东北大学学报(自然科学版) ›› 2025, Vol. 46 ›› Issue (12): 85-93.DOI: 10.12068/j.issn.1005-3026.2025.20249038

张银霞1,2,3, 梁蓝夫1,2,3, 宋作鹏1,2,3, 李梦琪1,2,3

收稿日期:2024-08-02

出版日期:2025-12-15

发布日期:2026-02-09

通讯作者:

张银霞

基金资助:Yin-xia ZHANG1,2,3, Lan-fu LIANG1,2,3, Zuo-peng SONG1,2,3, Meng-qi LI1,2,3

Received:2024-08-02

Online:2025-12-15

Published:2026-02-09

Contact:

Yin-xia ZHANG

摘要:

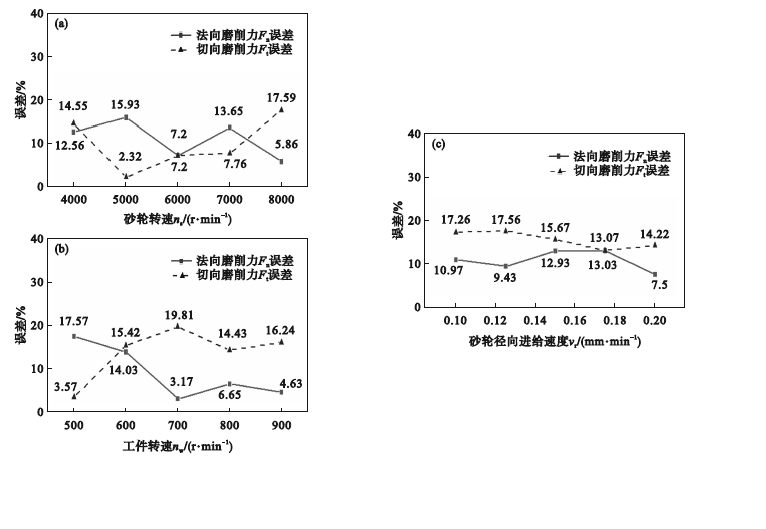

为了研究工艺参数对18CrNiMo7-6渗碳钢V型缺口成形外圆磨削力的影响规律,基于缺口疲劳试样的加工过程,构建通过空间随机平面切割正六面体生成的随机多面体CBN(cubic boron nitride)砂轮磨粒模型,利用ABAQUS有限元仿真软件建立V型缺口成形外圆磨削三维仿真模型.以砂轮转速ns、工件转速nw及砂轮径向进给速度vr为自变量,开展单因素试验,研究法向磨削力Fn和切向磨削力Ft的变化规律,并通过成形磨削力试验验证缺口成形切入磨削仿真模型的有效性.结果表明:法向磨削力始终大于切向磨削力;相较于工件转速和砂轮径向进给速度,砂轮转速对磨削力的影响更为显著.磨削力仿真结果与试验结果一致,ns,nw及vr通过仿真所预测的法向磨削力平均误差分别为11.06%,9.21%,10.77%,切向磨削力平均误差分别为9.89%,13.89%,15.55%.

中图分类号:

张银霞, 梁蓝夫, 宋作鹏, 李梦琪. 成形磨削18CrNiMo7-6钢磨削力仿真与试验验证[J]. 东北大学学报(自然科学版), 2025, 46(12): 85-93.

Yin-xia ZHANG, Lan-fu LIANG, Zuo-peng SONG, Meng-qi LI. Simulation and Experimental Verification of Grinding Forces in Profile Grinding of 18CrNiMo7-6 Steel[J]. Journal of Northeastern University(Natural Science), 2025, 46(12): 85-93.

| C | Si | Mn | S | P | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.15~0.21 | 0.4 | 0.50~0.90 | ≤0.035 | ≤0.035 | 1.50~1.80 | 1.40~1.70 | 0.25~0.35 | 余量 |

表1 18CrNiMo7-6渗碳钢化学成分(质量分数) (%)

Table 1 Chemical composition of 18CrNiMo7-6 steel (mass fraction)

| C | Si | Mn | S | P | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.15~0.21 | 0.4 | 0.50~0.90 | ≤0.035 | ≤0.035 | 1.50~1.80 | 1.40~1.70 | 0.25~0.35 | 余量 |

| 材料 | 弹性模量/GPa | 泊松比 | 密度/(kg·m-3) | 硬度 |

|---|---|---|---|---|

| CBN | 706 | 0.15 | 3 450 | 8 000(HV) |

| 18CrNiMo7-6 | 210 | 0.30 | 7 800 | 60(HRC) |

表2 CBN砂轮与工件材料基本物理参数

Table 2 Basic physical parameters of CBN grinding wheel and workpiece materials

| 材料 | 弹性模量/GPa | 泊松比 | 密度/(kg·m-3) | 硬度 |

|---|---|---|---|---|

| CBN | 706 | 0.15 | 3 450 | 8 000(HV) |

| 18CrNiMo7-6 | 210 | 0.30 | 7 800 | 60(HRC) |

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 263 | D1 | 0.05 | |

| Bm/MPa | 624 | D2 | 0.80 |

| Cm | 0.017 | D3 | -1.54 |

| m | 1.3 | D4 | 0.01 |

| n | 0.26 | D5 | 1 |

表3 18CrNiMo7-6钢本构模型参数值 (18CrNiMo7-6 steel)

Table 3 Parameter values of constitutive model for

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 263 | D1 | 0.05 | |

| Bm/MPa | 624 | D2 | 0.80 |

| Cm | 0.017 | D3 | -1.54 |

| m | 1.3 | D4 | 0.01 |

| n | 0.26 | D5 | 1 |

| 序号 | 砂轮转速ns/(r·min-1) | 工件转速nw/(r·min-1) | 砂轮径向进给速度vr/(mm·min-1) |

|---|---|---|---|

| 1 | 4 000,5 000,6 000,7 000,8 000 | 700 | 0.15 |

| 2 | 6 000 | 500,600,700,800,900 | 0.15 |

| 3 | 6 000 | 700 | 0.1,0.125,0.15,0.175,0.2 |

表4 单因素试验工艺参数

Table 4 Process parameters of single-factor experiment

| 序号 | 砂轮转速ns/(r·min-1) | 工件转速nw/(r·min-1) | 砂轮径向进给速度vr/(mm·min-1) |

|---|---|---|---|

| 1 | 4 000,5 000,6 000,7 000,8 000 | 700 | 0.15 |

| 2 | 6 000 | 500,600,700,800,900 | 0.15 |

| 3 | 6 000 | 700 | 0.1,0.125,0.15,0.175,0.2 |

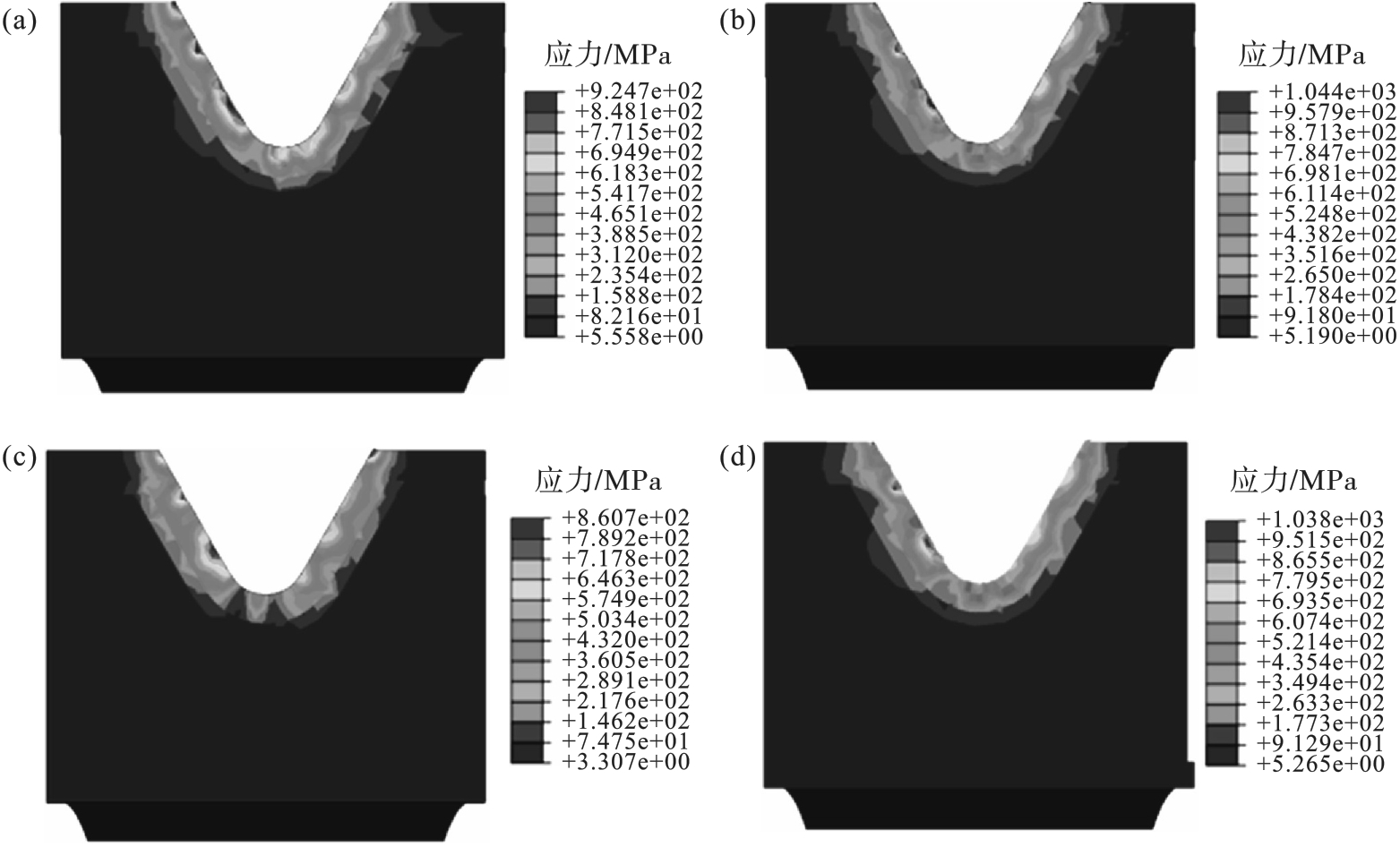

图10 V形缺口外圆磨削仿真得到工件上的应力分布(a)—nw=500 r/min; (b)—nw=600 r/min; (c)—nw=700 r/min; (d)—nw=800 r/min.

Fig.10 Stress distribution on workpiece obtained by V-notch’s cylindrical grinding simulation

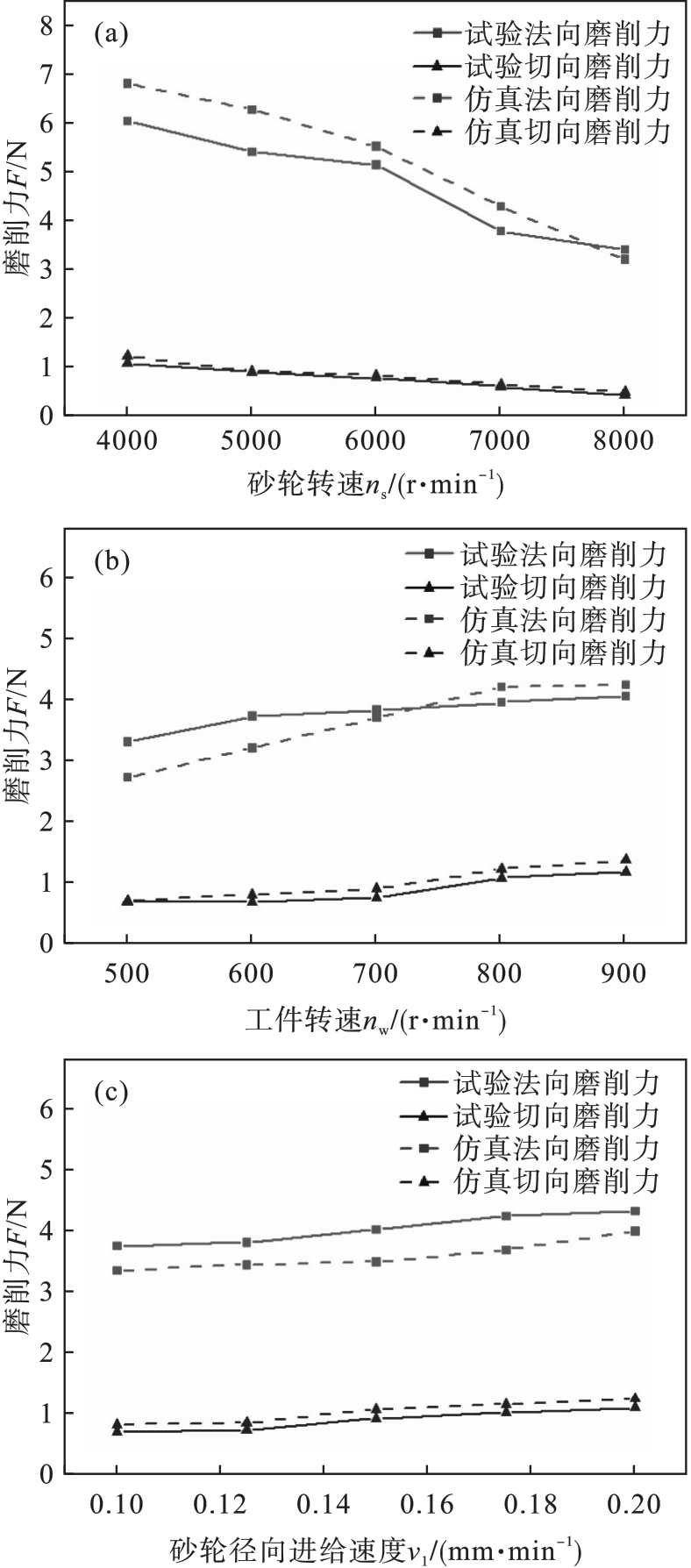

图13 不同工艺参数对磨削力的影响(a)—当nw=700 r/min,vr=0.15 mm/min时,砂轮转速对磨削力的影响; (b)—当ns=6 000 r/min,vr=0.15 mm/min时,工件转速对磨削力的影响; (c)—当ns=6 000 r/min,nw=700 r/min时,砂轮径向进给速度对磨削力的影响.

Fig.13 Influence of different process parameters on grinding force

图14 不同工艺参数下磨削力仿真与试验结果对比(a)—当nw=700 r/min,vr=0.15 mm/min时,砂轮转速对误差的影响; (b)—当ns=6 000 r/min,vr=0.15 mm/min时,工件转速对误差的影响; (c)—当ns=6 000 r/min,nw=700 r/min时,砂轮径向进给速度对误差的影响.

Fig.14 Comparison of simulated and experimental results of grinding force under different process parameters

| [1] | Liao D, Zhu S P, Correia J A F O, et al. Recent advances on Notch effects in metal fatigue: a review[J]. Fatigue & Fracture of Engineering Materials & Structures, 2020, 43(4): 637-659. |

| [2] | Witkin D B, Patel D N, Bean G E. Notched fatigue testing of Inconel 718 prepared by selective laser melting[J]. Fatigue & Fracture of Engineering Materials & Structures, 2019, 42(1): 166-177. |

| [3] | Li Z L, Shi D Q, Li S L, et al. A systematical weight function modified critical distance method to estimate the creep-fatigue life of geometrically different structures[J]. International Journal of Fatigue, 2019, 126: 6-19. |

| [4] | Meng Q Y, Guo B, Zhao Q L, et al. Modelling of grinding mechanics: a review[J]. Chinese Journal of Aeronautics, 2023, 36(7): 25-39. |

| [5] | Zhang Y B, Li C H, Ji H J, et al. Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms[J]. International Journal of Machine Tools and Manufacture, 2017, 122: 81-97. |

| [6] | Gao P E, Tian P E, Tang Z H, et al. Comprehensive review of simulation methods in grinding processes: models, mechanisms, applications, and future directions[J]. Journal of Metals, 2025,77(9): 1-18. |

| [7] | 高腾,李长河,张彦彬,等.纳米增强生物润滑剂CFRP材料去除力学行为与磨削力预测模型[J].机械工程学报,2023,59(13):325-342. |

| Gao Teng, Li Chang-he, Zhang Yan-bin, et al. Mechanical behavior of material removal and predictive force model for CFRP grinding using nano reinforced biological lubricant[J]. Journal of Mechanical Engineering, 2023, 59(13): 325-342. | |

| [8] | Yang S Y, Liang R J, Chen W F, et al. Modelling and experiment for grinding forces of gear form grinding considering complete tooth depth engagement[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2022, 236(13): 1738-1750. |

| [9] | Azizi A, Mohamadyari M. Modeling and analysis of grinding forces based on the single grit scratch[J]. The International Journal of Advanced Manufacturing Technology, 2015, 78(5): 1223-1231. |

| [10] | Sun J, Wu Y H, Zhou P, et al. Simulation and experimental research on Si3N4 ceramic grinding based on different diamond grains[J]. Advances in Mechanical Engineering, 2017, 9(6): 168781401770559. |

| [11] | Ding H H, Han Y C, Zhou K, et al. Grinding force modeling and experimental verification of rail grinding[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(8):1254-1264. |

| [12] | 刘超杰. 钛基复合材料高速磨削加工磨削力仿真分析[J]. 机械制造与自动化, 2019, 48(2): 89-93. |

| Liu Chao-jie. Simulation analysis of grinding force in high speed grinding of titanium matrix composites [J]. Machine Building & Automation, 2019, 48(2): 89-93. | |

| [13] | 王子乐. 18CrNiMo7-6钢外圆磨削仿真与试验研究[D]. 郑州:郑州大学, 2021. |

| Wang Zi-le. Simulation and experimental research on cylindrical grinding of 18CrNiMo7-6 steel[D]. Zhengzhou: Zhengzhou University, 2021. | |

| [14] | Fu P, Jiang C H, Ji V. Microstructural evolution and mechanical response of the surface of 18CrNiMo7-6 steel after multistep shot peening during annealing[J]. Materials Transactions, 2013, 54(12): 2180-2184. |

| [15] | 张银霞,杨鑫,原少帅,等.18CrNiMo7-6钢高速外圆磨削的残余应力[J].中国机械工程,2021,32(5):540-546. |

| Zhang Yin-xia, Yang Xin, Yuan Shao-shuai, et al. Residual stress of high-speed cylindrical grinding of 18CrNiMo7-6 steel [J]. China Mechanical Engineering, 2021,32(5): 540-546. | |

| [16] | Zhang Y X, Yuan S S, Yang X,et al.Dry hard turning versus grinding: the influence of machining-induced surface integrity on fatigue performance[J].Coatings, 2023, 13:809. |

| [17] | 马少奇. 18CrNiMo7-6钢外圆磨削力及表面完整性研究[D]. 郑州:郑州大学,2021. |

| Ma Shao-qi. Research on grinding force and surface integrity of 18CrNiMo7-6 steel in cylindrical grind [D]. Zhengzhou: Zhengzhou University, 2021. | |

| [18] | 吴少洋. 18CrNiMo7-6合金钢外圆及缺口磨削仿真研究与试验验证[D]. 郑州:郑州大学,2022. |

| Wu Shao-yang. Simulation study and experimental verification of cylindrical and notch grinding of 18CrNiMo7-6 alloy steel [D]. Zhengzhou: Zhengzhou University, 2022. | |

| [19] | Li X K, Wolf S, Zhi G, et al. The modelling and experimental verification of the grinding wheel topographical properties based on the ‘through-the-process’ method[J]. The International Journal of Advanced Manufacturing Technology, 2014, 70(1): 649-659. |

| [20] | Li C S, Sun L, Yang S, et al. Three-dimensional characterization and modeling of diamond electroplated grinding wheels[J]. International Journal of Mechanical Sciences, 2018, 144: 553-563. |

| [21] | 张银霞, 韩程宇, 杨鑫, 等. GCr15钢平面磨削力仿真分析与实验研究[J]. 表面技术, 2019, 48(10): 342-348. |

| Zhang Yin-xia, Han Cheng-yu, Yang Xin, et al. Simulation analysis and experimental research on surface grinding force of GCr15 steel[J]. Surface Technology, 2019, 48(10): 342-348. | |

| [22] | 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 超硬磨料 粒度检验: [S]. 北京:中国标准出版社,2016. |

| General Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of the People’s Repubilc of China. Superabrasive—checking the grain size: [S]. Beijing: Standards Press of China,2016. | |

| [23] | 王栋, 王建军, 李宁. 外圆磨削18CrNiMo7-6表面完整性研究[J]. 重庆理工大学学报(自然科学版), 2020, 34(4): 76-86. |

| Wang Dong, Wang Jian-jun, Li Ning. Study on surface integrity of cylindrical grinding 18CrNiMo7-6[J]. Journal of Chongqing University of Technology (Natural Science), 2020,34(4): 76-86. | |

| [24] | Johnson G R, Cook W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures[J]. Engineering Fracture Mechanics, 1985, 21(1): 31-48. |

| [25] | Özel T. The influence of friction models on finite element simulations of machining[J]. International Journal of Machine Tools and Manufacture, 2006, 46(5): 518-530. |

| [1] | 辛博, 李宏亮, 孙文鑫, 刘洺君. 基于迁移学习的NiCo-FGM机器人砂带磨削工艺[J]. 东北大学学报(自然科学版), 2025, 46(6): 66-75. |

| [2] | 辛博, 曹刚, 秦嘉鑫, 赵显力. 激光定向能量沉积NiCo-FGMs的磨削工艺优化[J]. 东北大学学报(自然科学版), 2025, 46(2): 85-95. |

| [3] | 巩亚东, 李远峰, 温泉, 任启震. 2.5D Cf/SiC复合材料与SiC陶瓷微磨削性能对比试验研究[J]. 东北大学学报(自然科学版), 2025, 46(1): 52-60. |

| [4] | 李远峰, 温泉, 巩亚东, 唐本甲. 2.5D Cf /SiC复合材料微尺度磨削试验研究[J]. 东北大学学报(自然科学版), 2024, 45(8): 1143-1149. |

| [5] | 马廉洁, 孙立业, 邱喆, 李红双. 二维超声振动辅助磨削的磨削力建模[J]. 东北大学学报(自然科学版), 2024, 45(8): 1135-1142. |

| [6] | 周云光, 田川川, 王书海, 陈晗. SiC陶瓷的磨削去除机理及参数对磨削力影响[J]. 东北大学学报(自然科学版), 2024, 45(4): 548-554. |

| [7] | 温雪龙, 桂宏泽, 巩亚东, 王蒙山. 高熵合金微尺度磨削力实验研究[J]. 东北大学学报(自然科学版), 2024, 45(12): 1734-1743. |

| [8] | 杨欣, 樊振刚, 张根保, 冉琰. 数控转台蜗轮转动元动作的热变形有限元分析[J]. 东北大学学报(自然科学版), 2024, 45(1): 76-84. |

| [9] | 于长永,赵楚,马海涛刘晓寒, 邹平, 曲圆辉, 方立廷. 提升304不锈钢加工表面的单激励三维振动切削装置设计[J]. 东北大学学报(自然科学版), 2023, 44(6): 816-823. |

| [10] | 卢晓红, 顾瀚, 丛晨, 阮飞翔. Inconel 718介观尺度薄壁件微铣削力预测[J]. 东北大学学报(自然科学版), 2023, 44(2): 242-250. |

| [11] | 温雪龙, 王承宝, 巩亚东, 孙付强. 涂层微磨具的制备及磨削表面质量实验研究[J]. 东北大学学报(自然科学版), 2022, 43(5): 681-688. |

| [12] | 罗忠 , 刘家希 , 刘凯宁 , 孙凯. 弹性环式支承结构动刚度分析及其对转子系统的影响[J]. 东北大学学报(自然科学版), 2022, 43(5): 667-673. |

| [13] | 修世超, 卢跃, 孙聪, 李清良. 端面磨削动态热力耦合效应及对表面去除过程影响[J]. 东北大学学报(自然科学版), 2021, 42(3): 389-395. |

| [14] | 周云光, 董彪, 岳新伟, 谭雁清. 牙科氧化锆陶瓷微尺度磨削力研究[J]. 东北大学学报:自然科学版, 2020, 41(4): 557-562. |

| [15] | 牛艺静, 孙聪, 庞刚, 修世超. 预应力时效性对磨削强化表面应力的影响[J]. 东北大学学报:自然科学版, 2020, 41(4): 546-550. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||