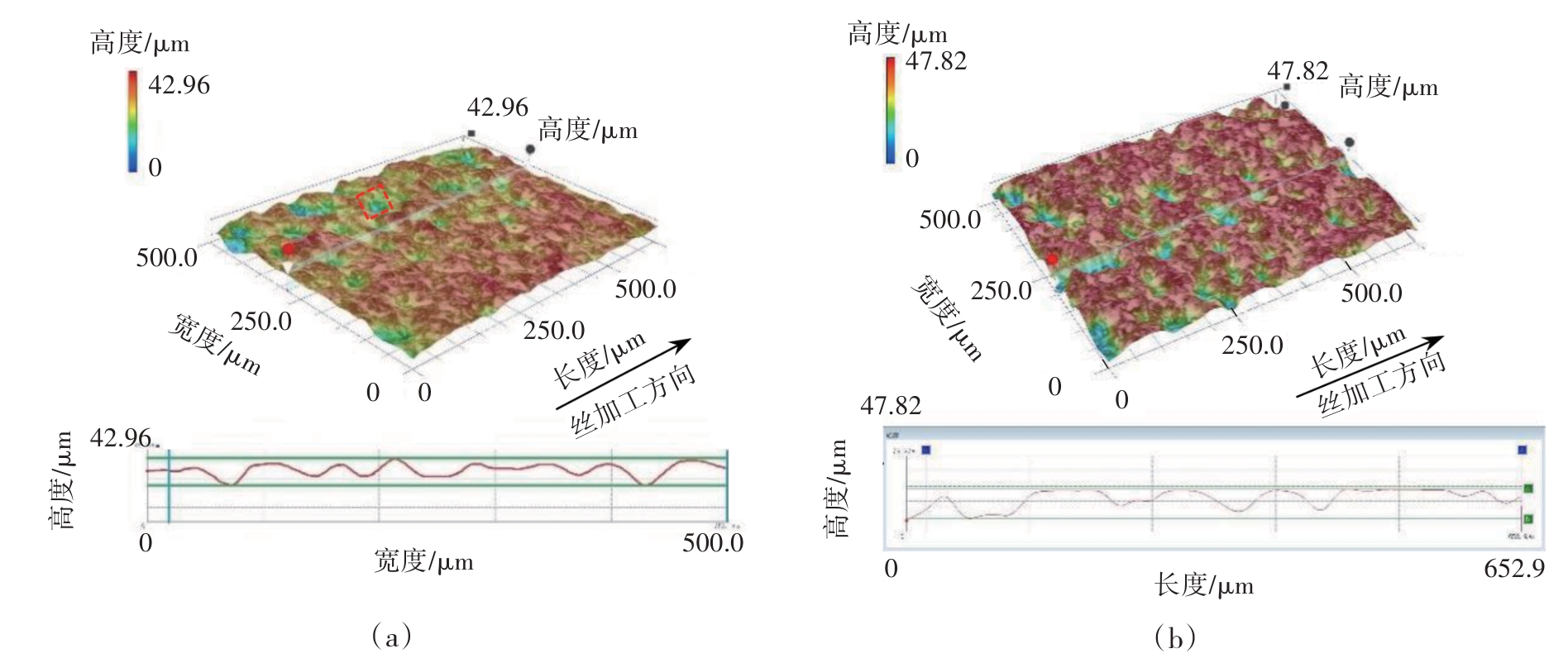

图4 不同峰值电流下单晶硅低速走丝电火花加工表面形貌(a)—Ip=230 A;(b)—Ip=320 A.

Fig. 4 Surface morphology of the monocrystalline silicon machined by low-speed wire EDM with various Ip

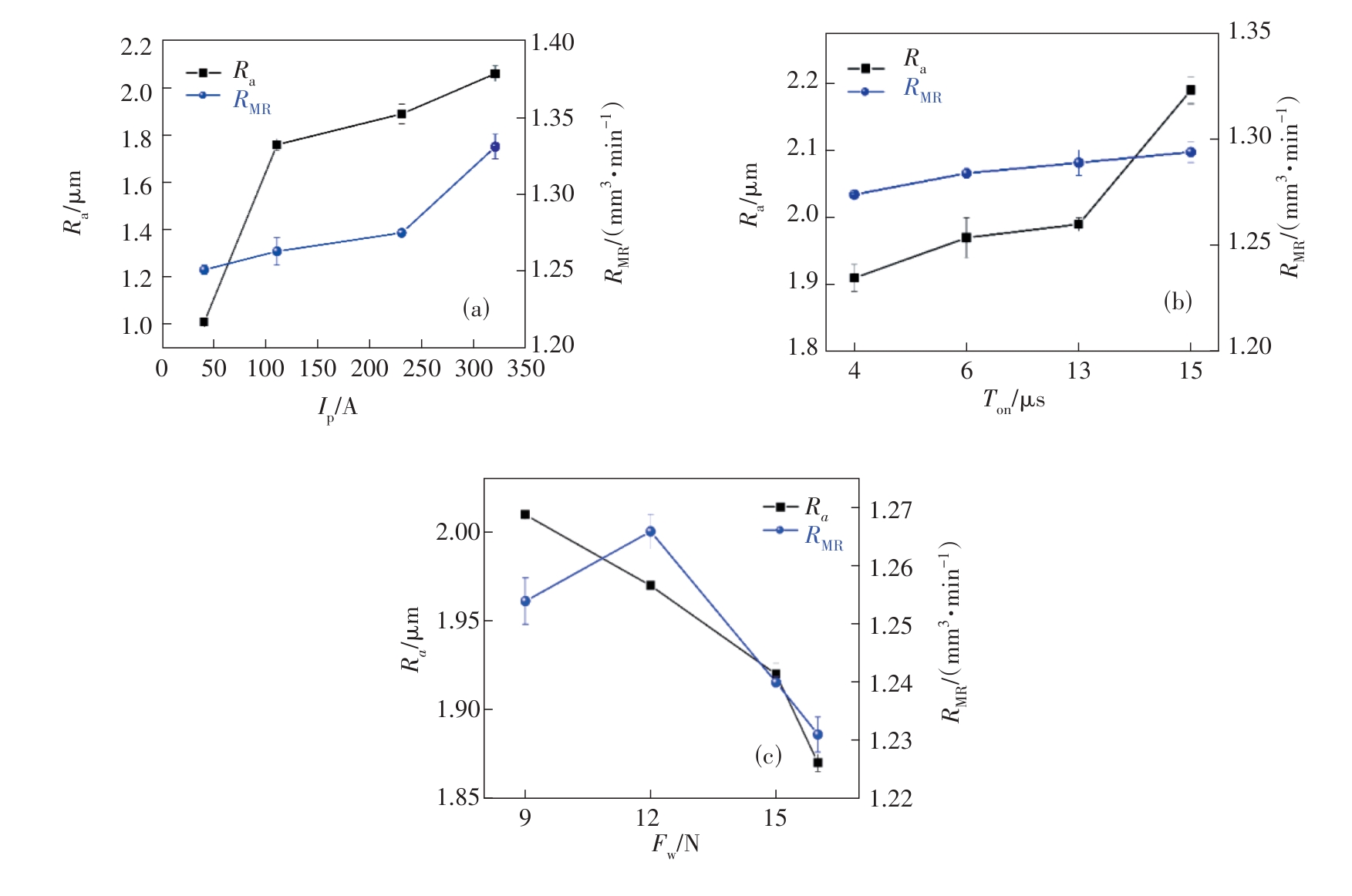

图6 单晶硅低速走丝电火花线切割加工表面粗糙度和材料去除率(a)—峰值电流对Ra和RMR的影响;(b)—脉冲宽度对Ra和RMR的影响;(c)—电极丝张力对Ra和RMR的影响.

Fig. 6 Ra and RMR of the monocrystalline silicon machined by LS-WEDM

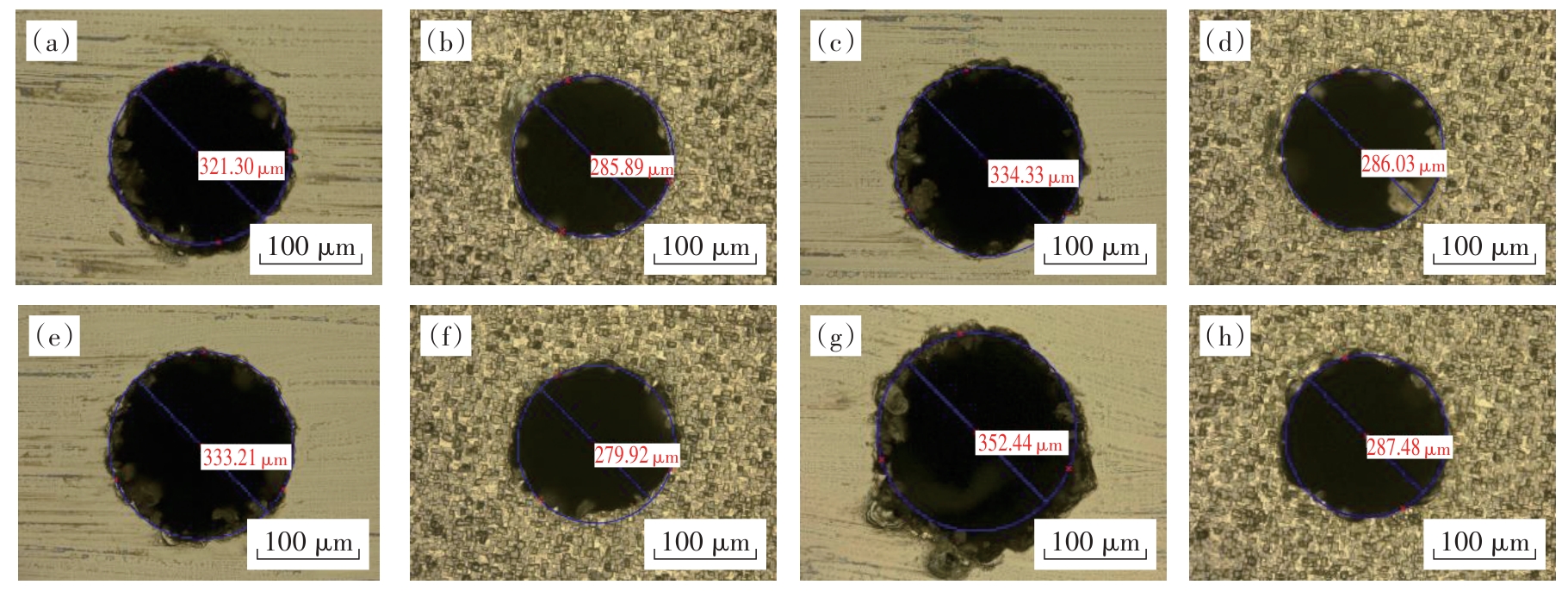

图7 电火花加工单晶硅微孔的出入口形貌(a)—第1个孔入口;(b)—第1个孔出口;(c)—第5个孔入口;(d)—第5个孔出口;(e)—第15个孔入口;(f)—第15个孔出口;(g)—第30个孔入口;(h)—第30个孔出口.

Fig. 7 Inlet and outlet morphology of the monocrystalline silicon micro-hole machined by EDM

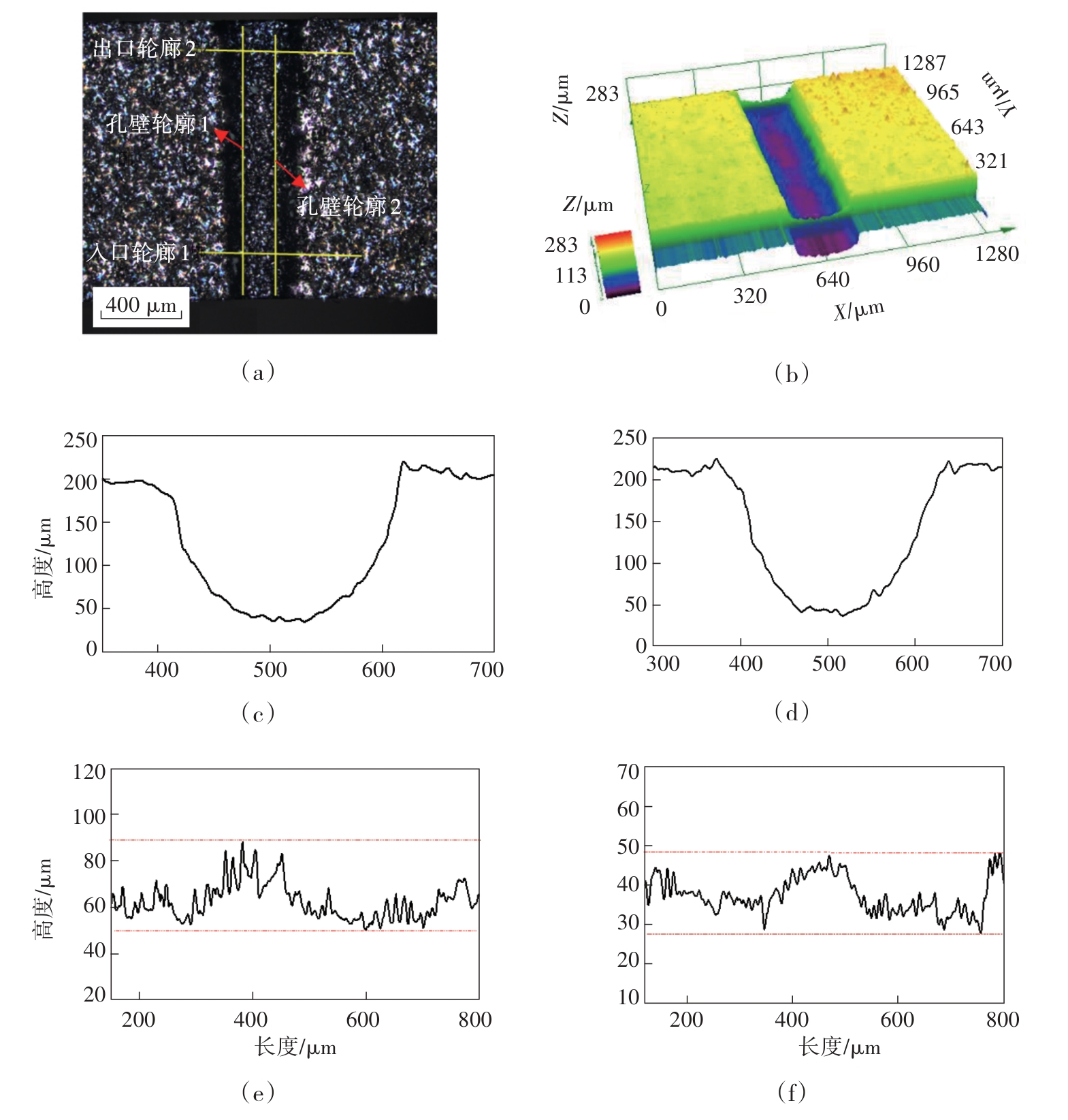

图10 电火花加工单晶硅微孔剖面轮廓和三维形貌(a)—加工后的形貌;(b)—孔1的入口形貌;(c)—轮廓1入口截面;(d)—轮廓2出口截面;(e)—轮廓1孔壁截面;(f)—轮廓2孔壁截面.

Fig. 10 Cross-sectional profiles and three-dimensional surface of the micro-holes on the monocrystalline silicon machined by EDM

| 1 | Wang X Z, Yi S, Easton M, et al. Active gap capacitance electrical discharge machining of polycrystalline diamond[J]. Journal of Materials Processing Technology, 2020, 280: 116598. |

| 2 | Sun Y, Gong Y D, Wen X L, et al. Micro milling characteristics of LS-WEDM fabricated helical and corrugated micro end mill[J]. International Journal of Mechanical Sciences, 2020, 167: 105277. |

| 3 | Coelho F, Koshy P. Vibration damping capability of electrical discharge machined surfaces: characteristics, mechanism and application[J]. International Journal of Machine Tools and Manufacture, 2022, 177: 103888. |

| 4 | Bangash M K, Casalegno V, Kumar D A, et al. Surface machining of Ti6Al4V by means of micro-electrical discharging to improve adhesive joining[J]. Journal of Materials Processing Technology, 2020, 286: 116813. |

| 5 | Kuriachen B, Varghese A, Somashekhar K P, et al. Three-dimensional numerical simulation of microelectric discharge machining of Ti-6Al-4V[J]. The International Journal of Advanced Manufacturing Technology, 2015, 79: 147-160. |

| 6 | Li G D, Natsu W, Yu Z Y. Elucidation of the mechanism of the deteriorating interelectrode environment in micro EDM drilling[J]. International Journal of Machine Tools and Manufacture, 2021, 167: 103747. |

| 7 | Hosseini E, Rehman S, Alimoradi A. Surface integrity of fatigue strength of nickel based super alloy in turning by wire electrical discharge process[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2022, 236(3): 135-145. |

| 8 | 高连, 刘志东, 邱明波, 等. 电火花线切割单晶硅的损伤层[J]. 硅酸盐学报, 2011,39(5): 874-879. |

| Gao Lian, Liu Zhi-dong, Qiu Ming-bo, et al. Damaged layer of monocrystalline silicon cut by wire electrical discharge machining[J]. Journal of the Chinese Ceramic Society, 2011, 39(5): 874-879. | |

| 9 | Xu B, Feng T, Wu X Y, et al. Micro-EDM of micro-stepped hole based on the wear of micro-bit[J]. Materials and Manufacturing Processes, 2022, 37(3): 349-358. |

| 10 | Barman S, Hanumaiah N, Puri A B. Investigation on shape, size, surface quality and elemental characterization of high-aspect-ratio blind micro holes in die sinking micro EDM[J]. The International Journal of Advanced Manufacturing Technology, 2015, 76: 115-126. |

| 11 | Liu Q Y, Zhang Q H, Zhang M, et al. Effects of surface layer of AISI 304 on micro EDM performance[J]. Precision Engineering, 2019, 57: 195-202. |

| 12 | Bellotti M, Qian J, Reynaerts D. Enhancement of the micro-EDM process for drilling through-holes[J]. Procedia CIRP, 2018, 68: 610-615. |

| 13 | Tiwary A P, Pradhan B B, Bhattacharyya B. Investigation on the effect of dielectrics during micro-electro-discharge machining of Ti-6Al-4V[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95: 861-874. |

| 14 | Tamang S K, Natarajan N, Chandrasekaran M. Optimization of EDM process in machining micro holes for improvement of hole quality[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2017, 39(4): 1277-1287. |

| 15 | Kuriakose S, Patowari P K, Bhatt J. Effect of micro-EDM machining parameters on the accuracy of micro hole drilling in Zr-based metallic glass[J]. Engineering Research Express, 2020, 2(1): 015001. |

| 16 | 路雄, 李淑娟, 辛彬, 等. 单晶硅的电火花线切割过程建模与控制[J]. 机械工程学报, 2018,54(17): 149-156. |

| Lu Xiong, Li Shu-juan, Xin Bin, et al. Modeling and control of WEDM process of silicon single crystal[J]. Journal of Mechanical Engineering, 2018, 54(17): 149-156. | |

| 17 | 葛培琪, 陈自彬, 王沛志. 单晶硅切片加工技术研究进展[J]. 金刚石与磨料磨具工程, 2020,40(4): 12-18. |

| Ge Pei-qi, Chen Zi-bin, Wang Pei-zhi. Review of monocrystalline silicon slicing technology[J]. Diamond & Abrasives Engineering, 2020, 40(4): 12-18. | |

| 18 | 周云光, 巩亚东, 高奇, 等. 单晶硅微尺度侧磨表面质量影响因素试验研究[J]. 东北大学学报(自然科学版), 2017, 38(7): 983-988. |

| Zhou Yun-guang, Gong Ya-dong, Gao Qi, et al. Experimental study on influencing factor of surface quality in micro side grinding of single crystal silicon[J]. Journal of Northeastern University (Natural Science), 2017, 38(7): 983-988. | |

| 19 | Sun Z W, To S, Yu K M. Feasibility investigation on ductile machining of single-crystal silicon for deep micro-structures by ultra-precision fly cutting[J]. Journal of Manufacturing Processes, 2019, 45: 176-187. |

| [1] | 李远峰, 温泉, 巩亚东, 唐本甲. 2.5D Cf /SiC复合材料微尺度磨削试验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1143-1149. |

| [2] | 杨震宇, 邹平, 周亮, 王安琪. 单颗CBN磨粒超声振动辅助磨削AISI 304材料去除机理[J]. 东北大学学报(自然科学版), 2024, 45(7): 1011-1019. |

| [3] | 代峰, 柳静献. 钢铁企业除尘用涤纶滤料在复杂烟气环境下的老化行为分析[J]. 东北大学学报(自然科学版), 2024, 45(6): 883-889. |

| [4] | 乔冠尧, 徐嘉忆, 赵春雨. 基于运动误差的3-D表面形貌检测方法[J]. 东北大学学报(自然科学版), 2024, 45(12): 1726-1733. |

| [5] | 张家豪, 邹平, 魏事宇, 梁付强. 单激励三维超声车削加工技术的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1152-1159. |

| [6] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [7] | 温雪龙, 李佳育, 李欣妍. TiC涂层微磨具磨削表面质量影响因素[J]. 东北大学学报(自然科学版), 2022, 43(4): 534-540. |

| [8] | 赵春雨, 程大众, 耿浩博. 车削工件2-D表面形貌检测方法研究[J]. 东北大学学报(自然科学版), 2021, 42(9): 1299-1306. |

| [9] | 侯壮壮, 修世超, 王雨时, 姚云龙. 不锈钢材料预应力磨削表面耐蚀性能数值模拟[J]. 东北大学学报(自然科学版), 2021, 42(7): 972-979. |

| [10] | 巩亚东, 金丽雅, 孙瑶, 苏志朋. 低速WEDM制备的微织构螺旋微铣刀的铣削实验研究[J]. 东北大学学报:自然科学版, 2020, 41(8): 1111-1115. |

| [11] | 屈硕硕, 巩亚东, 杨玉莹, 舍跃斌. 2.5D Cf/SiC复合材料磨削工艺试验研究[J]. 东北大学学报:自然科学版, 2020, 41(2): 252-257. |

| [12] | 温雪龙, 于兴晨, 巩亚东, 孟凡涛. FeCoNiCrMo高熵合金磨削机理及表面粗糙度[J]. 东北大学学报:自然科学版, 2020, 41(2): 246-251. |

| [13] | 徐辑林, 邹平, 王文杰, 杨旭磊. 基于烧蚀原理的激光抛光的数值建模与分析[J]. 东北大学学报:自然科学版, 2020, 41(12): 1760-1766. |

| [14] | 巩亚东, 孟凡涛, 孙瑶, 于兴晨. 镍基单晶高温合金的微孔加工对比实验研究[J]. 东北大学学报:自然科学版, 2020, 41(1): 84-89. |

| [15] | 赵绪峰, 于天彪, 李长河, 王宛山. 纳米MoS2含量对纳米微量润滑磨削CFRPs的影响[J]. 东北大学学报:自然科学版, 2019, 40(8): 1127-1131. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||