东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (12): 57-65.DOI: 10.12068/j.issn.1005-3026.2025.20240137

温雪龙, 竺光升, 张文波, 韩凤兵

收稿日期:2024-06-19

出版日期:2025-12-15

发布日期:2026-02-09

通讯作者:

温雪龙

基金资助:Xue-long WEN, Guang-sheng ZHU, Wen-bo ZHANG, Feng-bing HAN

Received:2024-06-19

Online:2025-12-15

Published:2026-02-09

Contact:

Xue-long WEN

摘要:

利用激光熔覆成形技术制备陶瓷颗粒增强高熵合金.采用电子维氏硬度仪测量试件硬度,分析激光工艺参数、SiC陶瓷颗粒增强相含量及Al元素含量对激光熔覆高熵合金硬度的影响.结果表明:高熵合金熔覆层硬度值随激光功率增大变化不明显;随着扫描速度与送粉速率的增大,熔覆层硬度呈逐渐增大趋势;随着SiC陶瓷颗粒增强相含量增加,试件内部产生晶格畸变且微观应力增大,高熵合金硬度明显提升;Al元素对陶瓷颗粒增强高熵合金的性能具有调控作用,可进一步提高合金硬度.

中图分类号:

温雪龙, 竺光升, 张文波, 韩凤兵. 激光熔覆SiC陶瓷颗粒增强高熵合金硬度的实验研究[J]. 东北大学学报(自然科学版), 2025, 46(12): 57-65.

Xue-long WEN, Guang-sheng ZHU, Wen-bo ZHANG, Feng-bing HAN. Experimental Study on Hardness of SiC Ceramic Particles-Reinforced High-Entropy Alloy by Laser Cladding[J]. Journal of Northeastern University(Natural Science), 2025, 46(12): 57-65.

| 实验序号 | 激光功率P/W | 送粉速率vf/(r∙min-1) | 扫描速度vs/(mm∙min-1) |

|---|---|---|---|

| 1 | 1 000,1 250,1 500,1 750,2 000 | 1.1 | 8 |

| 2 | 1 500 | 0.7,0.9,1.1,1.3,1.5 | 8 |

| 3 | 1 500 | 1.1 | 4,6,8,10,12 |

表1 单因素实验方案

Table 1 Single-factor experimental schemes

| 实验序号 | 激光功率P/W | 送粉速率vf/(r∙min-1) | 扫描速度vs/(mm∙min-1) |

|---|---|---|---|

| 1 | 1 000,1 250,1 500,1 750,2 000 | 1.1 | 8 |

| 2 | 1 500 | 0.7,0.9,1.1,1.3,1.5 | 8 |

| 3 | 1 500 | 1.1 | 4,6,8,10,12 |

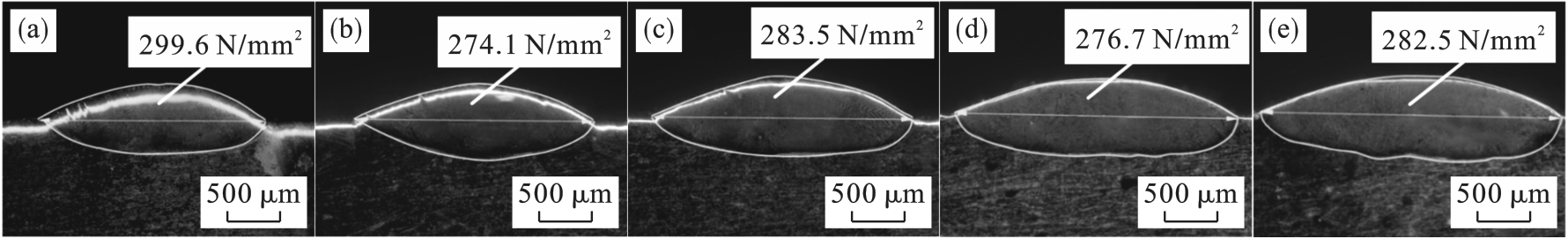

图5 不同激光功率下熔覆层硬度(a)—P=1 000 W; (b)—P=1 250 W; (c)—P=1 500 W; (d)—P=1 750 W; (e)—P=2 000 W.

Fig.5 Hardness of cladding layer under different laser powers

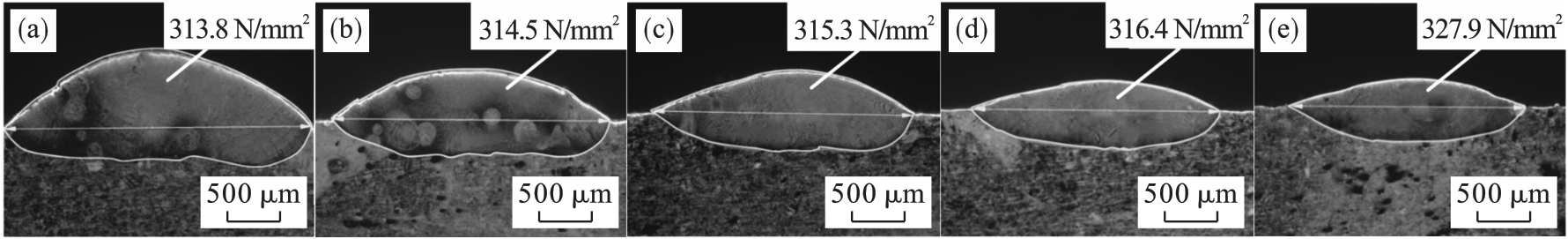

图7 不同扫描速度下熔覆层硬度(a)—vs=4 mm/s; (b)—vs=6 mm/s; (c)—vs=8 mm/s; (d)—vs=10 mm/s; (e)—vs=12 mm/s.

Fig.7 Hardness of cladding layer at different scanning speeds

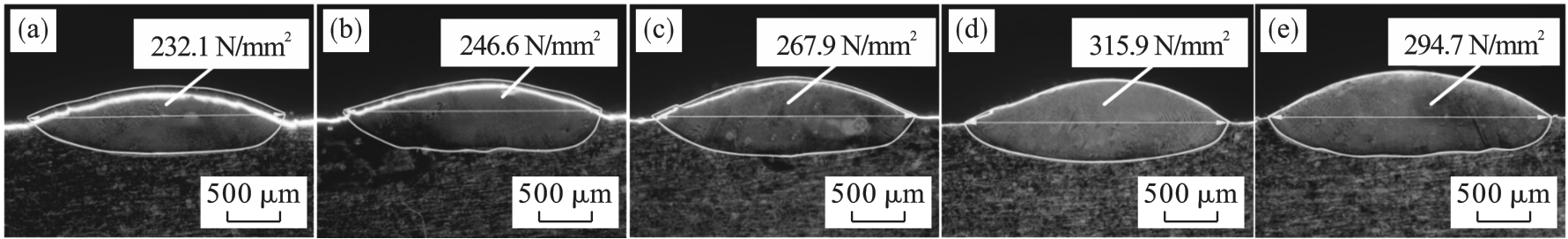

图9 不同送粉速率下熔覆层硬度(a)—vf=0.7 mm/s; (b)—vf=0.9 mm/s; (c)—vf=1.1 mm/s; (d)—vf=1.3 mm/s; (e)—vf=1.5 mm/s.

Fig.9 Hardness of cladding layer at different powder feeding rates

| [1] | Guo Y J, Li C G, Zeng M, et al. In-situ TiC reinforced CoCrCuFeNiSi0.2 high-entropy alloy coatings designed for enhanced wear performance by laser cladding[J]. Materials Chemistry and Physics, 2020,242:122522. |

| [2] | Zhou X L, He L J, Zhang M N, et al. Effect of ceramic particles on microstructure and properties of CoCrMoNbTi high-entropy alloy coating fabricated by laser cladding[J]. Optik, 2023,285:170987. |

| [3] | Ghanbariha M, Farvizi M, Ebadzadeh T, et al. Effect of ZrO2 particles on the nanomechanical properties and wear behavior of AlCoCrFeNi-ZrO2 high entropy alloy composites[J]. Wear, 2021,484/485:204032. |

| [4] | Lian G F, Yang J H, Chen C R, et al. Influences of Ti and Mo alloying on the microstructure and properties of laser cladding for CoCrFeNi high-entropy alloys[J]. Journal of Materials Research and Technology, 2023,27:5945-5964. |

| [5] | He Y L, Cong M Q, Lei W N, et al. Microstructure, mechanical and corrosion properties of FeCrNiCoMnSi0.1 high-entropy alloy coating via TIG arc melting technology and high-frequency ultrasonic impact with welding[J]. Materials Today Advances, 2023,20:100443. |

| [6] | Liu B C, Chen H S, Zhou J, et al. Interfacial bonding behavior of WC/AlCoCrFeNi2.1 eutectic high-entropy alloy matrix composites fabricated by fast hot pressing sintering[J]. Vacuum, 2023,217:112574. |

| [7] | Wang Y, Li P J, Ma N, et al. Effect of Y2O3 on the microstructure and tribology property of WMoTaNb refractory high entropy alloy coating prepared by laser cladding[J]. International Journal of Refractory Metals and Hard Materials, 2023,115:106273. |

| [8] | Chen B, Li X M, Tian L Y, et al. The CrFeNbTiMo x refractory high-entropy alloy coatings prepared on the 40Cr by laser cladding[J]. Journal of Alloys and Compounds, 2023,966:171630. |

| [9] | Shen Q K, Kong X D, Chen X Z, et al. Powder plasma arc additive manufactured CoCrFeNi(SiC) x high-entropy alloys: microstructure and mechanical properties[J]. Materials Letters, 2021,282:128736. |

| [10] | Zhu T, Wu H, Zhou R, et al. Microstructures and tribological properties of TiC reinforced FeCoNiCuAl high-entropy alloy at normal and elevated temperature[J]. Metals, 2020,10(3):387. |

| [11] | Bartkowski D, Kinal G. Microstructure and wear resistance of Stellite-6/WC MMC coatings produced by laser cladding using Yb:YAG disk laser[J]. International Journal of Refractory Metals and Hard Materials, 2016,58:157-164. |

| [12] | Grewal H S, Nair R B, Arora H S. Complex concentrated alloy bimodal composite claddings with enhanced cavitation erosion resistance[J]. Surface and Coatings Technology, 2020,392:125751. |

| [13] | 徐勇勇, 孙琨, 邹增琪, 等. 选区激光熔化制备 Al0.5CoCrFeNi高熵合金的工艺参数及组织性能[J].西安交通大学学报, 2018,52(1):151-157. |

| Xu Yong-yong, Sun Kun, Zou Zeng-qi, et al. Processing parameters, microstructure and properties of Al0.5CoCrFeNi high entropy alloy prepared by selective laser melting [J]. Journal of Xi'an Jiaotong University, 2018,52(1):151-157. | |

| [14] | 李刚, 温影, 于中民, 等. Al 含量对 CrFeNiAl x Si 系高熵合金性能的影响[J].材料研究学报,2021,35(9):712-720. |

| Li Gang, Wen Ying, Yu Zhong-min, et al. Effect of Al content on the properties of CrFeNiAl x Si high entropy alloy [J]. Chinese Journal of Materials Research, 2021,35(9):712-720. |

| [1] | 任启震, 孟贵如, 巩亚东, 李远峰. 异质材料修复K403叶片界面组织及力学性能研究[J]. 东北大学学报(自然科学版), 2025, 46(9): 102-112. |

| [2] | 温雪龙, 赵正豪, 宋林原, 王承宝. 选区激光熔化FeCoNiCr系高熵合金机械性能实验研究[J]. 东北大学学报(自然科学版), 2025, 46(6): 76-85. |

| [3] | 张贺, 梁超杰, 孙聪. 激光热辅助渗碳磨削20CrMnTi表面强化机理[J]. 东北大学学报(自然科学版), 2025, 46(5): 54-61. |

| [4] | 巩亚东, 李远峰, 温泉, 任启震. 2.5D Cf/SiC复合材料与SiC陶瓷微磨削性能对比试验研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 52-60. |

| [5] | 李远峰, 温泉, 巩亚东, 唐本甲. 2.5D Cf /SiC复合材料微尺度磨削试验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1143-1149. |

| [6] | 杨尚武, 瞿海霞, 黎恒君, 刘常升. 激光熔覆(Ti,W)C增强镍基涂层的性能[J]. 东北大学学报(自然科学版), 2024, 45(7): 953-959. |

| [7] | 王梦奇, 刘越, 肖春林, 刘春明. SiCp粒径级配对55%SiCp/6061Al复合材料组织和性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(6): 802-807. |

| [8] | 孙行, 陈伟, 罗昌, 刘常升. 高钒半高速钢合金熔覆层回火态显微组织和性能[J]. 东北大学学报(自然科学版), 2024, 45(5): 636-642. |

| [9] | 周云光, 田川川, 王书海, 陈晗. SiC陶瓷的磨削去除机理及参数对磨削力影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 548-554. |

| [10] | 蒋金哲, 刘越, 刘春明. 二次碳化物特征调控及其对高碳高合金马氏体钢耐磨性的影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 490-498. |

| [11] | 姚文博, 刘忱, 商硕, 刘常升. 扫描速度对激光熔覆Fe-Al合金熔覆层组织及性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(2): 170-178. |

| [12] | 温雪龙, 桂宏泽, 巩亚东, 王蒙山. 高熵合金微尺度磨削力实验研究[J]. 东北大学学报(自然科学版), 2024, 45(12): 1734-1743. |

| [13] | 温雪龙, 张文波, 巩亚东, 李俊鹏. FeCoNiCr系高熵合金铣削力仿真与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(11): 1579-1586. |

| [14] | 刘俊汝, 张国华, 周国治. w(Fe)/w(Ni)对Mo2FeB2基金属陶瓷的影响[J]. 东北大学学报(自然科学版), 2023, 44(9): 1269-1278. |

| [15] | 乔百友, 郝元卿, 唐忠, 汪锐. 一种NMI结合HSIC0的台风移动轨迹多因素相关分析方法[J]. 东北大学学报(自然科学版), 2023, 44(9): 1234-1244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||