Journal of Northeastern University(Natural Science) ›› 2025, Vol. 46 ›› Issue (10): 96-103.DOI: 10.12068/j.issn.1005-3026.2025.20249012

• Materials & Metallurgy • Previous Articles Next Articles

Yu-bo GAO1,2, Yan-ping BAO1, Min WANG1, Ying WANG2

Received:2024-03-18

Online:2025-10-15

Published:2026-01-13

CLC Number:

Yu-bo GAO, Yan-ping BAO, Min WANG, Ying WANG. Numerical Simulation on Deformation Behavior of High-Carbon Steel Billet During Mechanical Reduction Process[J]. Journal of Northeastern University(Natural Science), 2025, 46(10): 96-103.

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.86 | 0.20 | 0.52 | ≤0.010 | ≤0.010 | ≤0.05 | ≤0.03 |

Table 1 Chemical composition of studied steel grade

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.86 | 0.20 | 0.52 | ≤0.010 | ≤0.010 | ≤0.05 | ≤0.03 |

| 断面尺寸 | 弧形半径/m | 结晶器有效长度 | 二冷区长度/m | 压辊直径/mm | 压下覆盖区间/m |

|---|---|---|---|---|---|

| mm×mm | mm | ||||

| 160×160 | 10 | 800 | 7.7 | 450 | 13.6~18.0 |

Table 2 Basic parameters of billet caster

| 断面尺寸 | 弧形半径/m | 结晶器有效长度 | 二冷区长度/m | 压辊直径/mm | 压下覆盖区间/m |

|---|---|---|---|---|---|

| mm×mm | mm | ||||

| 160×160 | 10 | 800 | 7.7 | 450 | 13.6~18.0 |

| 拉速/(m·min-1) | 二冷强度/(L·kg-1) | 过热度/℃ | 单辊压下量区间/mm | 压下位置区间 |

|---|---|---|---|---|

| 2.3 | 0.35 | 20~35 | 1~5 | 0.1~0.9 |

Table 3 Parameters for casting and reduction

| 拉速/(m·min-1) | 二冷强度/(L·kg-1) | 过热度/℃ | 单辊压下量区间/mm | 压下位置区间 |

|---|---|---|---|---|

| 2.3 | 0.35 | 20~35 | 1~5 | 0.1~0.9 |

| 参数 | 2# | 3# | 4# | 5# | 6# |

|---|---|---|---|---|---|

| 压下作用力计算值/kN | 32.6 | 109.1 | 203.8 | 306.8 | 254.4 |

| 压下作用力实测值/kN | 31 | 106 | 196 | 295 | 264 |

| 偏差/% | 4.91 | 2.84 | 3.83 | 3.85 | -3.77 |

Table 4 Comparison of calculated values and measured values of reduction reaction forces

| 参数 | 2# | 3# | 4# | 5# | 6# |

|---|---|---|---|---|---|

| 压下作用力计算值/kN | 32.6 | 109.1 | 203.8 | 306.8 | 254.4 |

| 压下作用力实测值/kN | 31 | 106 | 196 | 295 | 264 |

| 偏差/% | 4.91 | 2.84 | 3.83 | 3.85 | -3.77 |

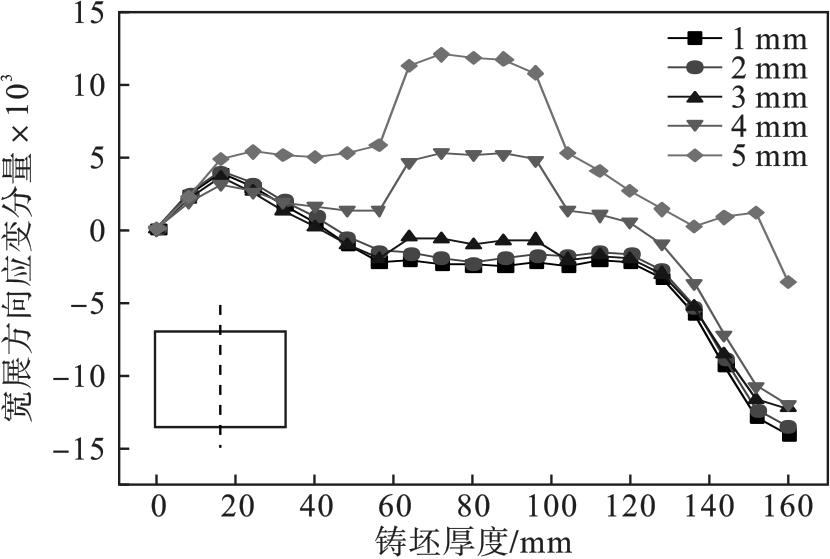

Fig.15 Effect of reduction amount on distribution of strain component in spread direction along vertical central line of billet surface strain component in spread direction

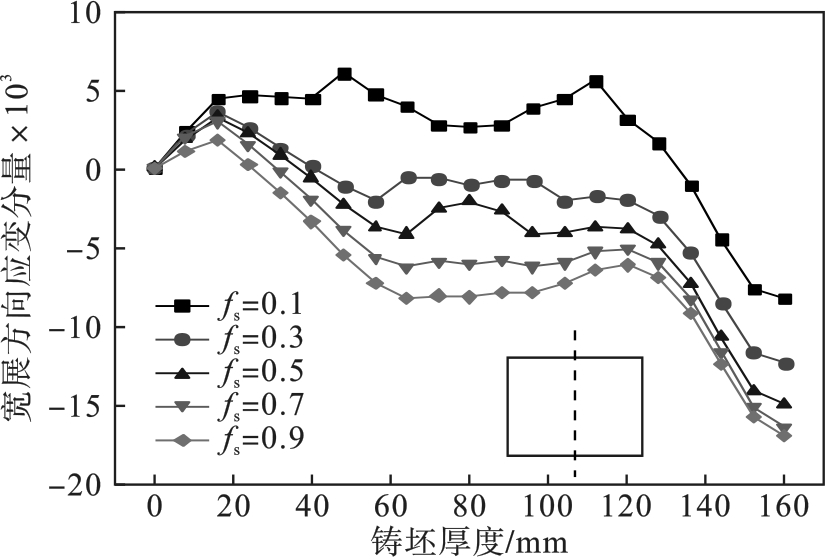

Fig.17 Effect of reduction position on distribution of strain component in spread direction along vertical central line of billet surface strain component in spread direction

| [1] | Chen C Y, Wang L, Sun M, et al. Recent advances in inclusions and central segregation control technology in tyre cord steel and saw wire steel[J]. Ironmaking & Steelmaking, 2023, 50(2): 179-214. |

| [2] | Sivesson P, Ortlund T, Widell B. Improvement of inner quality in continuously cast billets through thermal soft reduction and use of multivariate analysis of saved process variables[J]. Ironmaking & Steelmaking, 1996, 23(6): 504-511. |

| [3] | Zhang Z, Wu M H, Zhang H J, et al. Modeling of the as-cast structure and macrosegregation in the continuous casting of a steel billet: effect of M-EMS[J]. Journal of Materials Processing Technology, 2022, 301: 117434. |

| [4] | Han Y S, Yan W, Zhang J S, et al. Comparison and integration of final electromagnetic stirring and thermal soft reduction on continuous casting billet[J]. Journal of Iron and Steel Research International, 2021, 28(2): 160-167. |

| [5] | Zhang M Y, Bao Y P, Zhao L H, et al. Improvement of carbon segregation in cast bloom and heredity in hot-rolled bar[J]. Metallurgical Research & Technology, 2021, 118(6): 610. |

| [6] | Zong N F, Jing T, Liu Y. Comparative studies on a chamfer technology and a convex roll technology during the soft reduction process[J]. Archives of Metallurgy and Materials, 2021, 66(3): 819-829. |

| [7] | Zhang J Y, Wu C H, Ji C, et al. Evolution of microporosities in wide-thick continuous casting slab during heavy reduction process[J]. Steel Research International, 2022, 93(7): 2000601. |

| [8] | Yang B, Wang M L, Zhang H, et al. Optimization of heavy reduction process on continuous-casting bloom[J]. Metals, 2022, 12(11): 1873. |

| [9] | Chen X H, Deng W, Niu S. Industrial application of mechanical reduction on continuous casting of bearing steel bloom[J]. Processes, 2021, 9(12): 2280. |

| [10] | Okimori M, Nishihara R, Fukunaga S, et al. Development of soft reduction techniques for preventing center porosity occurrence in large size bloom[J]. Tetsu-to-Hagane, 1994, 80(8): 120-123. |

| [11] | Byrne C, Tercelli C. Mechanical soft reduction in billet casting[J]. Steel Times International, 2002, 26(10): 33-35. |

| [12] | Ludlow V, Normanton A, Anderson A, et al. Strategy to minimise central segregation in high carbon steel grades during billet casting[J]. Ironmaking & Steelmaking, 2005, 32(1): 68-74. |

| [13] | Zeng J, Chen W Q, Wang Q X, et al. Improving Inner quality in continuous casting rectangular billets: comparison between mechanical soft reduction and final electromagnetic stirring[J]. Transactions of the Indian Institute of Metals, 2016, 69(8): 1623-1632. |

| [14] | Nabeshima S, Nakato H, Fujii T, et al. Control of centerline segregation in continuously cast blooms by continuous forging process[J]. ISIJ International, 1995, 35(6): 673-679. |

| [15] | Gao Y B, Bao Y.P, Wang Y, et al. Development of a novel strand reduction technology for the continuous casting of homogeneous high-carbon steel billet[J]. Steel Research International, 2023, 94(5): 2200740. |

| [16] | Zhang M Y, Bao Y P, Zhao L H, et al. Formation and control of central cracks in alloy steel ZKG223[J]. Steel Research International, 2022, 93(11): 2200289. |

| [17] | Wu C H, Ji C, Zhu M Y. Numerical simulation of bulging deformation for wide-thick slab under uneven cooling conditions[J]. Metallurgical and Materials Transactions B, 2018, 49(3): 1346-1359. |

| [18] | Zong N F, Huang J, Liu Y, et al. Controlling centre segregation and shrinkage cavities without internal crack in as-cast bloom of steel GCr15 induced by soft reduction technologies[J]. Ironmaking & Steelmaking, 2021, 48(8): 944-952. |

| [1] | Yun-long HAO, Qing-hua XIE, Pei-yuan NI, Ying LI. Study on Multiphase Flow and Homogenization Behavior During Rare Earth Alloying of Molten Steel [J]. Journal of Northeastern University(Natural Science), 2025, 46(9): 73-80. |

| [2] | Qiang WANG, Qi-chi LE, Xiang-jie WANG. Development and Application of Key Generic Technologies for Electromagnetic Regulation in Large-Sized Metal Billet Preparation [J]. Journal of Northeastern University(Natural Science), 2025, 46(7): 131-138. |

| [3] | Bai-ling CHEN, Jin-hui NIU, Lian-guang WANG, Gang XU. Numerical Simulation Analysis of Prefabricated Steel-Tubular and Larsen Steel-Sheet Pile Cofferdam Structure [J]. Journal of Northeastern University(Natural Science), 2025, 46(6): 102-112. |

| [4] | Hai-yan WANG, Yan FENG, Qing-chao WANG, Wan-chun YU. Mechanical Characteristic Analysis of Carbon Fiber Reinforced Polymer Bolted Joints [J]. Journal of Northeastern University(Natural Science), 2025, 46(5): 71-79. |

| [5] | Xiu-li LIN, Min FAN, Jin-shuo YANG, Jing-xian LIU. Characteristics and Measurement of Air Velocity and Particulate Matter Mass Concentration Distribution in Upstream and Downstream of 90° Elbow [J]. Journal of Northeastern University(Natural Science), 2025, 46(5): 113-125. |

| [6] | Yu-chao HAN, Qing-hua XIE, Pei-yuan NI, Ying LI. Effect of Swirling-Flow Gas Injection Angle on Multiphase Flow and Mixing Behavior in RH Refining Process [J]. Journal of Northeastern University(Natural Science), 2025, 46(4): 16-23. |

| [7] | Ke-fan YU, Liang ZHAO, Hui DONG, Yong-qing HE. Effect of Initial Inclination Angle of Elastic Pillars on Heat Transfer Enhancement in Microchannel [J]. Journal of Northeastern University(Natural Science), 2025, 46(2): 42-49. |

| [8] | Shu-hong WANG, Ming-zhu REN, Shi-yu LI, Fu-rui DONG. Control of Unequal Strength Grouting Deformation During Close Distance Crossing of an Existing Station [J]. Journal of Northeastern University(Natural Science), 2025, 46(2): 126-135. |

| [9] | Xi YUAN, Ming-xu MA, Jie CHEN, Zhe-ying WANG. Numerical Simulation Study on Spindle Cooling Device for Oil-Free Scroll Vacuum Pumps [J]. Journal of Northeastern University(Natural Science), 2025, 46(1): 92-98. |

| [10] | Zhong-zheng LI, Zhao-xia WU, Jin-yang WANG, Zeng-xin KANG. Numerical Simulation of Mass and Heat Transfer in Iron Ore Sintering Process [J]. Journal of Northeastern University(Natural Science), 2025, 46(1): 35-43. |

| [11] | Zhi-qun ZHENG, Xian-zhen HUANG, Zhi-yuan JIANG, Xing-lin MIAO. Flow and Heat Transfer Characteristics and Structure Optimization of Helically Corrugated Tubes Based on Kriging Model [J]. Journal of Northeastern University(Natural Science), 2024, 45(7): 992-1001. |

| [12] | Jin-rui ZHANG, Xi-wen YAO, Kai-li XU, Xiu SUN. Optimization of CO Sensor Carrying Position of Mine Intelligent Inspection Vehicle [J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 721-728. |

| [13] | Xiang-ning MENG, Ming-jiang WANG, Xiang-yang LIU, Yue-wei SHENG. Analysis on Buffer Oscillation Behavior for Continuous Casting Mold [J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 668-674. |

| [14] | Jin-song ZUO, Yue-zhong DI, Dian-qiao GENG. Numerical Simulation of Multiple Physical Fields for the Preparation of Magnesium Hydroxide by Electrodeposition [J]. Journal of Northeastern University(Natural Science), 2024, 45(5): 652-659. |

| [15] | Yu-chao YAO, Zhong-qiu LIU, Wen-jie RONG, Bao-kuan LI. Effect of Feeding Steel Strip Carbon Content on Macrosegregation Distribution in Large Continuous Casting Round Bloom [J]. Journal of Northeastern University(Natural Science), 2024, 45(4): 499-506. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||