东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (11): 73-81.DOI: 10.12068/j.issn.1005-3026.2025.20240108

收稿日期:2024-05-09

出版日期:2025-11-15

发布日期:2026-02-07

通讯作者:

李小彭

基金资助:

Xiao-peng LI1,2( ), Xue-dong LI1, Bin LIU2, Bai-tao LI3

), Xue-dong LI1, Bin LIU2, Bai-tao LI3

Received:2024-05-09

Online:2025-11-15

Published:2026-02-07

Contact:

Xiao-peng LI

摘要:

为了分析滚道凹槽对圆柱滚子轴承动力学性能和振动特性的影响,以牵引电机圆柱滚子轴承为研究对象,建立具有波纹状凹槽的圆柱滚子轴承轴电流损伤模型.首先,采用分段函数描述由轴承滚道局部缺陷引起的附加位移,建立轴承局部缺陷损伤模型;其次,基于圆柱滚子轴承弹簧-质量简化模型,建立考虑滚道缺陷的轴承动力学模型;最后,通过仿真和实验研究了不同损伤程度对轴承振动特性及轴承载荷分布的影响规律,验证所建轴承模型的可靠性.结果表明,该模型有效反映了轴电流损伤引起的冲击激励和周期性变化规律,随着局部缺陷损伤程度的增加,轴承的振动响应和载荷分布波动加剧,轴承转动稳定性降低.

中图分类号:

李小彭, 李雪东, 刘彬, 李柏涛. 含局部缺陷的圆柱滚子轴承动力学建模与振动分析[J]. 东北大学学报(自然科学版), 2025, 46(11): 73-81.

Xiao-peng LI, Xue-dong LI, Bin LIU, Bai-tao LI. Dynamic Modeling and Vibration Analysis of Cylindrical Roller Bearings with Local Defects[J]. Journal of Northeastern University(Natural Science), 2025, 46(11): 73-81.

| 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|

| 外圈外径 | D1o | mm | 52 |

| 内圈外径 | D1i | mm | 34 |

| 外圈内径 | D2o | mm | 46 |

| 内圈内径 | D2i | mm | 25 |

| 滚子直径 | Db | mm | 6 |

| 滚子长度 | L1 | mm | 10 |

| 滚子数量 | Z | 个 | 13 |

| 轴承节圆直径 | Dp | mm | 40 |

表 1 N205EM轴承参数

Table 1 N205EM bearing parameters

| 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|

| 外圈外径 | D1o | mm | 52 |

| 内圈外径 | D1i | mm | 34 |

| 外圈内径 | D2o | mm | 46 |

| 内圈内径 | D2i | mm | 25 |

| 滚子直径 | Db | mm | 6 |

| 滚子长度 | L1 | mm | 10 |

| 滚子数量 | Z | 个 | 13 |

| 轴承节圆直径 | Dp | mm | 40 |

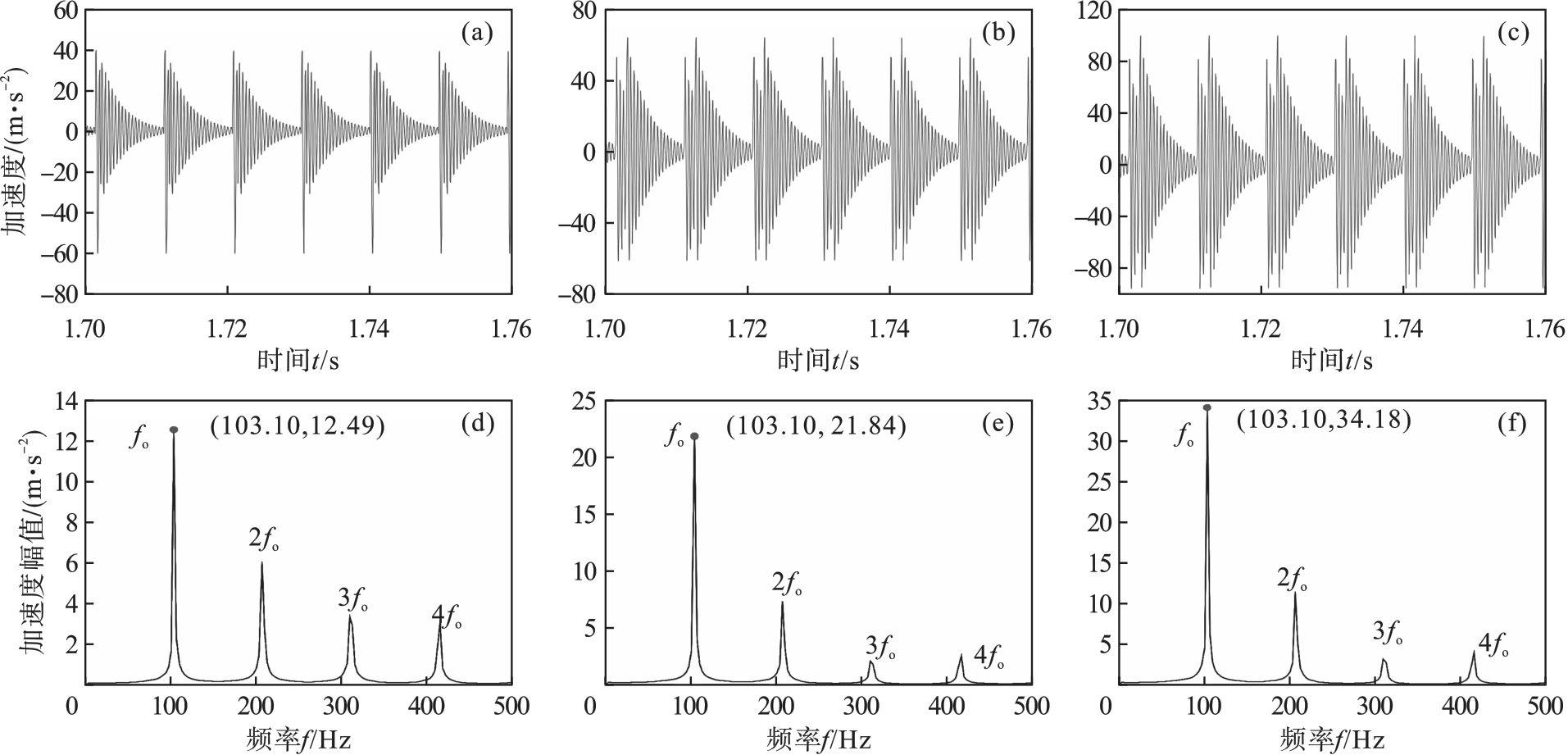

图11 不同损伤宽度的轴承动力学响应(a)—L=1 mm时的时域图; (b)—L=2 mm时的时域图; (c)—L=3 mm时的时域图;(d)—L=1 mm时的包络谱; (e)—L=2 mm时的包络谱; (f)—L=3 mm时的包络谱.

Fig.11 Dynamic response of bearings with different damage widths

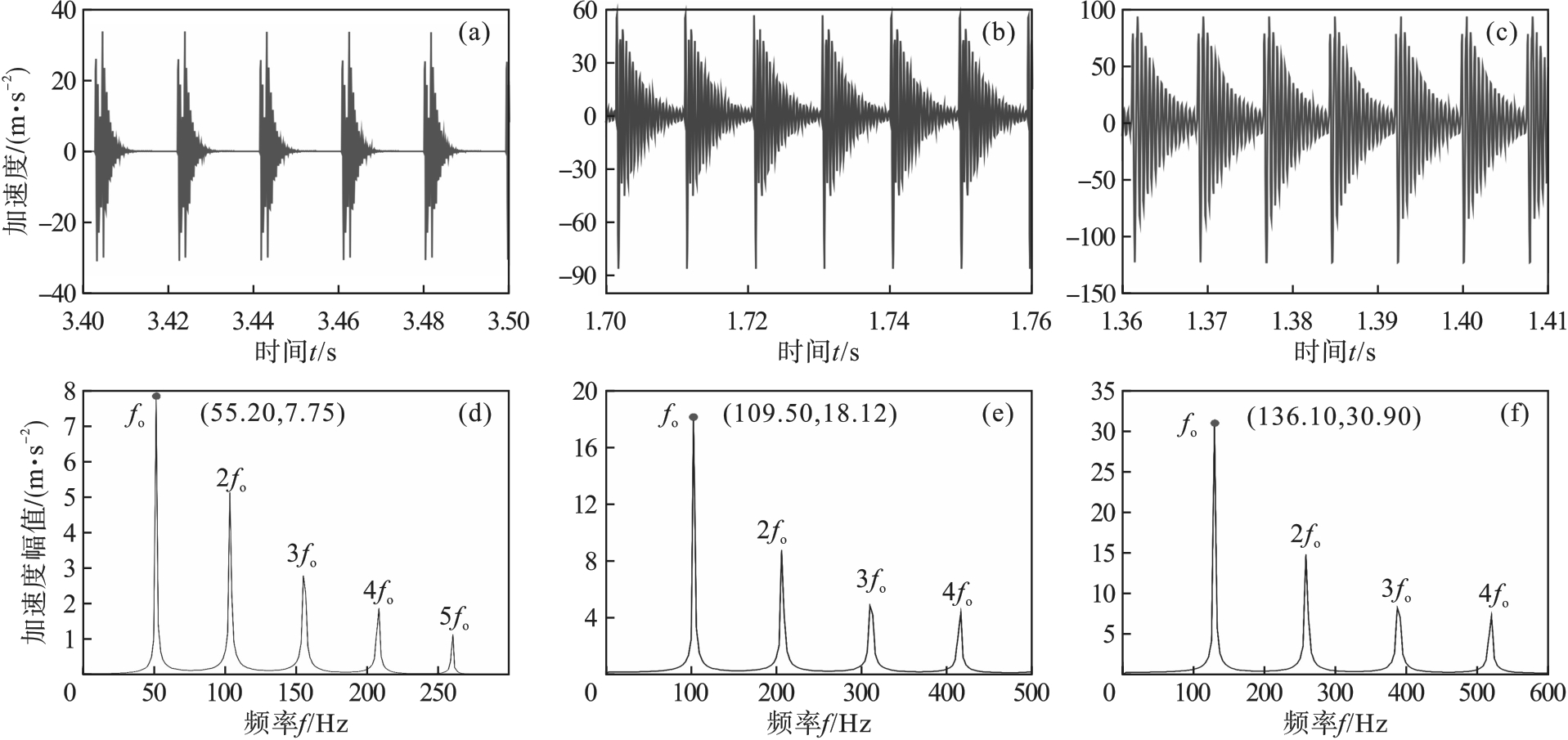

图12 不同转速的损伤轴承动力学响应(a)—n=600 r/min时的时域图; (b)—n=1 200 r/min时的时域图; (c)—n=1 500 r/min时的时域图;(d)—n=600 r/min的包络谱; (e)—n=1 200 r/min的包络谱; (f)—n=1 500 r/min的包络谱.

Fig.12 Dynamic response of damaged bearings at different rotating speeds

工况 转速 | 相对 误差 | 仿真误差 | 实验误差 | |||

|---|---|---|---|---|---|---|

| r/min | Hz | Hz | % | Hz | % | % |

| 600 | 55.20 | 53.71 | 2.70 | 55.25 | 0.09 | 2.79 |

| 1 200 | 109.50 | 106.20 | 3.01 | 110.50 | 0.90 | 3.89 |

| 1 500 | 136.10 | 131.84 | 3.13 | 138.13 | 1.47 | 4.56 |

表2 振动响应实验误差分析 (response)

Table 2 Experimental error analysis of vibration

工况 转速 | 相对 误差 | 仿真误差 | 实验误差 | |||

|---|---|---|---|---|---|---|

| r/min | Hz | Hz | % | Hz | % | % |

| 600 | 55.20 | 53.71 | 2.70 | 55.25 | 0.09 | 2.79 |

| 1 200 | 109.50 | 106.20 | 3.01 | 110.50 | 0.90 | 3.89 |

| 1 500 | 136.10 | 131.84 | 3.13 | 138.13 | 1.47 | 4.56 |

| [1] | Li Y, Qiu L, Zhi Y J, et al. An overview of bearing voltages and currents in rail transportation traction motors[J]. Journal of Zhejiang University: Science, 2023, 24(3): 226-242. |

| [2] | 李小彭, 曲兴超, 李柏涛, 等. 含轴电流损伤的球轴承动力学建模及特性分析[J]. 东北大学学报(自然科学版), 2023, 44(10): 1431-1439. |

| Li Xiao-peng, Qu Xing-chao, Li Bai-tao, et al. Dynamic modeling and property analysis of ball bearings with shaft current damage[J]. Journal of Northeastern University (Natural Science), 2023, 44(10): 1431-1439. | |

| [3] | Ma J J, Xue Y J, Han Q K, et al. Motor bearing damage induced by bearing current: a review[J]. Machines, 2022, 10(12): 1167. |

| [4] | 张轶东, 张苗, 赵博煊, 等. 海上风电机组发电机轴承电腐蚀检测及原因分析[J]. 船舶工程, 2022, 44(sup1): 106-110. |

| Zhang Yi-dong, Zhang Miao, Zhao Bo-xuan, et al. Detection and cause analysis of electrical corrosion on generator bearings of offshore wind turbines[J]. Ship Engineering, 2022, 44(sup1): 106-110. | |

| [5] | 温毅. 基于多模态流形的风力发电机轴承电流损伤识别与状态预测研究[D]. 湘潭: 湖南科技大学, 2019. |

| Wen Yi. Research on current damage identification and state prediction of wind turbine bearing based on multi-modal manifold[D]. Xiangtan: Hunan University of Science and Technology, 2019. | |

| [6] | Prudhom A, Antonino-Daviu J, Razik H, et al. Time-frequency vibration analysis for the detection of motor damages caused by bearing currents[J]. Mechanical Systems and Signal Processing, 2017, 84: 747-762. |

| [7] | Liu Y Q, Chen Z G, Li W, et al. Dynamic analysis of traction motor in a locomotive considering surface waviness on races of a motor bearing[J]. Railway Engineering Science, 2021, 29(04): 379-393. |

| [8] | Liu Y Q, Chen Z G, Zhai W M, et al. Dynamic investigation of traction motor bearing in a locomotive under excitation from track random geometry irregularity[J]. International Journal of Rail Transportation, 2022, 10(1): 72-94. |

| [9] | Patra P, Saran V H, Harsha S P. Chaotic dynamics of cylindrical roller bearing supported by unbalanced rotor due to localized defects[J]. Journal of Vibration and Control, 2020, 26(21/22): 1898-1908. |

| [10] | Niu L K, Cao H R, Hou H P, et al. Experimental observations and dynamic modeling of vibration characteristics of a cylindrical roller bearing with roller defects[J]. Mechanical Systems and Signal Processing, 2020, 138: 106553. |

| [11] | Cao H R, Su S M, Jing X, et al. Vibration mechanism analysis for cylindrical roller bearings with single/multi defects and compound faults[J]. Mechanical Systems and Signal Processing, 2020, 144: 106903. |

| [12] | Shi Z F, Liu J. An improved planar dynamic model for vibration analysis of a cylindrical roller bearing[J]. Mechanism and Machine Theory, 2020, 153: 103994. |

| [13] | Wang F T, Jing M Q, Yi J, et al. Dynamic modelling for vibration analysis of a cylindrical roller bearing due to localized defects on raceways[J]. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics, 2015, 229(1): 39-64. |

| [14] | Mattar A H A, Sayed H, Younes Y K, et al. Experimental verification and nonlinear dynamic response analysis of a rolling element bearing with localized defects[J]. Journal of Failure Analysis and Prevention, 2022, 22(4): 1753-1770. |

| [15] | 刘静. 滚动轴承缺陷非线性激励机理与建模研究[D]. 重庆: 重庆大学, 2014. |

| Liu Jing. Nonlinear vibration mechanisms and modeling of defects in rolling element bearings[D]. Chongqing: Chongqing University, 2014. | |

| [16] | Patel V N, Tandon N, Pandey R K. A dynamic model for vibration studies of deep groove ball bearings considering single and multiple defects in races[J]. Journal of Tribology, 2010, 132(4): 041101. |

| [17] | Randall R B, Antoni J. Rolling element bearing diagnostics: a tutorial[J]. Mechanical Systems and Signal Processing, 2011, 25(2): 485-520. |

| [1] | 李松, 于艺弘, 秦高梧. 热力学远平衡条件下制备金属新材料[J]. 东北大学学报(自然科学版), 2025, 46(8): 57-76. |

| [2] | 尚融雪, 孙浩英, 孙奇琪, 谭鑫悦. O2/CO2气氛下CH4/H2/空气层流预混火焰传播特性[J]. 东北大学学报(自然科学版), 2025, 46(6): 147-154. |

| [3] | 李小彭, 刘海龙, 樊星, 石冰. 输电线巡检机器人越障工况下基座旋转关节性能分析[J]. 东北大学学报(自然科学版), 2025, 46(4): 52-60. |

| [4] | 袁畅, 胡贤忠, 张娟. 惰性气体对C2H6可燃极限的影响及其产生原因[J]. 东北大学学报(自然科学版), 2025, 46(10): 74-80. |

| [5] | 王志强, 雷震宇. 表面周期性粗糙度对接触黏滑行为的影响[J]. 东北大学学报(自然科学版), 2025, 46(1): 76-82. |

| [6] | 罗忠, 赵江, 许春阳, 曹航. 考虑关节间隙的可调矢量喷管动力学特性[J]. 东北大学学报(自然科学版), 2025, 46(1): 61-67. |

| [7] | 刘明, 王鹏飞, 官宏, 马辉. 含耦合不对中的深沟球轴承灵敏度分析[J]. 东北大学学报(自然科学版), 2025, 46(1): 83-91. |

| [8] | 李小彭, 付嘉兴, 刘海龙, 尹猛. 柔性空间机械臂RBF神经网络补偿滑模控制策略[J]. 东北大学学报(自然科学版), 2024, 45(9): 1258-1267. |

| [9] | 刘芳名, 孙伟. 基于管-实体单元耦合的串联管路动力学建模及降应力优化[J]. 东北大学学报(自然科学版), 2024, 45(9): 1277-1286. |

| [10] | 赵英博, 修世超, 洪远, 步新宇. 户外型AGV越障仿真方法与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1107-1114. |

| [11] | 周晓光, 马鑫, 姜珊, 刘振宇. ESP工艺下DP600热轧双相钢铁素体相变模型[J]. 东北大学学报(自然科学版), 2024, 45(4): 483-489. |

| [12] | 周云光, 王书海, 陈晗, 李明. 精密车削镍基单晶高温合金去除机理仿真与实验[J]. 东北大学学报(自然科学版), 2024, 45(10): 1452-1458. |

| [13] | 郭俊, 印万忠, 杨斌, 朱张磊. 酸蚀对白云石可浮性的影响及其作用机理[J]. 东北大学学报(自然科学版), 2024, 45(1): 93-100. |

| [14] | 王方, 王鹏, 焦育威. 优化算法中均值信息利用研究[J]. 东北大学学报(自然科学版), 2024, 45(1): 49-57. |

| [15] | 胡兵, 黄贤振, 杜姗珊. 风电轴承疲劳寿命的可靠性灵敏度分析[J]. 东北大学学报(自然科学版), 2023, 44(8): 1128-1135. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||