东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 20-31.DOI: 10.12068/j.issn.1005-3026.2025.20240217

陈明辉, 宋凯利, 甄宇, 王福会

收稿日期:2024-11-25

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

陈明辉

作者简介:陈明辉(1984—),男,湖南茶陵人,东北大学教授,博士生导师基金资助:Ming-hui CHEN, Kai-li SONG, Yu ZHEN, Fu-hui WANG

Received:2024-11-25

Online:2025-08-15

Published:2025-11-24

Contact:

Ming-hui CHEN

摘要:

传统自润滑复合材料虽通过多相协同作用展现优异摩擦学性能,却面临力学性能不足和高温氧化失效的双重挑战.前者限制承载能力,后者导致氧化膜增厚引发运动滞涩.基于氧化调控的新策略通过诱导摩擦过程原位生成特定氧化产物或结构,可有效提升复合材料的综合性能.通过系统梳理高温自润滑复合材料研究现状以及面临的问题,重点阐述3类氧化调控策略,分别为选择性生成易烧结氧化物、原位构建表面织构、自生润滑相,建立动态润滑机制,为开发兼具优异力学性能、摩擦学性能与抗氧化的自润滑复合材料提供理论支持与技术参考.

中图分类号:

陈明辉, 宋凯利, 甄宇, 王福会. 金属基高温自润滑复合材料研究现状及展望[J]. 东北大学学报(自然科学版), 2025, 46(8): 20-31.

Ming-hui CHEN, Kai-li SONG, Yu ZHEN, Fu-hui WANG. Research Status and Prospects of Metal Matrix High-Temperature Self-lubricating Composites[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 20-31.

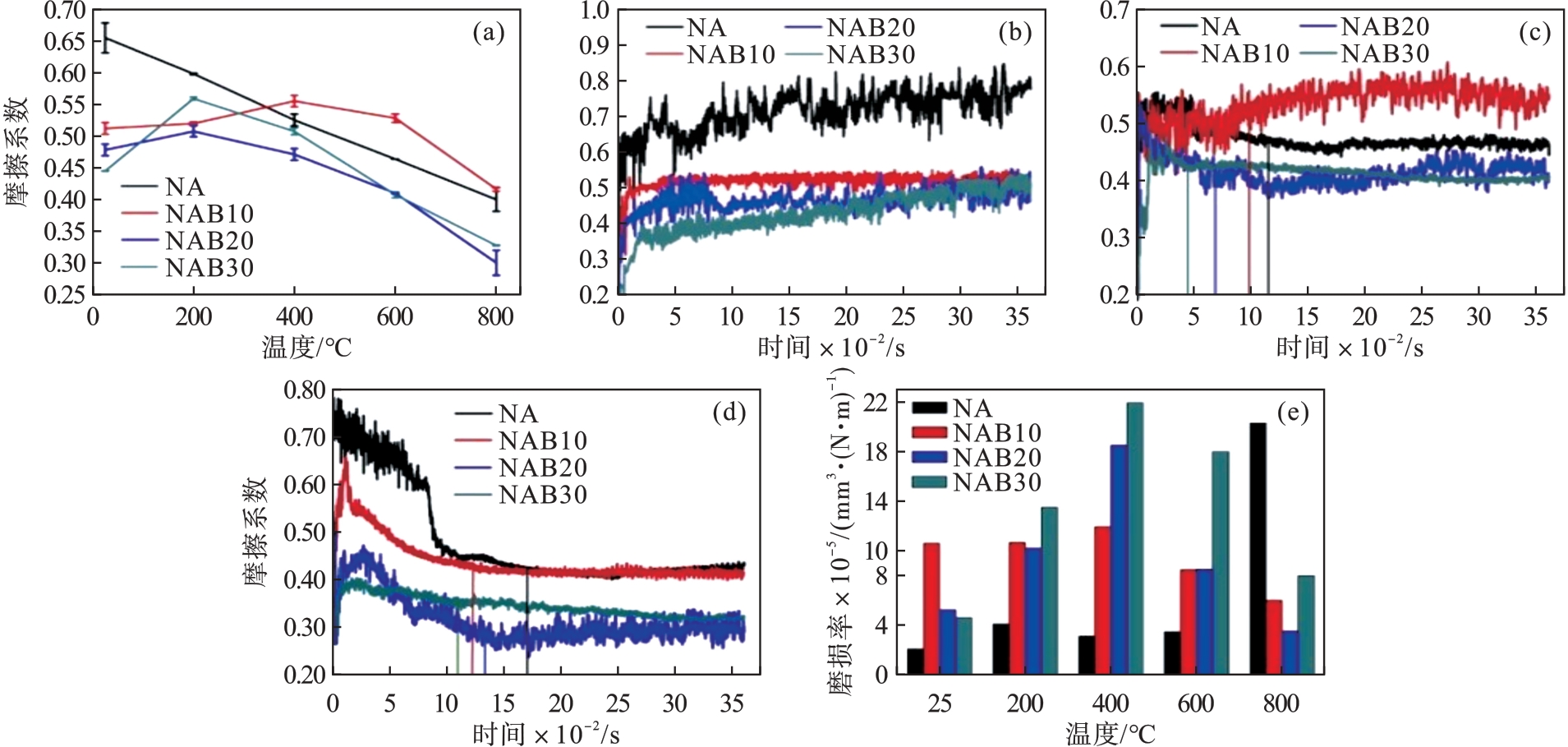

图1 NiAl和NiAl-AgNbO3复合材料的摩擦和磨损性能[26](a)—摩擦系数与温度的关系; (b)—25 ℃时摩擦系数与时间的关系; (c)—600 ℃时摩擦系数与时间的关系;(d)—800 ℃时摩擦系数与时间的关系; (e)—磨损率与温度的关系.

Fig.1 Friction and wear properties of NiAl and NiAl-AgNbO3 composites [26]

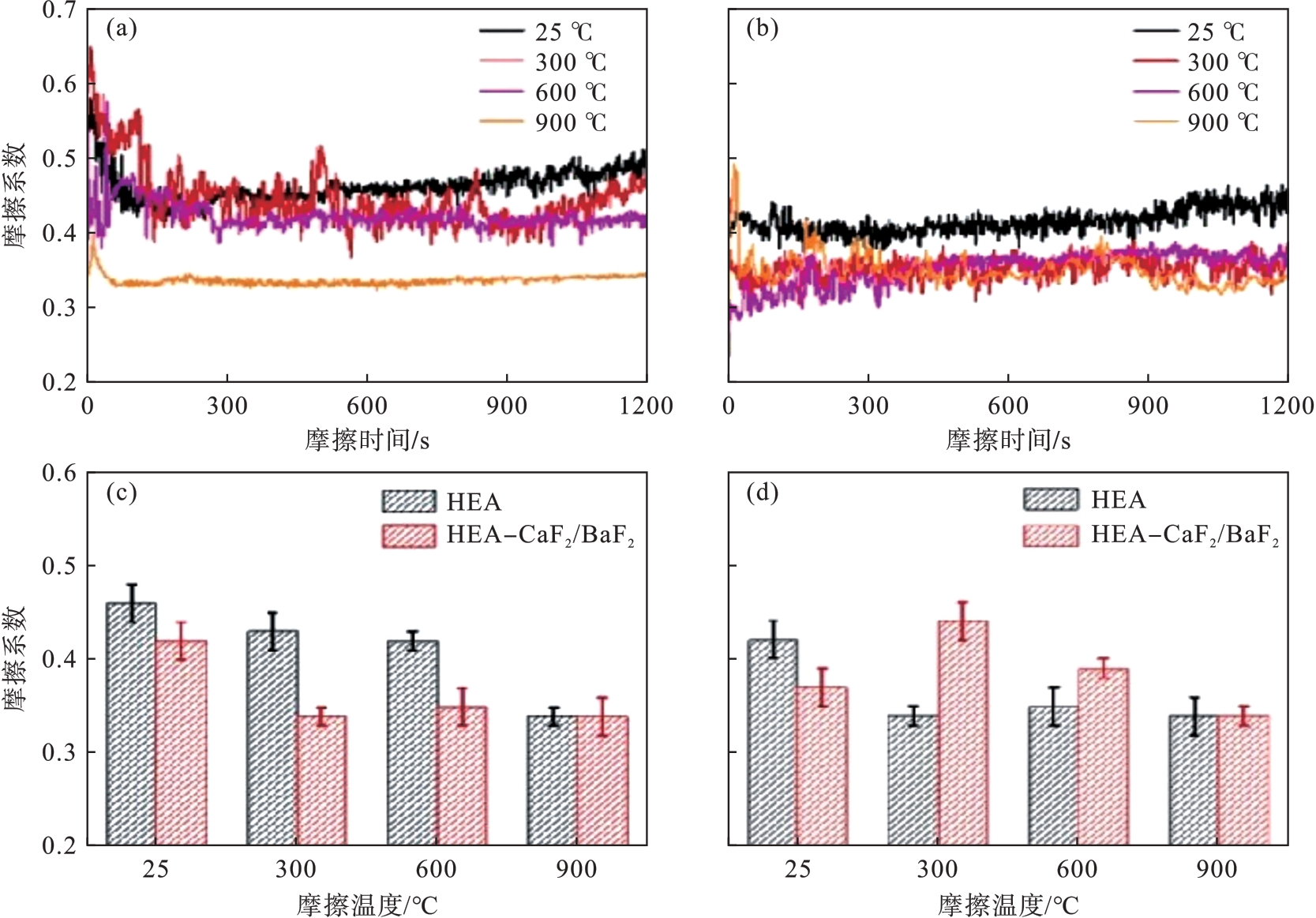

图2 HEA和HEA-CaF2/BaF2固体自润滑材料的摩擦和磨损性能[39](a)—块体HEA摩擦系数随时间变化关系; (b)—块体HEA-CaF2/BaF2摩擦系数随时间变化关系;(c)—在不同温度下HEA与HEA-CaF2/BaF2平均摩擦系数比较;(d)—在不同温度下HEA-CaF2/BaF2与HEA-Ag平均摩擦系数比较.

Fig.2 Friction and wear properties of HEA and HEA-CaF2/BaF2 solid self-lubricating materials[39]

| 材料种类 | 摩擦系数 | ||

|---|---|---|---|

| 204 ℃ | 316 ℃ | 593 ℃ | |

| 无氧化物润滑物质 | 0.46~0.78 | 0.75 | 0.60~0.80 |

PbO B2O3 CrO3 Re2O7 ReO2 Cu2O CuO CoO MoO3 WO3 Fe3O4 Fe2O3 V2O5 TiO2 Al2O3 Cr2O3 NiO | 0.19 0.64 0.14 0.35 0.64 0.30 0.60 0.46 0.51 0.41 0.60 0.46 0.53 0.68 0.77 0.41 0.70 | 0.10 0.51 — 0.23 — 0.14 0.50 0.38 0.69 0.60 — — 0.52 — — 0.64 — | 0.10 0.18 — — 0.27 0.48 0.22 0.18 0.38 0.56 0.40 0.42 0.32 — — — 0.69 |

表1 一些金属氧化物在3种温度下的摩擦系数[40] (three temperatures[40])

Table 1 Friction coefficients of some metal oxides at

| 材料种类 | 摩擦系数 | ||

|---|---|---|---|

| 204 ℃ | 316 ℃ | 593 ℃ | |

| 无氧化物润滑物质 | 0.46~0.78 | 0.75 | 0.60~0.80 |

PbO B2O3 CrO3 Re2O7 ReO2 Cu2O CuO CoO MoO3 WO3 Fe3O4 Fe2O3 V2O5 TiO2 Al2O3 Cr2O3 NiO | 0.19 0.64 0.14 0.35 0.64 0.30 0.60 0.46 0.51 0.41 0.60 0.46 0.53 0.68 0.77 0.41 0.70 | 0.10 0.51 — 0.23 — 0.14 0.50 0.38 0.69 0.60 — — 0.52 — — 0.64 — | 0.10 0.18 — — 0.27 0.48 0.22 0.18 0.38 0.56 0.40 0.42 0.32 — — — 0.69 |

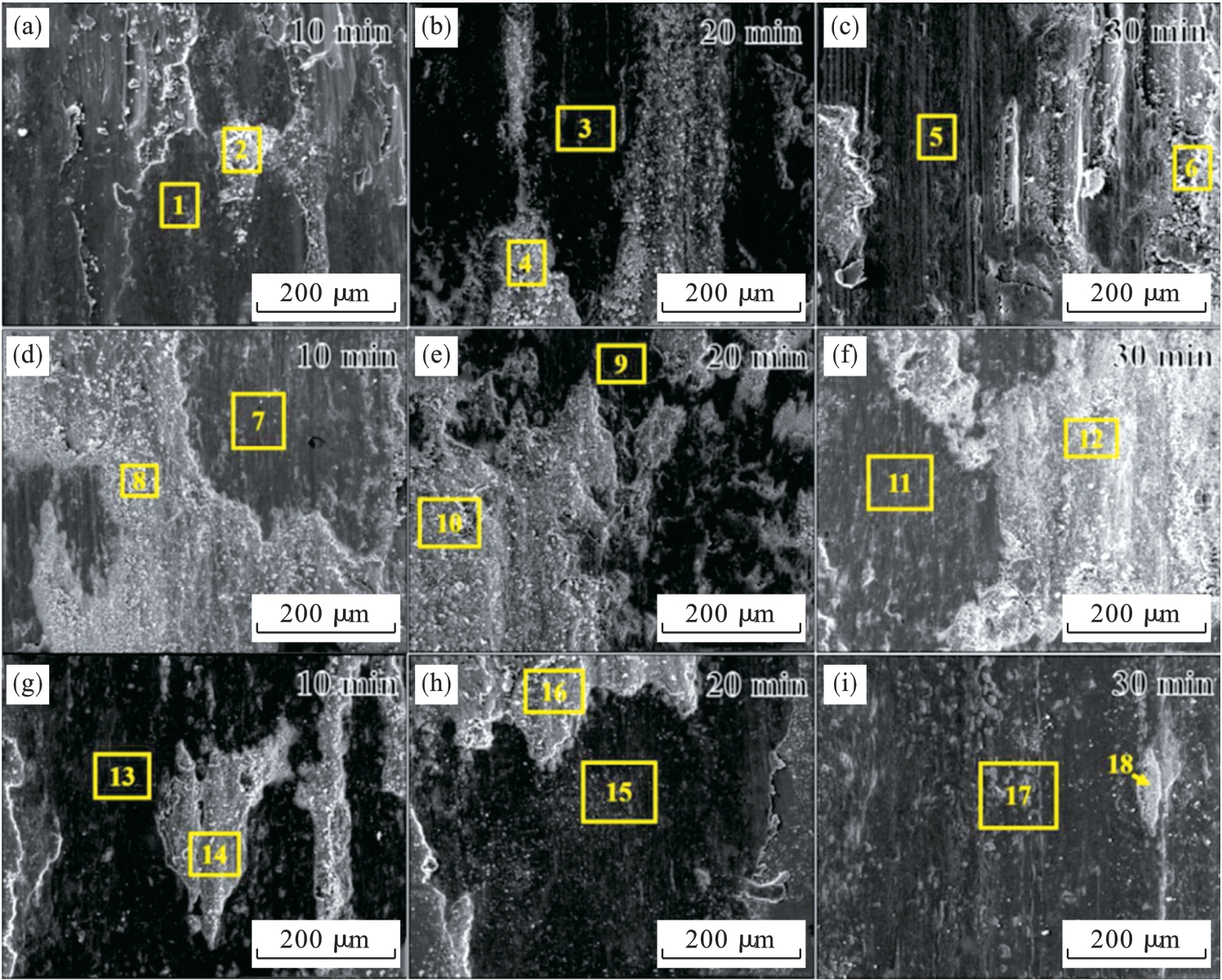

图6 3种高熵合金在400 ℃下摩擦不同时间后的磨损形貌[64]

Fig.6 Wear morphologies of three high entropy alloys after friction at 400 °C for different durations[64] (a~c)—AM-Co10Cr5; (d~f)—MA-Co10Cr10; (g~i)—MA-Co15Cr5[64].

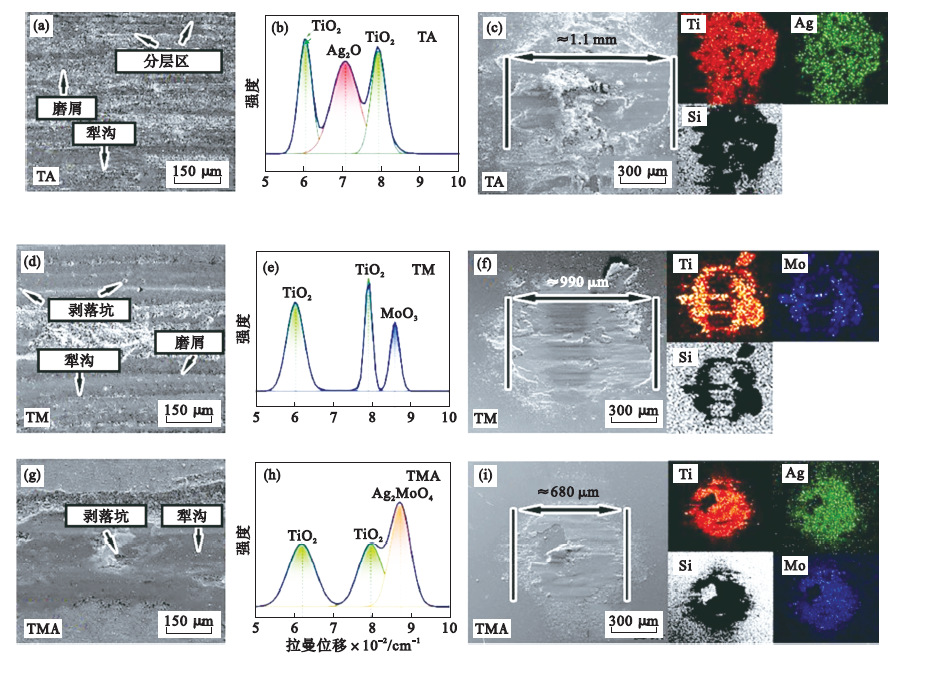

图9 复合材料TA(Ti+15%Ag),TM(Ti+10%Mo)以及TMA(Ti+10%Mo+15%Ag)磨损表面的表征[77]

Fig.9 Wear scar characteristics of three composites of TA(Ti+15%Ag), TM(Ti+10%Mo) and TMA(Ti+10%Mo+15%Ag)[77]

| [1] | Luo J B, Liu M, Ma L. Origin of friction and the new frictionless technology-superlubricity: advancements and future outlook [J]. Nano Energy, 2021, 86: 106092. |

| [2] | 谭国煌, 武兴华, 肖明豪, 等. TC4钛合金超疏水表面/超润滑表面的制备及防冷凝性防冰性能研究[J]. 表面技术, 2023, 52(12): 419-427,448. |

| Tan Guo-huang, Wu Xing-hua, Xiao Ming-hao, et al. The anti-condensation, anti-icing performance of superhydrophobic and SLIPS TC4 titanium alloy surfaces[J]. Surface Technology, 2023, 52(12): 419-427, 448. | |

| [3] | 郝菊文, 党兴武, 彭斌. 动静涡旋盘齿顶摩擦副摩擦力分形预测模型[J]. 计算力学学报, 2024, 42(4): 678-684. |

| Hao Ju-wen, Dang Xing-wu, Peng Bin. Fractal prediction model for friction force of tip friction pair of fixed and orbiting scroll plates [J]. Chinese Journal of computational Mechanics, 2024, 42(4): 678-684. | |

| [4] | 雒建斌. 超滑与摩擦起源的探索[J]. 科学通报, 2020, 65(27): 2967-2978, 2966. |

| Luo Jian-bin. Investigation on the origin of friction and superlubricity [J]. Chinese Science Bulletin, 2020, 65(27): 2967-2978, 2966. | |

| [5] | 郝恩康, 安宇龙, 赵晓琴, 等. 热喷涂高温自润滑涂层研究现状[J]. 表面技术, 2018, 47(6): 104-111. |

| Hao En-kang, An Yu-long, Zhao Xiao-qin, et al. High temperature self-lubricating coatings prepared by thermal spraying[J]. Surface Technology, 2018, 47(6): 104-111. | |

| [6] | Roy A, Patel P, Sharifi N, et al. Binary and ternary lubricious oxides for high temperature tribological applications: a review[J]. Results in Surfaces and Interfaces, 2023, 11: 100117. |

| [7] | Liu Z M, Childs T H C. The study of wear characteristics of sintered high speed steels containing CaF2, MnS and TiC additives at elevated temperature[J]. Wear, 2004, 257(3/4): 435-440. |

| [8] | 徐笑笑, 梁斐, 张亚平, 等. 梯度纳米结构轴承钢的高温摩擦磨损行为[J]. 中国表面工程, 2024, 37(5): 77-87. |

| Xu Xiao-xiao, Liang Fei, Zhang Ya-ping, et al. Tribological behavior of gradient nanostructured bearing steel at elevated temperatures [J]. China Surface Engineering, 2024, 37(5): 77-87. | |

| [9] | 甄金明, 李斐, 朱圣宇, 等. Ti对镍基高温自润滑复合材料力学和摩擦学性能的影响[J]. 摩擦学学报, 2014, 34(5): 586-591. |

| Zhen Jin-ming, Li Fei, Zhu Sheng-yu, et al. The influence of Ti on the mechanical and tribological properties of nickel-based high-temperature self-lubricating composites[J]. Tribology, 2014, 34(5): 586-591. | |

| [10] | Sliney H E. Wide temperature spectrum self-lubricating coatings prepared by plasma spraying[J]. Thin Solid Films, 1979, 64(2): 211-217. |

| [11] | Dellacorte C, Fellenstein J A. The effect of compositional tailoring on the thermal expansion and tribological properties of PS300: a solid lubricant composite coating[J]. Tribology Transactions, 1997, 40(4): 639-642. |

| [12] | Dellacorte C. The evaluation of a modified chrome oxide based high temperature solid lubricant coating for foil gas bearings[J]. Tribology Transactions, 2000, 43(2): 257-262. |

| [13] | Balić E E, Blanchet T A. Thrust-washer tribological evaluation of PS304 coatings against Rene 41 [J]. Wear, 2005,259(7): 876-881. |

| [14] | Ding C H, Li P L, Ran G, et al. Tribological property of self-lubricating PM304 composite[J]. Wear, 2007, 262(5/6): 575-581. |

| [15] | Dellacorte C. The effect of counterface on the tribological performance of a high temperature solid lubricant composite from 25 to 650℃[J]. Surface and Coatings Technology, 1996, 86/87(2): 486-492. |

| [16] | Wang W C. Application of a high temperature self-lubricating composite coating on steam turbine components[J]. Surface and Coatings Technology, 2004, 177/178: 12-17. |

| [17] | Zhang A J, Han J S, Su B, et al. Microstructure, mechanical properties and tribological performance of CoCrFeNi high entropy entropy alloy matrix self-lubricating composite[J]. Materials & Design, 2017, 114: 253-263. |

| [18] | 燕松山, 谢鹏, 解芳. Ag-Cu-Sn/金属陶瓷润滑层高温摩擦配副特性研究[J]. 润滑与密封, 2018, 43(5): 7-12, 18. |

| Yan Song-shan, Xie Peng, Xie Fang. Wear behaviors of Ag-Cu-Sn cermet lubricating coatings with different materials at high temperature[J]. Lubrication Engineering, 2018, 43(5): 7-18. | |

| [19] | 李超. 高温自补偿润滑的热力耦合驱动模型及成膜机理研究[D]. 济南: 济南大学, 2017. |

| Li Chao. Research on thermo-mechanical coupled driven model and film-formating mechanisms of high temperature self-compensation lubricating composites [D]. Jinan: Jinan University, 2017. | |

| [20] | Liu Z X, Shen Y, Liu J, et al. Effects of double-sided textures matching on friction and wear performance in reciprocating contact interface[J]. Wear, 2024, 556: 205522. |

| [21] | Li B, Gao Y M, Jia J H, et al. Influence of heat treatments on the microstructure as well as mechanical and tribological properties of NiCrAlY-Mo-Ag coatings[J]. Journal of Alloys and Compounds, 2016, 686: 503-510. |

| [22] | Wang X P, Feng X C, Lu C, et al. Mechanical and tribological properties of plasma sprayed NiAl composite coatings with addition of nanostructured TiO2/Bi2O3 [J]. Surface and Coatings Technology, 2018, 349: 157-165. |

| [23] | Wang J Y, Wang W Z, Jia J H. The oxidation resistance and tribological properties of Ni-based composites with in situ/ex situ Al2O3 and TiC ceramic phases at high temperatures[J]. Journal of Materials Research, 2016, 31(20): 3262-3271. |

| [24] | Feng X C, Jia J H, Wang W Z, et al. Mechanical and tribological properties of NiAl-NbC-Ag composites prepared by hot-pressing sintering[J]. Journal of Materials Research, 2017, 32(12): 2361-2372. |

| [25] | Li B, Jia J H, Gao Y M, et al. Microstructural and tribological characterization of NiAl matrix self-lubricating composite coatings by atmospheric plasma spraying[J]. Tribology International, 2017, 109: 563-570. |

| [26] | Feng X C, Lu C, Jia J H, et al. High temperature tribological behaviors and wear mechanisms of NiAl-NbC-Ag composites formed by in-situ decomposition of AgNbO3 [J]. Tribology International, 2020, 141: 105898. |

| [27] | 丁春华, 丁永超, 李亚云. 采用粉末冶金法制备Ag2MoO4/Ag自润滑涂层及其性能研究[J]. 应用力学学报, 2019, 36(5): 1082-1087, |

| ⅵ. | |

| Ding Chun-hua, Ding Yong-chao, Li Ya-yun. Preparation and properties of Ag2MoO4/Ag self-lubricating coatings by powder metallurgy[J]. Chinese Journal of Applied Mechanics, 2019, 36(5): 1082-1087,ⅵ. | |

| [28] | 李建, 李长生, 段昭宇. MoS2-Ag-V2O5对镍基材料摩擦磨损性能的影响[J]. 粉末冶金技术, 2021, 39(2): 141-146. |

| Li Jian, Li Chang-sheng, Duan Zhao-yu. Effect of MoS2-Ag-V2O5 on friction and wear properties of nickel-based composites [J]. Powder Metallurgy Technology, 2021, 39(2): 141-146. | |

| [29] | 李建. NiCrW基高温合金自润滑复合材料的制备及摩擦学性能研究[D]. 镇江: 江苏大学, 2020. |

| Li Jian. Preparation and tribological properties of NiCrW-based superalloy self-lubricating composites[D]. Zhenjiang: Jiangsu University, 2020. | |

| [30] | 程书帅, 崔功军, 李方舟, 等. 纳米SiC增强CoCrMo高温抗磨复合材料及摩擦学性能[J]. 摩擦学学报, 2022, 42(6): 1127-1137. |

| Cheng Shu-shuai, Cui Gong-jun, Li Fang-zhou, et al. High-temperature wear resistant CoCrMo matrix composites reinforced by nano-SiC and tribological properties [J]. Tribology, 2022, 42(6): 1127-1137. | |

| [31] | Cui G J, Liu Y P, Li S, et al. Nano-TiO2 reinforced CoCr matrix wear resistant composites and high-temperature tribological behaviors under unlubricated condition[J]. Scientific Reports, 2020, 10(1): 6816. |

| [32] | Cui G J, Qian Y, Bian C X, et al. CoCrNi matrix high-temperature wear resistant composites with micro- and nano-Al2O3 reinforcement[J]. Composites Communications, 2020, 22: 100461. |

| [33] | 钱钰, 李赛, 崔功军, 等. 纳米ZrO2增强CoCrW基复合材料的制备及高温摩擦学性能研究[J]. 润滑与密封, 2021, 46(9): 29-31. |

| Qian Yu, Li Sai, Cui Gong-jun, et al. Preparation and high-temperature tribological properties of nano-ZrO2 reinforced CoCrW matrix composites[J]. Lubrication Engineering, 2021, 46(9): 40-46. | |

| [34] | 程书帅. SiC(纳米)/CoCrMo 高温抗磨复合材料的设计及摩擦学性能研究[D]. 太原: 太原理工大学, 2022. |

| Cheng Shu-shuai.Design and tribological properties of high-temperature wear resistant CoCrMo matrixcomposites reinforced by nano-SiC [D]. Taiyuan: Taiyuan University of Technology, 2022. | |

| [35] | Liu H Q, Cui G J, Shi R B, et al. MoS2/CoCrNi self-lubricating composite coating and its high-temperature tribological properties[J]. Rare Metal Materials and Engineering, 2020,49(12): 4280-4289. |

| [36] | 钱钰, 崔功军, 卞灿星, 等. WS2增强CoCrTi复合材料的制备及高温摩擦学性能[J]. 金属热处理, 2021, 46(12): 94-99. |

| Qian Yu, Cui Gong-jun, Bian Can-xing, et al. Preparation and high-temperature tribological properties of WS2 reinforced CoCrTi composites[J]. Heat Treatment of Metals, 2021, 46(12): 94-99. | |

| [37] | Cui G J, Liu H Q, Li S, et al. Design and high-temperature tribological properties of CoCrW with rare earth fluoride composites[J]. Journal of Materials Research and Technology, 2020, 9(2): 2402-2411. |

| [38] | Ren Q C, Cui G J, Li T Y, et al. High-temperature wear behavior of cobalt matrix composites reinforced by LaF3 and CeO2 [J]. Tribology Letters, 2021, 69(4): 149. |

| [39] | Nguyen C, Tieu A K, Su L H, et al. Microstructure, mechanical and tribological properties of Al0.3CrFeNiTi0.3-CaF2/BaF2 self-lubricating composite fabricated by spark plasma sintering[J]. Tribology International, 2023, 188: 108855. |

| [40] | 熊党生, 李建亮. 高温摩擦磨损与润滑[M]. 西安: 西北工业大学出版社, 2013. |

| (Xiong Dang-sheng, Li Jian-liang [M]. Xi’an: Northwestern Polytechnical University Press, 2013.) | |

| [41] | Finkin E F. A theory for the effects of film thickness and normal load in the friction of thin films[J]. Journal of Lubrication Technology, 1969, 91(3): 551-556. |

| [42] | Aouadi S M, Gao H, Martini A, Scharf T W, Muratore C. Lubricious oxide coatings for extreme temperature applications: a review [J]. Surface and Coatings Technology, 2014, 257: 266-277. |

| [43] | Stone D, Liu J, Singh D P, et al. Layered atomic structures of double oxides for low shear strength at high temperatures[J]. Scripta Materialia, 2010, 62(10): 735-738. |

| [44] | Erdemir A. A crystal chemical approach to the formulation of self-lubricating nanocomposite coatings [J]. Surface and Coatings Technology, 2005, 200(5/6): 1792-1796. |

| [45] | Finkin E F. Theoretical analysis of factors controlling the wear of solid-film-lubricated ball-bearings [J]. Wear, 1984, 94(2): 211-217. |

| [46] | Aouadi S M, Singh D P, Stone D S, et al. Adaptive VN/Ag nanocomposite coatings with lubricious behavior from 25 to 1 000 °C [J]. Acta Materialia, 2010, 58(16): 5326-5331. |

| [47] | Albrecht T A, Stern C L, Poeppelmeier K R. The Ag2O-V2O5-HF(aq) system and crystal structure of α-Ag3VO4 [J]. Inorganic Chemistry, 2007, 46(5): 1704-1708. |

| [48] | Murakami T, Ouyang J H, Umeda K, et al. High-temperature friction properties of BaSO4 and SrSO4 powder films formed on Al2O3 and stainless steel substrates[J]. Materials Science and Engineering: A, 2006, 432(1/2): 52-58. |

| [49] | Liu C, Zou J M, Yang J Z, et al. Boosting sodium-ion storage performance by tailoring intragranular porous WS2/C nanocomposites anode[J]. Applied Surface Science, 2023, 616: 156532. |

| [50] | Kong X, Sun W Y, Wang Q C, et al. Improving high-temperature wear resistance of NiCr matrix self-lubricating composites by controlling oxidation and surface texturing[J]. Journal of Materials Science & Technology, 2022, 131: 253-263. |

| [51] | Liu S S, Chen Y H, An Z B, et al. Microstructure and oxidation of NiCr alloys studied by analytical in situ environmental TEM[J]. Corrosion Science, 2023, 224: 111525. |

| [52] | 彭玉春, 陈泷, 张祥雷, 等. 高温滑动摩擦中釉质层的综述研究[J]. 材料保护, 2022, 55(6): 147-153. |

| Peng Yu-chun, Chen Long, Zhang Xiang-lei, et al. A review on glaze layers in high temperature sliding friction[J]. Material Protection, 2022, 55(6): 147-153. | |

| [53] | Stott F H, Wood G C. The influence of oxides on the friction and wear of alloys[J]. Tribology International, 1978, 11(4): 211-218. |

| [54] | Barnes D J, Wilson J E, Stott F H, et al. The influence of oxide films on the friction and wear of Fe-5% Cr alloy in controlled environments[J]. Wear, 1977, 45(2): 161-176. |

| [55] | Jiang J R, Stott F H, Stack M M. A generic model for dry sliding wear of metals at elevated temperatures[J]. Wear, 2004, 256(9/10): 973-985. |

| [56] | Inman I A, Datta P K, Du H L, et al. Studies of high temperature sliding wear of metallic dissimilar interfaces[J]. Tribology International, 2005, 38(9): 812-823. |

| [57] | Lepesant P, Boher C, Berthier Y, et al. A phenomenological model of the third body particles circulation in a high temperature contact[J]. Wear, 2013, 298: 66-79. |

| [58] | Zhao Z K, Shen Y, Liu Y, et al. Low and high temperature effects on friction and wear performance of Cr-plated cylinder liner[J]. Wear, 2024, 546: 205329. |

| [59] | Motallebzadeh A, Atar E, Cimenoglu H. Sliding wear characteristics of molybdenum containing Stellite 12 coating at elevated temperatures[J]. Tribology International, 2015, 91: 40-47. |

| [60] | Jiang J J, Xin B B, Zhang A J, et al. Investigation of mechanical properties and high temperature wear resistance of CoFeNi1.5VZr0.4Si x high entropy alloys optimized by Si alloying[J]. Tribology International, 2024, 200: 110165. |

| [61] | Chen W, Peng Y C, Wang Y F, et al. Research on high-temperature friction and wear performances of Stellite 12 laser cladding layer against coated boron steels[J]. Wear, 2023, 520: 204665. |

| [62] | Ouyang J, Liang X S, Liu Z G, et al. Friction and wear properties of hot-pressed NiCr-BaCr2O4 high temperature self-lubricating composites[J]. Wear, 2013, 301(1/2): 820-827. |

| [63] | Li J L, Xiong D S, Huang Z J, et al. Effect of Ag and CeO2 on friction and wear properties of Ni-base composite at high temperature[J]. Wear, 2009, 267(1/2/3/4): 576-584. |

| [64] | Xu J, Kong X, Chen M H, et al. High-entropy FeNiCoCr alloys with improved mechanical and tribological properties by tailoring composition and controlling oxidation[J]. Journal of Materials Science & Technology, 2021, 82: 207-213. |

| [65] | Kato H. Severe-mild wear transition by supply of oxide particles on sliding surface[J]. Wear, 2003, 255: 426-429. |

| [66] | Dreano A, Fouvry S, Sao-Joao S, et al. The formation of a cobalt-based glaze layer at high temperature: a layered structure[J]. Wear, 2019, 440: 203101. |

| [67] | Dreano A, Baydoun S, Fouvry S, et al. Influence of a pre-existing glaze layer on the fretting-wear response of HS25 cobalt-based alloy subjected to various temperature conditions[J]. Wear, 2022, 488: 204144. |

| [68] | Viat A, Dreano A, Fouvry S, et al. Fretting wear of pure cobalt chromium and nickel to identify the distinct roles of HS25 alloying elements in high temperature glaze layer formation[J]. Wear, 2017, 376: 1043-1054. |

| [69] | 李甜甜, 孙耀宁, 张丽, 等. 表面织构化对摩擦学性能影响的研究进展[J]. 机械工程材料, 2020, 44(5): 44-48. |

| Li Tian-tian, Sun Yao-ning, Zhang Li, et al. Research progress on effect of surface texturing on tribological properties[J]. Materials for Mechanical Engineering, 2020, 44(5): 44-48. | |

| [70] | Grabon W, Koszela W, Pawlus P, et al. Improving tribological behaviour of piston ring-cylinder liner frictional pair by liner surface texturing[J]. Tribology International, 2013, 61: 102-108. |

| [71] | 魏晓凤. 激光干涉制备人工髋关节仿生微纳结构表面技术的研究[D]. 长春: 长春理工大学, 2016. |

| Wei Xiao-feng. Fabrication of bionic micro and nano surface structures of artificial hip joints by laser interference[D]. Changchun: Changchun University of Science and Technology, 2016. | |

| [72] | 孔轩. NiCr基核壳结构自润滑复合材料的设计与摩擦学性能研究[D]. 沈阳: 东北大学, 2023. |

| Kong Xuan. Design and tribological properties of the NiCr based self-lubricating composites with core-shell structure [D]. Shenyang: Northeastern University, 2023. | |

| [73] | Kong X, Liu Y, Chen M H, et al. Heterostructured NiCr matrix composites with high strength and wear resistance[J]. Journal of Materials Science & Technology, 2022, 105: 142-152. |

| [74] | Hoagland R G, Kurtz R J, Henager C H. Slip resistance of interfaces and the strength of metallic multilayer composites[J]. Scripta Materialia, 2004, 50(6): 775-779. |

| [75] | Gouveia A F, Sczancoski J C, Ferrer M M, et al. Experimental and theoretical investigations of electronic structure and photoluminescence properties of β-Ag2MoO4 microcrystals[J]. Inorganic Chemistry, 2014, 53(11): 5589-5599. |

| [76] | Hao E K, An Y L, Chen J, et al. In-situ formation of layer-like Ag2MoO4 induced by high-temperature oxidation and its effect on the self-lubricating properties of NiCoCrAlYTa/Ag/Mo coatings[J]. Journal of Materials Science & Technology, 2021, 75: 164-173. |

| [77] | Zhen Y, Chen M H, Yu C T, et al. High temperature self-lubricating Ti-Mo-Ag composites with exceptional high mechanical strength and wear resistance[J]. Journal of Materials Science & Technology, 2024, 180: 80-90. |

| [78] | Shi X L, Yao J, Xu Z S, et al. Tribological performance of TiAl matrix self-lubricating composites containing Ag, Ti3SiC2 and BaF2/CaF2 tested from room temperature to 600℃[J]. Materials & Design, 2014, 53: 620-633. |

| [79] | Wang L, Liu Z Q, Li S F, et al. Few-layered Ti3C2 MXene-coated Ti-6Al-4V composite powder for high-performance Ti matrix composite [J]. Composites Communications, 2022, 33: 101238. |

| [80] | Shi X L, Xu Z S, Wang M, et al. Tribological behavior of TiAl matrix self-lubricating composites containing silver from 25 to 800 ℃ [J]. Wear, 2013, 303(1/2): 486-494. |

| [81] | Xu Z S, Shi X L, Wang M, et al. Effect of Ag and Ti3SiC2 on tribological properties of TiAl matrix self-lubricating composites at room and increased temperatures [J]. Tribology Letters, 2014, 53(3): 617-629. |

| [82] | Shen Q, Shi X L, Yang K, et al. Tribological performance of TiAl matrix composites containing silver and V2O5 nanowires at elevated temperatures [J]. RSC Advances, 2016, 6(61): 56294-56302. |

| [1] | 赵阳, 王宇航, 张涛, 王福会. 半导体制程设备铝合金涂层腐蚀失效行为研究进展[J]. 东北大学学报(自然科学版), 2025, 46(3): 28-45. |

| [2] | 陈猛, 杨新明, 王瑜婷, 张通. 聚丙烯纤维混凝土高温传热性能多尺度计算模型[J]. 东北大学学报(自然科学版), 2025, 46(2): 111-117. |

| [3] | 巩亚东, 李远峰, 温泉, 任启震. 2.5D Cf/SiC复合材料与SiC陶瓷微磨削性能对比试验研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 52-60. |

| [4] | 徐运超, 巩亚东, 田近民, 张伟健. 镍基单晶高温合金磨削表面白层的形成规律[J]. 东北大学学报(自然科学版), 2024, 45(9): 1301-1308. |

| [5] | 夏瑜, 刘静, 何绪文, 杨洪英. 臭氧催化氧化对城市污水反渗透浓水中有机物的去除特性[J]. 东北大学学报(自然科学版), 2024, 45(9): 1342-1351. |

| [6] | 马廉洁, 孙立业, 邱喆, 李红双. 二维超声振动辅助磨削的磨削力建模[J]. 东北大学学报(自然科学版), 2024, 45(8): 1135-1142. |

| [7] | 李远峰, 温泉, 巩亚东, 唐本甲. 2.5D Cf /SiC复合材料微尺度磨削试验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1143-1149. |

| [8] | 代峰, 柳静献. 钢铁企业除尘用涤纶滤料在复杂烟气环境下的老化行为分析[J]. 东北大学学报(自然科学版), 2024, 45(6): 883-889. |

| [9] | 王梦奇, 刘越, 肖春林, 刘春明. SiCp粒径级配对55%SiCp/6061Al复合材料组织和性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(6): 802-807. |

| [10] | 孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642. |

| [11] | 左晋松, 狄跃忠, 耿佃桥. 电沉积制备氢氧化镁多物理场的数值模拟[J]. 东北大学学报(自然科学版), 2024, 45(5): 652-659. |

| [12] | 张磊, 蒋开喜, 谢锋, 路殿坤. 氧化铜精矿熔炼过程中铜、钴、铁的还原行为[J]. 东北大学学报(自然科学版), 2024, 45(3): 337-345. |

| [13] | 冯宇庭, 成丽, 王可媚, 胡恩柱. 金属矿物对丁铵黑药在饱和多孔介质中迁移特性的影响[J]. 东北大学学报(自然科学版), 2024, 45(3): 401-406. |

| [14] | 陈猛, 洪宇. RTP-PVA混杂纤维的工程水泥基复合材料干缩性能试验研究[J]. 东北大学学报(自然科学版), 2024, 45(3): 407-414. |

| [15] | 宋岩, 赵冰, 李艳军, 赵羚伯. 某金矿氰化尾渣氧化焙烧无害化处置及机理研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 262-269. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||