东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (8): 41-56.DOI: 10.12068/j.issn.1005-3026.2025.20240163

潘虎成, 王森, 任玉平, 秦高梧

收稿日期:2024-09-05

出版日期:2025-08-15

发布日期:2025-11-24

通讯作者:

秦高梧

作者简介:潘虎成(1988—),男,安徽六安人,东北大学教授,博士生导师基金资助:Hu-cheng PAN, Sen WANG, Yu-ping REN, Gao-wu QIN

Received:2024-09-05

Online:2025-08-15

Published:2025-11-24

Contact:

Gao-wu QIN

摘要:

镁及镁合金因其密度低、比强度高等优点,在航空、航天、轨道交通以及海洋工程等多种领域具有广泛的应用前景.然而,进一步提升镁合金在复杂环境下的服役性能还面临较大挑战.综述了高温、低温、高速变形和腐蚀等复杂环境对镁合金微观组织的影响规律以及力学性能的变化.通过归纳和总结,提出了镁合金在复杂环境下服役性能提升的具体策略和建议,旨在促进镁合金新材料在相关环境领域的服役应用,为其在国防和民用领域的大规模应用提供了理论指导.

中图分类号:

潘虎成, 王森, 任玉平, 秦高梧. 复杂环境下服役的镁合金研究进展[J]. 东北大学学报(自然科学版), 2025, 46(8): 41-56.

Hu-cheng PAN, Sen WANG, Yu-ping REN, Gao-wu QIN. Research Progress of Magnesium Alloys Serving in Complex Environments[J]. Journal of Northeastern University(Natural Science), 2025, 46(8): 41-56.

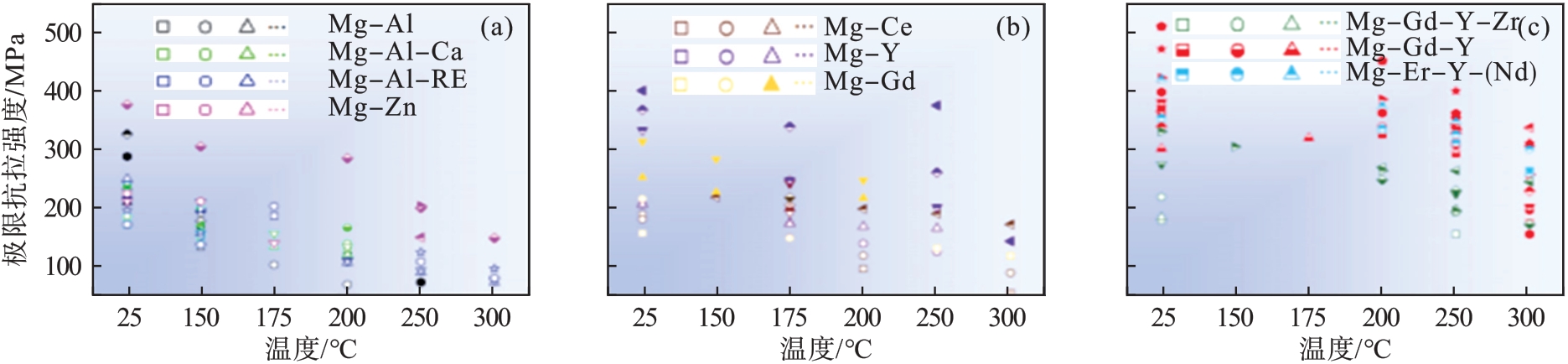

图1 不同体系镁合金的σb与温度之间的关系[12](a)—Mg-Al; (b)—Mg-RE(单组元RE); (c)—Mg-RE(多组元RE).

Fig.1 Relationship between σb and temperature of magnesium alloy in different systems [12]

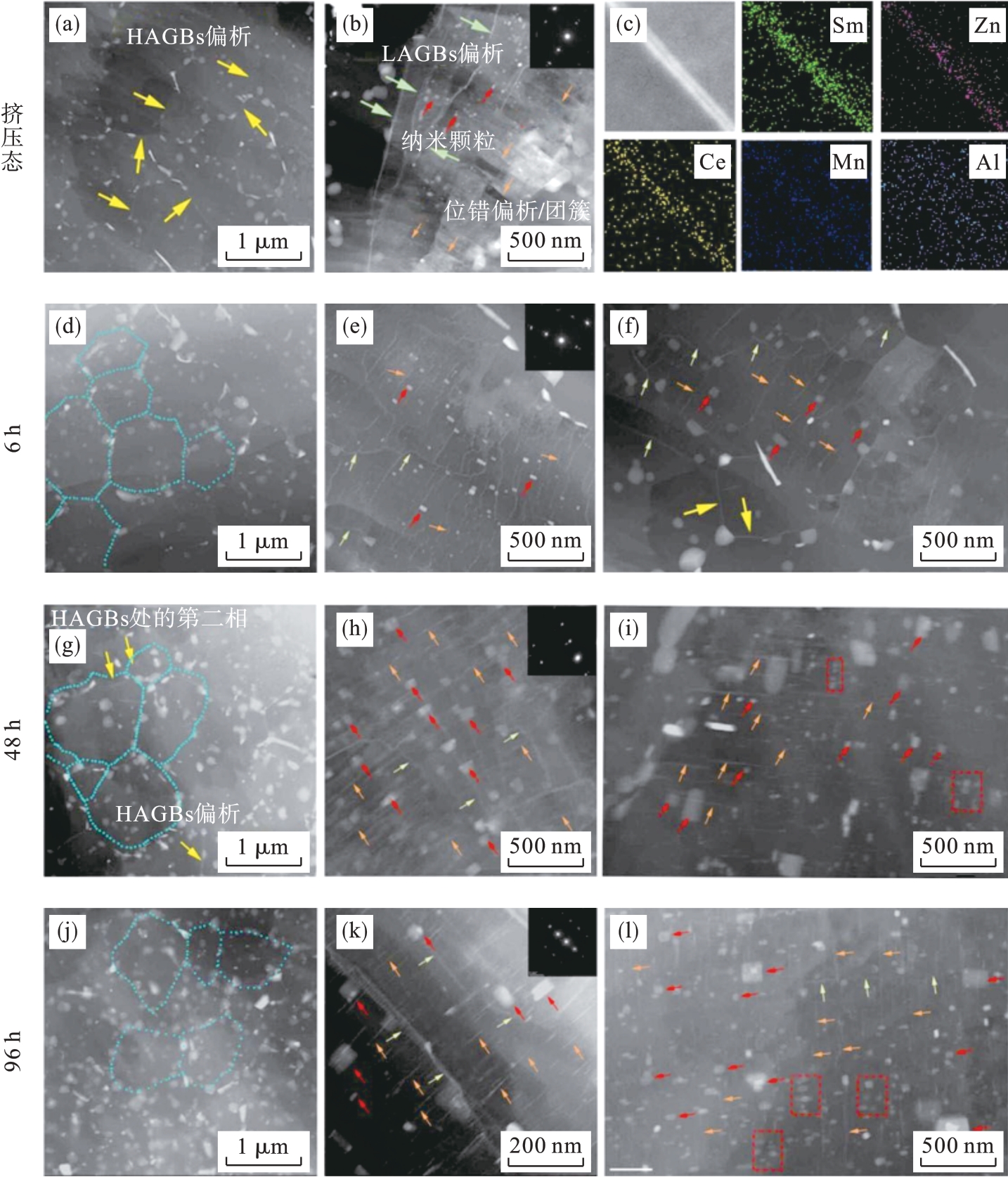

图3 250 ℃热暴露不同时间的Mg样品的HAADF-STEM(高角度环形暗场-扫描透射电子显微镜)图[36](a)—挤压态合金晶界处的第二相; (b)—挤压态合金LAGBs处的第二相; (c)—挤压态合金LAGBs处的偏析;(d)—热暴露6h后晶界处的第二相; (e)—热暴露6h后LAGBs处的第二相; (f)—热暴露6h后位错处的第二相;(g)—热暴露48h后晶界处的第二相; (h)—热暴露48h后LAGBs处的第二相; (i)—热暴露48h后位错处的第二相;(j)—热暴露96h后晶界处的第二相; (k)—热暴露96h后LAGBs处的第二相; (l)—热暴露96h后位错处的第二相.

Fig.3 HAADF-STEM(high-angle annular dark field-scanning transmission electron microscope) images of Mg samples exposed at 250 °C for different durations[36]

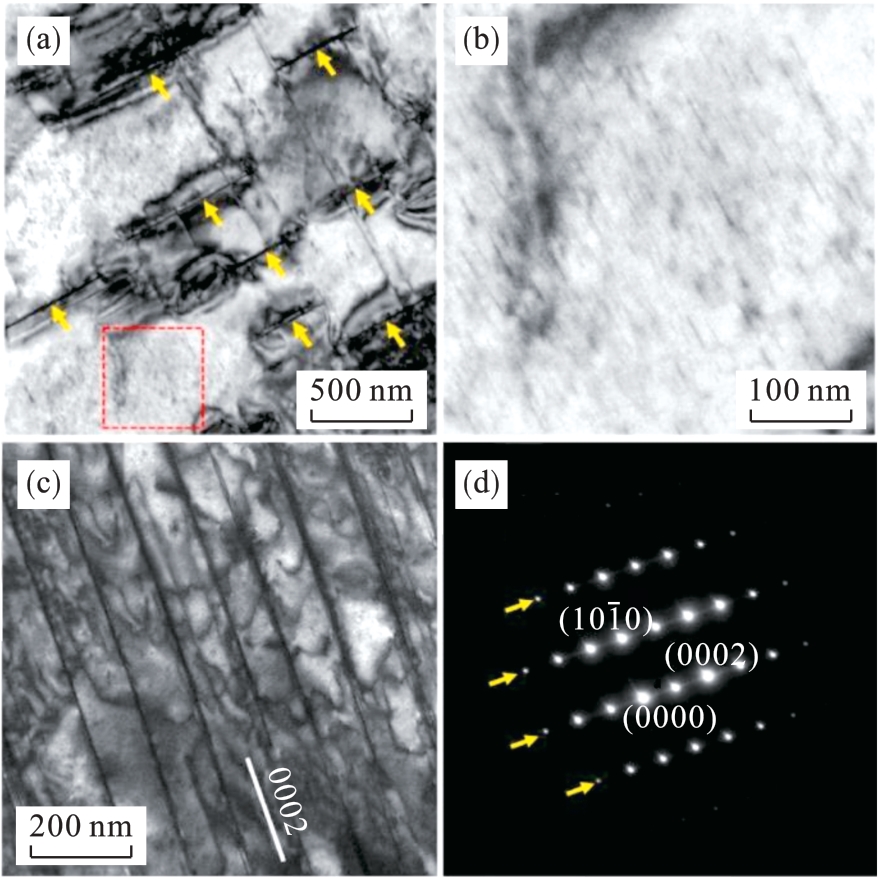

图4 高温变形后的TEM图[39](a)—200 ℃/100 MPa,SYZ420合金中的γ″相; (b)—图4a红色区域的放大图; (c)—SYZ420合金200 ℃拉伸试验后的层错结构; (d)—图4c晶体对应的选区电子衍射图.

Fig.4 TEM images after high-temperature deformation [39]

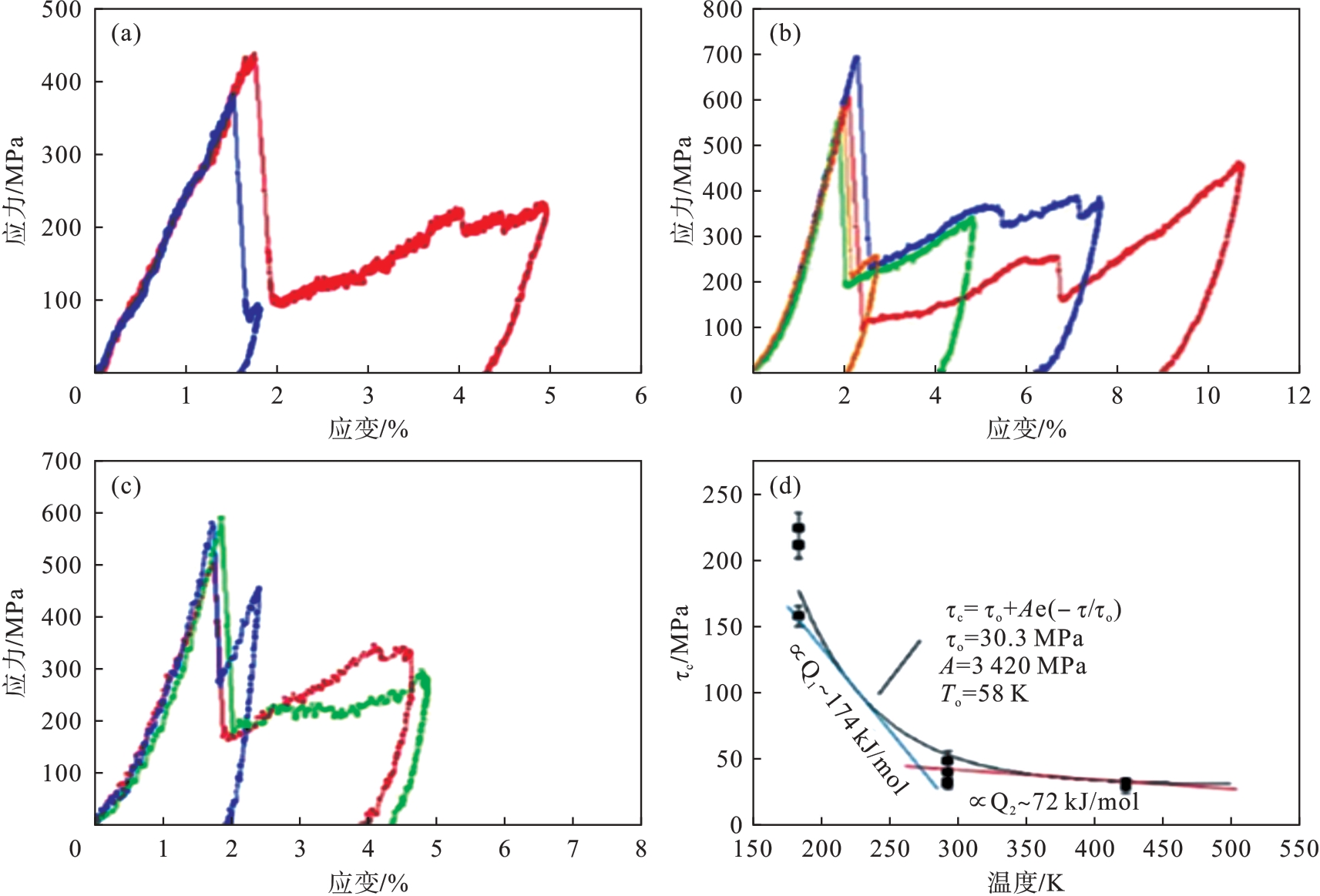

图6 Mg单晶在184 K低温下的应力-应变曲线和孪晶的τc与温度之间的关系[51-52]注:τ0为晶格摩擦力;A为与热激活过程相关的材料常数;Q1和Q2分别为第一、第二阶段激活能;To为热激活敏感度的特征温度.(a)—应变速率为10-4 /s的应力-应变曲线; (b)—应变速率为5×10-3 /s的应力-应变曲线;(c)—应变速率为5×10-1 /s的应力-应变曲线; (d)—孪晶的τc.

Fig.6 Stress-strain curves of Mg single crystals at 184 K and relationship between τc of twins and temperature[51-52]

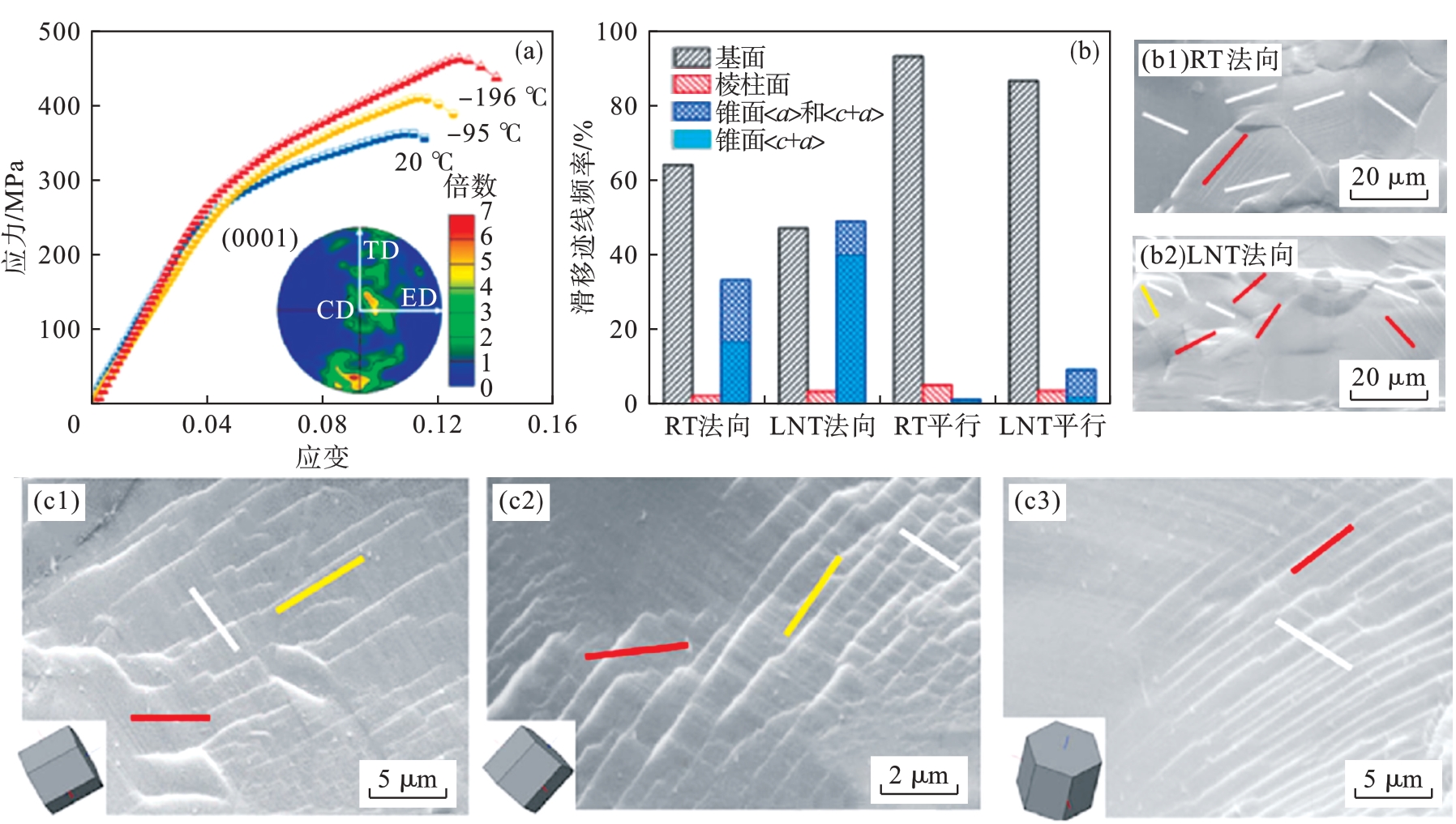

图7 WE43在不同温度下的应力-应变曲线和激活的位错[56]注:(a)—应力-应变曲线; (b)—应变为-0.05时室温和液氮温度下不同位错的滑移迹线频率; (b1)—应变为0.05时室温(RT)下不同位错的滑移轨迹频率; (b2)—应变为0.05时液氮温度(LNT)下不同位错的滑移轨迹频率; (c1,c2,c3)—不同位错之间的交叉滑移.

Fig.7 Stress-strain curves of WE43 at different temperatures and activated dislocations [56]

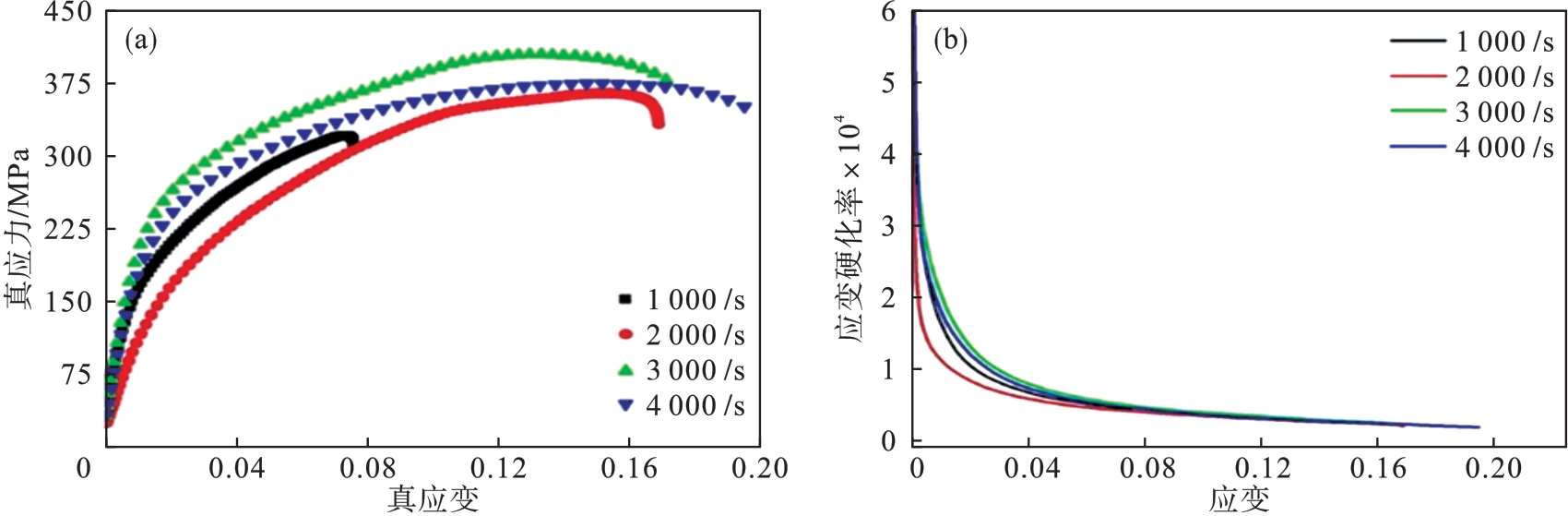

图8 ZK61镁合金在1 000~4 000 /s应变速率下的真应力-真应变曲线及应变硬化率随应变的变化曲线[68](a)—真应力-真应变曲线; (b)—应变硬化率随应变的变化曲线.

Fig.8 True stress-strain curves of ZK61 magnesium alloy at strain rates of 1 000~4 000 /s and variation curves of strain hardening rate with strain [68]

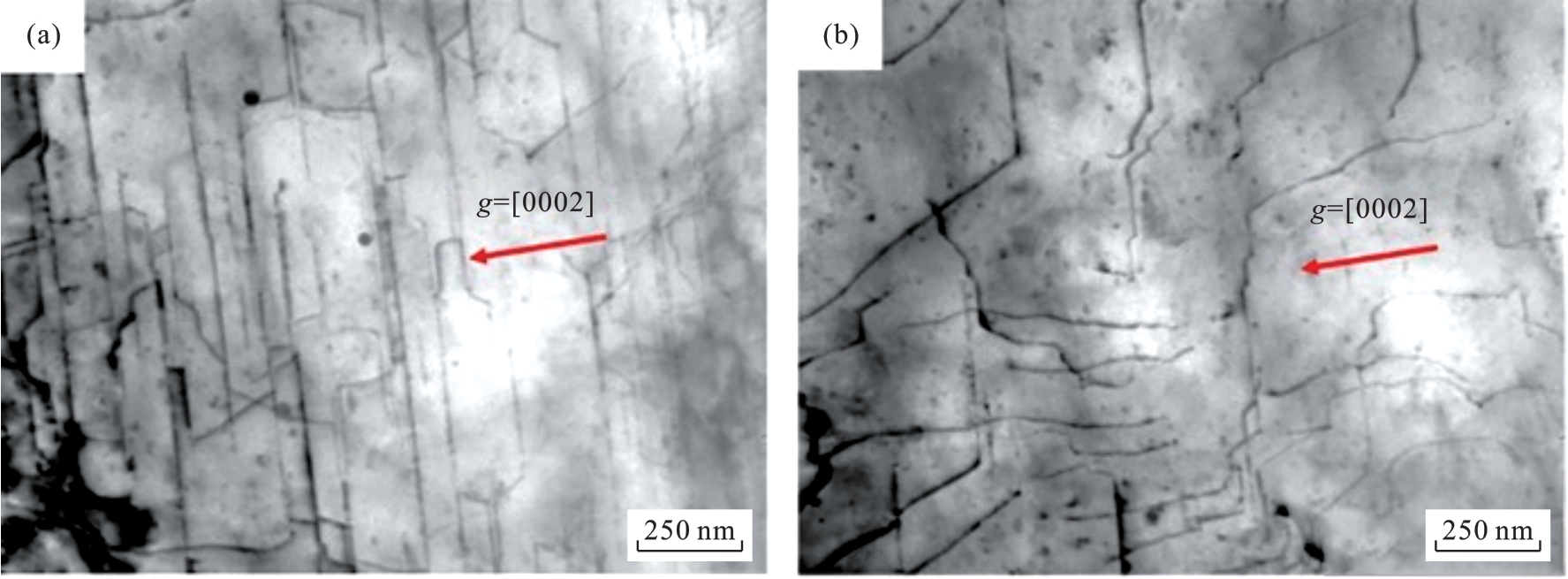

图9 挤压态纯Mg经过应变量为9%的高速压缩变形后晶粒中的〈c+a〉位错[67]注:g为倒易点阵矢量.(a)—区域1; (b)—区域2.

Fig.9 〈c+a〉 dislocations in grains of as-extruded pure Mg after high-speed compression deformation with a strain of 9%[67]

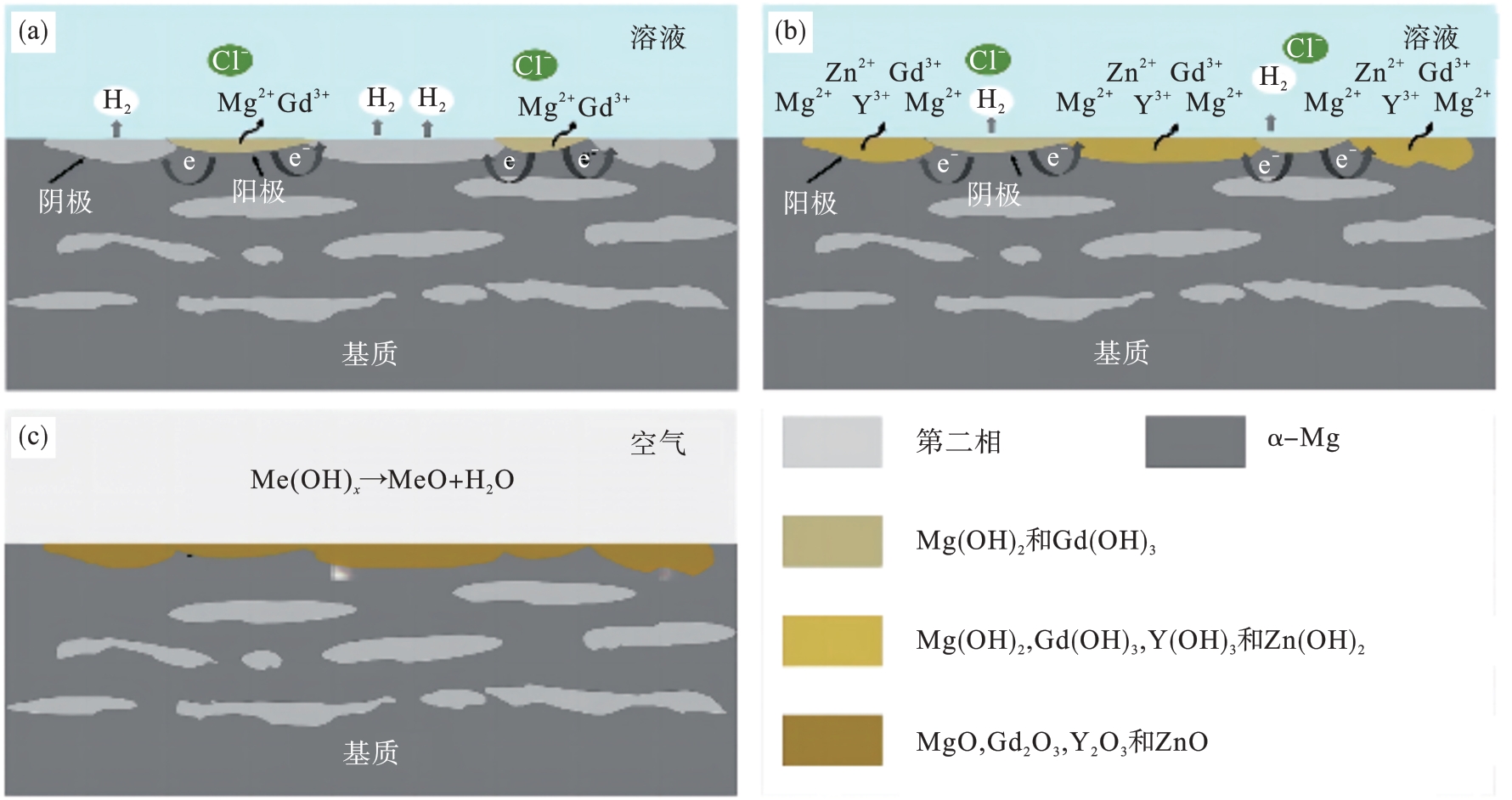

图10 变形Mg-9Gd-3Y-2Zn-0.5Zr合金在模拟沿海储存环境中的腐蚀发展模型[83](a)—优先腐蚀发生在第二相周围; (b)—第二相随后发生腐蚀;(c)—在试样表面生成对基体具有保护作用的含Cd和Y的腐蚀产物.

Fig.10 Corrosion development model of deformed Mg-9Gd-3Y-2Zn-0.5Zr alloy in simulated coastal storage environment [83]

| [1] | Bai J Y, Yang Y, Wen C, et al. Applications of magnesium alloys for aerospace: a review[J]. Journal of Magnesium and Alloys, 2023, 11(10): 3609-3619. |

| [2] | 潘复生,张津,张喜燕,等.轻合金材料新技术[M]. 北京:化学工业出版社,2008: 1-20. |

| Pan Fu-sheng, Zhang Jin, Zhang Xi-yan, et al. New technology of light alloy materials[M]. Beijing:Chemical Industry Press, 2008: 1-20. | |

| [3] | 张春香,陈培磊,陈海军,等.镁合金在汽车工业中的应用及其研究进展[J].铸造技术,2008, 29(4): 531-535. |

| Zhang Chun-xiang, Chen Pei-lei, Chen Hai-jun, et al. Application and research progress of magnesium alloys in automobile industry[J]. Foundry Technology, 2008, 29(4): 531-535. | |

| [4] | Hagihara K, Yokotani N, Kinoshita A, et al. Role of the microstructure on the deformation behavior in Mg12ZnY with a long-period stacking ordered structure[C]//Materials Research Society Symposium. San Francisco. 2009: 553. |

| [5] | Feng X, Guo Q. The lunar surface temperature real-time model[J]. National Remote Sensing Bulletin, 2017, 21(6): 928-938. |

| [6] | 阮莹,胡亮,闫娜,等.空间材料科学研究进展与未来趋势[J].中国科学:技术科学,2020, 50(6): 603-649. |

| Ruan Ying, Hu Liang, Yan Na, et al. Recent advances and future perspectives of space materials science[J]. Scientia Sinica (Technologica), 2020, 50(6): 603-649. | |

| [7] | 周慧敏,黄须强,孔令菲,等.海洋大气环境下镁合金腐蚀行为研究进展[J].稀有金属材料与工程,2024, 53(4): 1170-1180. |

| Zhou Hui-min, Huang Xu-qiang, Kong Ling-fei, et al. Research advances in corrosion behavior of magnesium alloy in marine atmospheric environment[J]. Rare Metal Materials and Engineering, 2024, 53(4): 1170-1180. | |

| [8] | Zhang K, Shao Z T, Daniel C S, et al. A comparative study of plastic deformation mechanisms in room-temperature and cryogenically deformed magnesium alloy AZ31[J]. Materials Science and Engineering: A, 2021, 807: 140821. |

| [9] | Li B, Joshi S, Azevedo K, et al. Dynamic testing at high strain rates of an ultrafine-grained magnesium alloy processed by ECAP [J]. Materials Science and Engineering: A, 2009, 517(1/2): 24-29. |

| [10] | Luo A A. Recent magnesium alloy development for elevated temperature applications [J]. International Materials Reviews, 2004, 49(1): 13-30. |

| [11] | 陈娇,赵超宇,刘冬.耐热镁合金在航空航天工业的应用[J].热加工工艺,2024, 22: 11-14. |

| Chen Jiao, Zhao Chao-Yu, Liu Dong. Application of heat-resistant magnesium alloy in aerospace [J]. Hot working process, 2024, 22: 11-14. | |

| [12] | Yang H, Xie W L, Song J F, et al. Current progress of research on heat-resistant Mg alloys: a review[J]. International Journal of Minerals, Metallurgy and Materials, 2024, 31(6): 1406-1425. |

| [13] | Bayani H, Saebnoori E. Effect of rare earth elements addition on thermal fatigue behaviors of AZ91 magnesium alloy [J]. Journal of Rare Earths, 2009, 27(2): 255-258. |

| [14] | Mahmudi R, Kabirian F, Nematollahi Z. Microstructural stability and high-temperature mechanical properties of AZ91 and AZ91+2RE magnesium alloys[J]. Materials & Design, 2011, 32(5): 2583-2589. |

| [15] | Zhang W Q, Xiao W L, Wang F, et al. Development of heat resistant Mg-Zn-Al-based magnesium alloys by addition of La and Ca: microstructure and tensile properties[J]. Journal of Alloys and Compounds, 2016, 684: 8-14. |

| [16] | Dong X X, Feng L Y, Wang S H, et al. On the exceptional creep resistance in a die-cast Gd-containing Mg alloy with Al addition[J]. Acta Materialia, 2022, 232: 117957. |

| [17] | Jafari N H R, Wu G H, Liu W C, et al. Effect of Gd content on high temperature mechanical properties of Mg-Gd-Y-Zr alloy[J]. Materials Science and Engineering: A, 2016, 651: 840-847. |

| [18] | Xu W L, Su C, Chen X H, et al. Achieving superior elevated-temperature strength of Mg-12Gd-3Y alloys by Nd addition[J]. Materials Science and Engineering: A, 2023, 867: 144730. |

| [19] | Zhou J X, Luo X J, Yang H, et al. Introducing lamellar LPSO phase to regulate room and high-temperature mechanical properties of Mg-Gd-Y-Zn-Zr alloys by altering cooling rate[J]. Journal of Materials Research and Technology, 2023, 24: 7258-7269. |

| [20] | Chapuis A, Driver J H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals[J]. Acta Materialia, 2011, 59(5): 1986-1994. |

| [21] | Sim G D, Xie K Y, Hemker K J, et al. Effect of temperature on the transition in deformation modes in Mg single crystals [J]. Acta Materialia, 2019, 178: 241-248. |

| [22] | Liu J N, Zhang X R, Lyu W X, et al. Microstructure and mechanical properties of Mg-2.0Gd-1.2Y-1.0Zn-0.2Zr alloy[J]. Metals and Materials International, 2021, 27(7): 1969-1979. |

| [23] | Wang H, Boehlert C J, Wang Q D, et al. In-situ analysis of the tensile deformation modes and anisotropy of extruded Mg-10Gd-3Y-0.5Zr (wt%) at elevated temperatures[J]. International Journal of Plasticity, 2016, 84: 255-276. |

| [24] | Stanford N, Sotoudeh K, Bate P S. Deformation mechanisms and plastic anisotropy in magnesium alloy AZ31[J]. Acta Materialia, 2011, 59(12): 4866-4874. |

| [25] | Su N, Wu Y J, Deng Q C, et al. Synergic effects of Gd and Y contents on the age-hardening response and elevated-temperature mechanical properties of extruded MgGd(Y) ZnMn alloys[J]. Materials Science and Engineering: A, 2021, 810: 141019. |

| [26] | 束德林.工程材料力学性能[M]. 2版.北京:机械工业出版社, 2007. |

| Shu De-lin. Mechanical properties of engineering materials[M]. 2nd ed. Beijing: China Machine Press, 2007. | |

| [27] | Pekguleryuz M, Celikin M. Creep resistance in magnesium alloys[J]. International Materials Reviews, 2010, 55(4): 197-217. |

| [28] | Pekguleryuz M O, Kaya A A. Creep resistant magnesium alloys for powertrain applications [J]. Advanced Engineering Materials, 2003, 5(12): 866-878. |

| [29] | 徐闻繁.MgGd(YZn) Zr系合金的蠕变性能与微观组织研究[D].上海:上海交通大学,2014. |

| Xu Wen-fan. The creep properties and microstructure of MgGdYZn) Zr alloys [D]. Shanghai: Shanghai Jiao Tong University, 2014. | |

| [30] | Zhu S M, Nie J F, Gibson M A, et al. Microstructure and creep behavior of high-pressure die-cast magnesium alloy AE44 [J]. Metallurgical and Materials Transactions A, 2012, 43(11): 4137-4144. |

| [31] | Zhang Y C, Liu Z, Pang S, et al. Investigation of tensile creep behavior of Mg-Gd-Y-Zr alloy based on creep constitutive model[J]. Materials Science and Engineering: A, 2021, 805: 140567. |

| [32] | Shi Y F, Luo L, Huo Q H, et al. Enhancing creep properties of a hot-rolled Mg-4Y binary alloy via a new thought of inhibiting cross-slip[J]. Materials Characterization, 2019, 147: 64-71. |

| [33] | Luo Y H, Cheng W L, Yu H, et al. Tailoring the microstructural characteristics and enhancing creep properties of as-cast Mg-5Bi-5Sn alloy through Mn addition[J]. Journal of Magnesium and Alloys, 2023, 11(9): 3350-3361. |

| [34] | Spigarelli S, El Mehtedi M, Regev M. Enhanced plasticity and creep in an extruded Mg-Zn-Zr alloy[J]. Scripta Materialia, 2010, 63(6): 617-620. |

| [35] | Kim W J, Park I B. Enhanced superplasticity and diffusional creep in ultrafine-grained Mg-6Al-1Zn alloy with high thermal stability[J]. Scripta Materialia, 2013, 68(3/4): 179-182. |

| [36] | Xie D S, Pan H C, Pan Z, et al. Achieving outstanding heat-resistant properties in Mg alloy via constructing stable solute-network[J]. Materials Research Letters, 2023, 11(5): 374-382. |

| [37] | Zhang D P, Li B Q, Zhang J H, et al. Influence of minor RE addition on microstructures, tensile properties, and creep resistance in a die-cast Mg-Al-Ca-Mn alloy[J]. Journal of Materials Research and Technology, 2023, 26: 3136-3145. |

| [38] | Jung Y G, Yang W, Kim Y J, et al. Effect of Ca addition on the microstructure and mechanical properties of heat-treated Mg-6.0Zn-1.2Y-0.7Zr alloy[J]. Journal of Magnesium and Alloys, 2021, 9(5): 1619-1631. |

| [39] | Zhang D D, Sun X Y, Pan H C, et al. Role of Yb in enhancing the heat resistance of cast Mg-Sm-Zn alloy[J]. Materials Science and Engineering: A, 2022, 841: 143009. |

| [40] | Ono N, Nowak R, Miura S. Effect of deformation temperature on Hall-Petch relationship registered for polycrystalline magnesium [J]. Materials Letters, 2004, 58(1/2): 39-43. |

| [41] | Wang H, Dong S L, Lyu G. Plastic deformation characteristics of an Mg-3Al-1Zn alloy at low temperatures[J]. Materials & Design, 2016, 92: 143-150. |

| [42] | Estrin Y Z, Zabrodin P A, Braude I S, et al. Low-temperature plastic deformation of AZ31 magnesium alloy with different microstructures[J]. Low Temperature Physics, 2010, 36(12): 1100-1106. |

| [43] | Shumilin S E, Janecek M, Isaev N V, et al. Low temperature plasticity of ultrafine-grained AE42 and AZ31 magnesium alloys[J]. Advanced Engineering Materials, 2013, 15(5): 352-357. |

| [44] | Pustovalov V V. Serrated deformation of metals and alloys at low temperatures (review)[J]. Low Temperature Physics, 2008, 34(9): 683-723. |

| [45] | Chen B, Zheng J X, Yang C M, et al. Mechanical properties and deformation mechanisms of Mg-Gd-Y-Zr alloy at cryogenic and elevated temperatures[J]. Journal of Materials Engineering and Performance, 2017, 26(2): 590-600. |

| [46] | Xiong C X, Zhang X M, Deng Y L, et al. Effects of cryogenic treatment on mechanical properties of extruded Mg-Gd-Y-Zr(Mn) alloys[J]. Journal of Central South University of Technology, 2007, 14(3): 305-309. |

| [47] | Zhang X F, Wu G H, Liu W C, et al. Low temperature mechanical properties of as-extruded Mg-10Gd-3Y-0.5Zr magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2883-2890. |

| [48] | 肖阳,张新明.Mg-9Gd-4Y-0.6Zr合金的低温塑性分析[J].特种铸造及有色合金,2010, 30(9): 794-796, |

| Ⅰ-Ⅱ. | |

| Xiao Yang, Zhang Xin-ming. Cryogenic plasticity analysis of Mg-9Gd-4Y-0.6Zr alloy [J]. Special casting & nonferrous alloys, 2010, 30(9): 794-796,Ⅰ-Ⅱ. | |

| [49] | Zhang K, Zheng J H, Huang Y, et al. Evolution of twinning and shear bands in magnesium alloys during rolling at room and cryogenic temperature[J]. Materials & Design, 2020, 193: 108793. |

| [50] | Lee S W, Kim S H, Park S H. Microstructural characteristics of AZ31 alloys rolled at room and cryogenic temperatures and their variation during annealing[J]. Journal of Magnesium and Alloys, 2020, 8(2): 537-545. |

| [51] | Della V N M, Tian C H, Sharma A, et al. Temperature dependent critical stress for {10 1 ¯ 2} twinning in magnesium micropillars at cryogenic temperatures [J]. Scripta Materialia, 2023, 226: 115195. |

| [52] | Della V N M, Sharma A, Kalácska S, et al. Evolution of deformation twinning mechanisms in magnesium from low to high strain rates[J]. Materials & Design, 2022, 217: 110646. |

| [53] | Somekawa H, Ogawa Y, Ono Y, et al. Deformation behavior at cryogenic temperature in extruded Mg-Al-Zn alloy[J]. Philosophical Magazine Letters, 2022, 102(11/12): 396-406. |

| [54] | Zhang K, Jiang J. Enhancement of plasticity in Mg-3Al-1Zn alloy at cryogenic temperature[J]. Journal of Materials Research and Technology, 2023, 25: 7454-7459. |

| [55] | Arul Kumar M, Gong M, Beyerlein I J, et al. Role of local stresses on co-zone twin-twin junction formation in HCP magnesium[J]. Acta Materialia, 2019, 168: 353-361. |

| [56] | Zhang K, Zheng J H, Hopper C, et al. Enhanced plasticity at cryogenic temperature in a magnesium alloy[J]. Materials Science and Engineering: A, 2021, 811: 141001. |

| [57] | Ding Q Q, Fu X Q, Chen D K, et al. Real-time nanoscale observation of deformation mechanisms in CrCoNi-based medium-to high-entropy alloys at cryogenic temperatures[J]. Materials Today, 2019, 25: 21-27. |

| [58] | Chaudry U M, Noh Y, Hamad K, et al. Effect of deformation temperature on the slip activity in pure Mg and AZX211[J]. Journal of Materials Research and Technology, 2022, 19: 3406-3420. |

| [59] | Wang S, Pan H C, Xie D S, et al. Grain refinement and strength enhancement in Mg wrought alloys: a review[J]. Journal of Magnesium and Alloys, 2023, 11(11): 4128-4145. |

| [60] | Zeng Z H, Pan H C, Pan Z, et al. Effect of Sm and Ce content on microstructure and mechanical property of newly developed Mg-Sm-Ce-Mn based alloy[J]. Materials Characterization, 2023, 206: 113420. |

| [61] | Pan Z, Pan H C, Huang Y, et al. Improving mechanical properties of Mg-Sn alloys by co-addition of Li and Al[J]. Progress in Natural Science: Materials International, 2023, 33(3): 355-363. |

| [62] | Ulacia I, Dudamell N V, Gálvez F, et al. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates[J]. Acta Materialia, 2010, 58(8): 2988-2998. |

| [63] | Figueiredo R B, Poggiali F S, Silva C L, et al. The influence of grain size and strain rate on the mechanical behavior of pure magnesium [J]. Journal of Materials Science, 2016, 51: 3013-3024. |

| [64] | Nagarajan S, Gurao N P, Parameswaran V. On the kinetics of texture development in Al-Mg alloy under high strain rate tension [J]. Materials Characterization, 2020, 163: 110303. |

| [65] | Li L, Muránsky O, Flores-Johnson E A, et al. Effects of strain rate on the microstructure evolution and mechanical response of magnesium alloy AZ31[J]. Materials Science and Engineering: A, 2017, 684: 37-46. |

| [66] | Asgari H, Szpunar J A, Odeshi A G. Texture evolution and dynamic mechanical behavior of cast AZ magnesium alloys under high strain rate compressive loading[J]. Materials & Design, 2014, 61: 26-34. |

| [67] | Dixit N, Xie K Y, Hemker K J, et al. Microstructural evolution of pure magnesium under high strain rate loading[J]. Acta Materialia, 2015, 87: 56-67. |

| [68] | Malik A, Wang Y W, Cheng H W, et al. Fracture behavior of twin induced ultra-fine grained ZK61 magnesium alloy under high strain rate compression[J]. Journal of Materials Research and Technology, 2019, 8(4): 3475-3486. |

| [69] | Dudamell N V, Ulacia I, Gálvez F, et al. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature[J]. Acta Materialia, 2011, 59(18): 6949-6962. |

| [70] | Asgari H, Szpunar J A, Odeshi A G, et al. Effect of grain size on high strain rate deformation of rolled Mg-4Y-3RE alloy in compression [J]. Materials Science and Engineering: A, 2015, 633: 92-102. |

| [71] | Wang Z, Cao G S, Wang F, et al. Investigation of the microstructure and properties of extrusion-shear deformed ZC61 magnesium alloy under high strain rate deformation[J]. Materials Characterization, 2021, 172: 110839. |

| [72] | Petronio B M, Pietrantonio M, Pietroletti M, et al. Metal speciation and bio-availability in marine sediments of Nothern Adiatic sea [C]//7th FECS Conference on Chemistry and the Environment. Porto. 2000: 320. |

| [73] | Cao F Y, Zhao C, You J, et al. The inhibitive effect of artificial seawater on magnesium corrosion[J]. Advanced Engineering Materials, 2019, 21(8): 1900363. |

| [74] | Jönsson M, Persson D, Leygraf C. Atmospheric corrosion of field-exposed magnesium alloy AZ91D[J]. Corrosion Science, 2008, 50(5): 1406-1413. |

| [75] | Yang L H, Liu C, Wang Y, et al. Dynamic marine atmospheric corrosion behavior of AZ91 Mg alloy sailing from Yellow Sea to Western Pacific Ocean[J]. Materials, 2024, 17(10): 2294. |

| [76] | Jiang Q T, Lu D Z, Cheng L R, et al. The corrosion characteristic and mechanism of Mg-5Y-1.5Nd-xZn-0.5Zr (x=0, 2, 4, 6 wt%) alloys in marine atmospheric environment[J]. Journal of Magnesium and Alloys, 2024, 12(1): 139-158. |

| [77] | Jiang Q T, Lu D Z, Wang N, et al. The corrosion behavior of Mg-Nd binary alloys in the harsh marine environment[J]. Journal of Magnesium and Alloys, 2021, 9(1): 292-304. |

| [78] | 林梦晓,张杰,蒋全通,等.海水中小球藻对Mg-3Y-1.5Nd镁合金腐蚀行为的影响[J].材料工程,2020, 48(1): 98-107. |

| Lin Meng-xiao, Zhang Jie, Jiang Quan-tong, et al. Effect of chlorella vulgaris on corrosion behavior of Mg-3Y-1.5Nd alloy in natural seawater[J]. Journal of Materials Engineering, 2020, 48(1): 98-107. | |

| [79] | Man C, Dong C F, Wang L, et al. Long-term corrosion kinetics and mechanism of magnesium alloy AZ31 exposed to a dry tropical desert environment[J]. Corrosion Science, 2020, 163: 108274. |

| [80] | Song G L, StJohn D. Corrosion behaviour of magnesium in ethylene glycol[J]. Corrosion Science, 2004, 46(6): 1381-1399. |

| [81] | Pang M Y, Zhong T, Jin S Y, et al. Tailoring the degradation rate of magnesium-lithium alloy with alloying elements of gadolinium and nickel[J]. Journal of Alloys and Compounds, 2024, 976: 173115. |

| [82] | Xie Q Y, Ma A B, Jiang J H, et al. Tailoring the corrosion behavior and mechanism of AZ31 magnesium alloys by different Ca contents for marine application[J]. Corrosion Science, 2021, 192: 109842. |

| [83] | Chen J H, Zhang C, Hu Z H, et al. Corrosion behavior of the second phase in Mg-9Gd-3Y-2Zn-0.5Zr alloy under simulated coastal storage environment[J]. NPJ Materials Degradation, 2024, 8(1): 69. |

| [84] | Wang J H, Liu B Y, Sun Q, et al. Effects of Y substituting Gd on the microstructure evolution, mechanical properties and dissolution behaviors in the Mg-Gd-Ni alloys used as fracturing plugging tools[J]. Journal of Materials Research and Technology, 2024, 28: 4262-4274. |

| [85] | Dai C N, Zhang S L, Wang Y, et al. Elucidation of the corrosion rate enhancement mechanism in Mg-Er-Gd-Ni alloys with high volume fraction of LPSO phase and different Gd contents after extrusion[J]. Journal of Materials Research and Technology, 2023, 27: 522-541. |

| [86] | Feng B J, Zhu K, Shang X Q, et al. Improving the corrosion and mechanical properties of Mg-8Gd-3Y-0.4Zr alloy synergistically via regulating micro-galvanic corrosion and dislocation density[J]. Corrosion Science, 2024, 237: 112275. |

| [87] | Jiang Q T, Lu D Z, Cheng L R, et al. The corrosion behavior of EW75 magnesium alloy in the research vessel KEXUE during the ocean voyage[J]. NPJ Materials Degradation, 2022, 6(1): 28. |

| [88] | Feng B J, Shang X Q, Xie T, et al. Influence of texture on the corrosion behavior of an as-extruded Mg-8Al-0.5In alloy sheet[J]. Journal of Materials Research and Technology, 2023, 27: 1497-1508. |

| [89] | Tang C Y, Pan J Y, Wu J Y, et al. Surroundings-adaptive coating enabling robustness of magnesium alloys[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2024, 696: 134385. |

| [90] | Zhao X, Wei J F, Li B C, et al. A self-healing superamphiphobic coating for efficient corrosion protection of magnesium alloy[J]. Journal of Colloid and Interface Science, 2020, 575: 140-149. |

| [91] | Liu L, Li X, Lei J L, et al. Superamphiphobic magnesium alloys with extraordinary environmental adaptability[J]. Langmuir, 2021, 37(14): 4267-4275. |

| [92] | Wang Y, Gu Z P, Liu J, et al. An organic/inorganic composite multi-layer coating to improve the corrosion resistance of AZ31B Mg alloy[J]. Surface and Coatings Technology, 2019, 360: 276-284. |

| [1] | 张涛, 刘闯, 张一, 王福会. 硅烷化处理对镁合金表面微弧氧化涂层降解性能的影响[J]. 东北大学学报(自然科学版), 2025, 46(8): 105-112. |

| [2] | 乐启炽, 周晨, 贾伟涛, 丁云鹏. AZ31B镁合金近等温轧制过程中的热变形行为[J]. 东北大学学报(自然科学版), 2025, 46(8): 124-132. |

| [3] | 陈明辉, 宋凯利, 甄宇, 王福会. 金属基高温自润滑复合材料研究现状及展望[J]. 东北大学学报(自然科学版), 2025, 46(8): 20-31. |

| [4] | 赵阳, 王宇航, 张涛, 王福会. 半导体制程设备铝合金涂层腐蚀失效行为研究进展[J]. 东北大学学报(自然科学版), 2025, 46(3): 28-45. |

| [5] | 陈猛, 杨新明, 王瑜婷, 张通. 聚丙烯纤维混凝土高温传热性能多尺度计算模型[J]. 东北大学学报(自然科学版), 2025, 46(2): 111-117. |

| [6] | 徐运超, 巩亚东, 田近民, 张伟健. 镍基单晶高温合金磨削表面白层的形成规律[J]. 东北大学学报(自然科学版), 2024, 45(9): 1301-1308. |

| [7] | 代峰, 柳静献. 钢铁企业除尘用涤纶滤料在复杂烟气环境下的老化行为分析[J]. 东北大学学报(自然科学版), 2024, 45(6): 883-889. |

| [8] | 朱庆丰, 黄建航, 高扬, 张恩阁. 稳定化退火温度对5059铝合金冷轧板材组织及性能的影响[J]. 东北大学学报(自然科学版), 2024, 45(3): 323-330. |

| [9] | 余犇, 王冬晓, 刘禹, 李建平. AZ31镁合金薄板热油恒温成形数值模拟与实验研究[J]. 东北大学学报(自然科学版), 2024, 45(2): 179-186. |

| [10] | 周云光, 王书海, 陈晗, 李明. 精密车削镍基单晶高温合金去除机理仿真与实验[J]. 东北大学学报(自然科学版), 2024, 45(10): 1452-1458. |

| [11] | 李凤华, 刘肖, 李英楠, 樊瑞. 锰源对合成锂离子筛及吸附性能影响[J]. 东北大学学报(自然科学版), 2023, 44(9): 1279-1284. |

| [12] | 李娜, 高成康, 巴乔, 那洪明. 重型柴油货车排放因子本地化研究:以辽中南为例[J]. 东北大学学报(自然科学版), 2023, 44(8): 1119-1127. |

| [13] | 张雅静, 王金朋, 陈鑫, 吴航宇. 医用可降解Zn-3Cu-xMn合金的制备及性能研究[J]. 东北大学学报(自然科学版), 2023, 44(8): 1104-1110. |

| [14] | 杨虎, 潘晓林, 吴鸿飞, 于海燕. 三水铝石矿低温焙烧脱碳脱水与溶出性能[J]. 东北大学学报(自然科学版), 2023, 44(7): 944-952. |

| [15] | 柳静献, 代峰, 毛宁. 酸碱交互腐蚀对芳纶滤料性能的影响[J]. 东北大学学报(自然科学版), 2023, 44(7): 1034-1040. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||