东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (9): 119-125.DOI: 10.12068/j.issn.1005-3026.2025.20240016

收稿日期:2024-01-17

出版日期:2025-09-15

发布日期:2025-12-03

通讯作者:

张通

作者简介:陈 猛(1981—),男,辽宁开原人,东北大学副教授,博士.

基金资助:

Meng CHEN1, Fu-cheng LIU1, Tong ZHANG1( ), Di WU2

), Di WU2

Received:2024-01-17

Online:2025-09-15

Published:2025-12-03

Contact:

Tong ZHANG

摘要:

为探究再生细骨料(RFA)对超高韧性水泥基复合材料(UHTCC)工作性能和力学性能的影响规律,对RFA替代石英砂比率分别为0,25%,50%,75%和100%的UHTCC进行了流动性、抗压和单轴抗拉试验.结果表明:RFA替代率对UHTCC流动度影响不显著;UHTCC抗压强度和单轴抗拉强度均随RFA替代率的增加而降低,当RFA替代率达到50%后下降幅度增大,分别比全石英砂骨料时下降了13.9%~19.9%和11.3%~16.7%;直拉作用下UHTCC极限应变和裂缝数量随RFA替代率的增加而增加,当RFA替代率达到50%后,极限应变比全石英砂骨料时提升了27.2%~40.9%,试件逐渐呈现“饱和”细密多裂缝的破坏状态.微观结构分析表明,RFA替代率的增加有利于PVA纤维从UHTCC基体中拔出,纤维桥连裂缝作用增强.

中图分类号:

陈猛, 刘富成, 张通, 吴迪. 再生细骨料UHTCC力学性能及作用机理[J]. 东北大学学报(自然科学版), 2025, 46(9): 119-125.

Meng CHEN, Fu-cheng LIU, Tong ZHANG, Di WU. Mechanical Properties and Working Mechanism of UHTCC with Recycled Fine Aggregate[J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 119-125.

| 长度 | 直径 | 抗拉强度 | 弹性模量 | 密度 |

|---|---|---|---|---|

| mm | μm | MPa | GPa | kg·m-3 |

| 12 | 39 | 1 600 | 40 | 1 300 |

表1 PVA纤维物理性能

Table 1 Physical properties of PVA fibers

| 长度 | 直径 | 抗拉强度 | 弹性模量 | 密度 |

|---|---|---|---|---|

| mm | μm | MPa | GPa | kg·m-3 |

| 12 | 39 | 1 600 | 40 | 1 300 |

| 编号 | 水泥 | 粉煤灰 | 石英砂 | RFA | 水 | 减水剂 | PVA纤维 |

|---|---|---|---|---|---|---|---|

| S100R0 | 544 | 653 | 435 | 0 | 335 | 14 | 26 |

| S75R25 | 544 | 653 | 326 | 109 | 335 | 14 | 26 |

| S50R50 | 544 | 653 | 218 | 218 | 335 | 14 | 26 |

| S25R75 | 544 | 653 | 109 | 326 | 335 | 14 | 26 |

| S0R100 | 544 | 653 | 0 | 435 | 335 | 14 | 26 |

表2 UHTCC配合比 (kg/m3)

Table 2 Mix proportions of UHTCC

| 编号 | 水泥 | 粉煤灰 | 石英砂 | RFA | 水 | 减水剂 | PVA纤维 |

|---|---|---|---|---|---|---|---|

| S100R0 | 544 | 653 | 435 | 0 | 335 | 14 | 26 |

| S75R25 | 544 | 653 | 326 | 109 | 335 | 14 | 26 |

| S50R50 | 544 | 653 | 218 | 218 | 335 | 14 | 26 |

| S25R75 | 544 | 653 | 109 | 326 | 335 | 14 | 26 |

| S0R100 | 544 | 653 | 0 | 435 | 335 | 14 | 26 |

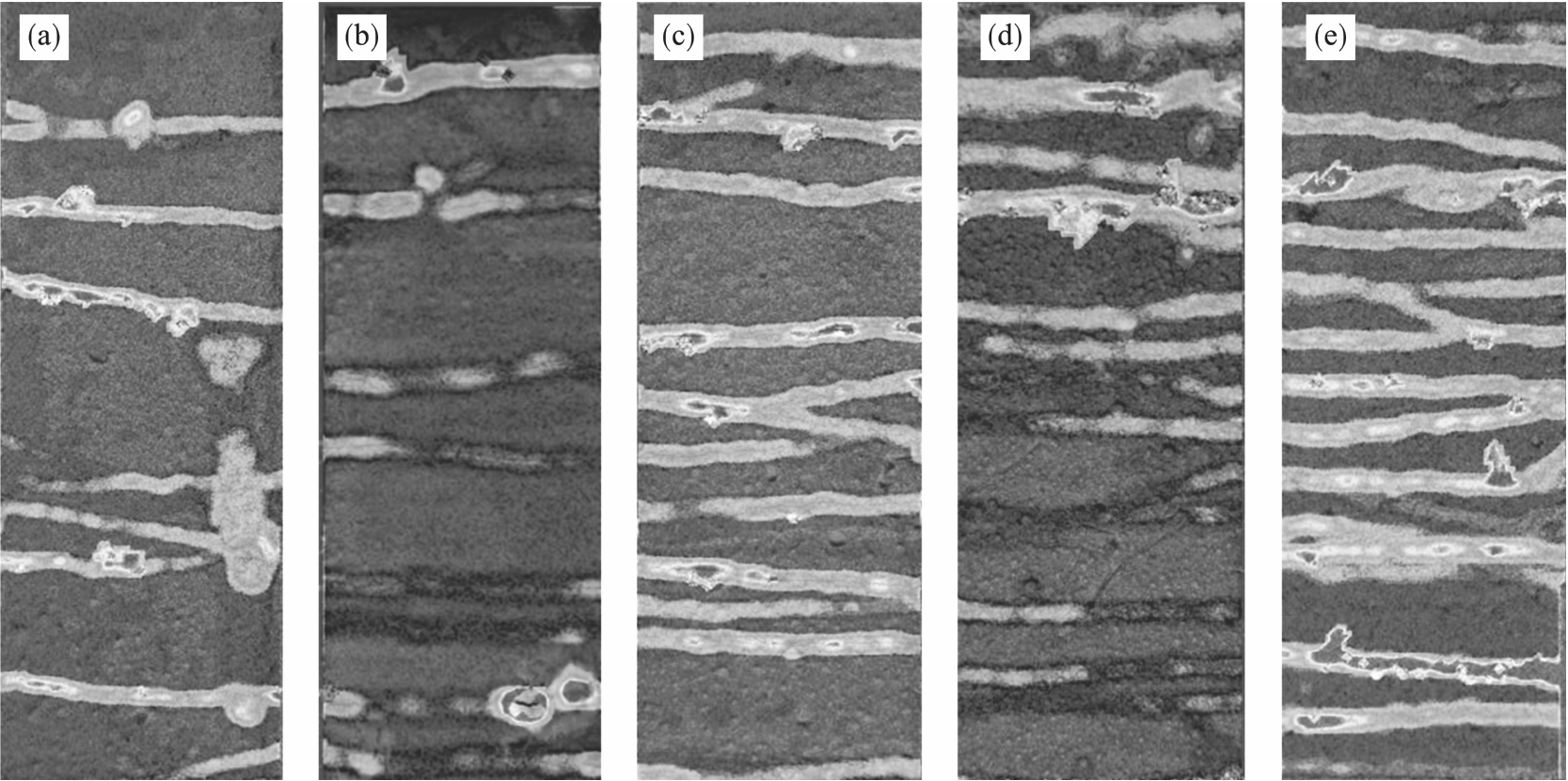

图8 UHTCC裂缝分布随RFA替代率的变化(a)—S100R0; (b)—S75R25; (c)—S50R50; (d)—S25R75; (e)—S0R100.

Fig.8 Variation of RFA replacement ratio on crack distribution of UHTCC

| [1] | 徐世烺, 李贺东. 超高韧性水泥基复合材料直接拉伸试验研究[J]. 土木工程学报, 2009, 42(9): 32-41. |

| Xu Shi-lang, Li He-dong. Uniaxial tensile experiments of ultra-high toughness cementitious composite[J]. China Civil Engineering Journal, 2009, 42(9): 32-41. | |

| [2] | Li V C. Engineered cementitious composites (UHTCC): bendable concrete for sustainable and resilient infrastructure[M].Germany: Springer, 2019: 1-15. |

| [3] | 肖建庄,叶涛华,隋同波,等. 废弃混凝土再生微粉的基本问题及应用[J].材料导报, 2023, 37(10):5-14. |

| Xiao Jian-zhuang, Ye Tao-hua, Sui Tong-bo, et al. Fundamental problems and applications of recycled fine powder derived from waste concrete[J]. Materials Reports, 2023, 37(10): 5-14. | |

| [4] | Duan Z H, Hou S D, Xiao J Z, et al. Study on the essential properties of recycled powders from construction and demolition waste[J]. Journal of Cleaner Production, 2020, 253: 119865. |

| [5] | Cuenca-Moyano G M, Martín-Pascual J, Martín-Morales M, et al. Effects of water to cement ratio, recycled fine aggregate and air entraining/plasticizer admixture on masonry mortar properties[J]. Construction and Building Materials, 2020, 230: 116929. |

| [6] | Ju M, Park K, Park W J. Mechanical behavior of recycled fine aggregate concrete with high slump property in normal- and high-strength[J]. International Journal of Concrete Structures and Materials, 2019, 14(1): 109-121. |

| [7] | Bai M Y, Wu Y C, Xiao J Z, et al. Workability and hardened properties of 3D printed engineered cementitious composites incorporating recycled sand and PE fibers[J]. Journal of Building Engineering, 2023, 71: 106477. |

| [8] | 曹明莉, 许玲, 张聪. 高延性纤维增强水泥基复合材料的微观力学设计、性能及发展趋势[J]. 硅酸盐学报, 2015, 43(5): 632-642. |

| Cao Ming-li, Xu Ling, Zhang Cong. Review on micromechanical design, performance and development tendency of engineered cementitious composite[J]. Journal of the Chinese Ceramic Society, 2015, 43(5): 632-642. | |

| [9] | Yokota H, Rokugo K, Sakata N. Recommendations for design and construction of high performance fiber reinforced cement composite with multiple fine cracks (HPFRCC)[J]. Japan Society of Civil Engineers, 2008, 82: 6-10. |

| [10] | Lotfy A, Al-Fayez M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate[J]. Cement and Concrete Composites, 2015, 61: 36-43. |

| [11] | Leite M B, Figueire do Filho J G L, Lima P R L. Workability study of concretes made with recycled mortar aggregate[J]. Materials and Structures, 2013, 46(10): 1765-1778. |

| [12] | 杜婷 .高性能再生混凝土微观结构及性能试验研究[D].武汉:华中科技大学,2006. |

| Du Ting. Experimental study on the microstructure and basic behaviors of recycled high performance concrete[D]. Wuhan: Huazhong University of Science and Technology, 2006. | |

| [13] | Wang X J, Wu Y J, Zhu P H, et al. Improvement of mechanical properties and carbonation durability of recycled fine aggregate engineered cementitious composites for structural strengthening[J]. Journal of Building Engineering, 2023, 76: 107277. |

| [14] | Liu J, Ma K L, Shen J B, et al. Influence of recycled concrete aggregate enhancement methods on the change of microstructure of ITZs in recycled aggregate concrete[J]. Construction and Building Materials, 2023, 371: 130772. |

| [15] | 闫增辉. 低温养护再生混凝土粉超高韧性水泥基复合材料力学性能研究[D]. 郑州: 郑州大学, 2021. |

| Yan Zeng-hui. Study on mechanical properties of ultra-high toughness cement-based composites with recycled concrete powder cured at low temperature[D]. Zhengzhou: Zhengzhou University, 2021. | |

| [16] | Tosun-Felekoğlu K, Felekoğlu B, Ranade R, et al. The role of flaw size and fiber distribution on tensile ductility of PVA-ECC[J]. Composites Part B: Engineering, 2014, 56: 536-545. |

| [17] | Adesina A, Das S. Development of sustainable engineered cementitious composites using recycled concrete aggregates—feasibility study based on mechanical properties[J]. ACI Materials Journal, 2021, 118(4): 97-107. |

| [18] | Curosu I, Liebscher M, Alsous G, et al. Tailoring the crack-bridging behavior of strain-hardening cement-based composites (SHCC) by chemical surface modification of poly(vinyl alcohol) (PVA) fibers[J]. Cement and Concrete Composites, 2020, 114: 103722. |

| [19] | Bai M Y, Xiao J Z, Gao Y, et al. Pore structure characteristics and mechanical property of engineered cementitious composites (ECC) incorporating recycled sand[J]. Construction and Building Materials, 2023, 408: 133721. |

| [1] | 姜世杰, 李曙光, 许子沼, 王菲. 金属材料挤出成型生坯试件的静力学性能[J]. 东北大学学报(自然科学版), 2025, 46(9): 95-101. |

| [2] | 胡贤磊, 韩鹏, 解勤诚, 支颖. 轧制差厚板预成形工艺对Al-Si镀层的影响[J]. 东北大学学报(自然科学版), 2025, 46(9): 65-72. |

| [3] | 任启震, 孟贵如, 巩亚东, 李远峰. 异质材料修复K403叶片界面组织及力学性能研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 102-112. |

| [4] | 王营, 顾晓薇, 王青, 胥孝川. 石灰基矿渣-钢渣复合胶凝材料性能及水化机理[J]. 东北大学学报(自然科学版), 2024, 45(10): 1459-1468. |

| [5] | 柳静献, 代峰, 毛宁. 酸碱交互腐蚀对芳纶滤料性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(7): 1034-1040. |

| [6] | 毛宁, 牛荟蓉, 柳静献. 聚芳恶二唑纤维耐酸特性的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(5): 719-725. |

| [7] | 任朝晖, 李竺鸿, 王云贺, 张梓婷. 超声滚压微锻造增材件表面力学性能[J]. 东北大学学报(自然科学版), 2023, 44(5): 634-641. |

| [8] | 王海涛, 李家栋, 邓想涛, 王昭东. 固溶温度对Fe-20Mn-9Al-1.2C低密度钢组织性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(5): 609-616. |

| [9] | 邸洪双, 柯浩鹏, 张天宇. 多步热处理对含Cu中碳低合金钢组织与性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(3): 340-348. |

| [10] | 左玉波, 凌放, 韩友, 朱庆丰. 固溶后冷轧变形量对2195铝锂合金组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(2): 199-205. |

| [11] | 田妮 , 张耀中, 周轶然, 秦广华. Zr对Al-10Zn-2.5Mg-1.6Cu合金板材组织与性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(7): 951-958. |

| [12] | 赵宇辉, 高孟秋, 赵吉宾, 贺晨. 增减材复合制造WC颗粒增强316L不锈钢材料组织性能[J]. 东北大学学报(自然科学版), 2022, 43(2): 197-205. |

| [13] | 王胤, 李勇, 钱晓明, 张博四. 真空离心铸造冷却速率对7055铝合金组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(12): 1769-1776. |

| [14] | 张广泰, 吴锐, 李雪藩, 阿迪力·赛买提. 老化-荷载作用下叠层轮胎隔震垫时变力学性能[J]. 东北大学学报(自然科学版), 2021, 42(8): 1180-1186. |

| [15] | 高彩茹, 屈兵兵, 田余东, 杜林秀. 回火温度对在线淬火Q690q桥梁钢显微组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2021, 42(7): 927-933. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||