东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (9): 102-112.DOI: 10.12068/j.issn.1005-3026.2025.20240019

收稿日期:2024-01-22

出版日期:2025-09-15

发布日期:2025-12-03

通讯作者:

巩亚东

作者简介:任启震(1998—),男,山西兴县人,东北大学硕士研究生

Qi-zhen REN, Gui-ru MENG, Ya-dong GONG( ), Yuan-feng LI

), Yuan-feng LI

Received:2024-01-22

Online:2025-09-15

Published:2025-12-03

Contact:

Ya-dong GONG

摘要:

以K403损伤叶片为基体,采用激光熔覆IN718合金粉末对熔覆层和基体结合的界面区域进行修复再制造.基于正交试验对激光熔覆IN718合金工艺进行优化,研究工艺参数对熔覆层成形尺寸和质量的影响规律,分析修复界面区域的组织特征以及裂纹形成机制.结果表明,裂纹从基体区萌生并向熔覆层扩展,裂纹萌生位置受熔池形状影响,裂纹数量与熔合区形貌相关;热处理后,熔覆层晶粒间的析出相由颗粒状Laves相转变为针状δ相,界面区域实现冶金结合;热处理对K403基体影响不大,但使界面区域硬度过渡更为平滑,熔覆层硬度提升近50%,热影响区宽度约为2.1 mm;抗拉强度达731.7 MPa,伸长率为3.7%,断裂类型是以脆性断裂为主的准解理断裂.

中图分类号:

任启震, 孟贵如, 巩亚东, 李远峰. 异质材料修复K403叶片界面组织及力学性能研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 102-112.

Qi-zhen REN, Gui-ru MENG, Ya-dong GONG, Yuan-feng LI. Study on Interface Microstructure and Mechanical Performance of K403 Blade Repaired with Heterogeneous Material[J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 102-112.

| 元素 | Cr | Fe | Mo | Nb | Ti | Al | Co | W | Si | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| K403基体 | 10~12 | <2 | 3.8~4.5 | — | 2.3~2.9 | 5.3~5.9 | 4.5~6 | 4.8~5.5 | — | 余量 |

| IN718粉末 | 19.23 | 19.3 | 3.05 | 5.14 | 0.99 | 0.58 | <0.005 | — | 0.055 | 余量 |

表1 K403基材和IN718粉末的化学成分(质量分数) (%)

Table 1 Chemical composition of K403 substrate and IN718 powder (mass fraction)

| 元素 | Cr | Fe | Mo | Nb | Ti | Al | Co | W | Si | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| K403基体 | 10~12 | <2 | 3.8~4.5 | — | 2.3~2.9 | 5.3~5.9 | 4.5~6 | 4.8~5.5 | — | 余量 |

| IN718粉末 | 19.23 | 19.3 | 3.05 | 5.14 | 0.99 | 0.58 | <0.005 | — | 0.055 | 余量 |

| 试验材料 | K403 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 温度/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1 000 |

| 线膨胀系数×10-6/C | 11.3 | 12.3 | 12.3 | 12.6 | 12.9 | 13.0 | 13.4 | 13.8 | 14.3 | 15.1 |

| 热导率/(W·(m·C)-1) | 14.27 | 14.52 | 17.12 | 18.25 | 19.72 | 20.43 | 22.27 | 23.53 | 24.82 | — |

| 熔化温度/℃ | 1 260~1 338 | |||||||||

| 密度/(g·cm-3) | 8.1 | |||||||||

| 试验材料 | IN718 | |||||||||

| 温度/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1 000 |

| 线膨胀系数×10-6/C | 11.8 | 13.0 | 13.5 | 14.1 | 14.4 | 14.8 | 15.4 | 17.0 | 18.4 | 18.7 |

| 热导率/(W·(m·C)-1) | 14.7 | 15.9 | 17.8 | 18.3 | 19.6 | 21.2 | 22.8 | 23.6 | 27.6 | 30.4 |

| 熔化温度/℃ | 1 260~1 320 | |||||||||

| 密度/(g·cm-3) | 8.24 | |||||||||

表2 K403和IN718的热物理参数

Table 2 Thermophysical parameters of K403 and IN718

| 试验材料 | K403 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 温度/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1 000 |

| 线膨胀系数×10-6/C | 11.3 | 12.3 | 12.3 | 12.6 | 12.9 | 13.0 | 13.4 | 13.8 | 14.3 | 15.1 |

| 热导率/(W·(m·C)-1) | 14.27 | 14.52 | 17.12 | 18.25 | 19.72 | 20.43 | 22.27 | 23.53 | 24.82 | — |

| 熔化温度/℃ | 1 260~1 338 | |||||||||

| 密度/(g·cm-3) | 8.1 | |||||||||

| 试验材料 | IN718 | |||||||||

| 温度/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1 000 |

| 线膨胀系数×10-6/C | 11.8 | 13.0 | 13.5 | 14.1 | 14.4 | 14.8 | 15.4 | 17.0 | 18.4 | 18.7 |

| 热导率/(W·(m·C)-1) | 14.7 | 15.9 | 17.8 | 18.3 | 19.6 | 21.2 | 22.8 | 23.6 | 27.6 | 30.4 |

| 熔化温度/℃ | 1 260~1 320 | |||||||||

| 密度/(g·cm-3) | 8.24 | |||||||||

| 序号 | P/W | v/(mm·min-1) | f/(r·min-1) | W/μm | H/μm | D/μm | W/H | η | HV |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 800 | 240 | 1.6 | 2 682.37 | 349.18 | 420.07 | 7.68 | 0.66 | 413.7 |

| 2 | 800 | 360 | 1.8 | 2 560.10 | 186.90 | 485.83 | 13.70 | 0.73 | 440.3 |

| 3 | 800 | 480 | 2 | 2 443.30 | 171.54 | 454.02 | 14.24 | 0.77 | 416.5 |

| 4 | 800 | 600 | 2.2 | 2 375.13 | 130.63 | 419.08 | 18.18 | 0.78 | 490.8 |

| 5 | 1 000 | 240 | 1.8 | 3 060.28 | 434.98 | 583.41 | 7.04 | 0.63 | 374 |

| 6 | 1 000 | 360 | 1.6 | 2 883.74 | 247.06 | 510.73 | 11.67 | 0.73 | 428.6 |

| 7 | 1 000 | 480 | 2.2 | 2 689.63 | 208.65 | 459.17 | 12.89 | 0.75 | 479.5 |

| 8 | 1 000 | 600 | 2 | 2 603.46 | 151.56 | 444.29 | 17.18 | 0.80 | 473.7 |

| 9 | 1 200 | 240 | 2 | 3 508.66 | 402.25 | 655.39 | 8.72 | 0.69 | 430.9 |

| 10 | 1 200 | 360 | 2.2 | 3 045.69 | 352.94 | 498.96 | 8.63 | 0.69 | 448.9 |

| 11 | 1 200 | 480 | 1.6 | 2 936.33 | 172.32 | 519.73 | 17.04 | 0.81 | 479.5 |

| 12 | 1 200 | 600 | 1.8 | 2 783.05 | 119.38 | 488.60 | 23.31 | 0.85 | 475.4 |

| 13 | 1 400 | 240 | 2.2 | 3 433.22 | 438.06 | 586.17 | 7.84 | 0.65 | 438.1 |

| 14 | 1 400 | 360 | 2 | 3 209.00 | 215.57 | 588.58 | 14.89 | 0.78 | 477.6 |

| 15 | 1 400 | 480 | 1.8 | 2 954.33 | 119.03 | 520.42 | 24.82 | 0.83 | 461.6 |

| 16 | 1 400 | 600 | 1.6 | 2 884.78 | 73.62 | 495.20 | 39.19 | 0.87 | 437.8 |

表3 激光熔覆IN718合金正交试验方案及结果

Table 3 Orthogonal test scheme and results of laser cladding IN718 alloy

| 序号 | P/W | v/(mm·min-1) | f/(r·min-1) | W/μm | H/μm | D/μm | W/H | η | HV |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 800 | 240 | 1.6 | 2 682.37 | 349.18 | 420.07 | 7.68 | 0.66 | 413.7 |

| 2 | 800 | 360 | 1.8 | 2 560.10 | 186.90 | 485.83 | 13.70 | 0.73 | 440.3 |

| 3 | 800 | 480 | 2 | 2 443.30 | 171.54 | 454.02 | 14.24 | 0.77 | 416.5 |

| 4 | 800 | 600 | 2.2 | 2 375.13 | 130.63 | 419.08 | 18.18 | 0.78 | 490.8 |

| 5 | 1 000 | 240 | 1.8 | 3 060.28 | 434.98 | 583.41 | 7.04 | 0.63 | 374 |

| 6 | 1 000 | 360 | 1.6 | 2 883.74 | 247.06 | 510.73 | 11.67 | 0.73 | 428.6 |

| 7 | 1 000 | 480 | 2.2 | 2 689.63 | 208.65 | 459.17 | 12.89 | 0.75 | 479.5 |

| 8 | 1 000 | 600 | 2 | 2 603.46 | 151.56 | 444.29 | 17.18 | 0.80 | 473.7 |

| 9 | 1 200 | 240 | 2 | 3 508.66 | 402.25 | 655.39 | 8.72 | 0.69 | 430.9 |

| 10 | 1 200 | 360 | 2.2 | 3 045.69 | 352.94 | 498.96 | 8.63 | 0.69 | 448.9 |

| 11 | 1 200 | 480 | 1.6 | 2 936.33 | 172.32 | 519.73 | 17.04 | 0.81 | 479.5 |

| 12 | 1 200 | 600 | 1.8 | 2 783.05 | 119.38 | 488.60 | 23.31 | 0.85 | 475.4 |

| 13 | 1 400 | 240 | 2.2 | 3 433.22 | 438.06 | 586.17 | 7.84 | 0.65 | 438.1 |

| 14 | 1 400 | 360 | 2 | 3 209.00 | 215.57 | 588.58 | 14.89 | 0.78 | 477.6 |

| 15 | 1 400 | 480 | 1.8 | 2 954.33 | 119.03 | 520.42 | 24.82 | 0.83 | 461.6 |

| 16 | 1 400 | 600 | 1.6 | 2 884.78 | 73.62 | 495.20 | 39.19 | 0.87 | 437.8 |

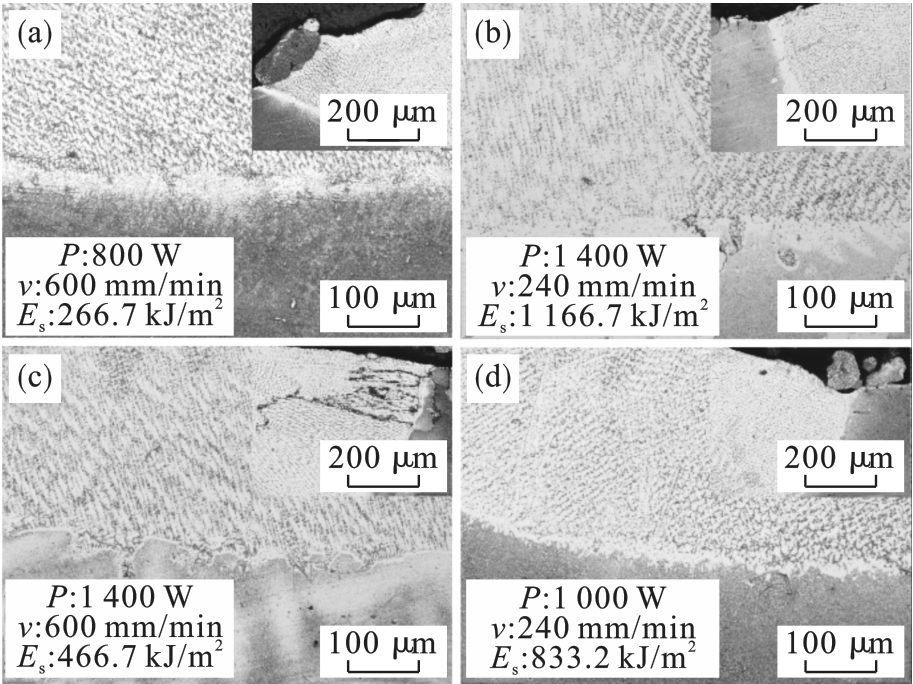

图4 比能对熔覆层微观组织的影响(a)—Es=266.7 kJ/m2; (b)—Es=1 166.7 kJ/m2;(c)—Es=466.7 kJ/m2; (d)—Es=833.2 kJ/m2.

Fig.4 Influence of specific energy on microstructure of cladding layer

| 测试点 | Al | Ti | Cr | Fe | Co | Ni | Nb | Mo | W |

|---|---|---|---|---|---|---|---|---|---|

| A | 1.25 | 3.70 | 14.32 | 10.29 | — | 40.89 | 23.90 | 5.65 | — |

| B | 1.70 | 2.34 | 17.64 | 12.41 | — | 60.96 | 2.64 | 2.31 | — |

| C | 0.46 | 0.82 | 16.90 | 15.13 | — | 54.86 | 8.83 | 3.00 | — |

| D | 0.20 | 0.96 | 14.01 | 12.40 | — | 56.78 | 12.61 | 3.05 | — |

| E | 0.40 | 0.69 | 19.92 | 17.99 | — | 54.69 | 3.60 | 2.70 | — |

| F | 0.01 | 40.21 | 1.97 | — | 0.08 | 2.69 | — | 16.55 | 38.48 |

| G | 5.30 | 2.45 | 10.11 | — | 4.70 | 69.02 | — | 3.08 | 5.34 |

表4 热处理后熔覆层和基体各点的EDS化学成分(质量分数) (treatment (mass fraction) %)

Table 4 EDS chemical composition of each point in cladding layer and substrate after heat

| 测试点 | Al | Ti | Cr | Fe | Co | Ni | Nb | Mo | W |

|---|---|---|---|---|---|---|---|---|---|

| A | 1.25 | 3.70 | 14.32 | 10.29 | — | 40.89 | 23.90 | 5.65 | — |

| B | 1.70 | 2.34 | 17.64 | 12.41 | — | 60.96 | 2.64 | 2.31 | — |

| C | 0.46 | 0.82 | 16.90 | 15.13 | — | 54.86 | 8.83 | 3.00 | — |

| D | 0.20 | 0.96 | 14.01 | 12.40 | — | 56.78 | 12.61 | 3.05 | — |

| E | 0.40 | 0.69 | 19.92 | 17.99 | — | 54.69 | 3.60 | 2.70 | — |

| F | 0.01 | 40.21 | 1.97 | — | 0.08 | 2.69 | — | 16.55 | 38.48 |

| G | 5.30 | 2.45 | 10.11 | — | 4.70 | 69.02 | — | 3.08 | 5.34 |

| 样品 | 屈服强度 | 抗拉强度 | 断后伸长率 |

|---|---|---|---|

| 未热处理 | 404.9 | 668.8 | 15.4 |

| 热处理 | 706.5 | 731.7 | 3.7 |

| K403基体 | — | 773.8 | 3.4 |

表5 试样常温拉伸性能 (temperature)

Table 5 Tensile properties of specimens at room

| 样品 | 屈服强度 | 抗拉强度 | 断后伸长率 |

|---|---|---|---|

| 未热处理 | 404.9 | 668.8 | 15.4 |

| 热处理 | 706.5 | 731.7 | 3.7 |

| K403基体 | — | 773.8 | 3.4 |

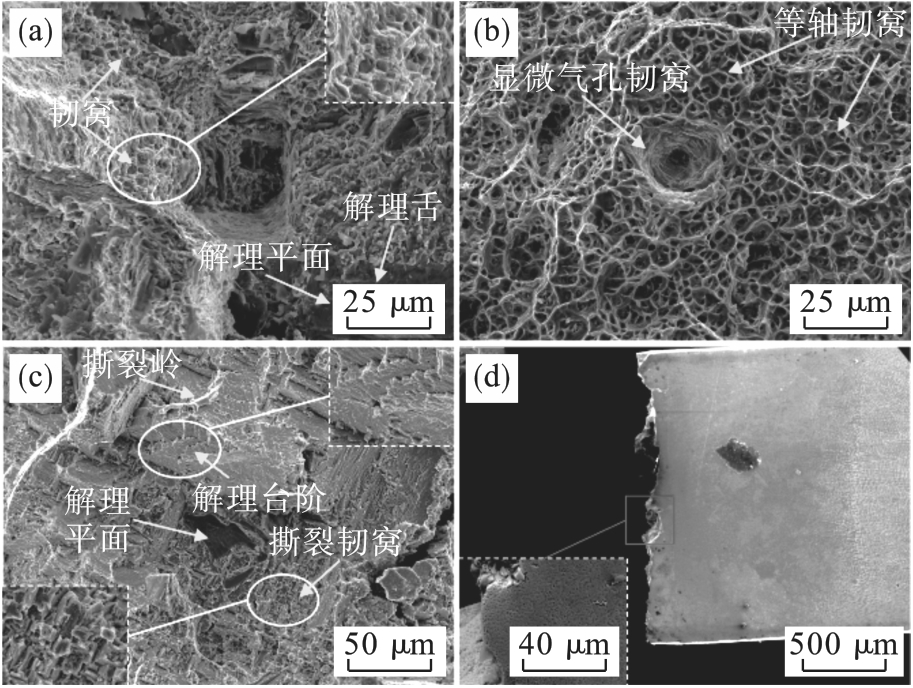

图11 K403基体和热处理前后试样断口形貌(a)—K403基体; (b)—热处理前; (c)—热处理后;(d)—热处理后试样断裂纵截面宏微观形貌.

Fig.11 Fracture morphology of K403 substrate and specimens before and after heat treatment

| [1] | Talu Ü S, Gahn L, Kittel J, et al. Process development for tip repair of complex shaped turbine blades with IN718[J]. Procedia Manufacturing, 2020, 47: 1050-1057. |

| [2] | Zhuo Y M, Chen Y H, Yang C L. Research status and prospect of welding repair technology for aero-engine blades[J]. Aeronautical Manufacturing Technology, 2021, 64(8):22-28. |

| [3] | Song H Y, Lei J B, Xie J C, et al. Laser melting deposition of K403 superalloy: the influence of processing parameters on the microstructure and wear performance[J]. Journal of Alloys and Compounds, 2019, 805: 551-564. |

| [4] | 李鹏涛, 左洪福, 肖文, 等. 航空发动机叶片损伤及其修复技术研究与展望[J]. 航空学报, 2024, 45(15): 029635. |

| Li Peng-tao, Zuo Hong-fu, Xiao Wen, et al. Research and prospect of aero engine blade damage and its repair technology[J]. Acta Aeronautica et Astronautica Sinica, 2024, 45(15): 029635. | |

| [5] | 鲁耀钟, 雷卫宁, 任维彬, 等. 激光熔覆Inconel718合金裂纹分析及裂纹控制研究[J]. 表面技术, 2020, 49(9): 233-243. |

| Lu Yao-zhong, Lei Wei-ning, Ren Wei-bin, et al. Crack analysis and control of laser cladding Inconel718 alloy[J]. Surface Technology, 2020, 49(9): 233-243. | |

| [6] | Xu L, Cao H J, Liu H L, et al. Study on laser cladding remanufacturing process with FeCrNiCu alloy powder for thin-wall impeller blade[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(5): 1383-1392. |

| [7] | Sun D, Cai Y C, Zhu L S, et al. High-temperature oxidation and wear properties of TiC-reinforced CrMnFeCoNi high entropy alloy composite coatings produced by laser cladding[J]. Surface and Coatings Technology, 2022, 438: 128407. |

| [8] | Liu J C, Wang C, Tong L J, et al. Study on the effect mechanism of aluminizing on fatigue performance of K403 nickel-based superalloy[J]. Journal of Alloys and Compounds, 2020, 835: 155277. |

| [9] | Han L, Zheng S W, Tao M, et al. Service damage mechanism and interface cracking behavior of Ni-based superalloy turbine blades with aluminized coating[J]. International Journal of Fatigue, 2021, 153: 106500. |

| [10] | Gao Z N, Wang L L, Wang Y N, et al. Crack defects and formation mechanism of FeCoCrNi high entropy alloy coating on TC4 titanium alloy prepared by laser cladding[J]. Journal of Alloys and Compounds, 2022, 903: 163905. |

| [11] | Dmitrieva A, Klimova-Korsmik O, Gushchina M, et al. Effect of the laser cladding parameters on the crack formation and microstructure during nickel superalloy gas turbine engines repair[J]. Metals, 2023, 13(2): 393. |

| [12] | 周中波, 杨明波, 张建中, 等. K403合金高压导向叶片的组织及热疲劳机理分析[J]. 铸造技术, 2023, 44(3): 246-251. |

| Zhou Zhong-bo, Yang Ming-bo, Zhang Jian-zhong, et al. Microstructure and thermal fatigue mechanism of K403 alloy high pressure guide-vane[J]. Foundry Technology, 2023, 44(3): 246-251. | |

| [13] | Sui S, Chen J, Ma L, et al. Microstructures and stress rupture properties of pulse laser repaired Inconel 718 superalloy after different heat treatments[J]. Journal of Alloys and Compounds, 2019, 770: 125-135. |

| [1] | 陈猛, 刘富成, 张通, 吴迪. 再生细骨料UHTCC力学性能及作用机理[J]. 东北大学学报(自然科学版), 2025, 46(9): 119-125. |

| [2] | 胡贤磊, 韩鹏, 解勤诚, 支颖. 轧制差厚板预成形工艺对Al-Si镀层的影响[J]. 东北大学学报(自然科学版), 2025, 46(9): 65-72. |

| [3] | 姜世杰, 李曙光, 许子沼, 王菲. 金属材料挤出成型生坯试件的静力学性能[J]. 东北大学学报(自然科学版), 2025, 46(9): 95-101. |

| [4] | 杨尚武, 瞿海霞, 黎恒君, 刘常升. 激光熔覆(Ti,W)C增强镍基涂层的性能[J]. 东北大学学报(自然科学版), 2024, 45(7): 953-959. |

| [5] | 孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642. |

| [6] | 姚文博, 刘忱, 商硕, 刘常升. 扫描速度对激光熔覆Fe-Al合金熔覆层组织及性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(2): 170-178. |

| [7] | 王营, 顾晓薇, 王青, 胥孝川. 石灰基矿渣-钢渣复合胶凝材料性能及水化机理[J]. 东北大学学报(自然科学版), 2024, 45(10): 1459-1468. |

| [8] | 柳静献, 代峰, 毛宁. 酸碱交互腐蚀对芳纶滤料性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(7): 1034-1040. |

| [9] | 王海涛, 李家栋, 邓想涛, 王昭东. 固溶温度对Fe-20Mn-9Al-1.2C低密度钢组织性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(5): 609-616. |

| [10] | 任朝晖, 李竺鸿, 王云贺, 张梓婷. 超声滚压微锻造增材件表面力学性能[J]. 东北大学学报(自然科学版), 2023, 44(5): 634-641. |

| [11] | 毛宁, 牛荟蓉, 柳静献. 聚芳恶二唑纤维耐酸特性的实验研究[J]. 东北大学学报(自然科学版), 2023, 44(5): 719-725. |

| [12] | 邸洪双, 柯浩鹏, 张天宇. 多步热处理对含Cu中碳低合金钢组织与性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(3): 340-348. |

| [13] | 左玉波, 凌放, 韩友, 朱庆丰. 固溶后冷轧变形量对2195铝锂合金组织和力学性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(2): 199-205. |

| [14] | 田妮 , 张耀中, 周轶然, 秦广华. Zr对Al-10Zn-2.5Mg-1.6Cu合金板材组织与性能的影响[J]. 东北大学学报(自然科学版), 2022, 43(7): 951-958. |

| [15] | 赵宇辉, 高孟秋, 赵吉宾, 贺晨. 增减材复合制造WC颗粒增强316L不锈钢材料组织性能[J]. 东北大学学报(自然科学版), 2022, 43(2): 197-205. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||